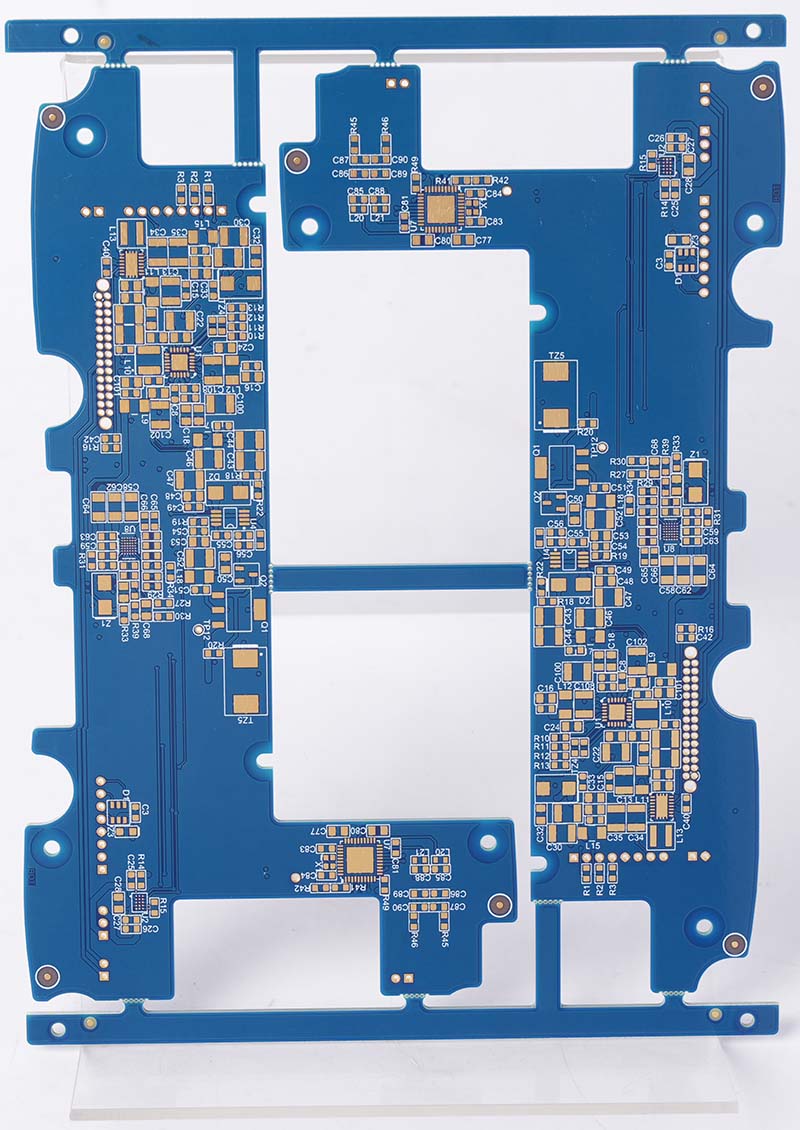

PCB manufacturing Johannesburg‚Äč refers to the industry of designing and fabricating printed circuit boards within South Africa’s economic hub. This guide explores the top service providers in Johannesburg and how they power innovation across the region.

Sourcing PCBs should be straightforward, but engineers and procurement managers often face significant hurdles. What common frustrations can derail a project?

- Prototype Delays: Slow international turnaround slows innovation and pushes back launch dates.

- Communication Gaps: Language and time zones make technical discussions slower and less accurate.

- Unpredictable Costs: Shipping, duties, and currency swings create unexpected budget pressure.

- Inconsistent Quality: Defective boards trigger test failures, rework, and schedule slips.

- Limited Technical Support: Hard to access experts for HDI, impedance control, and special materials.

Partnering with a top-tier local manufacturer directly resolves these issues.‚Äč A leading PCB manufacturing Johannesburg‚Äč provider offers integrated solutions for a smoother process. Here‚Äôs how:

- Accelerated Lead Times:‚Äč Local production enables faster prototyping, often within days instead of weeks.

- Seamless Collaboration:‚Äč Direct communication in the same time zone ensures clear, efficient technical support.

