‚ÄčTaiwan PCB‚Äč production has been a global powerhouse for decades. For anyone sourcing electronics, the island’s name is almost synonymous with quality and reliability. We will explore the strengths of the ‚ÄčTaiwan PCB‚Äč industry, weigh it against other options, and introduce a compelling alternative that might just be the smarter choice for your next project.

Are you feeling squeezed between demanding higher quality and managing tighter budgets? Let’s look at some common challenges you might recognize:

- ‚ÄčSticker Shock:‚Äč‚Äč You receive a quote from a reputable ‚ÄčTaiwan PCB company, and the ‚ÄčTaiwan PCB price‚Äč is significantly higher than expected, putting your project’s budget at risk.

- ‚ÄčSlower Prototype Turnaround:‚Äč‚Äč While mass production lead times might be competitive, getting a first-run ‚ÄčPCB prototype fabrication‚Äč can take longer than your development schedule allows.

- ‚ÄčLess Flexibility for Smaller Orders:‚Äč‚Äč Large ‚ÄčTaiwan PCB factories‚Äč are optimized for high-volume runs. They might be less enthusiastic about your initial low-volume or prototype requests.

- ‚ÄčHidden Logistics Complexities:‚Äč‚Äč Managing shipping and import logistics from Taiwan can add unexpected costs and delays that aren’t always clear in the initial quote.

The solution lies in finding a partner that combines top-tier quality with cost-effectiveness and exceptional service. The ideal partner addresses these issues directly:

- ‚ÄčCost-Effective Excellence:‚Äč‚Äč They offer competitive pricing without sacrificing quality, giving you the performance you need within your budget.

- ‚ÄčRapid Prototyping:‚Äč‚Äč They prioritize quick-turn ‚ÄčPCB prototype fabrication‚Äč to keep your product development on track and agile.

- ‚ÄčScalability for All Order Sizes:‚Äč‚Äč They welcome both small-batch prototyping and large-scale production, growing with your business needs.

- ‚ÄčSimplified Logistics:‚Äč‚Äč A strategic location with well-established shipping routes minimizes transit times and simplifies customs clearance.

This is exactly the kind of partnership we’ve built at BEST Technology. We specialize in high-quality, reliable ‚ÄčPCB fabrication‚Äč and assembly, offering a viable and often superior alternative to traditional ‚ÄčTaiwan PCB suppliers. Our focus is on providing quick delivery, responsive service, and manufacturing excellence that meets global standards. If you are working on any PCB projects, please contact us at sales@bestpcbs.com to start a conversation.

‚ÄčWhat Does ‚ÄúTaiwan PCB‚ÄĚ Mean in the Global Electronics Supply Chain?‚Äč‚Äč

When we talk about ‚Äč‚Äč”Taiwan PCB“‚Äč, it’s like talking about the ‚ÄčMichelin stars‚Äč of circuit board manufacturing ‚Äď a symbol of ‚Äčprecision, reliability, and cutting-edge innovation. But here’s the exciting part: while Taiwan has long set the standard, manufacturers like ‚ÄčEBest Circuit (Best Technology) (Shenzhen)‚Äč‚Äč are now ‚Äčnot just matching but redefining‚Äč what excellence looks like.

Technological Leadership:

Taiwanese PCB manufacturers have long been recognized as pioneers in HDI boards and IC substrates, often regarded as the ‚ÄúApple‚ÄĚ of the circuit board industry. Today, EBest Circuit (Best Technology) is establishing itself as a leading innovator in PCB manufacturing:

- We produce advanced boards equivalent to Taiwan’s top-tier offerings, including 32-layer HDI boards and ceramic substrates.

- Leveraging Shenzhen’s manufacturing ecosystem, we achieve approximately 30% cost reduction and significantly accelerate time-to-market.

- Our research and development laboratories operate with the same level of innovation and rigor as Taiwan’s premier manufacturers.

