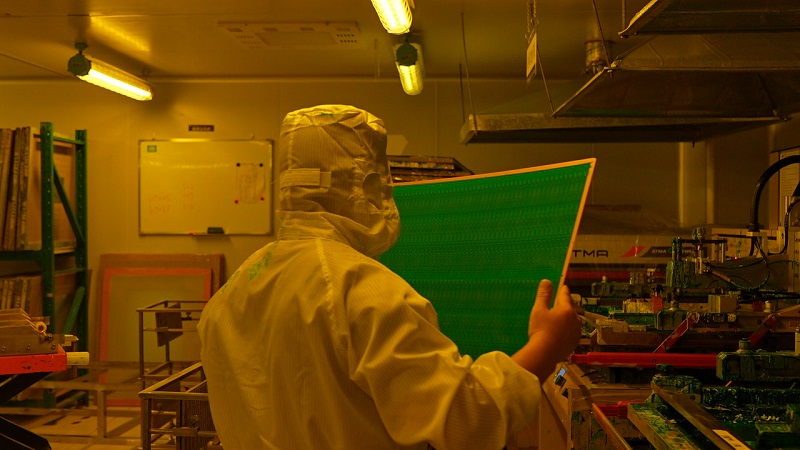

Printed circuit board maker is the first thing many electronics developers search for when starting a new design. Whether you are prototyping or scaling to full production, choosing the right partner can save you time and cost. This blog explores global PCB manufacturing options and why EBest Circuit (Best Technology) stands out in this crowded field.

EBest Circuit (Best Technology) is a tech-driven printed circuit board maker, providing a wide range of PCBs, like FR4, ceramic PCB, MCPCB, and PCB assembly. We can offer custom PCB and custom solutions to suit your project needs. You can rest assured that Printed Circuit Board quality making by EBest Circuit (Best Technology) is guaranteed.  Kindly contact us at sales@bestpcbs.com for any custom PCB needs.

Printed Circuit Board Maker in India

India has become a growing hub for PCB manufacturing, thanks to its competitive pricing, increasing technological advancement, and government support. Many global brands now turn to Indian PCB makers for high-volume and prototype solutions.

- AT&S India Pvt. Ltd. (Andhra Pradesh)

- A subsidiary of Austria’s AT&S Group, this company operates one of Indiaâs most advanced PCB factories. It focuses on high-end PCBs for automotive, medical, and industrial applications. With state-of-the-art facilities and automation, AT&S meets global quality standards like IATF16949 and ISO13485.

- Shogini Technoarts Pvt. Ltd. (Pune)

- With over three decades in the industry, Shogini is known for producing single-sided, double-sided, and multilayer PCBs. Their capabilities support small to medium-volume production runs and a variety of industries including lighting, consumer electronics, and automotive.

- Genus Electrotech Ltd. (Gujarat)

- Genus is a vertically integrated manufacturer offering everything from PCB design to final assembly. They serve a wide range of sectors including power, smart meters, and consumer products. Their manufacturing meets global standards and is RoHS-compliant.

Indiaâs PCB makers are fast adapting to global demand with investments in automation and quality control. For companies looking for affordability with improving capabilities, India presents a strong option.

Printed Circuit Board Maker in Canada

Canadaâs PCB industry is shaped by high standards, clean manufacturing processes, and strong R&D. Canadian PCB makers are known for their quality assurance and capability to handle complex, multilayer boards.

- Bittele Electronics (Toronto, Ontario)

- Bittele offers turnkey PCB assembly and manufacturing services, specializing in low-volume and prototype runs. They are known for their quick turnaround, and strong online ordering system. They serve clients globally, especially in North America.

- Candor Industries Inc. (Toronto, Ontario)

- Candor stands out with its environmentally friendly processes and capability to handle high-frequency and HDI PCBs. They have an open-culture model with direct communication between engineers and customers, which supports complex design solutions.

- Circuits Central Inc. (Ontario)

- Circuits Central provides full-service PCB fabrication and assembly. With a focus on industrial, medical, and telecom sectors, they offer design support, rapid prototyping, and full manufacturing runs. Their facility meets ISO standards and supports high-complexity builds.

Canadian PCB makers provide a mix of precision, environmental responsibility, and technical expertise. If your project needs detailed design support and compliance with international standards, Canada is a strong choice.

Printed Circuit Board Maker UK

The UKâs PCB sector is known for engineering excellence, with a strong emphasis on R&D and high-end industrial applications. Manufacturers here focus on performance, reliability, and customization.

