Counterbore vs countersink refers to two distinct machining processes for creating recessed holes, critical for component seating and fastener flush-mounting in PCB assemblies. This article provides a comprehensive guide to their design, symbols, applications, and how partnering with a specialist manufacturer ensures reliability in your PCB projects.

Choosing the wrong recessed hole type often leads to avoidable design errors, assembly delays, and reliability risks later in the PCB lifecycle.

- Drawing Confusion: Misreading countersink symbol or counterbore symbol on fabrication drawings

- Incorrect Fit: Wrong hole type or dimensions prevent screws from sitting flush

- Cost Overruns: Overusing counterbore machining when a countersink is sufficient

- Assembly Errors: Poorly defined counterbore hole or countersink geometry disrupts SMT or mechanical assembly

- Reliability Risks: Mismatched fasteners (counterbore vs countersink screws) weaken joints or damage boards

How can a professional PCB partner resolve these issues?

- DFM & Drawing Support: Correct use of counterbore and countersink symbols per standards (ASME Y14.5)

- Precision Machining: Tight control of counterbore hole dimensions and countersink angles

- Cost-Driven Design Advice: Clear guidance on countersink vs counterbore advantages

- Assembly-First Engineering: Hole designs optimized for SMT and mechanical assembly

- Material Expertise: Proper counterbore tool and process selection for FR-4, ceramic, and specialty substrates

At EBest Circuit (Best Technology), we are a professional PCB and assembly manufacturer specializing in complex, high-precision board fabrication. Our core strength lies in transforming intricate designs‚ÄĒespecially those requiring precise counterbore and countersink‚Äč features‚ÄĒinto reliable, high-performance assemblies. Trust us to navigate the details so your design excels. Pls feel free to contact us at sales@bestpcbs.com‚Äč for your next printed circuit board or SMT PCB manufacturing project.

What Is Counterbore vs Countersink?

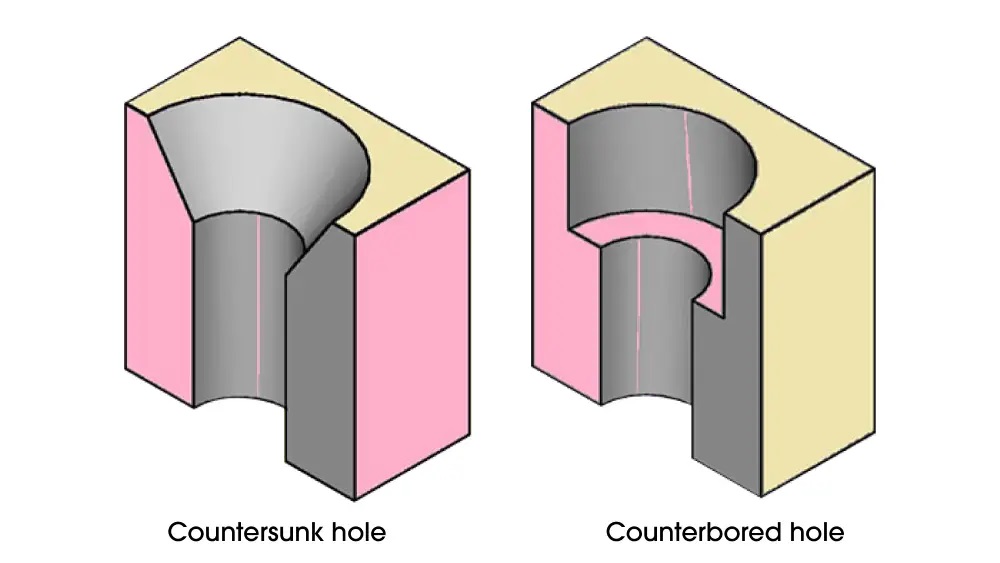

In PCB design and mechanical assembly, counterbore vs countersink‚Äč describes two methods for creating a recess around a drilled hole. The fundamental difference between counterbore and countersink‚Äč lies in their geometry and purpose.

