Reflow process soldering is one of the most widely used assembly techniques in modern electronics manufacturing. From consumer devices to automotive control modules, the reflow process soldering workflow allows engineers to achieve consistent joints, high throughput, and repeatable thermal control.

This guide explains the full workflow in practical engineering terms, including equipment selection, temperature phases, alloy choices, and troubleshooting methods used in real SMT production environments.

What Is the Reflow Process of Soldering?

Reflow process soldering is a thermal assembly method where solder paste is first printed onto PCB pads, components are placed, and then the entire board passes through a controlled heating profile. The solder paste melts, wets the pads and leads, and solidifies to form electrical and mechanical connections.

Unlike hand soldering, heat is not applied locally. Instead, the entire PCB follows a carefully designed temperature curve.

Key characteristics include:

- Uniform heating across the assembly

- Precise temperature ramp control

- Compatibility with fine-pitch components

- High automation suitability

The process is essential for modern surface-mount technology because it supports high-density layouts, micro-pitch packages, and large production volumes.

What Is the Reflow Process of Soldering?

Why Is It Called Reflow Soldering?

The term âreflowâ refers to the melting and flowing behavior of solder paste during heating. Before entering the oven, solder paste is in a semi-solid state containing metal particles and flux. As temperature rises above the alloyâs liquidus point, the solder melts and flows across the pad surface.

This flow action allows:

- Surface tension to align components

- Oxides to be removed by flux activation

- Metallurgical bonding between lead and pad

After peak temperature, controlled cooling solidifies the joint, locking components into position.

What Equipment Is Used for Reflow?

A standard reflow process soldering line includes several interconnected machines. Each stage influences solder joint quality.

Typical equipment:

- Stencil printer â applies consistent solder paste volume

- SPI inspection system â checks paste height and coverage

- Pick-and-place machine â positions components with precision

- Reflow oven â creates the temperature profile

- AOI system â verifies final joint integrity

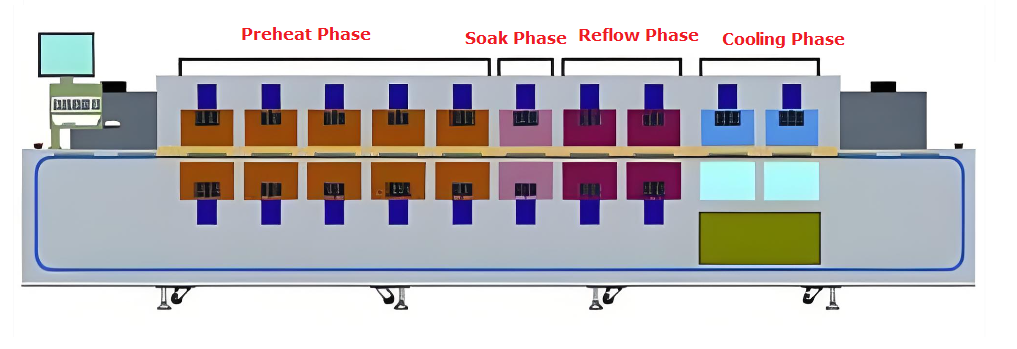

Modern convection reflow ovens are divided into multiple heating zones. These zones gradually raise temperature rather than applying sudden thermal stress.

For advanced assemblies, nitrogen reflow ovens reduce oxidation and improve wetting, especially for fine-pitch components.

At What Temperature Does Solder Reflow?

The reflow temperature depends mainly on alloy composition. Engineers must distinguish between liquidus temperature and peak profile temperature.

Typical examples:

SAC305 lead-free alloy

- Liquidus: ~217 °C

- Peak profile: 235â245 °C

Sn63/Pb37 eutectic alloy

- Liquidus: 183 °C

- Peak profile: 205â215 °C

The peak value must be high enough to ensure full melting but low enough to avoid damaging components or PCB materials. Excessive temperature can cause pad cratering, delamination, or component warpage.

What Are the 7 Steps of Soldering?

In modern SMT manufacturing, soldering is not a single action but a controlled sequence of operations. Each step influences joint strength, electrical stability, and long-term reliability. Whether used in prototype assembly or high-volume PCBA production, these seven stages form a structured workflow that engineers follow to maintain process consistency.

1. Surface Preparation and PCB Cleaning

Before any solder is applied, the PCB surface must be clean and free from oxidation, dust, or residual oils. Even microscopic contamination can prevent proper wetting during heating.

