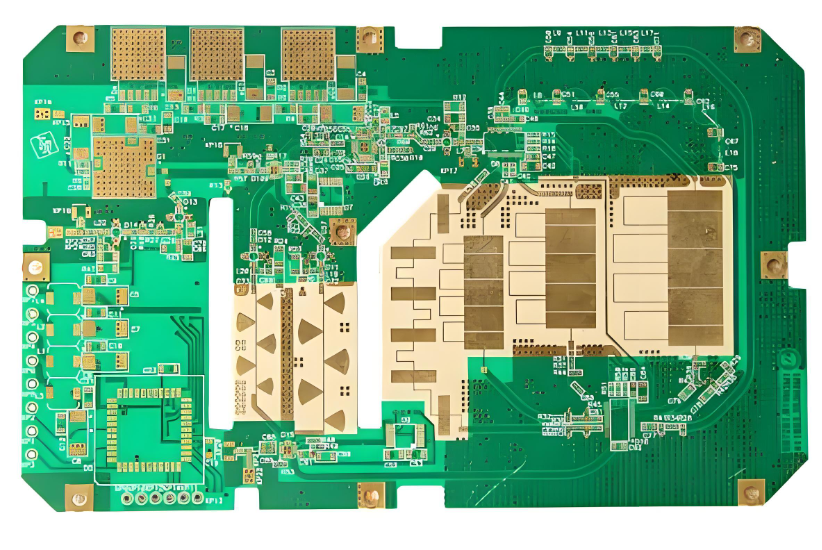

Choosing the right RF PCB manufacturer in the USA directly affects signal integrity, insertion loss, and long-term product reliability. In RF systems operating above 1 GHz, even a ±5% variation in dielectric constant (Dk) or ±1 mil trace deviation can cause impedance mismatch and measurable signal degradation.

For applications such as 5G base stations, radar modules, satellite communication, medical imaging, and defense electronics, RF PCBs demand more than standard multilayer fabrication. This guide reviews the top 10 RF PCB manufacturers in the USA, explains how they were evaluated, and helps buyers identify what truly defines a capable RF PCB manufacturing partner.

What Is an RF PCB Manufacturer?

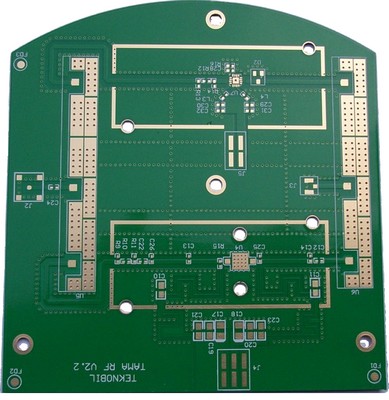

An RF PCB manufacturer is a factory equipped to control high-frequency electrical behavior, not just fabricate boards using RF laminates.

A qualified RF PCB manufacturer typically demonstrates:

- Controlled impedance tolerance of ±5â10%

- Proven experience with Rogers, Taconic, PTFE, and hybrid RF stack-ups

- Line width and spacing control down to ±1 mil

- RF-aware stack-up and grounding validation

- Process consistency between prototype and volume production

Unlike standard digital PCBs, RF designs are sensitive to copper roughness, resin distribution, and prepreg variation. Manufacturers without RF-specific process control often struggle to deliver repeatable RF performance.

Common Challenges When Choosing an RF PCB Manufacturer in the USA

Despite the strong PCB ecosystem in the USA, RF buyers frequently encounter the following issues:

- Impedance drift between batches, especially in volume production

- Limited experience with hybrid RF stack-ups (Rogers + FR-4)

- RF performance verified only at prototype stage, not scaled production

- Long RF laminate lead times (often 4â6 weeks)

- Minimal engineering feedback beyond Gerber fabrication

According to industry feedback, over 30% of RF PCB project delays are caused by material handling or impedance inconsistencies rather than design errors. This highlights why RF capability must be validated beyond certifications.

How We Evaluated the Top RF PCB Manufacturers in the USA?

Manufacturers were evaluated using practical RF manufacturing benchmarks, not marketing claims.

Key evaluation criteria included:

- RF material portfolio (Rogers RO4350B, RO4003C, RO5880, Taconic, PTFE)

- Demonstrated impedance control capability (†±10%)

- Experience with multilayer RF and mixed-signal designs

- Quality certifications relevant to RF applications

- Ability to support prototype + mid-volume production

Factories focusing only on RF prototyping without scalable production control were ranked lower.