- Newbury Electronics Ltd. (Berkshire)

- This company offers rapid PCB prototyping and manufacturing services. They support everything from single-sided boards to complex multilayer PCBs. With in-house assembly and CAD support, Newbury is a top choice for engineers looking for fast development cycles.

- Trackwise Designs Plc (Gloucestershire)

- Trackwise specializes in advanced RF and flexible PCBs, especially for aerospace and automotive sectors. Their patented length-unlimited FPC technology is well-known across Europe. They serve as a strategic partner for high-frequency and high-reliability needs.

- Exception PCB Ltd. (Wiltshire)

- Exception PCB serves critical industries such as defense, aerospace, and medical devices. They provide multilayer and high-speed PCBs with advanced quality assurance and traceability systems. Their global customer base values their engineering strength and production precision.

UK PCB manufacturers offer engineering-driven services with tight tolerances and customization. For projects that require reliability and innovation, British PCB makers remain among the top-tier options globally

How Long Does It Take to Make a Printed Circuit Board?

Timeframes vary. For simple single-layer PCBs, it may take 24-48 hours. Complex multilayer boards may need 7-10 days. Delays often come from unclear Gerber files, missing BOMs, or design flaws. Thatâs why working with a responsive printed circuit board maker helps reduce back-and-forth and speeds things up.

How Many Layers Can a Printed Circuit Board Have?

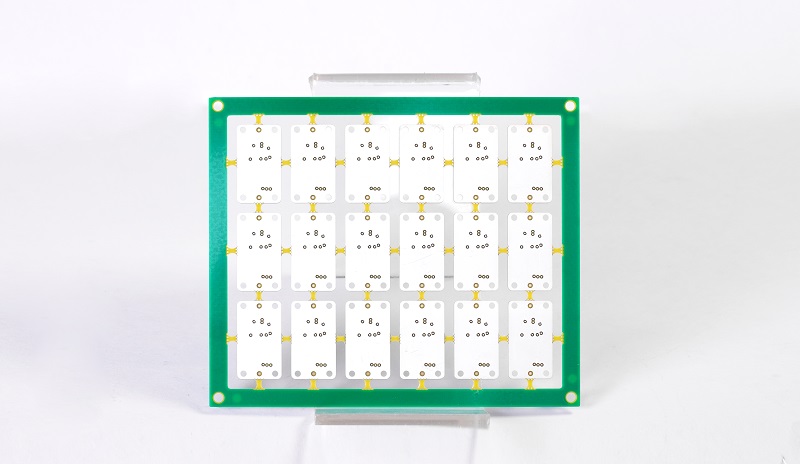

A printed circuit board can have 1 to over 40 layers, depending on design needs. Consumer electronics often use 2 to 8 layers. Aerospace or telecom PCBs go higher. EBest Circuit (Best Technology) supports a wide layer range with excellent impedance control and layer stack-up guidance.

How to Make a Printed Circuit Board?

