Are you looking for France metal core manufacturers? This blog is mainly about manufacturers list and selection guide to France metal core PCB manufacturers.

Are you worried about these issues now?

- Will Your Thermal Management Fail at 150°C? Prototypes Passed, Production Burned.

- Delayed Shipments Killing Your Time-to-Market? 4-Week Promises Became 8-Week Nightmares.

- Getting Invisible Cost Surprises in Final Invoice? Uncontrolled Budget Spikes.

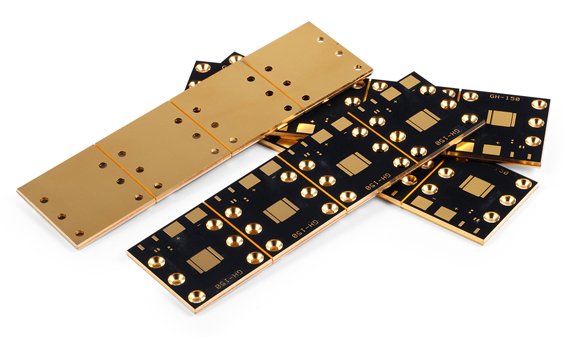

As a professional MCPCB manufacturer, EBest Circuit (Best Technology) can provide you service and solutions:

- Guaranteed Thermal Reliability: 1.2W/mK Aluminum Base + Dielectric Layer Withstanding 200°C Continuous Load.

- On-Time Delivery Guarantee: Dedicated production lines for urgent orders accelerate product launch cycles

- 100% Cost Transparency: No any hidden cost and provide turnkey price.

Welcome to contact us if you have any request for metal core PCB design, prototyping, mass production and assembly: sales@bestpcbs.com.

Top 10 Metal Core PCB Manufacturers in France

1. Eurocircuits France

- Main Business: Small-batch PCB fabrication for design houses and R&D teams. They support many European clients.

- Advantages: Strong online tooling. Good design-for-manufacturing feedback. Easy ordering for single boards and small runs.

- Manufacturing Capabilities: Aluminum-based MCPCBs, standard copper thickness up to 70 ”m, ENIG and OSP finishes, routing and CNC milling for complex shapes. They run batch and panelized production.

- Delivery Time: Typical lead time 7â12 working days for small batches. Express options often around 3â5 days for prototype panels.

2. Elvia PCB Group

- Main Business: Mid- to high-volume production for industrial, aerospace, and defense. They make many rigid and thermal boards.

- Advantages: Deep process control. Strong certification record. Proven supply to regulated industries.

- Manufacturing Capabilities: Heavy copper plating, hybrid metal cores (aluminum + copper layers), multi-layer options with thermal vias, tight impedance control, and automated optical inspection.

- Delivery Time: Standard 10â20 working days. Expedited jobs can be negotiated for urgent runs.