- Countersink:‚Äč A conical-shaped recess cut into the material. Its primary goal is to allow a conical screw head (e.g., flat head) to sit flush with or below the surface.

- Counterbore:‚Äč A cylindrical, flat-bottomed recess cut into the material. It is designed to allow a bolt head or hex-head fastener to sit below the surface, often topped with a fillister or cap.

| Feature | Countersink | Counterbore |

|---|---|---|

| Shape‚Äč | Conical | Cylindrical |

| Purpose‚Äč | Flush-mount conical screws | Seat bolt heads below surface |

| Bottom‚Äč | Tapers to a point | Flat |

| Typical Fastener‚Äč | Flat-head screw | Socket-head cap screw |

Understanding this counterbore vs countersink hole‚Äč distinction is the first step toward reliable design. Choosing correctly ensures proper component seating, avoids interference, and contributes to a professional finish.

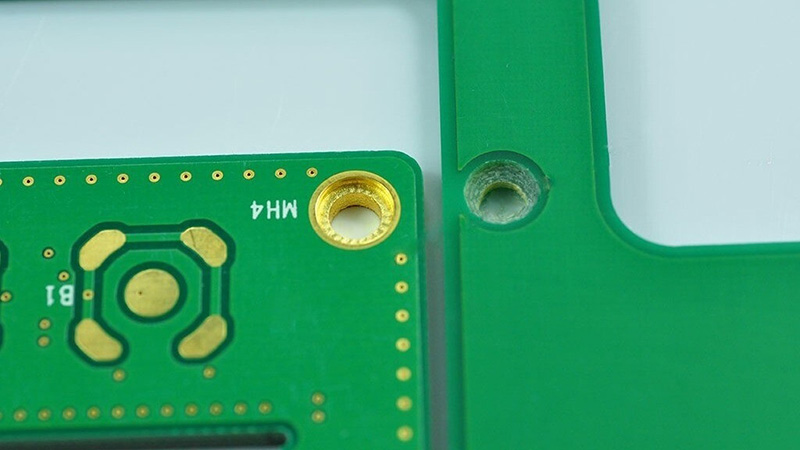

Understanding Counterbore Hole Geometry and Typical Dimensions

A counterbore hole‚Äč is defined by specific, measurable parameters crucial for fabrication. Unlike a tapering countersink, its cylindrical nature demands precise control.

Key dimensions for a counterbore hole‚Äč include:

- Through-Hole Diameter:‚Äč The diameter of the primary pilot hole for the fastener shaft.

- Counterbore Diameter:‚Äč The larger diameter of the recess, which must accommodate the fastener head.

- Counterbore Depth:‚Äč The depth of the recess, controlling how far the head sits below the surface.

- Tolerance:‚Äč Critical for fit; tight tolerances (e.g., ¬Ī0.05mm) prevent fastener wobble or binding.

- Corner Condition:‚Äč A sharp corner vs. a small radius can affect stress concentration and tool selection.

Proper specification prevents issues‚ÄĒa depth too shallow leaves the head protruding, while a diameter too small makes assembly impossible. For reliable PCB design and SMT services, communicating these dimensions clearly is non-negotiable.

How to Read Countersink Symbol and Counterbore Symbol on Engineering Drawings?

Engineering drawings use standardized symbols to convey counterbore and countersink‚Äč requirements efficiently, eliminating textual ambiguity. Misreading these is a common source of fabrication errors.

- Countersink Symbol:‚Äč Often represented by a ‚ÄėV‚Äô shape drawn over the hole leader line. The callout typically specifies the diameter at the surface (or the included angle) and the angle itself (e.g., ‚ąÖ6.0 X 82¬į).