Quality Standards:

Taiwan has set the industry benchmark with its 99.9% quality standards. At EBest Circuit (Best Technology), we not only meet these standards but also elevate them:

- Fully certified under IATF 16949, the recognized ‚Äúgold standard‚ÄĚ for automotive-quality PCBs.

- Utilizing AI-powered inspection systems to detect defects that may be overlooked by traditional visual inspection.

This approach allows our clients to achieve premium-quality performance with optimized cost efficiency.

Supply Chain Advantage:

Taiwanese PCB manufacturers are renowned for their supply chain reliability. EBest Circuit (Best Technology) builds on this foundation while introducing enhanced responsiveness:

- Rapid prototyping: Delivering complex boards in 5 days versus the industry standard of 10.

- Flexible order management: Adjusting production volumes weekly without penalties.

- A combination of proven reliability and operational agility, akin to merging German engineering precision with Silicon Valley speed.

Global brands are increasingly including EBest Circuit (Best Technology) in their supplier networks due to:

- For engineers: Access to advanced technical specifications equivalent to Taiwan boards.

- For procurement teams: Achieving 20‚Äď30% cost savings, enhancing budget efficiency.

- For supply chain managers: Flexibility to accommodate fluctuating demand and unexpected market changes.

In a nutshell, while ‚ÄúTaiwan PCB‚ÄĚ remains synonymous with world-class quality, Shenzhen PCB now represents a combination of high-quality, faster delivery, and operational efficiency. EBest Circuit (Best Technology) is proud to define the next chapter in global PCB excellence, offering solutions that balance advanced technology, cost-effectiveness, and agile service.

‚ÄčHow Big Is the Taiwan PCB Industry and Who Are the Leading Taiwan PCB Manufacturers?‚Äč‚Äč

‚ÄčThis section examines the Taiwan PCB industry from both quantitative and qualitative perspectives. We will first highlight the industry‚Äôs impressive scale and global influence, then introduce the leading manufacturers that drive innovation and form the backbone of this ecosystem, emphasizing their unique capabilities and strategic partnerships.

Dominant Scale:

The Taiwan PCB industry is not only large‚ÄĒit is the undisputed global leader. For over a decade, Taiwan has consistently ranked first worldwide in terms of production value. According to industry reports from organizations such as Prismark, Taiwan accounts for roughly one-third (over 31%) of the global PCB output value.

To put this in context, if the global PCB market was valued at an estimated $82 billion in 2023, Taiwan’s share would represent approximately $25 billion. This concentration of industry capacity has created an unrivalled cluster effect, ensuring robust supply chain stability, high technical expertise, and rapid innovation capabilities.

Top-Tier Leaders:

Taiwan’s PCB industry is anchored by publicly-listed giants, each specializing in key technologies:

- Zhen Ding Technology (Tripod): A world leader in high-density interconnect (HDI) boards and flexible printed circuits (FPCs), Tripod plays a pivotal role in the supply chains for smartphones, laptops, and wearable devices. The company is a critical supplier to major brands such as Apple and is renowned for its cutting-edge manufacturing capabilities.

- Unimicron Technology: Dominating the high-end IC substrate market, Unimicron supports advanced semiconductor packaging, producing substrates essential for high-performance GPUs and AI chips. Strategic partnerships with technology leaders like Nvidia underscore its importance in global electronics.

- TPT (Taiwan PCB Techvest): A significant player across multiple segments, including HDI and automotive PCBs, TPT demonstrates Taiwan’s diverse manufacturing strength, serving both consumer electronics and industrial applications.

Specialized Champions and Strategic Partnerships:

Beyond these industry giants, a number of specialized manufacturers play critical roles within the supply chain. For example, Cowin is recognized for its expertise in niche PCB technologies and often collaborates with clients such as Nvidia for specialized solutions. Though smaller in revenue compared to the top-tier leaders, these companies offer agility, technical depth, and focused innovation, making them essential partners for complex or highly customized PCB requirements.