3. CIRE Group

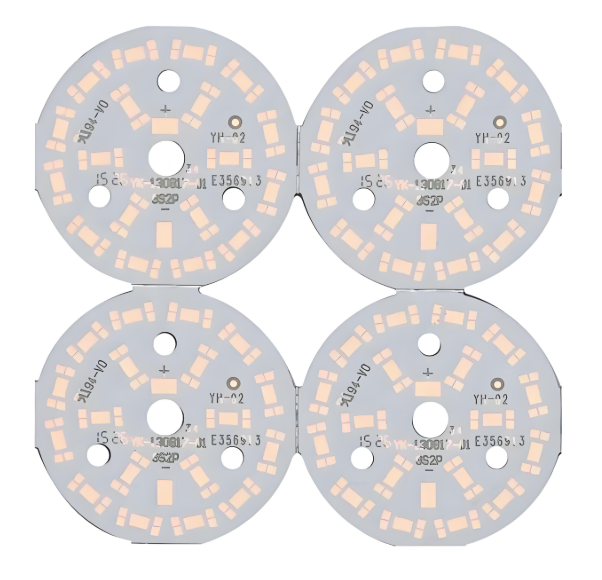

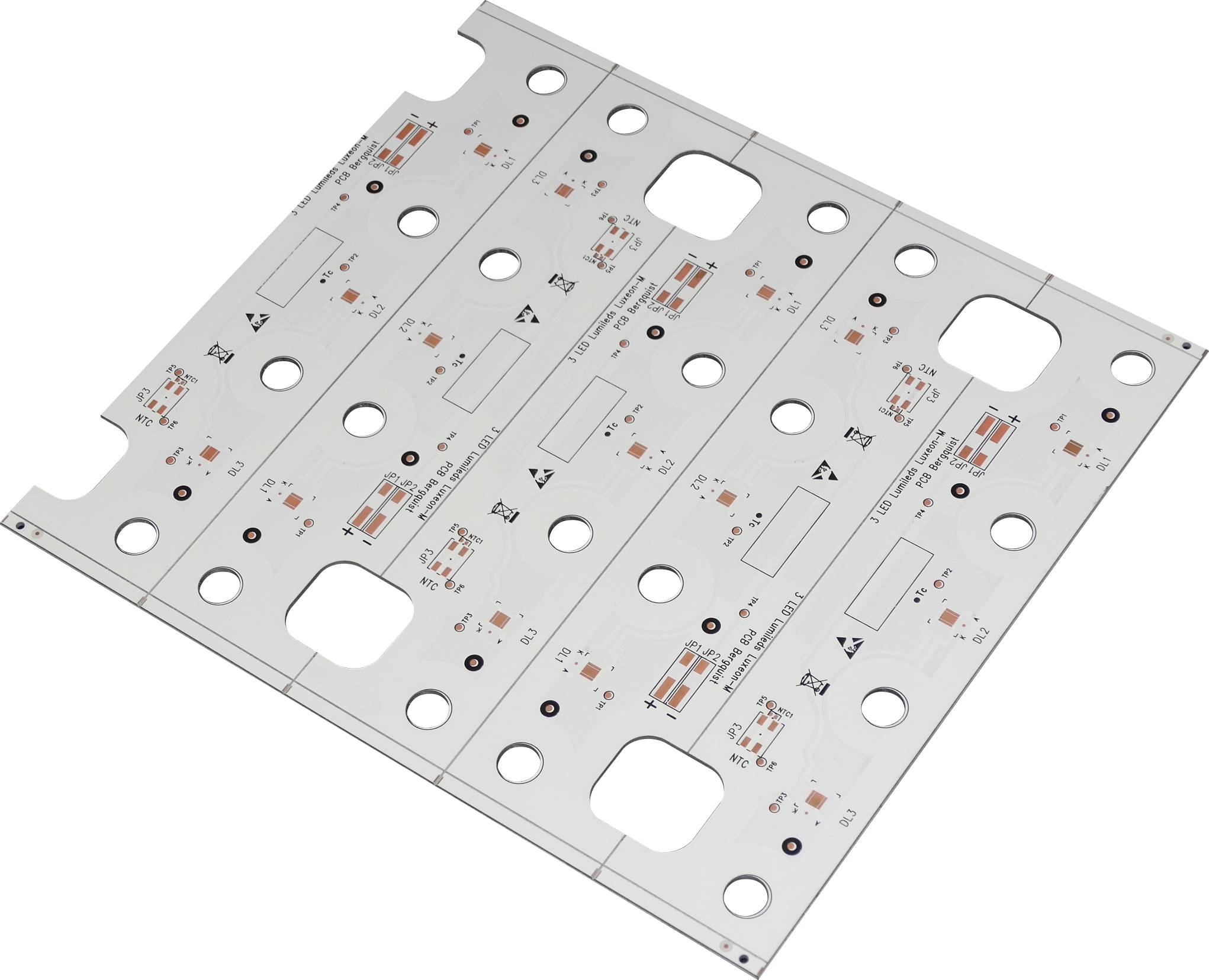

- Main Business: MCPCBs for lighting and automotive subsystems. Focus on thermal management designs.

- Advantages: Hands-on engineering help. Strong plating and surface finish control. Good for mid-power LED boards.

- Manufacturing Capabilities: Dielectric materials tuned for 1â3 W/mK thermal conductivity, edge-routing, nickel-gold finishes, and selective plating. They also offer assembly and conformal coating.

- Delivery Time: Usually 8â14 working days. Faster service for prototypes if file-ready.