- Counterbore Symbol:‚Äč Usually represented by a square ‚Äė‚Ćī‚Äô shape drawn over the hole leader line. The callout specifies the counterbore hole dimensions: diameter and depth (e.g., ‚ąÖ8.0 X 3.2 DEEP).

| Symbol | Shape | Callout Example | Meaning |

|---|---|---|---|

| Countersink‚Äč | ‘V’ | ‚ąÖ6.0 X 82¬į | Machine a 82¬į cone to a 6.0mm top diameter. |

| Counterbore‚Äč | ‘‚Ćī’ | ‚ąÖ8.0 X 3.2 DEEP | Machine a cylindrical recess 8.0mm in diameter and 3.2mm deep. |

Mastering these counterbore vs countersink symbols‚Äč ensures your design intent is communicated flawlessly to the manufacturer, a cornerstone of reliable PCB design.

Countersink vs Counterbore Advantages

The advantages of countersink vs counterbore‚Äč guide the selection process. Each offers benefits suited to different applications.

- Countersink Advantages:

- Flush Surface:‚Äč Creates a completely smooth, uninterrupted surface ideal for sliding parts or aesthetic finishes.

- Self-Centering:‚Äč The conical shape can help guide the screw head into place during assembly.

- Material Efficiency:‚Äč Often removes less material than a counterbore, which can be beneficial for thin substrates.

- Wide Availability:‚Äč Standardized angles (82¬į, 90¬į, 100¬į) and tools are readily available.

- Counterbore Advantages:

- Precise Head Seating:‚Äč Flat bottom provides positive, stable seating for bolt heads, offering excellent counterbore vs countersink strength‚Äč in shear applications.

- Space for a Washer:‚Äč The cylindrical recess can accommodate a washer under the fastener head.

- Cleaner for Hex/Allen Keys:‚Äč Provides unobstructed access for tools to drive socket-head fasteners.

- Easier to Measure:‚Äč Cylindrical dimensions are simpler to verify with standard pin gauges or micrometers than conical angles.

Choosing based on these countersink vs counterbore advantages‚Äč directly impacts the functionality and manufacturability of your assembly.

Counterbore vs Countersink Screws: Which Fasteners Work with Each Hole Type

The hole type is dictated by the fastener. Using the wrong pairing is a guaranteed assembly failure.

- Fasteners for Countersinks:‚Äč Designed for conical recesses.

- Flat Head Screws:‚Äč The most common type, with a head angle (e.g., 82¬į) matching the countersink angle.

- Oval or Raised Countersunk Heads:‚Äč Provide a decorative finish while still sitting within the conical recess.

- Fasteners for Counterbores:‚Äč Designed for cylindrical recesses.

- Socket Head Cap Screws (Allen Bolts):‚Äč The standard choice, with a cylindrical head and flat bottom.

- Button Head or Flat Socket Head Screws:‚Äč Offer a lower profile within the counterbore hole.

- Hex Bolts with Washers:‚Äč The counterbore‚Äč depth must account for both the head and washer thickness.

The rule is absolute: a conical screw requires a countersink; a cylindrical-headed bolt requires a counterbore. This compatibility is vital for reliable SMT services‚Äč that include mechanical mounting.

Counterbore vs Countersink vs Spotface: How These Hole Types Differ in Practice

While counterbore and countersink‚Äč are common, spotfacing‚Äč is a related operation. Understanding counterbore vs countersink vs spotface‚Äč prevents specification errors.

- Spotface:‚Äč A very shallow counterbore. Its primary purpose is not to recess a fastener head but to create a flat, smooth, and perpendicular seating surface on an otherwise rough or uneven workpiece (e.g., on a casting). The depth is minimal, just enough to clean up the surface.

- Key Difference:‚Äč A spotface‚Äč is about creating a finishand squaresurface; a counterbore‚Äč is about creating depthfor clearance. In PCB contexts, true spotfacing‚Äč is rare; most recesses for fastener heads are counterbores.