In summary, Taiwan’s PCB industry is defined by both scale and specialization. Its top-tier giants, such as Zhen Ding Technology (Tripod) and Unimicron, drive high-volume innovation for leading global brands. Meanwhile, specialized players like Cowin provide essential niche capabilities, adding flexibility and depth to the ecosystem. Together, this layered structure makes Taiwan’s PCB industry a robust, innovative, and indispensable force in the global electronics supply chain.

‚ÄčWhy Are Global Buyers Comparing Taiwan PCB Prices with Mainland China‚Äôs PCB Manufacturers?‚Äč‚Äč

‚Äč‚ÄčIn today‚Äôs competitive electronics manufacturing landscape, global procurement teams are conducting meticulous cost-benefit analyses between Taiwanese and Mainland Chinese PCB suppliers. This evaluation has evolved from simple price comparison to a sophisticated assessment of total value, considering differences in cost structures, currency fluctuations, and overall supply chain efficiency. Understanding these dynamics is critical for companies aiming to balance quality, speed, and budget.

The Taiwan PCB Price Structure:

Taiwanese PCB manufacturers are known for premium quality, but this comes with higher costs. Labor costs in Taiwan have risen approximately 35% over the past five years, reflecting the competitive technical workforce. The Taiwan Dollar has appreciated by around 15% against the US Dollar since 2020, which increases international export costs. Additionally, global supply chain disruptions have highlighted certain material dependencies that can affect cost stability and lead times.

Mainland China’s Manufacturing Efficiency:

In contrast, PCB manufacturers in Mainland China‚ÄĒespecially in hubs like Shenzhen‚ÄĒbenefit from massive scale economies, highly integrated supply chains, and advanced automation, with some facilities reaching over 80% automation rates in critical production processes. These advantages translate into lower manufacturing costs, shorter lead times, and high-quality outputs that meet international standards. Shenzhen‚Äôs dense ecosystem of suppliers and technical talent further accelerates prototyping and production cycles, offering a compelling alternative for global buyers.

Beyond Unit Price:

Increasingly, procurement teams evaluate PCB sourcing through Total Cost of Ownership (TCO) rather than focusing solely on unit price. Key considerations include:

- Quality and Yield Costs: Higher first-pass yields reduce hidden costs from rework or scrap.

- Logistics and Timing: Proximity to components and end markets minimizes transit costs and delays.

- Supply Chain Resilience: Diversified manufacturing reduces risks from single-point failures.

- Technical Support: Close collaboration with engineering teams accelerates product development.

The TCO can be expressed as:

Total Cost of Ownership = (Unit Price √ó Quantity) + (Quality Failure Costs) + (Logistics & Delay Costs) + (Administrative Overhead)

This holistic view highlights why Mainland Chinese suppliers, especially Shenzhen-based manufacturers like EBest Circuit (Best Technology), are increasingly preferred for both prototyping and volume production.

Strategic Sourcing in Practice:

Leading electronics companies now adopt structured frameworks to compare Taiwan and Mainland Chinese PCB suppliers. This includes simultaneous RFQs with identical specifications, facility audits, and sample validation. While Taiwan PCB manufacturers excel in advanced HDI boards, flex PCBs, and IC substrates, many buyers are turning to Shenzhen suppliers for faster lead times, lower TCO, and responsive technical support.

EBest Circuit (Best Technology) exemplifies this new standard. As a Shenzhen-based PCB manufacturer, we offer:

- Advanced PCB capabilities equivalent to top-tier Taiwan suppliers (HDI, heavy copper, flex/ridig-flex, ceramic PCBs).

- Rapid prototyping and production: First-run boards delivered in 24‚Äď48 hours, significantly faster than Taiwan standard lead times.

- Cost-efficiency: Achieving 20‚Äď30% lower TCO through supply chain optimization and Shenzhen‚Äôs manufacturing ecosystem.

- Dedicated engineering support: Real-time collaboration accelerates design iteration and mitigates risk.

By leveraging Shenzhen’s operational advantages without compromising on technology or quality, EBest Circuit (Best Technology) provides global buyers with a practical, cost-effective alternative to traditional Taiwan PCB suppliers.