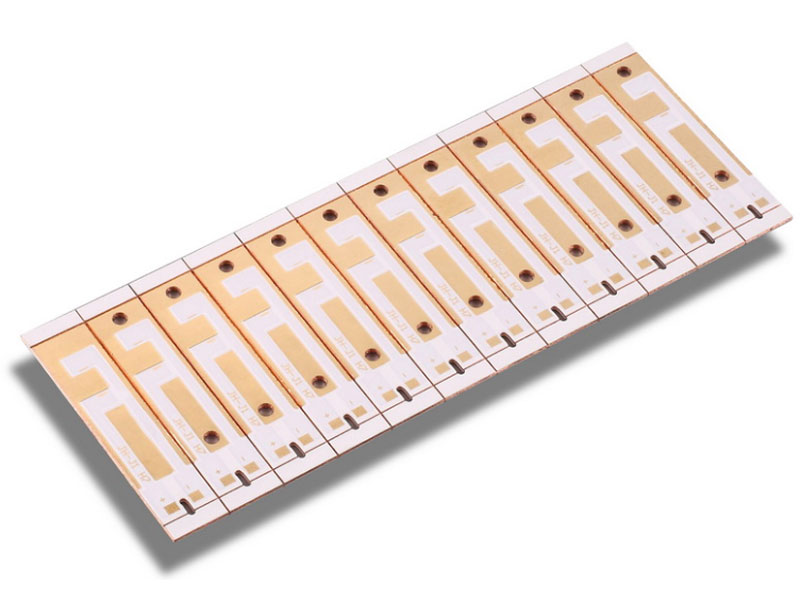

4. SELP Circuits

- Main Business: Practical, cost-effective PCBs for consumer lighting and industrial tools.

- Advantages: Competitive pricing for small and medium runs. Shorter batch sizes accepted.

- Manufacturing Capabilities: Aluminum MCPCBs with single-sided copper traces, common ENIG finish, basic thermal testing, and simple SMT assembly options.

- Delivery Time: Often 5â10 working days for prototypes and small production runs.

5. Cofidur EMS

- Main Business: Turnkey electronics services with integrated PCB supply, assembly, and testing.

- Advantages: One-stop shop for board plus assembly. Simplifies supply chain and reduces lead time variance.

- Manufacturing Capabilities: MCPCB fabrication through trusted partners, integrated functional testing, automatic optical inspection (AOI), and wave or selective soldering for assemblies.

- Delivery Time: Typical 10â18 working days for PCB + assembly. Prototypes can be faster if BOM is ready.

6. ALL Circuits

- Main Business: Electronics manufacturing services for OEMs who need procurement and production.

- Advantages: Strong sourcing and logistics. Good at combining PCB runs with immediate assembly.

- Manufacturing Capabilities: Outsourced MCPCB production via vetted partners, quality control on incoming boards, and multi-step testing for assembled systems.

- Delivery Time: Delivery depends on combined supplier lead times. Plan on 10â20 working days for turnkey orders.

7. Novalec

- Main Business: Low-to-medium volume PCBs for industrial controls and lighting systems.

- Advantages: Careful process control and low defect rates for small series. Personalized customer service.

- Manufacturing Capabilities: Single and double-sided MCPCBs, plated through-holes for mechanical strength, custom thickness for thermal needs, and basic reliability tests.

- Delivery Time: Often 7â14 working days for MCPCB fabrication.

8. Cirly

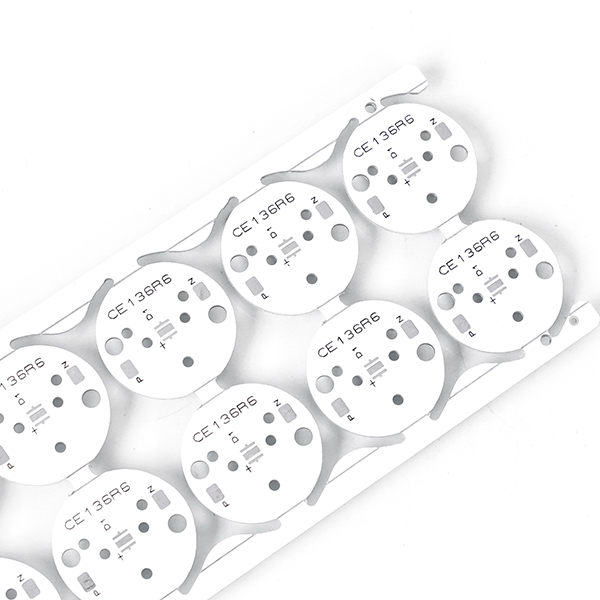

- Main Business: Fast prototyping and small series for product developers and labs.