- Cost Transparency:‚Äč Local pricing in ZAR eliminates hidden international fees and currency risk.

- Quality Assurance:‚Äč Proximity allows for better oversight and consistent adherence to IPC standards.

- Advanced Engineering Expertise:‚Äč Access to local DFM (Design for Manufacturability) support for sophisticated projects.

Among the leading PCB manufacturing companies‚Äč in China, BEST Technology‚Äč stands out with over 19 years of experience. We offer full turnkey services, from advanced PCB fabrication to assembly, specializing in fast-turn prototypes and complex builds. For a consultation, pls feel free to contact us at sales@bestpcbs.com.

Why Johannesburg is the Epicenter for PCB Manufacturing South Africa?

Choosing a base for electronics production requires strategic thinking. Within South Africa, PCB manufacturing Johannesburg stands out due to its strong industrial demand, powerful logistics, concentrated talent, and an integrated support network that accelerates every stage of development.

1. Strong Industrial Demand

- Johannesburg, as South Africa’s financial and industrial core, hosts telecom, fintech, automotive, mining, and automation sectors. This creates constant demand for electronic components and gives PCB manufacturing companies in the city a broad and stable customer base.

2. Superior Logistics

- With O.R. Tambo International Airport supporting Africa’s highest cargo throughput, Johannesburg offers the fastest access to imported laminates and components. This speeds up raw-material flow and finished-product shipping, strengthening lead times for PCB manufacturing South Africa operations.

3. Engineering Talent Concentration

- Local universities and technical institutes supply a skilled workforce trained for electronics and manufacturing. As a result, PCB manufacturing Johannesburg providers benefit from accessible expertise in design, process control, and technical troubleshooting.

4. Complete Local Supply Chain

- Johannesburg’s ecosystem includes chemical suppliers, machining shops, component distributors, and testing labs. This reduces reliance on long-distance services and makes the manufacturing PCB process more agile.

5. Hub for Innovation and Collaboration

- Corporate centers, R&D hubs, and industry events cluster in Johannesburg, enabling faster feedback between designers and manufacturers. This environment keeps PCB manufacturing Johannesburg aligned with evolving technology trends.

In summary, Johannesburg leads PCB manufacturing South Africa due to its industrial scale, logistics strength, skilled talent pool, integrated supply chain, and collaborative business culture. For teams seeking a resilient partner and efficient production flow, Johannesburg remains the most strategic location.

Top Rated PCB Manufacturing Johannesburg

Here is a curated list of the top PCB manufacturers and electronics contract manufacturers based in Johannesburg, Gauteng. These companies offer a range of services from prototyping to high-volume assembly.

Top 10 PCB Manufacturing Johannesburg

| Company Name | Board Type | Certifications |

|---|---|---|

| ICAPE Trax | Multilayer, High-Density Interconnect (HDI), Aluminum Base | ISO 9001:2015, IPC-6012, RoHS, UL |

| Microtronix Manufacturing | Single-Sided, Double-Sided, Multilayer, SMT Assembly | ISO 9001:2015, IPC-A-610, AS9100D, IATF 16949 |

| Projects Concern Manufacturing | Custom PCB Design & Assembly, Class 3 Specifications | ISO 9001:2015, T√úV Certified |

| Repro Supplies | Prototyping, Standard PCBs, Rapid Turnaround | ISO 9001:2015, MASC Permits (Flameproof/Intrinsic Safety) |

| Bosco Printed Circuits | Single-Sided, Double-Sided, Aluminum Base | ISO 9001:2015, IPC Member |

| Central Circuits (Pty) Ltd | Prototyping, Low to Medium Series Production | ISO 9001:2008 |

| ExpandoWorks (Pty) Ltd | Surface Mount Technology (SMT), High Volume Assembly | ISO 9001:2016, AS9100D, IATF 16949 |

| Circuitboard Manufacturing | Innovative PCB Technologies (Established 1998) | Industry Standard |

| Deman MFG | Local Quick-Turn PCB Assembly, SMT & Through-Hole | ISO 9001, Rapid Turnaround (24-72 hrs) |

| Ashdan Electronics | PCB Assembly, Component Placement | ISO 9001, AS9100 Rev D |

💡 Selection Tips

- For Prototypes: Check if the manufacturer offers “Rapid Turnaround” (e.g., Repro Supplies or Deman MFG).