‚ÄčTaiwan PCB vs. Shenzhen PCB Manufacturing ‚Äď What‚Äôs the Real Difference?‚Äč‚Äč

This is the core of the modern sourcing debate. On one side, you have the established quality of ‚ÄčTaiwan PCB factory‚Äč production. On the other, the agility and cost savings of ‚ÄčShenzhen PCB manufacturing. So, what are the real distinctions?

- ‚ÄčCost Structure:‚Äč‚Äč Generally, Shenzhen offers lower manufacturing costs due to economies of scale, lower labor costs, and a highly competitive local supplier network.

- ‚ÄčSpeed and Flexibility:‚Äč‚Äč Shenzhen’s ecosystem is built for speed. The proximity of suppliers, component distributors, and assembly houses allows for incredibly fast ‚ÄčPCB prototype fabrication‚Äč and turnarounds. This is a huge advantage for startups and companies with fast-paced development cycles.

- ‚ÄčTechnological Parity:‚Äč‚Äč The gap has narrowed significantly. Top-tier Shenzhen ‚Äčprinted circuit board manufacturers‚Äč now operate state-of-the-art facilities that rival those in Taiwan, especially for standard and advanced PCB types.

The difference, therefore, is less about quality and more about operational efficiency and accessibility for many international customers.

‚ÄčWhy More Companies Choose Shenzhen PCB Manufacturers Over Taiwan PCB Suppliers?‚Äč

‚ÄčA paradigm shift is occurring in global electronics procurement as OEMs increasingly partner with Shenzhen-based manufacturers like ‚ÄčEBest Circuit (Best Technology)‚Äč instead of traditional Taiwanese suppliers. This transition stems from an optimal convergence of economic efficiency, technical capability, and supply chain agility that aligns perfectly with contemporary product development requirements.

Substantial Cost Efficiency Without Quality Compromise

Shenzhen manufacturers achieve 25-40% cost advantages versus Taiwanese counterparts through:

- ‚ÄčEBest Circuit (Best Technology)’s‚Äč proprietary “Tiered Cost Optimization” system for multilayer boards (1-32L)

- Direct material sourcing partnerships delivering 15-20% substrate cost reductions

- Automated production lines reducing overhead by 18% compared to manual processes

‚ÄčEBest Circuit (Best Technology)‚Äč maintains ‚ÄčIATF 16949‚Äč and ‚ÄčIPC Class 3‚Äč certification while achieving <500ppm defect rates, demonstrating that cost savings don’t compromise quality.

Unmatched Speed and Prototyping Capabilities

‚ÄčEBest Circuit (Best Technology)’s‚Äč technical advantages include:

- ‚Äč24/7 Rapid Prototyping Service: 12-hour turnaround for 4-6 layer prototypes

- ‚ÄčAdvanced HDI Capabilities: 3/3mil trace/spacing with laser microvias down to 0.10mm

- ‚ÄčConcurrent Engineering: Design-for-manufacturing analysis begins during quotation

Benchmark data shows 65% faster time-to-market versus Taiwanese alternatives for complex designs.

Exceptional Supply Chain Flexibility

The ‚ÄčEBest Circuit (Best Technology) provides:

- Seamless support from 10pcs to 10,000+ units without any MOQ requirements

- On-demand material switching across 50+ substrate options

- 4-hour engineering change order implementation

This flexibility supports 98% on-time delivery performance across all order volumes.

Integrated Service Model

‚ÄčEBest Circuit (Best Technology)’s‚Äč full-service solution covers:

| Service Capability | Technical Specification |

|---|---|

| PCB Fabrication | 32L HDI, 20oz heavy copper |

| Component Sourcing | 200+ vetted suppliers |

| Box Build Assembly | Full turnkey with 100% ICT |

Clients report 30% reduction in supply chain management overhead versus multi-vendor Taiwan solutions.