- Advantages: Very quick turn, friendly to iterative design. Helpful for thermal validation cycles.

- Manufacturing Capabilities: Rapid aluminum MCPCBs, quick-turn ENIG finishes, simple laser routing for complex outlines, and support for thermal vias.

- Delivery Time: Prototype options can be delivered in 24â72 hours for simple panels. Typical small runs 3â7 days.

9. ACB Group (serving France locally)

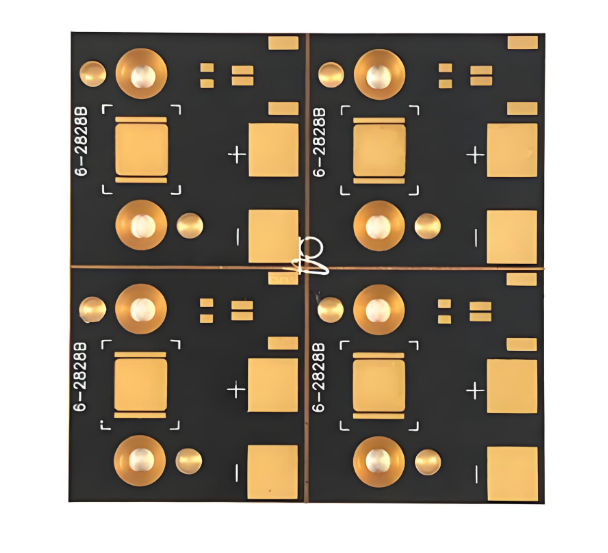

- Main Business: High-capacity production for clients needing heavy copper or specialized thermal boards.

- Advantages: Deep expertise in thick copper and demanding thermal designs. Good for power electronics.

- Manufacturing Capabilities: Heavy copper up to 400 ”m, multi-layer MCPCBs, robust plating, laser-drilled microvias, and advanced thermal management options

- Delivery Time: Standard production 12â25 working days. Fast lanes may be available for critical projects.

10. LCC â Le Circuits du Centre

- Main Business: Local supplier of standard PCBs and aluminum-based boards for lighting and industry.

- Advantages: Local service, personal account management, and flexible small-run policy.

- Manufacturing Capabilities: Aluminum MCPCBs, common finishes including HASL and ENIG, routing, and simple assembly.

- Delivery Time: Typical 6â12 working days for common items. Prototypes may be faster

Quality Standards of Metal Core PCB Manufacturers in France

- IPC-6012 and IPC-6012DS: Define acceptance for rigid PCBs. They cover plating, solderability, and physical tolerances. Use them as a base for acceptance criteria.

- IPC-2221 and IPC-2222: Cover generic and rigid printed board design rules. They help with trace width, spacing, and thermal via placement.

- IPC-A-600: For visual acceptance criteria. It helps you set pass/fail rules for appearance.

- ISO 9001: Confirms the manufacturer uses a formal quality management system. This shows process repeatability.

- EN 9100: Aerospace-specific quality management. Relevant if your MCPCBs will enter aerospace supply chains.

- UL: UL recognition helps with product acceptance in many markets and simplifies compliance for appliances and lighting sold in some regions

- RoHS: Restricts hazardous substances. Most France makers supply RoHS-compliant boards.

- REACH: Governs chemical safety in the EU. Ask for declarations if you need to certify end-products.

- Electrical testing standards: 100% electrical testing finds shorts and opens. Also request continuity and isolation tests for power paths. For high-reliability work, request burn-in and functional load tests.