- For High Volume: Look for companies with SMT lines (e.g., Microtronix or ExpandoWorks).

- For Aerospace/Defense: Ensure they have AS9100 certification (e.g., Projects Concern).

Why Local Teams Prefer Faster Prototype Support from PCB Manufacturing Johannesburg?

Speed decides competitiveness in electronics development. Local teams choose PCB manufacturing Johannesburg because they gain faster prototype cycles, closer collaboration, and more predictable development timelines. These advantages create a pace that overseas suppliers cannot match.

Drastically Shortened Iteration Cycles:

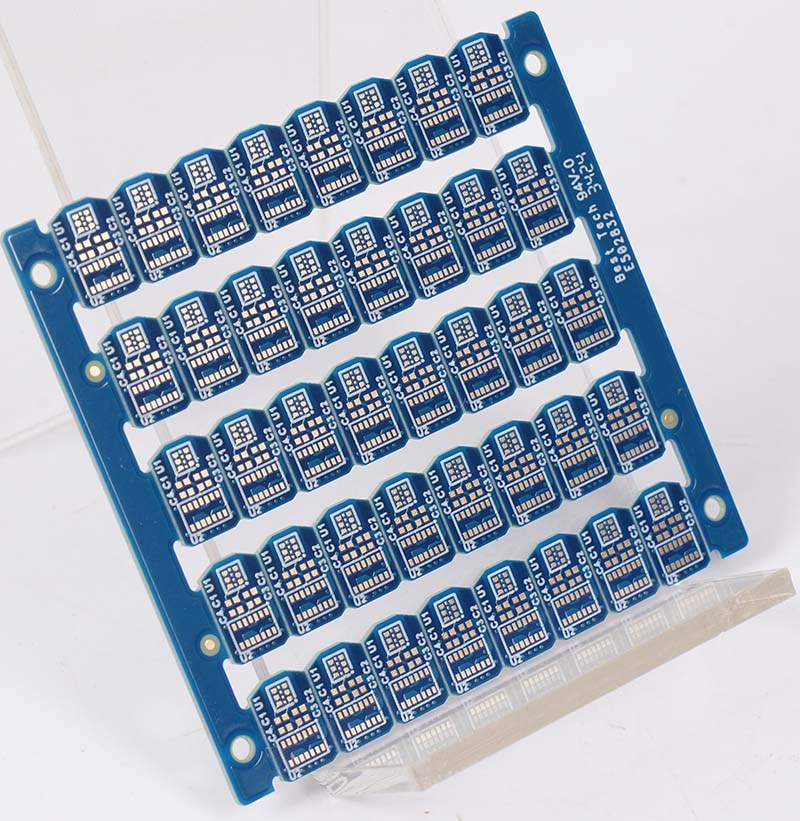

- Local manufacturers deliver prototypes within days, not weeks. This supports rapid testing and fast design refinement, turning long development cycles into tight, efficient sprints.

Elimination of Logistics Delays:

- Local delivery removes customs risks, transport delays, and unpredictable shipping schedules. Boards move quickly from factory to lab, keeping progress aligned with engineering needs.

Enhanced DFM Collaboration:

- Proximity enables real-time feedback and even on-site reviews. Clear communication reduces misunderstandings, lowers the number of prototype spins, and improves design accuracy.

Cost Efficiency Through Faster Development:

- Although the unit cost may be slightly higher, fewer revision cycles and shorter engineering time reduce total development cost. Earlier market entry strengthens overall project value.

In conclusion, local PCB manufacturing Johannesburg support gives teams faster cycles, better communication, and lower project risk. This speed-driven ecosystem helps engineers reach a stable, manufacturable design sooner and launch products with greater confidence.

How to Locate Reliable PCB Board Manufacturers Near Me in Gauteng?