Top 10 RF PCB Manufacturers in USA

| Rank | Company Name | RF PCB Capability | Key Advantages | Location |

| 1 | TTM Technologies | RF & microwave multilayers | Defense & aerospace expertise | California |

| 2 | Sanmina | High-reliability RF PCBs | End-to-end manufacturing | California |

| 3 | Summit Interconnect | RF multilayer & HDI | Quick-turn RF capability | California |

| 4 | Advanced Circuits | RF prototypes | Fast turnaround | Colorado |

| 5 | Sierra Circuits | High-frequency fabrication | Strong DFM support | California |

| 6 | Rush PCB | RF proto & low volume | Cost efficiency | California |

| 7 | Epec Engineered Technologies | RF & mixed-signal PCBs | Integrated PCBA | Massachusetts |

| 8 | Green Circuits | RF PCB manufacturing | EMS integration | California |

| 9 | All Flex Solutions | RF flexible circuits | Specialty RF flex | Minnesota |

| 10 | APCT | Complex RF multilayers | Advanced stack-ups | California |

Are US RF PCB Manufacturers Always the Best Choice?

US RF PCB manufacturers offer clear advantages:

- Local engineering communication

- ITAR and defense compliance

- Established aerospace and telecom experience

However, buyers should also consider:

- Higher manufacturing costs (often 30â50% above offshore)

- Limited RF laminate inventory

- Less flexibility for mid-volume scaling

As a result, many OEMs now adopt a hybrid sourcing strategy, using US suppliers for early development and qualified offshore RF PCB manufacturers for volume production.

Global Alternative RF PCB Manufacturer for USA Customers

As RF projects become more globalized, many USA companies now evaluate global RF PCB manufacturers that offer comparable RF performance with better lead time, cost flexibility, and material availability. Below is a representative list of global RF PCB manufacturers serving high-frequency and microwave applications, based on manufacturing capability, RF material experience, and export readiness.

| Rank | Company Name | Country / Region | RF PCB Capability | Key Strengths for USA Customers |

| 1 | EBest Circuit (Best Technology) | China / Vietnam | RF, microwave, hybrid stack-ups | Fast lead time, wide RF materials, 30â50% cost advantage |

| 2 | AT&S | Austria | RF, high-frequency, IC substrates | High-end RF technology, EU quality standards |

| 3 | Unimicron | Taiwan | RF, HDI, high-speed | Advanced multilayer RF capability |

| 4 | Compeq | Taiwan | RF & high-speed PCBs | Stable mass production for RF designs |

| 5 | Meiko Electronics | Japan | RF & automotive PCBs | High reliability, automotive RF experience |

| 6 | Shennan Circuits | China | RF & telecom PCBs | Strong telecom and RF infrastructure |

| 7 | Ibiden | Japan | RF & package substrates | Precision RF manufacturing |

| 8 | Kinwong | China | RF & mixed-signal PCBs | Cost-effective RF volume production |

| 9 | Chin Poon Industrial | Thailand | RF & automotive PCBs | Southeast Asia manufacturing flexibility |

| 10 | Dynamic Electronics | Taiwan | RF multilayer PCBs | Mature RF fabrication processes |

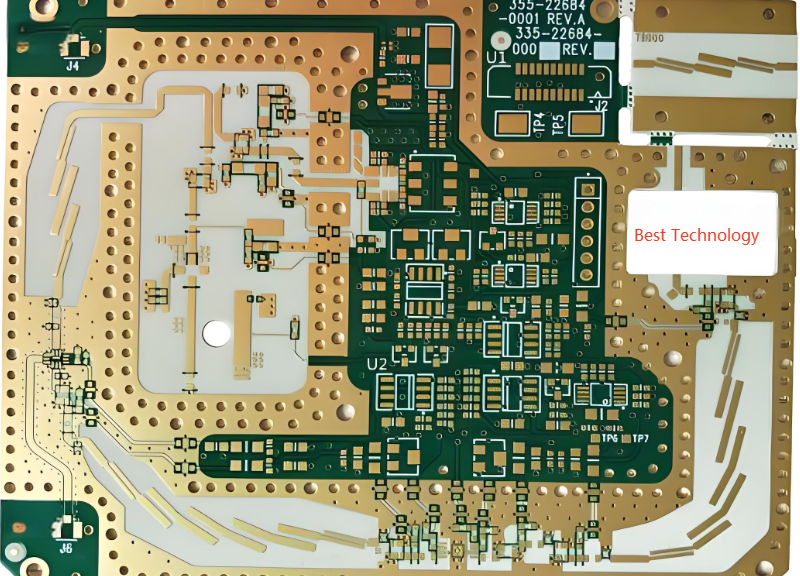

Why Global Buyers Choose EBest Circuit (Best Technology) as an Experienced RF PCB Manufacturer?