Common preparation practices include:

- Plasma cleaning or alcohol wiping for prototypes

- Controlled storage to avoid humidity absorption

- Verifying pad finish quality such as ENIG, HASL, or OSP

Proper preparation ensures the solder spreads evenly instead of forming isolated beads or weak fillets.

2. Solder Paste Printing or Flux Application

For reflow assemblies, solder paste is deposited onto pads using a laser-cut stencil. Paste volume directly determines final joint shape and reliability.

Key considerations during this step:

- Stencil thickness and aperture design

- Printing pressure and speed

- Paste viscosity and metal content

In manual or selective soldering, flux may be applied instead of paste to activate surfaces during heating.

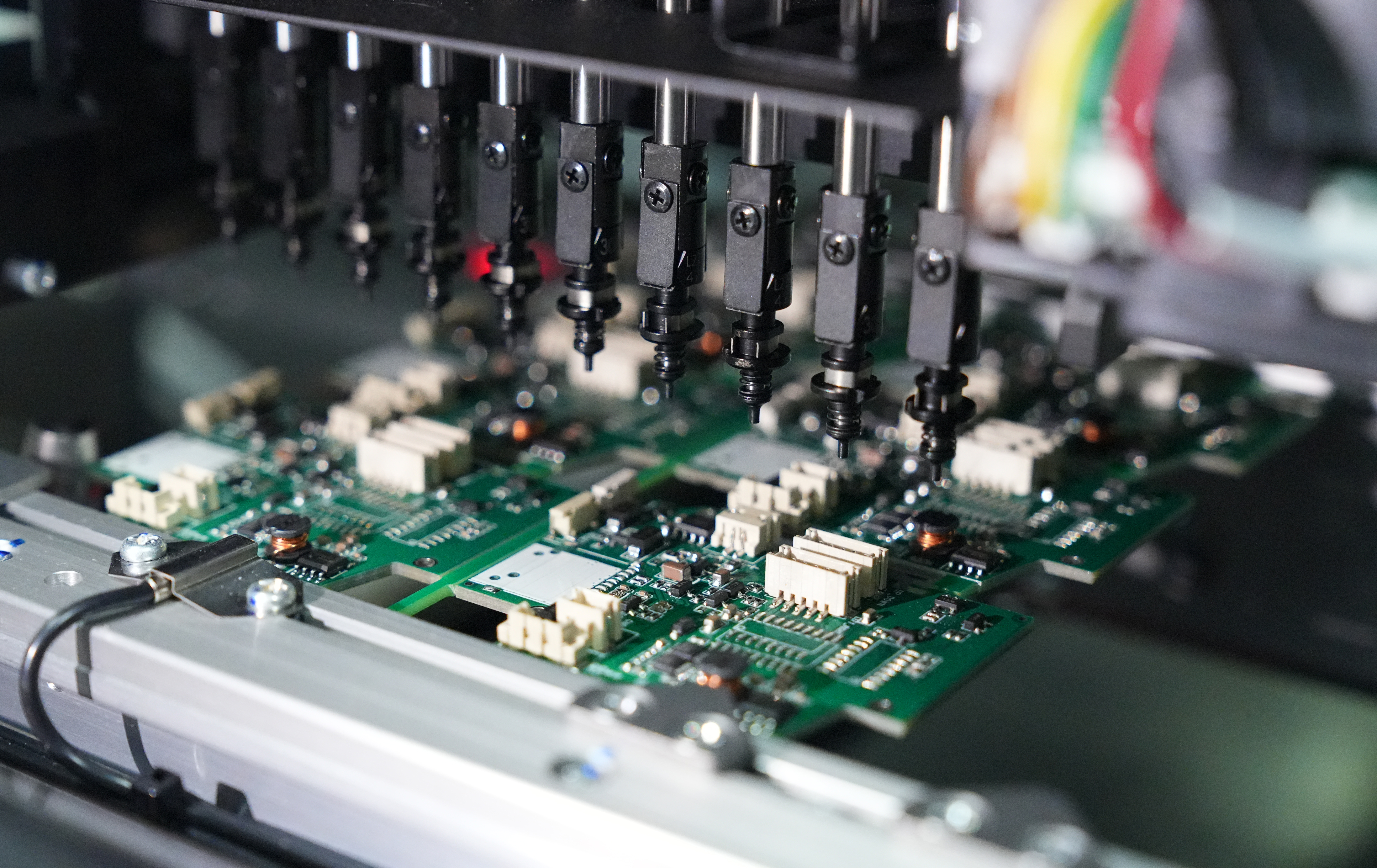

3. Component Placement and Alignment

After printing, components are positioned onto the solder paste deposits. Automated pick-and-place machines use vision systems to achieve precise alignment, while prototypes may be placed manually.