Finding dependable partners in Gauteng’s electronics sector requires a clear, efficient selection process. By focusing on precise searches, trusted resources, and direct engagement, teams can confidently identify PCB board manufacturers near me that match their technical needs.

Direct Engagement & RFQ Testing:

- Contact shortlisted factories to evaluate response speed, technical clarity, and willingness to provide DFM guidance. Their engagement style reflects how they will perform during real production.

Targeted Online Searches:

- Use specific regional terms such as ‚ÄúPCB manufacturing Johannesburg address‚ÄĚ or ‚ÄúPCB manufacturing Gauteng‚ÄĚ to filter accurate local suppliers. Prefer manufacturers with clear capability pages and transparent contact details.

Industrial Directories & B2B Platforms:

- Check verified sources that list certifications, capacity, and customer feedback. Filter only Gauteng-based PCB manufacturing companies and shortlist those aligned with your project scope.

Professional Networks & Associations:

- Leverage colleagues, meetups, and industry groups for real user experiences. First-hand recommendations often reveal reliability and communication quality better than websites alone.

In summary, locating reliable PCB board manufacturers near me‚Äč in Gauteng requires a systematic approach combining digital research, professional networking, and thorough direct evaluation. By methodically searching with precise terms, leveraging specialized directories, tapping into professional networks, and rigorously testing candidate manufacturers through direct engagement, you can identify partners who will contribute to your project’s success rather than becoming a source of delay or compromise.

Comparing Service Levels between PCB Manufacturing in Johannesburg, Cape Town, and Pretoria

Comparing PCB manufacturing in Johannesburg, Cape Town, and Pretoria helps engineering teams understand how each region supports different stages of electronics development. South Africa’s PCB landscape is not uniform; instead, each city has formed its own manufacturing profile shaped by speed, capacity, industry focus, and supply-chain depth. By reviewing measurable data rather than general descriptions, teams can identify the most strategic location for rapid prototyping, volume production, or specialized applications.

| Metric | Cape Town | Johannesburg | Pretoria |

|---|---|---|---|

| Prototype Lead Time (Days) | 3 | 7‚Äď10 | 10‚Äď14 |

| Volume Lead Time (Days) | 5 | 12‚Äď18 | 14‚Äď21 |

| SMT Capacity (Units/Day) | 1,500,000 | 8,000,000+ | 250,000 |

| On-Time Delivery (%) | 96 | 92 | 89 |

| Rework Rate (%) | 1.2 | 1.5 | 1.8 |

| Return Rate (%) | 0.8 | 1.1 | 1.3 |

| Prototype Cost Index | 1.25 | 1.00 | 1.10 |

| Volume Cost Index | 1.10 | 0.95 | 1.00 |

| Local Material Availability (%) | 40 | 70 | 55 |

| Logistics Efficiency (1‚Äď5) | 2 | 5 | 4 |

| Component Availability (1‚Äď5) | 3 | 5 | 3 |

| Export Efficiency (1‚Äď5) | 5 | 4 | 3 |

| Rapid Prototype Suitability (1‚Äď5) | 5 | 3 | 2 |

| IPC-3 / High-Reliability Fit (1‚Äď5) | 5 | 2 | 2 |

| High-Volume PCBA Fit (1‚Äď5) | 3 | 5 | 3 |

| Cost-Sensitive Project Fit (1‚Äď5) | 3 | 5 | 4 |

| Automotive / Defense Fit (1‚Äď5) | 4 | 3 | 5 |

| Consumer Electronics Fit (1‚Äď5) | 3 | 5 | 3 |

The data shows that PCB manufacturing in South Africa follows a clear regional pattern: Cape Town leads in high-end fabrication and fast prototype cycles, Johannesburg dominates in assembly strength and supply-chain agility, while Pretoria offers stable industry-specific production. Evaluating these differences through quantifiable metrics‚ÄĒrather than broad assumptions‚ÄĒgives teams a more accurate basis for choosing the right manufacturing partner. Whether the priority is speed, cost, reliability, or industry alignment, each city provides distinct advantages that can significantly influence project success.

