With 20 years of professional experience in PCBA manufacturing, EBest(Best Technology) provide high-quality PCB assembly Netherlands services that cover every stage from prototyping to mass production. Our focus on efficiency, strict quality control and reliable delivery makes us a trusted partner for businesses seeking seamless PCB assembly Netherlands solutions, addressing local pain points and meeting the region’s high standards for electronic components.

Are You Facing These Problems of PCB Assembly Netherlands?

- Do you struggle with unstable component supply that delays PCB assembly Netherlands projects?

- Is high cost a barrier when requesting small-batch prototyping for PCB assembly Netherlands?

- Do you face issues with fake/refurbished components affecting assembly quality in the Netherlands?

- Is meeting strict environmental compliance requirements for Dutch PCB assembly challenging?

- Do welding defects reduce reliability of electronic assemblies produced locally?

- Does poor communication with partners cause errors in Dutch PCB assembly orders?

- Is traceability of production processes a concern for Netherlands-based assembly projects?

- Is long lead time common when working with local Dutch PCB assembly providers?

One Stop PCB Assembly Netherlands Service: From Prototyping to Production

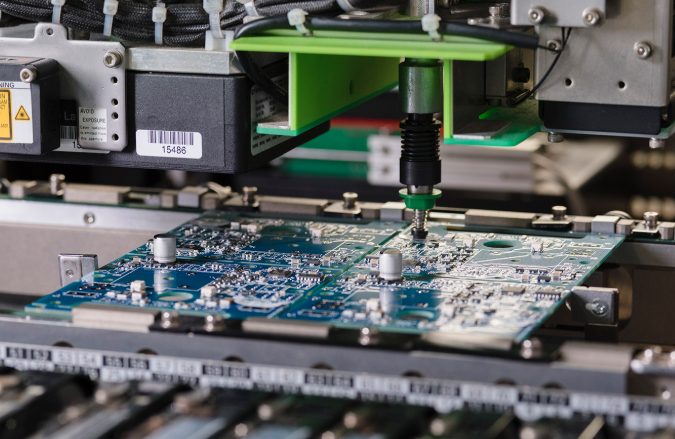

Rapid, precise and cost-effective prototyping kickstarts the one-stop PCB assembly process, offering flexible small-batch options from 1 to 100 units, ideal for validating designs without the wasteful cost of unnecessary large runs. High-precision SMT equipment guarantees every prototype aligns flawlessly with design specifications, minimizing rework and shortening product development cycles.

Completed in just 3-5 working days, prototyping enables quick testing, adjustments and refinements, moving PCB assembly Netherlands projects forward with confidence and reducing time-to-market significantly, a critical advantage in fast-paced electronic markets.‚Äč

Seamless scaling to mass production follows approved prototypes, with no disruptions or extra coordination, just smooth progress from design concept to finished products. Orders of all sizes are supported, from 100 to 100,000+ units, with every critical step integrated into a streamlined workflow: component procurement, SMT assembly, through-hole insertion, precision welding and comprehensive functional testing.

This all-in-one approach eliminates the hassle of managing multiple vendors, cuts communication errors and ensures consistent quality across every unit, saving time, reducing costs and delivering reliable results for PCB assembly Netherlands projects every time, aligned with the highest industry standards for precision and durability.

Why Choose EBest(Best Technology) for PCB Assembly Netherlands Partner?

Reasons why choose EBest( Best Technology) for PCB assembly Netherlands Parnter:

- One-Stop End-to-End Solution: Streamlines every stage from prototyping to mass production, wiping out the frustration of coordinating multiple vendors and cutting down project delays, letting your PCB assembly Netherlands projects move forward seamlessly, with zero unnecessary hassle and maximum efficiency.‚Äč

- 5-Year Quality Guarantee: Delivers uncompromising long-term reliability for your PCB assembly Netherlands products, slashing unplanned after-sales costs and eliminating the risk of costly product failures, giving you total peace of mind, knowing your investment is protected for years to come.‚Äč

- Full-Process Traceability via MES System: Solves traceability pain points for PCB assembly Netherlands production with real-time, end-to-end transparency, every manufacturing step is documented, ensuring compliance and letting you track your order‚Äôs progress at every turn, no guesswork required.‚Äč

- 99.2% On-Time Delivery Rate: Crushes long lead time frustrations for your PCB assembly Netherlands orders, keeping your projects on schedule and accelerating time-to-market, so you never miss a critical deadline or lose competitive edge in fast-paced electronic markets.‚Äč