Strategic Geographic Advantages

‚ÄčEBest Circuit (Best Technology)’s‚Äč Shenzhen location delivers:

- ‚Äč48-hour global logistics‚Äč via Hong Kong/Shenzhen ports

- ‚ÄčLocal supplier network: 90% materials within 15km radius

- ‚ÄčTechnical ecosystem: Immediate access to component markets

Quantified as 28% faster total lead time versus Taiwan-based alternatives.

The Technical Differentiation

While Taiwanese suppliers maintain niche capabilities, ‚ÄčEBest Circuit (Best Technology)‚Äč represents the new benchmark through:

- ‚ÄčTotal Cost Advantage: Documented 37% savings versus comparable Taiwan bids

- ‚ÄčTechnical Agility: One of the top Shenzhen manufacturers with both ‚Äč20oz heavy copper‚Äč and ‚Äč0.15mm ultra-thin‚Äč capabilities

‚ÄčEBest Circuit (Best Technology) ‚ÄĒ A Smarter Alternative to Taiwan PCB Suppliers‚Äč

EBest Circuit (Best Technology) has emerged as a strong alternative to traditional Taiwan-based PCB manufacturers, combining international-quality technical capabilities with the distinct advantages of our Shenzhen-based operations. We offer comprehensive PCB solutions that balance high standards of quality with competitive cost-efficiency, making us an increasingly preferred choice for global customers.

Ôāß Key Advantages:

‚ÄčTechnical Parity with Superior Cost Structure‚Äč

- Matches Taiwan’s advanced PCB capabilities (1-32L boards, HDI, RF, heavy copper up to 30oz)