Comparing PCB Manufacturing Cape Town vs. Johannesburg Costs

Cost differences between PCB manufacturing Cape Town and PCB manufacturing Johannesburg often come down to production scale, supply-chain density, and material access. While Cape Town performs well for smaller prototype batches, Johannesburg typically offers a more cost-efficient structure for mid-to-large volumes due to its concentrated logistics ecosystem and strong component availability. The most accurate comparison always comes from requesting matched quotes for your exact Gerber files, but the table below outlines common cost patterns observed in the South African market.

| Cost Factor | Cape Town | Johannesburg | Difference (%) |

|---|---|---|---|

| Prototype Cost Index | 1.25 | 1.00 | CT +25% |

| Volume Cost Index | 1.10 | 0.95 | CT +15% |

| Material Availability (%) | 40 | 70 | JHB +30% |

| Logistics Cost Level (1‚Äď5) | 4 | 2 | CT +50% |

| Average Lead Time Cost Impact | Medium | Low | JHB ‚Äď20% |

| Batch Production Efficiency (1‚Äď5) | 3 | 5 | JHB +40% |

(Index reference: 1.00 = baseline market pricing)

In summary, PCB manufacturing Cape Town is well-suited for precision prototypes and specialized, small-batch builds, whereas PCB manufacturing Johannesburg tends to deliver better cost efficiency for high-volume or recurring production runs. Johannesburg’s strong logistics infrastructure and higher material availability often reduce total manufacturing cost, not only the unit price. For an accurate assessment, companies should compare city-specific quotes using identical project inputs to confirm the most economical option for their manufacturing strategy.

How Does PCB Manufacturing Johannesburg Ensure the Quality During Manufacturing PCB Process?

Reputable PCB manufacturing Johannesburg‚Äč suppliers ensure quality throughout the manufacturing PCB process‚Äč with rigorous controls. This includes:

- Automated Optical Inspection (AOI):‚Äč To detect defects on inner layers and post-etch.

- Electrical Testing:‚Äč Flying probe and fixture-based testing to verify 100% electrical connectivity.

- Impedance Control:‚Äč Advanced testing to ensure signal integrity in high-frequency designs.

- Adherence to IPC-A-600 Standards:‚Äč Regular audits and checks to maintain the highest acceptance criteria for finished boards.

How to Evaluate and Choose Reliable PCB Manufacturing Companies?

Choosing among PCB manufacturing companies‚Äč requires a structured evaluation. Key factors include:

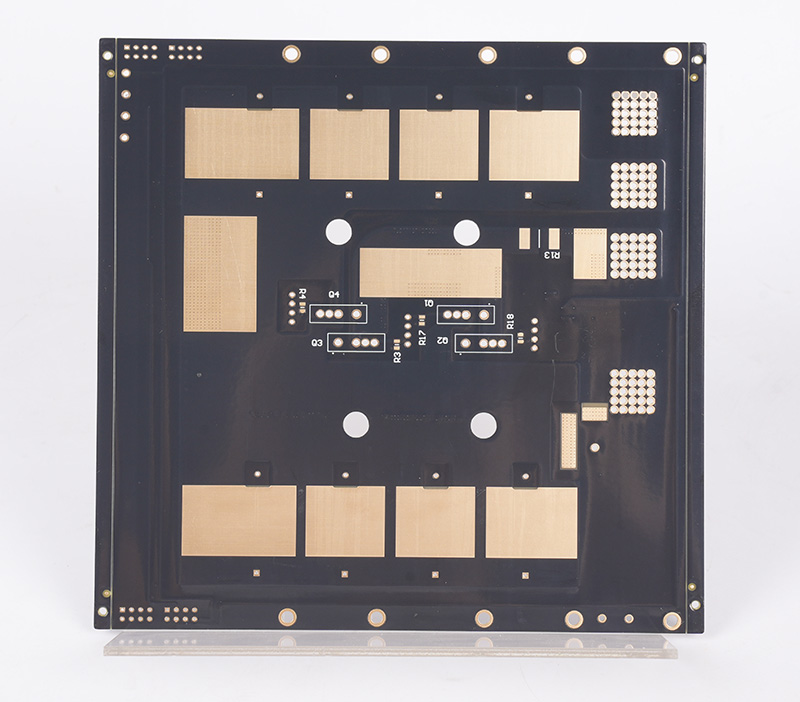

- Technical Capability:‚Äč Can they produce your specific board type (e.g., HDI, flex-rigid)?