France Metal Core PCB Manufacturers Selection Guide

A Detailed Selection Guide to France Metal Core PCB Manufacturers:

1. Technical Expertise & Process Capability

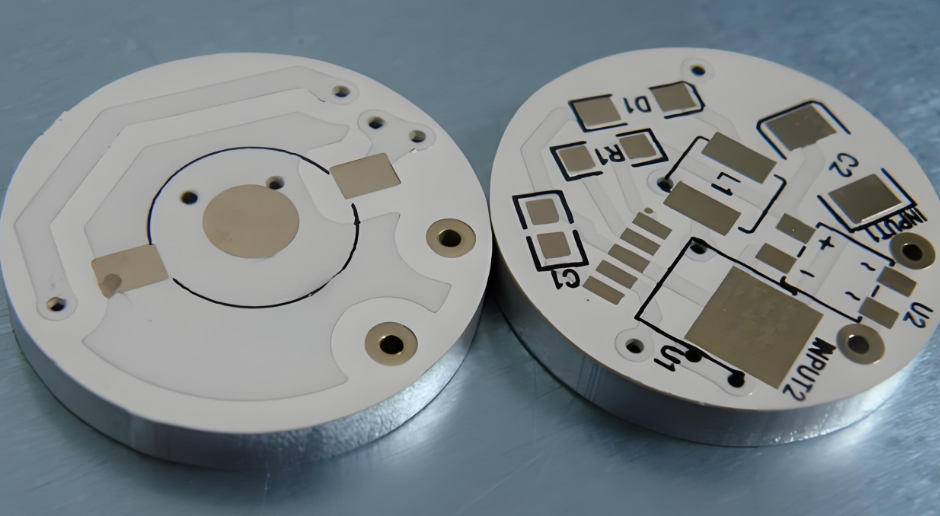

- Metal Substrate Options: Offer aluminum-based (e.g., 5052, 6061 with thermal conductivity 140-220 W/m·K) and copper-based (thermal conductivity ~385 W/m·K) substrates to match varying power density and thermal dissipation requirements.

- Process Details: Line width/spacing typically 0.20/0.20 mm, dielectric layer thickness 0.003-0.006 inch, and via diameter specifications to support high-density, high-power layouts.

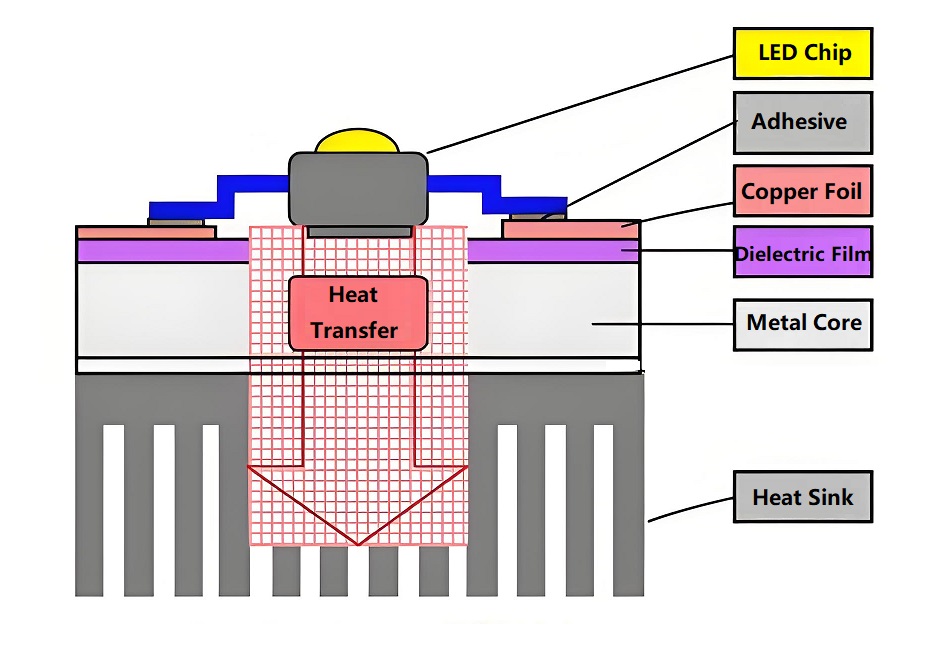

- Thermal Management Solutions: Provide thermal simulation reports and adopt innovative structures like Super Pillar to reduce thermal resistance and enhance heat dissipation efficiency.

2. Quality Certifications & Standards Compliance

- International Certifications: Prioritize manufacturers certified under ISO 9001 quality management systems to ensure standardized production controls.

- Industry Standards: Adhere to IPC-4101/4104 material standards and comply with RoHS, UL, and other safety/environmental directives for seamless market access in the EU.

3. Production Flexibility & Supply Chain Resilience

- Capacity & Lead Times: Understand regular production capacity, prototype lead times (typically 5-10 days), and bulk delivery reliability to avoid delays from production bottlenecks.