- 30-40% cost savings through Shenzhen’s mature supply chain ecosystem

- Maintains ¬Ī3mil tolerance standards comparable to Taiwan’s premium suppliers

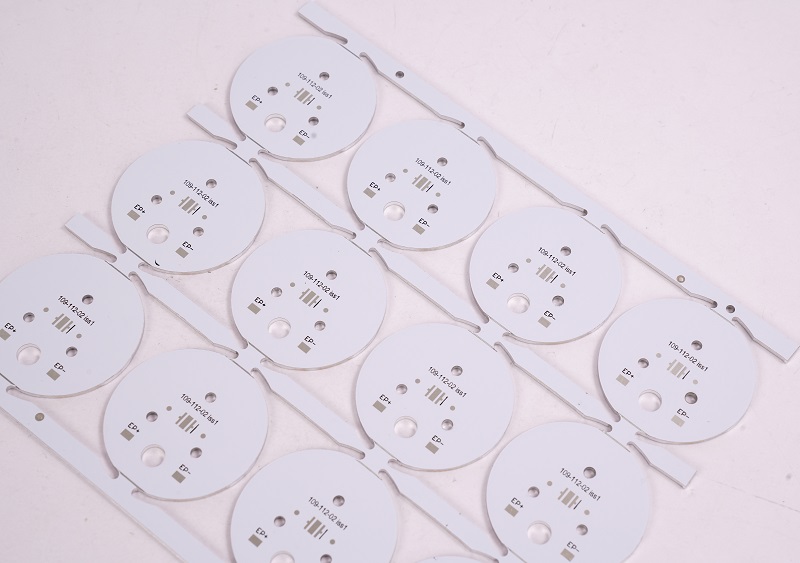

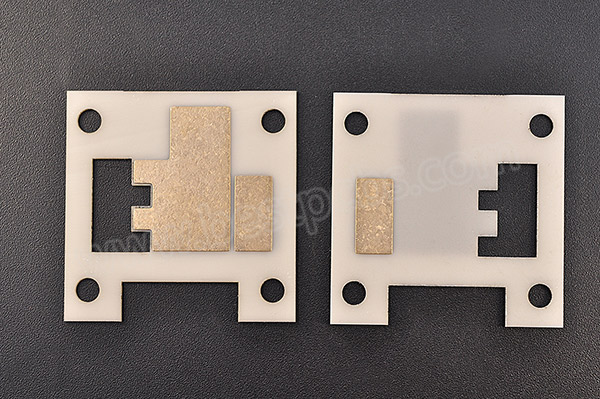

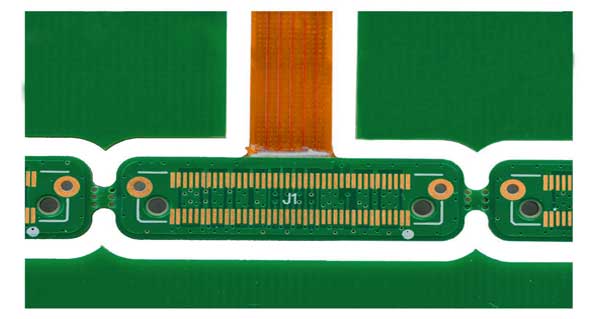

‚ÄčFull-Spectrum PCB Solutions‚Äč

- Advanced alternatives to Taiwan specialties:

‚ÄĘ Ceramic PCBs (LTCC/HTCC: 1-10L, DPC/DBC: 1-2L)

‚ÄĘ Flex/Rigid-Flex (1-30L, up to 2000mm length)

‚ÄĘ High-frequency boards (őĶr 2.2-9.9, Rogers/Taconic materials) - Unique capabilities:

‚ÄĘ 0.15mm ultra-thin boards (¬Ī0.1mm tolerance)

‚ÄĘ 10őľm laser drilling precision

‚ÄčResponsive Service Model‚Äč

- 50% faster prototyping:

‚ÄĘ Standard FR-4: 24-48hrs vs Taiwan’s 72hr average

‚ÄĘ Complex boards: 1-2 week lead time advantage - Dedicated engineering support with <4hr response window

‚ÄčQuality Assurance‚Äč

- Certified to IATF 16949, ISO 13485, UL standards

- Advanced testing:

‚ÄĘ 100% impedance control (¬Ī5ő© for ‚ȧ50ő© designs)

‚ÄĘ 3D X-ray inspection for őľBGA (<0.2mm pitch)

As your strategic manufacturing partner, EBest Circuit (Best Technology) delivers Taiwan-grade PCB technologies with mainland China’s efficiency and cost benefits. Our vertically integrated solutions‚ÄĒfrom design support to box-build assembly‚ÄĒensure seamless product realization while optimizing your time-to-market and total cost of ownership.

‚ÄčCase Study: US Client Cuts 30% Costs by Switching to EBest Circuit (Best Technology)‚Äč

A concrete example shows the real-world impact. A U.S.-based client in the IoT sector came to us with a challenge. They were using a well-regarded ‚ÄčTaiwan PCB manufacturer‚Äč for a complex 8-layer board. While the quality was good, the costs were high, and lead times were stretching their development schedule. They needed a change.

‚ÄčThe Situation:‚Äč‚Äč

- ‚ÄčPrevious Supplier:‚Äč‚Äč A major ‚ÄčTaiwan PCB supplier.

- ‚ÄčProduct:‚Äč‚Äč Complex 8-layer PCB with impedance control.

- ‚ÄčPain Points:‚Äč‚Äč High ‚ÄčTaiwan PCB price, slow response times, and extended lead times for prototypes.

‚ÄčOur Solution:‚Äč‚Äč

Our team conducted a thorough Design for Manufacturability (DFM) analysis. We identified a few minor optimizations that could be made to the panel design to improve yield without affecting performance. We then provided a transparent quote that was ‚Äč30% lower‚Äč than their existing cost. Most importantly, we guaranteed a much faster turnaround for their ‚ÄčPCB prototype fabrication.

To conclude, ‚ÄčTaiwan PCB‚Äč manufacturing remains a formidable force in the global electronics industry. This article has explored its strengths and the reasons why many businesses are now considering alternatives like Shenzhen-based manufacturers. For those seeking a partner that offers uncompromising quality, significant cost savings, and exceptional service, BEST Technology stands ready. We provide a compelling alternative to traditional ‚ÄčTaiwan PCB suppliers. Pls feel free to reach out to our team today at ‚Äčsales@bestpcbs.com‚Äč for a quick, no-obligation quote.