- Quality Certifications:‚Äč Look for ISO, UL, and IATF 16949 for automotive projects.

- Manufacturing Capacity & Lead Times:‚Äč Ensure they can handle your volume and timeline.

- Communication & Customer Service:‚Äč Assess their responsiveness and technical support.

- Transparent Pricing & Value:‚Äč Obtain detailed quotes and compare the overall value, not just the lowest price.

Why EBest Circuit (Best Technology) Is Your Ideal PCB Manufacturing Johannesburg Partner?

Local Market Understanding with Global Capabilities

- EBest Circuit (Best Technology) blends international manufacturing strength with responsive support tailored for Johannesburg. With more than 19 years of experience and over 1,700 clients across 40 countries, we deliver proven expertise backed by global certifications such as ISO 9001:2015 and IATF 16949:2016. Our one-on-one communication model and 12-hour response promise give Johannesburg teams the clarity and accessibility of working with a local partner.

Rapid Prototyping and Speed-to-Market

- Speed is a core advantage. Urgent boards can be completed within 24 hours, with clear fast-track options such as 24-hour turnaround for 1‚Äď2 layer FR4 prototypes and 48-hour service for 4-layer builds. A 97% on-time delivery rate ensures Johannesburg projects stay on schedule and move from concept to market faster.

Advanced Technical Expertise in Specialized Boards

- Our capabilities extend far beyond standard FR4. We support advanced technologies including MCPCB, Ceramic PCB, heavy-copper designs up to 20 oz, and rigid-flex structures. With production abilities such as up to 32-layer FR4 and 2 mil line/space HDI, powered by equipment from Hitachi and Posalux, we meet the demands of Johannesburg’s most complex electronic applications.

Uncompromising Commitment to Quality

- Quality is woven into every production stage. Our workflow includes stringent checks from materials to final inspection, supported by AOI, Flying Probe, Universal E-Testers, and X-Ray measurement tools. Full IPC compliance ensures Johannesburg customers receive consistently reliable, high-performance boards.

Comprehensive Turnkey Service

- Our end-to-end solution covers design, fabrication, sourcing from authorized distributors, SMT/THT assembly, and complete box-build integration. By consolidating the entire workflow into a single service channel, we reduce supply-chain complexity for Johannesburg clients and provide expert engineering guidance at every step.

Ultimately, our comprehensive turnkey service allows Johannesburg-based innovators to focus on their core design and business goals, while we expertly manage the entire manufacturing lifecycle.

To sum up, PCB manufacturing Johannesburg‚Äč represents a critical, high-capacity hub for the South African and broader African electronics industry, providing the scale, expertise, and speed essential for modern technology development. This guide has detailed why the city is a premier destination, how to select a partner, and what to expect from local services.

For teams seeking a partner that combines the advantages of the Johannesburg ecosystem with advanced technical capabilities and reliable service, the path is clear. BEST Technology‚Äč is committed to being your trusted PCB manufacturing Johannesburg‚Äč provider, ensuring your projects move from concept to market with efficiency and confidence. Pls feel free to contact our team at sales@bestpcbs.com‚Äč to discuss your requirements.

FAQs

What is PCB Manufacturing Machine Price?

- The PCB manufacturing machine price‚Äč varies enormously, from tens of thousands for basic equipment to millions for full automated production lines. The cost depends on the machine’s purpose (drilling, plating, imaging, testing), precision, and level of automation. Most businesses partner with a manufacturer rather than investing in their own machines.

In which regions of South Africa are PCB manufacturing companies most concentrated?

- PCB manufacturing companies‚Äč are predominantly concentrated in the Gauteng Province, specifically in and around Johannesburg‚Äč and Pretoria. This region is the nation’s industrial and economic heartland, offering the necessary infrastructure, supply chains, and skilled workforce. The Western Cape, centered on Cape Town, is another significant hub, particularly for the technology and innovation sectors.