Important factors include:

- Correct polarity and orientation

- Accurate placement height

- Avoiding paste smearing during placement

Surface tension during reflow can self-align small components, but accurate initial placement greatly reduces defects.

4. Preheating Stage

Preheating gradually raises the temperature of the entire assembly. This stage evaporates solvents inside the paste and reduces thermal shock.

Typical engineering goals:

- Uniform temperature distribution across large boards

- Prevention of sudden expansion in multilayer PCBs

- Early activation of flux chemistry

A controlled ramp rate, usually between 1 °C and 3 °C per second, prevents component cracking and solder splatter.

5. Reflow Heating and Solder Melting

During this stage, the temperature rises above the solder alloyâs liquidus point. The metal particles inside the paste melt and flow across the pad and component leads.

What happens physically:

- Flux removes oxides from metal surfaces

- Molten solder forms intermetallic bonds

- Surface tension pulls components into alignment

Engineers closely monitor time above liquidus to ensure complete wetting without overheating sensitive components.

6. Controlled Cooling and Solidification

Cooling begins immediately after peak temperature. This phase determines the internal grain structure of the solder joint.

Why controlled cooling matters:

- Rapid cooling may introduce thermal stress

- Extremely slow cooling can create coarse grain structures

- Balanced cooling produces strong, fatigue-resistant joints

Convection ovens often include dedicated cooling zones to stabilize the solidification process.

7. Inspection, Testing, and Quality Verification

The final step confirms that soldering produced reliable electrical and mechanical connections. Inspection methods vary depending on product complexity.

Typical verification tools:

- AOI to detect bridges, tombstoning, or insufficient solder

- X-ray inspection for hidden joints like BGA packages

- Functional testing or ICT for electrical validation

Feedback from inspection loops back into earlier steps, allowing engineers to fine-tune paste volume, placement accuracy, and temperature profiles.