- Supply Chain Management: Implement dual-sourcing strategies for critical materials (metal substrates, dielectric layers) to ensure stable supply during geopolitical or logistics disruptions.

4. Design Support & Response Efficiency

- Early-Stage Engagement: Provide DFM feedback during the design phase, including panelization schemes, slot positioning, and surface finish (HASL, ENIG) recommendations to minimize post-design modifications.

- Technical Responsiveness: Maintain a 24-48 hour feedback mechanism for urgent issues through email or phone support.

5. Customer Feedback & Industry Reputation

- Case References: Showcase past projects in automotive, aerospace, and premium lighting sectors with verified thermal performance and reliability data.

- Third-Party Reviews: Leverage independent platforms or peer evaluations to gauge long-term performance in delivery quality and collaborative communication.

6. Sample Validation & Reliability Testing

- Small-Batch Prototyping: Order samples before bulk production to test key parameters like thermal conductivity, dielectric strength (e.g., 2.5 kV), and dimensional accuracy.

- Environmental Testing: Supply reliability reports for thermal cycling, high-temperature/humidity exposure, and other harsh-condition tests to validate stability.

7. Cost Transparency & Long-Term Partnership Value

- Quotation Breakdown: Provide itemized quotes for materials, layer counts, and process fees to avoid hidden costs (e.g., 1.5 mm aluminum MCPCB at $0.50â$0.70/piece; 2.0mm copper MCPCB at $2.50-$4.00/piece).

- Value Assessment: Evaluate overall partnership value by considering yield rates, on-time delivery rates, technical support, and other implicit costs.

8. Environmental Compliance & Sustainability

- Eco-Friendly Materials: Ensure metal substrates and dielectric layers comply with EU RoHS, REACH, and other environmental regulations, supported by test reports.

- Green Manufacturing: Prioritize manufacturers with energy management systems (e.g., ISO 50001) or carbon reduction commitments to reflect long-term operational sustainability.

How to Evaluate the Mechanical and Finishing Quality of France MCPCB?

1. Base Metal and Substrate Quality

- Request metal alloy certificates: Ensure supplier provides material composition reports to confirm alloy grades (e.g., 1060, 3003 aluminum, or C11000 copper) comply with design specifications.

- Flatness inspection of the board surface: Place the panel on a known flat reference surface and measure the maximum gap with feeler gauges. Warpage exceeding IPC-6012 standards (typically â€0.75%) causes SMT misalignment.

- High-power applications require high-grade materials: Aluminum substrates recommended for 5052 or 6061 series with thermal conductivity up to 140 W/(m·K); copper substrates preferred for C1100 (thermal conductivity â„380 W/(m·K)) for better oxidation resistance at high temperatures.

- Thermal expansion coefficient matching: Confirm substrate CTE matches chip carriers (e.g., ceramic, silicon) to prevent solder joint cracking after temperature cycling.

2. Dielectric Properties and Laminate Structure

- Dielectric thickness and thermal conductivity: Require supplier to provide thickness (0.1mmâ0.18mm typical) and thermal conductivity values (FR-4 ~0.3â0.6 W/(m·K); high-performance fillers 2â5 W/(m·K)) for each dielectric layer.

- Comparison with thermal simulation: Input actual laminate structure (copper thickness, dielectric thickness, material k-values) into thermal simulation software to verify hotspot temperatures are within allowable limits. Quality suppliers assist in adjusting laminate schemes for optimized heat dissipation.

- Inspection of void defects: Request cross-sectional photos of dielectric layers to check for bubbles, delamination, or uneven resin filling. Voids reduce insulation strength and thermal pathways.