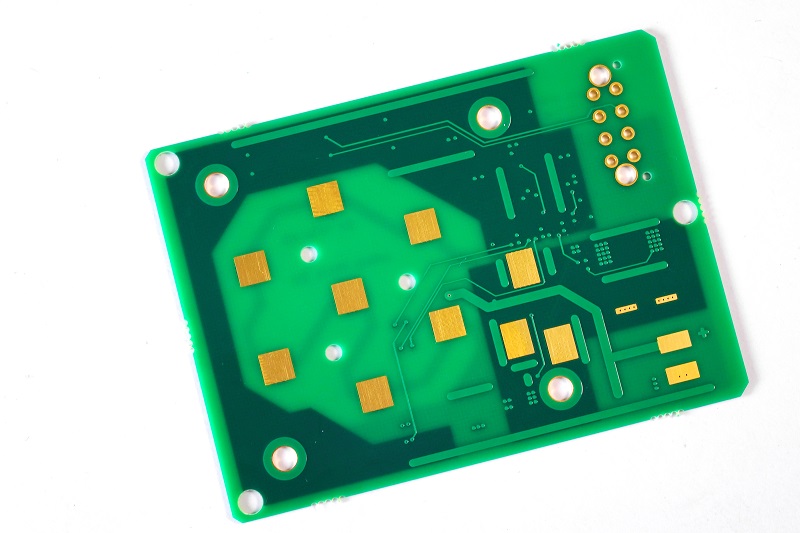

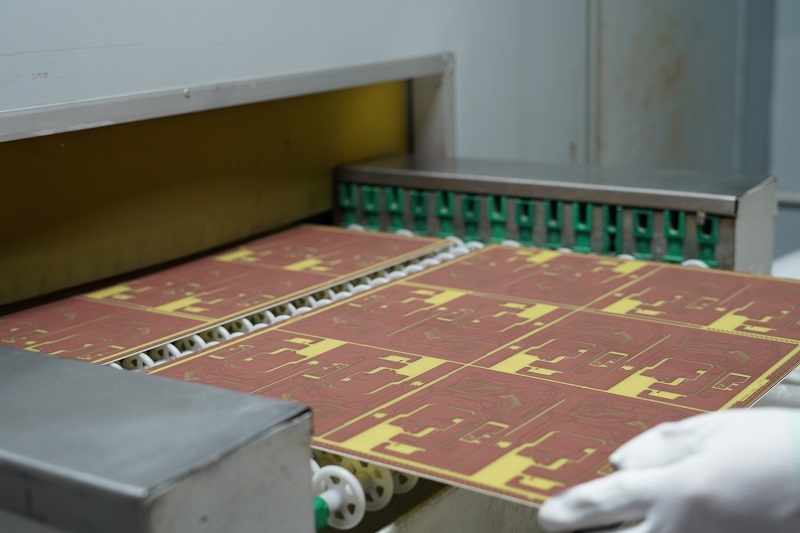

It starts with design. Once your schematic and layout are complete, generate Gerber files. Share them with your PCB partner. The process involves lamination, drilling, plating, etching, and solder mask application. A reliable printed circuit board maker will guide you at each step, especially during DFM (Design for Manufacturability).

Why Should You Choose EBest Circuit (Best Technology) as Your Trusted Printed Circuit Board Maker?

EBest Circuit (Best Technology) solves key pain points every customer faces. Letâs break it down:

1. Reliable Quality and On-Time Delivery

Many customers struggle with delayed delivery or inconsistent quality. We operate under ISO9001, ISO13485, IATF16949, and AS9100D systems. From material incoming checks to final inspection, every step meets international standards. Automated inspection reduces errors and improves reliability.

2. Full Compliance and Certification

Weâre fully RoHS, WEEE, and IPC compliant. Plus, our ESD protection covers every handling step. With a strong audit-ready system, we meet the strictest vendor verification protocols. That builds long-term trust and collaboration with top brands worldwide.

3. Advanced Design and Engineering Support

Some customers worry about lacking internal engineers. Our team helps with design review, BOM optimization, and stack-up suggestions. Early engagement avoids late-stage redesigns. Our DFM tools simplify development and lower your risk.

4. Fast Lead Times

Multilayer boards and HDI PCBs often have long cycles. We respond with lean production and MES-driven planning. Our digital system tracks each order step-by-step. Need a prototype in 2 days? Weâve got you.

5. Strong Quality Control System

PCB defects like poor soldering, scratches, or delamination are common pain points. Our AI-driven visual inspections detect micro-defects that even trained eyes miss. Multiple QC stagesâAOI, X-ray, ICT, and FQCâguarantee top quality with minimal waste.

6. Fast Response and Human Support

We understand the importance of clear communication. Especially in R&D phases or small-batch trials, a slow response ruins progress. Our engineering support runs 24/7, and sales teams speak fluent English. Quick replies, accurate quotes, and expert suggestions come standard.

7. Tech-Forward Manufacturing

We invest in smart systems. AI inspection, automated production, and MES dashboards enable real-time monitoring. From plating thickness to hole alignment, precision is built into our lines. That reduces rework and boosts throughput. Our smart factory plan hits 50% coverage by 2025.

8. Sustainable Manufacturing

As environmental standards rise, so do our green efforts. Our lines use water recycling, low-VOC materials, and waste tracking. Weâre pushing to grow our share in the green PCB market, which is forecast to hit 45% in 2025. Customers love this proactive approach.

In a nutshell, being a printed circuit board maker today isnât just about producing boards. Itâs about speed, trust, service, and innovation. EBest Circuit (Best Technology) understands your demands and brings real solutions. We deliver high-quality boards fast, support your design, and adapt to complex requests. From HDI to rigid-flex, from prototypes to mass productionâour team is ready to help you build better. Let us help you move faster, reduce errors, and grow smarter. Get in touch with us at sales@bestpcbs.com for your next PCB quote. With EBest Circuit (Best Technology), every board counts.