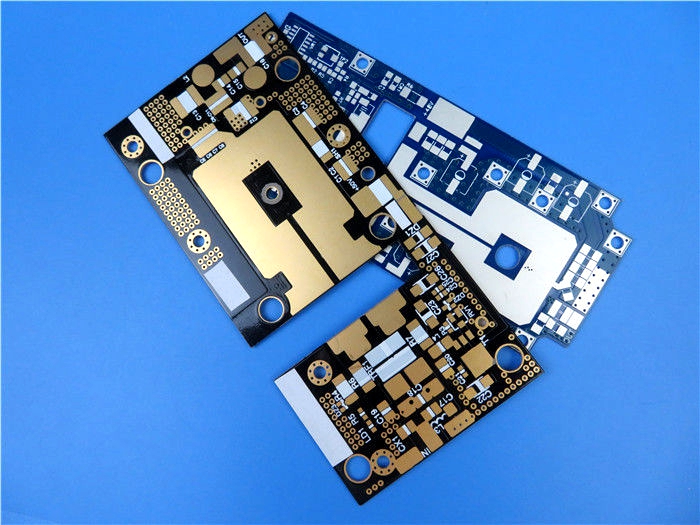

EBest Circuit (Best Technology) supports RF PCB programs with a focus on repeatability and manufacturability, not just RF materials.

Our RF PCB capability includes:

- Rogers, Taconic, Isola, and hybrid RF stack-ups

- Controlled impedance down to ±8%

- RF trace width control to ±1 mil

- Multilayer RF boards up to 20+ layers

- ISO 9001, ISO 13485, IATF 16949, and AS9100D certified systems

- MES-based traceability for materials and process control

This enables USA customers to transition smoothly from prototype to volume production without RF performance drift.

FAQs

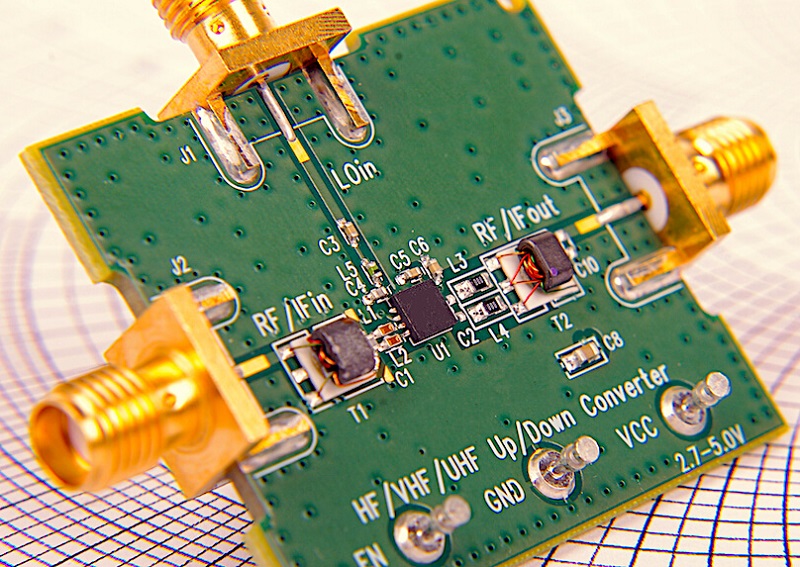

1. What materials do RF PCB manufacturers typically use?

Common materials include Rogers RO4000/RO5000 series, Taconic, PTFE, and selected low-loss FR-4.

2. Is FR-4 suitable for RF PCB applications?

FR-4 is generally suitable below 1 GHz; higher frequencies benefit from low-loss laminates.

3. How do RF PCB manufacturers control impedance?

Through stack-up modeling, dielectric thickness control, copper roughness management, and process calibration.

4. What is the typical lead time for RF PCB prototypes?

Most RF PCB prototypes ship within 7â12 working days, depending on material availability.

5. How can I verify an RF PCB manufacturerâs RF capability?

Review impedance data, RF material history, similar project experience, and quality certifications.