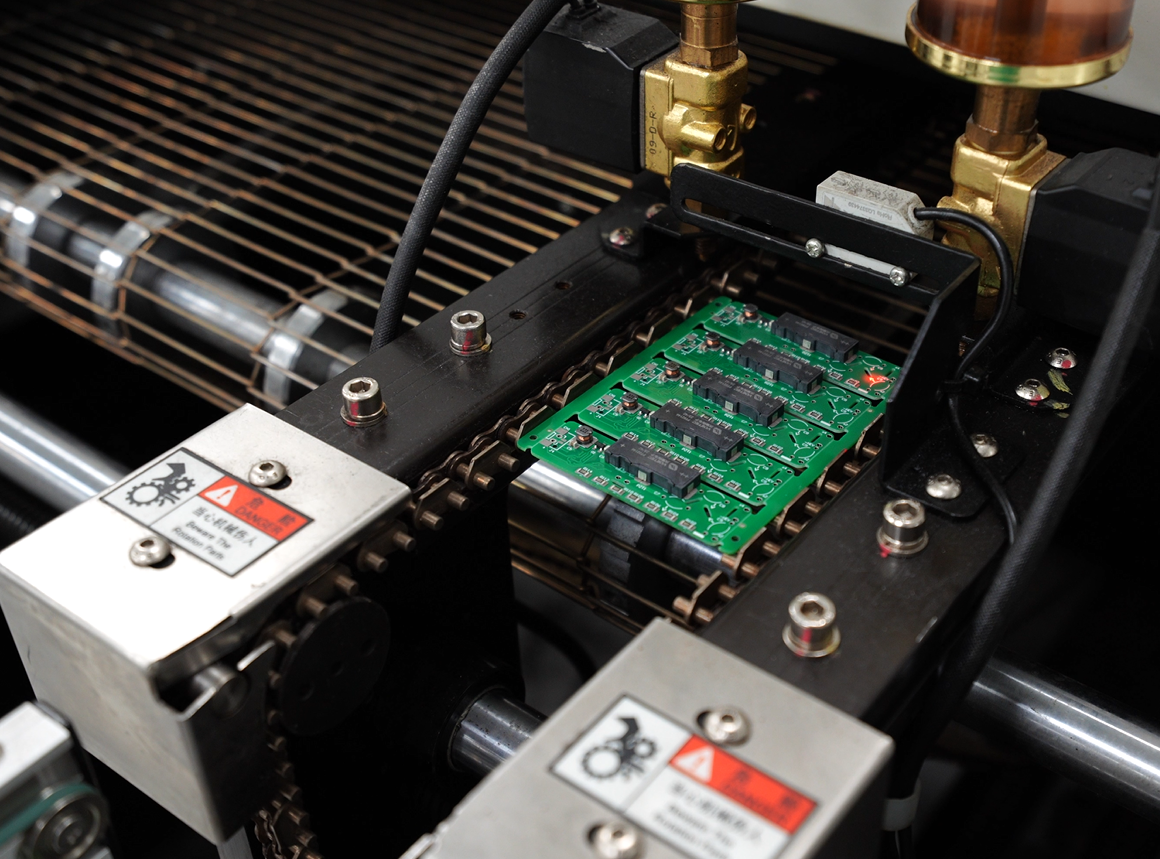

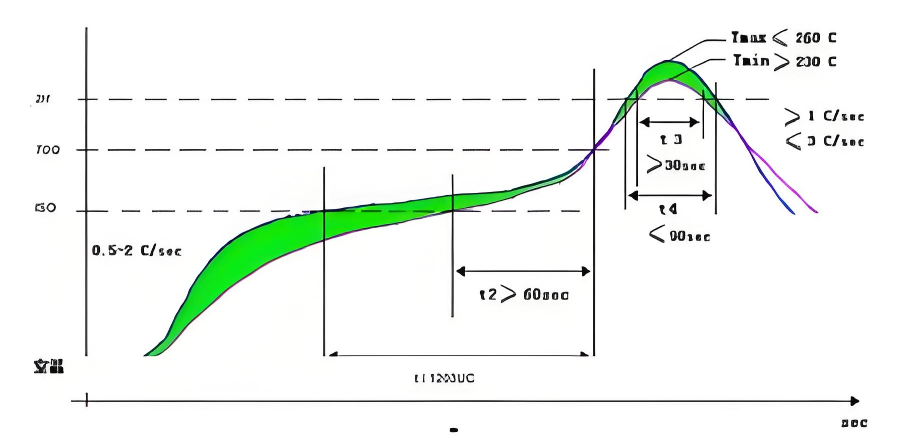

What Are the Phases of Reflow Soldering?

A reflow profile is divided into several thermal zones. Understanding these phases helps engineers fine-tune process stability.

Preheat Phase

Temperature rises gradually to avoid thermal shock. Solvents evaporate during this stage.

Typical ramp rate: 1â3 °C per second.

Soak Phase

The PCB temperature stabilizes between 150 °C and 180 °C. Flux activation begins, and temperature differences across the board reduce.

Reflow Phase

Temperature exceeds the alloy liquidus point. Solder melts and forms joints through wetting and surface tension.

Peak Phase

The highest temperature occurs briefly. Time above liquidus typically lasts 30â90 seconds.

Cooling Phase

Controlled cooling ensures strong grain structure. Rapid cooling may trap stress, while slow cooling can create large brittle grains.

Can You Reflow Without Flux?

Technically possible but rarely recommended.

Flux performs several essential roles:

- Removes oxide layers from metal surfaces

- Improves solder wetting

- Prevents re-oxidation during heating

Without flux, solder may ball up rather than spread. Joint reliability decreases significantly.

In specialized environments, such as vacuum or forming-gas atmospheres, fluxless reflow may be used. However, this requires advanced process control and is not common in standard SMT production.

What Is the 5 Ball Rule for Solders?

The â5 ball ruleâ is an informal guideline used during inspection. If multiple small solder balls appear around a joint, engineers evaluate whether they are cosmetic or reliability concerns.

General interpretation:

- Fewer than five isolated solder balls may be acceptable depending on IPC standards.

- Clusters or balls near fine-pitch leads indicate paste or profile issues.

Common causes include:

- Excessive flux activation

- Rapid temperature ramp

- Contaminated PCB surface

Process tuning often resolves these defects.

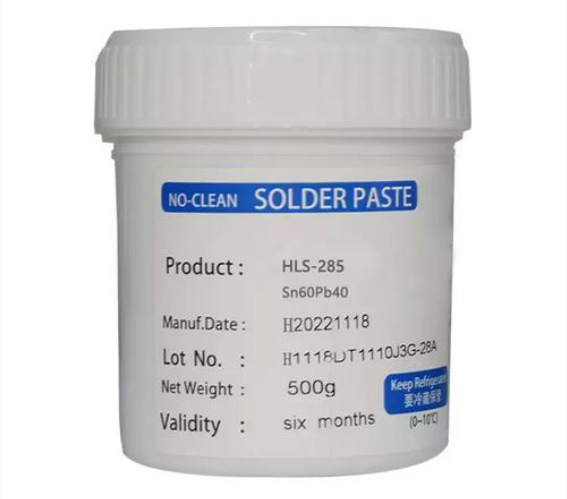

Which Solder Is Better, 60/40 or 63/37?