- Stable Global Component Supply Chain: Eliminates delays caused by component shortages, securing consistent, high-quality material availability for your PCB assembly Netherlands projects, no more project halts, no compromises on quality, just reliable progress.‚Äč

- Strict Environmental Compliance: Meets all international standards including RoHS, ensuring your PCB assembly Netherlands products pass local regulations effortlessly, complete with verifiable compliance reports, so you avoid costly penalties and market access barriers.‚Äč

- Advanced AOI & X-Ray Testing: Eradicates welding defects and counterfeit components for your PCB assembly Netherlands, guaranteeing ‚Äúnear-zero defect‚ÄĚ quality that exceeds industry standards, your products are rigorously tested, so you deliver only the best to your customers.‚Äč

- 24/7 Professional Communication Support: Eliminates costly miscommunication errors for your PCB assembly Netherlands orders, with round-the-clock support that ensures your questions are answered and needs are met, smooth collaboration, accurate execution, and zero delays.

How We Ensure On-Time Delivery for Netherlands PCBA Orders?

Methods about we ensure on-time delivery for Netherlands PCBA orders:

- Stable Global Component Procurement Network: Cooperates with 800+ global high-quality component suppliers, achieving 99.8% material availability rate and controlling component shortage risks below 0.2%, keeping PCB assembly Netherlands orders on track without delays.

- Real-Time MES System Monitoring: Features ‚ȧ10-minute response delay, 100% production progress visualization, and 40% improved schedule adjustment efficiency, eliminating delays in PCB assembly Netherlands production.

- Multi-Production Line Backup: Equipped with 6 independent production lines, enabling ‚ȧ30-minute faulty line switching and controlling production interruption time within 1 hour, ensuring delivery timelines for PCB assembly Netherlands orders are met.

- Streamlined Process Optimization: Shortens the transition cycle from prototyping to mass production by 25% and improves overall production efficiency by 30%, accelerating delivery for PCB assembly Netherlands projects.

- Reliable Global Logistics Partnerships: Cooperates with 5 top global logistics providers, achieving 99.6% finished product logistics on-time rate and reducing logistics-related delays to below 0.1% for PCB assembly Netherlands orders.

- Proactive Pre-Order Planning: Boasts 98% risk identification accuracy, ‚ȧ2-hour emergency plan response time, and prevents over 95% of potential delivery risks for PCB assembly Netherlands orders.

Our Quality Control Process for Netherlands PCB Assembly Orders

Below are our quality control process for Netherlands PCB assembly orders:

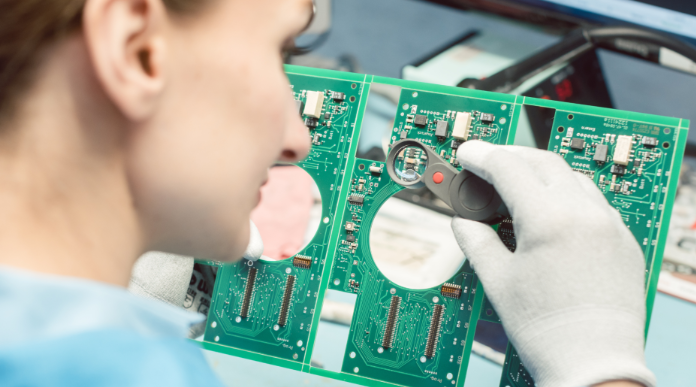

- Incoming Material Inspection (IQC): Follow AQL sampling standards to test components, PCB boards and auxiliary materials (e.g., solder paste) for authenticity, dimensional accuracy and performance, including component counterfeit verification and solder paste viscosity checks to achieve 99.9% defect detection rate and prevent fake or substandard materials from entering production for PCB assembly Netherlands.

- First Article Inspection (FAI): Conduct comprehensive checks on the first assembled product, cross-checking BOM and Gerber files with the physical product using automated verification tools to ensure 100% alignment between design and assembly, eliminating batch errors in PCB assembly Netherlands production.

- In-process Quality Control (IPQC): Perform 15-minute interval inspections of solder paste printing, component placement and reflow soldering processes, monitoring key parameters (e.g., soldering temperature, placement accuracy) with real-time alerts to maintain process stability within ¬Ī0.02mm tolerance for PCB assembly Netherlands.

- Automated Testing: Utilize high-precision AOI (99.8% defect detection rate) and X-ray testing equipment to identify welding defects (cold solder, bridging, tombstoning) and hidden issues (internal voids) that manual inspection misses, ensuring structural integrity of PCB assembly Netherlands products.