3. Copper Traces and Pad Quality

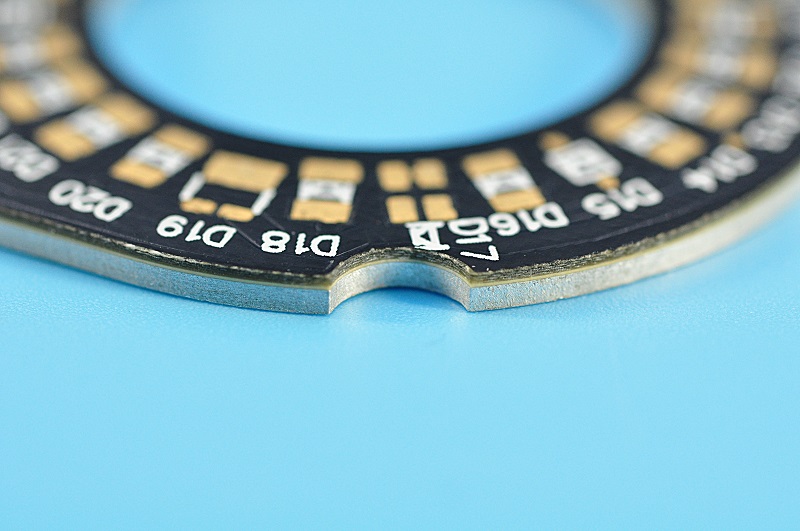

- Edge smoothness of copper traces: Inspect trace edges under 10x magnification for jaggedness, burrs, or excessive etching residues. Rough edges increase high-frequency losses and EMI.

- Copper thickness verification: Measure actual copper thickness via test coupons or microsections (1oz=35ÎŒm, 2oz=70ÎŒm) to ensure impedance control compliance.

- Plating uniformity report: Request plating thickness distribution maps (e.g., gold-plated buttons, electroless nickel). Thickness deviation â€Â±10%.

4. Copper Traces and Pad Quality

- Solder mask coverage integrity: Solder mask must fully cover non-pad areas including trace gaps and vias. Use optical microscopy to check for gaps or thin coverage.

- Pad perimeter quality: Monitor solder mask encroachment on pads (solder mask bridge breakage) or pad edge undercutâindicators of unstable process control.

- Silkscreen legibility: Characters and polarity marks must be sharp, blur-free, and aligned. Perform adhesion testing (tape peel) to confirm ink durability.

5. Surface Finish Uniformity

- ENIG (electroless nickel immersion gold): Surface should show uniform bright gold without black spots, haze, or nickel corrosion. Nickel thickness 3â6ÎŒm, gold 0.05â0.1ÎŒm.

- HASL (lead-free hot air leveling): Minor wave patterns permitted, but pad coating thickness must be uniform to avoid exposed copper.

- OSP (organic solderability preservative): Film should be uniform, non-peeling, and non-oxidized. For long-term storage, request supplier-provided shelf life data (typically 6â12 months).

6. Mechanical Strength and Adhesion Testing

- Peel strength test: Request copper-to-dielectric peel strength reports meeting IPC-TM-650 2.4.8 (â„1.0N/mm typical).

- Thermal cycling/thermal shock report: Suppliers provide test data for similar structures showing no solder joint or interlayer cracking during â40°C to +125°C cycles.

- Bending test: For flexible or pluggable rigid boards, perform bending tests (e.g., IPC-6013) to confirm laminate adhesion under mechanical stress.

7. Dimensional and Hole Quality Inspection

- Hole diameter and annular ring tolerance: Request drilling charts and measured data. Hole tolerance ±0.05mm typical; annular ring â„0.075mm (Class B) or 0.05mm (Class C).

- Edge and milling quality: Inspect board edges and slots for burrs or edge breaksâcritical for snap-fit assembly sealing.

8. Functional Verification

- Additional testing for high-frequency/high-speed boards: Request TDR reports for impedance control (±10% tolerance) and batch consistency of dielectric constant (Dk) and dissipation factor (Df) for RF boards.

- Electrical test report: Require 100% flying probe or bed-of-nails test reports listing all open/short and network continuity results.

- Thermal imaging data for LED boards: Capture infrared thermography at set currents (e.g., 350mA) to verify uniform heat diffusion and maximum temperature below material Tg.

Why France Clients Trust EBest Circuit (Best Technology) as Metal Core PCB Manufacturers?

Reasons Why Choose EBest Circuit (Best Technology) As Metal Core PCB Manufacturer:

- Price Competitiveness: EBest Circuit (Best Technology) reduces MCPCB costs by 8-12% through scaled procurement and automated production lines, offering 15% lower quotes than French local suppliers. Tiered pricing provides an additional 3-5% discount for bulk orders.

- Quality Consistency: ISO 9001:2015 certified processes, paired with AOI inspection (±2ÎŒm accuracy) and X-ray systems, ensure batch-to-batch thermal conductivity variation â€3% and electrical parameter deviation <1%, compliant with EU CE/REACH standards.