Both alloys belong to traditional tin-lead systems but behave differently during melting.

60/40 – Sn60/Pb40

- Melting range instead of single point

- Slightly wider plastic state

- More forgiving for manual soldering

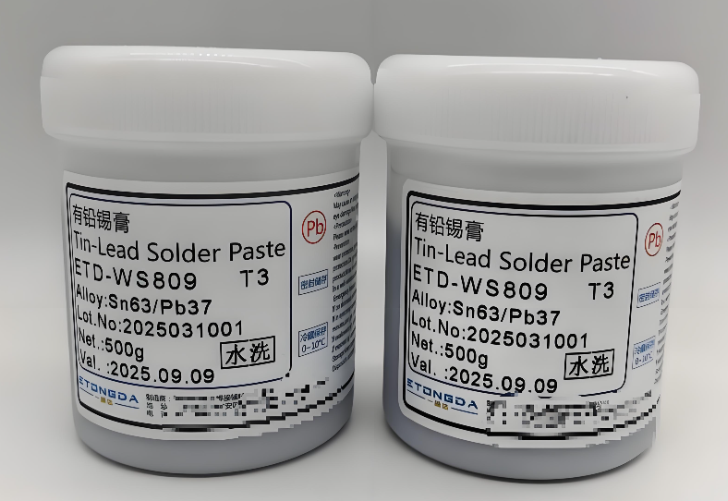

63/37 – Sn63/Pb37

- True eutectic alloy

- Sharp melting point at 183 °C

- Faster solidification and reduced cold joint risk

For automated reflow process soldering, Sn63/Pb37 generally provides better consistency due to its precise melting behavior. However, environmental regulations have pushed most production toward lead-free alloys like SAC305.

What Is the Difference Between Soldering and Reflow Soldering?

Traditional soldering and reflow soldering differ mainly in heat delivery method.

| Aspect | Traditional Soldering | Reflow Process Soldering |

| Heat Source | Localized iron or wave | Controlled oven profile |

| Assembly Type | Through-hole or manual repair | Surface-mount mass production |

| Process Control | Operator dependent | Automated and repeatable |

| Thermal Uniformity | Low | High |

Reflow provides higher throughput and consistency, which explains its dominance in modern electronics manufacturing.

FAQs

1. What Peak Temperature Should Be Used for SAC305 Reflow Process Soldering?

Most profiles target a peak between 235 °C and 245 °C. The exact value depends on board thickness, component sensitivity, and oven capability. Engineers often start with 240 °C and adjust based on wetting quality and component ratings.

2. Can a PCB Be Reflow Soldered Multiple Times Safely?

Yes, but the number of cycles should be limited. Excessive reflow passes may:

- Degrade laminate integrity

- Reduce pad adhesion strength

- Increase risk of microcracking

High-Tg materials and proper cooling help maintain reliability when double-sided assembly requires multiple passes.

3. Why Do Solder Balls Appear After Reflow Process Soldering?

Solder balls usually indicate process imbalance. Common root causes include:

- Too much solder paste volume

- Rapid heating during preheat phase

- Poor stencil release

- Moisture or contamination on PCB surfaces

Adjusting ramp rate and stencil design often eliminates the issue.

4. How to Verify a Reflow Profile Without Expensive Profiling Tools?

Although professional thermocouple profilers offer the highest accuracy, smaller facilities can still validate profiles by:

- Using temperature indicator labels

- Comparing joint wetting appearance

- Monitoring conveyor speed consistency

- Checking for uniform solder fillets across large boards

These practical methods provide reasonable validation for low-volume production.

5. Does Nitrogen Atmosphere Improve Reflow Process Soldering Reliability?

Nitrogen reduces oxygen concentration in the oven, which enhances solder wetting and decreases oxidation. Benefits include:

- Shinier solder joints

- Reduced solder ball formation

- Improved fine-pitch performance

However, nitrogen increases operational cost. Many manufacturers reserve it for high-density or high-reliability assemblies.

6. What Conveyor Speed Is Ideal for Small Batch Reflow Process Soldering?

There is no universal speed. Engineers typically adjust conveyor rate so total profile duration falls between 3 and 6 minutes. Thicker boards or heavy copper designs require slower speeds to ensure even heating.