- Final Quality Control (FQC): Conduct full functional and reliability testing of finished products, including power-on tests, signal integrity checks, and environmental stress screening (high/low temperature cycles), simulating real working conditions to confirm compliance with design specifications for PCB assembly Netherlands.

- Outgoing Inspection (OQC): Implement AQL 0.65 sampling inspection of shipped products, verifying product appearance, functionality, packaging integrity (ISTA standard compliance) and accompanying documents (test reports, certificates) to ensure zero defective shipments for PCB assembly Netherlands.

Our Netherlands PCBA Capabilities

| Item | Capabilities |

| Placer Speed | 13,200,000 chips/day |

| Bare Board Size | 0.2 x 0.2 inches – 20 x 20 inches/ 22*47.5 inches |

| Minimum SMD Component | 01005 |

| Minimum BGA Pitch | 0.25mm |

| Maximum Components | 50*150mm |

| Assembly Type | SMT, THT, Mixed assembly |

| Component Package | Reels, Cut Tape, Tube, Tray, Loose Parts |

| Lead Time | 1 – 5 days |

Case Studies of Our Medical PCB Assembly Netherlands

Project Background: A medical device company specializing in clinical monitoring equipment required high-reliability Netherlands PCB assembly for its portable clinical monitors. These devices are widely used in outpatient clinics and emergency scenarios, where stable performance directly affects diagnostic accuracy, demanding strict adherence to medical industry standards for reliability, safety and compliance.

Project Requirements: The PCB needed to be miniaturized and high-precision, supporting 01005 components (one of the smallest standard components, ideal for compact portable devices) and fully compliant with ISO 13485 (medical device quality management standard) and CE certifications. Additionally, 500 units were required to be delivered within 2 weeks to meet the client’s urgent market launch schedule for PCB assembly Netherlands.

Project Difficulties: Miniaturization meant component placement required ultra-high accuracy (down to ¬Ī0.05mm) to avoid bridging or poor contact; strict medical certifications added QC complexity, requiring multi-round compliance checks and complete documentation; the tight 2-week timeline left no room for delays, creating immense pressure for PCB assembly Netherlands.

Project Solutions: High-precision pick-and-place machines with ¬Ī0.05mm accuracy ensured precise placement of 01005 components, reducing assembly defects; ISO 13485 compliance was enforced with added environmental stress screening (including high-low temperature cycles) to simulate clinical use scenarios; optimized production plans (parallel processing of assembly and testing) met the tight 2-week delivery timeline for PCB assembly Netherlands.

Output Results: All 500 units were delivered on time, achieving a 99.8% pass rate, exceeding the medical PCB industry average of 99.5%. Each unit was fully compliant with ISO 13485 and CE certifications, with zero post-delivery quality complaints. Impressed by the reliability and efficiency, the client extended long-term cooperation for all its subsequent PCB assembly Netherlands projects.

FAQs about PCB Assembly in Netherlands

Q1: What factors affect the cost of PCB assembly in Netherlands?

A1: The main factors include component types (especially high-precision or medical-grade components), order quantity, assembly difficulty (such as miniaturization) and testing requirements. We provide transparent pricing and optimize component selection to help you reduce the cost of PCB assembly in Netherlands.‚Äč

Q2: How to ensure that PCB assembly Netherlands products meet local environmental regulations?

A2: We strictly comply with RoHS and other Dutch environmental standards, using lead-free solder and environmentally friendly materials. We also provide compliance test reports to prove that your PCB assembly Netherlands meets local requirements.‚Äč

Q3: Can you handle small-batch prototyping for PCB assembly Netherlands?

A3: Yes, we support small-batch prototyping from 1 unit, with a 3-5 working day delivery time. We ensure prototype accuracy matches your design, helping you quickly verify and adjust your product for PCB assembly Netherlands.‚Äč

Q4: What should I do if there are quality problems with PCB assembly Netherlands products?

A4: We provide a 5-year quality guarantee. Once quality problems occur, we will conduct failure analysis immediately, provide free rework or replacement, and optimize our processes to avoid similar issues in future PCB assembly Netherlands orders.‚Äč

Q5: How long is the general delivery time for PCB assembly Netherlands orders?

A5: Prototyping takes 3-5 working days, small-batch production (100-1000 units) takes 7-10 working days, and mass production (1000+ units) takes 10-20 working days. We maintain a 99.2% on-time delivery rate for all PCB assembly Netherlands orders.