- On-Time Delivery Rate 99.2%: Achieved through optimized production scheduling and global logistics coordination, enabling 99.2% on-time delivery for standard orders. Critical orders (e.g., medical PCBs) are fulfilled within 72 hours.

- Flexible Lead Times: 7-21 day multi-tier delivery options, with 3-5 day rapid prototyping (40% faster than industry average). Parallel production lines double capacity for bulk orders, supporting dynamic production adjustments for French clients.

- 25-Step Quality Control: Full traceability via unique QR codes on each board, covering raw material checks (e.g., copper foil thickness tolerance â€1%) to reliability testing (e.g., 1,000-cycle thermal shock from -40°C to 150°C).

- International Certifications: UL certification (E355848), RoHS 2.0, ISO 14001, and IATF 16949 (automotive-grade) with verifiable certificate numbers, ensuring compliance with French/EU safety and environmental regulations.

- 24/7 Bilingual Support: Chinese-English technical sales team provides <2-hour response times for DFM consultations, preventing rework costs from design flaws.

- Free DFM Analysis: Pre-production reports include signal integrity checks (impedance matching error <5%), thermal simulation (15-20% efficiency gain), and manufacturability assessments, reducing R&D cycles by >30%.

- Collaborative R&D: Custom solutions co-developed with French clients, such as high-power LED substrates with thermal conductivity â„200W/m·K or precision dielectric layer adjustments (±5% tolerance).

- Strategic Partnership Value: 85% client retention rate through continuous tech investment and value-added services like cost optimization advice and industry trend analysis, transitioning from transactional to strategic relationships.

On-Time MCPCB Delivery: 24 Hours Rapid Prototyping for Urgent Orders

- 24-Hour Quick-Turn Support: For urgent designs, we can produce MCPCB samples within 24 hours depending on complexity. This helps you validate design ideas faster.

- Shorter Development Cycle: Fast prototyping allows early thermal tests, brightness tests, or current flow checks. This speeds up approval and reduces delays.

- Reliable Europe-Focused Logistics: We ship frequently to France. Transit times remain stable, and shipment tracking is always available.

Consistent MCPCB Quality: ISO/IPC Certifications & 100% Electrical Testing

- Mechanical Inspection: We check flatness, drill accuracy, copper shape, and routing quality.

- Electrical Testing: Every MCPCB undergoes a complete electrical test to confirm zero shorts or opens.

- Thermal Reliability: Our dielectric materials are selected for stable thermal flow and strong bonding. We verify adhesion strength and insulation.

- Surface Finish Control: We inspect ENIG, OSP, HASL, and other finishes to ensure they support stable soldering.

Transparent MCPCB Pricing: Turnkey Solutions Without Hidden Costs

- Turnkey Support: If you need parts and assembly, the team can handle full service. This saves time for design houses and startups.

- Flexible Volume Options: You can order small runs, medium runs, or large production. The price stays fair.

Real-Time Online Communication: English-Speaking Teams & Dedicated Support

- Dedicated Engineers and Account Managers: French customers receive a direct point of contact who understands MCPCB requirements and offers timely updates.

- Clear Design Discussions: We provide clear design feedback, review files carefully, and share manufacturability suggestions in a direct way.

- Fast Replies: Quick responses reduce delays and help you adapt design changes without waiting days for clarification.

How to Get A Quote for Your Metal Core PCB Project?

Follow this short process to get clear quotes:

- Prepare your files: Gerbers, drill files, BOM, and stack-up. If possible, add a short note that lists the thermal target (e.g., “dissipate 3W across 20 mmÂČ at 30°C rise”).

- State quantity and target date: Include initial prototype qty and ramp volumes.

- Request sample test items: If in doubt, ask for a small sample batch with full test reports.

- Ask for production options: Compare one-off prototypes to panelized production pricing.

- Review the timelines: Confirm exact dates for PO acceptance, start, and ship.

- Confirm packaging and shipping: Choose protective packaging for plated holes and flatness.

- Approve and request a first article inspection (FAI): This confirms build quality before full runs.

Welcome to contact us if you have any request for metal core printed circuit board design, prototyping, mass production and assembly: sales@bestpcbs.com.