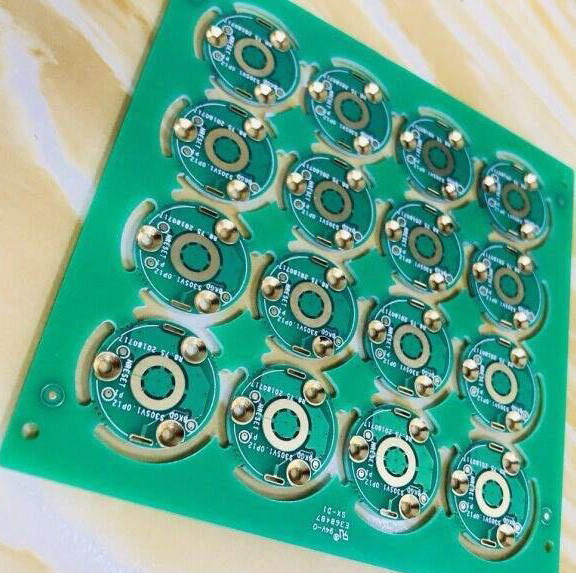

Countersink vs Counterbore PCB Applications in Electronics Assembly

In PCB design and SMT services, these features are not just for mechanical enclosures but are integral to the board itself.

- Countersink PCB Applications:

- Mounting boards flush into tight chassis with flat-head screws.

- Creating a smooth surface behind a display or touch panel.

- Reducing snag points on wearable or handheld devices.

- Counterbore PCB Applications:

- Seating standoffs or spacer nuts below the board surface.

- Providing clearance for the heads of screws that mount heatsinks or large components to the PCB.

- Allowing a connector or module to sit flush over a mounting screw location.

These PCB applications‚Äč highlight how counterbore and countersink‚Äč features enable compact, robust, and professional electronic assemblies.

When To Use Countersink vs Counterbore?

The decision of when to use countersink vs counterbore‚Äč follows a clear logic tree based on design requirements.

Use a COUNTERSINK when:

- The fastener has a conical head (flat head screw).

- A perfectly flush surface is mandatory.

- The application is primarily tensile (clamping force along the screw axis).

Use a COUNTERBORE when:

- The fastener has a cylindrical head (socket cap screw, hex bolt).

- The fastener head must be below the surface but a flat seating is needed for strength.

- You need tool clearance for an Allen key or hex driver.

- A washer is used under the fastener head.

For reliable PCB design, this choice must be made early in the layout phase to accommodate the necessary space and layer clearance.

How Counterbore vs Countersink Decisions Impact PCB Manufacturing Accuracy?

The counterbore vs countersink‚Äč choice directly affects manufacturability and cost. Precision is paramount.

- Accuracy Challenges:

- Countersink:‚Äč Controlling the angleand the diameter at the surfaceis critical. A slight angle error prevents a flush fit.

- Counterbore:‚Äč Controlling the depthand the cylindrical diameteris critical. Depth errors cause heads to protrude or sink too deep.

- Manufacturing Impact:‚Äč Counterbores‚Äč often require a tool change (a specific counterbore bit) after drilling the pilot hole, adding a process step. Countersinks‚Äč may be done with a dedicated bit or a chamfering tool. Both processes demand stable, CNC-controlled equipment to maintain positional accuracy relative to SMT pads and traces.

A manufacturer’s capability to hold tight tolerances on these features is a direct indicator of their suitability for high-reliability PCB projects.

Why Engineers Choose Best Technology for Counterbore vs Countersink PCB Projects?

Engineers choose partners who eliminate risk. For projects demanding precision counterbore and countersink‚Äč features, the choice involves several key considerations.

- Technical Expertise:‚Äč Deep understanding of counterbore vs countersink vs counter drill‚Äč operations and their implications on different PCB materials.

- Process Capability:‚Äč Investment in precision drilling/milling machinery and inspection tools (optical comparators, CMM) to verify counterbore hole dimensions‚Äč and countersink angles.

- Design Partnership:‚Äč Willingness to review countersink vs counterbore callouts‚Äč and suggest optimizations for yield and cost as part of reliable SMT services.

- Material Experience:‚Äč Knowledge of how materials like FR-4, Rogers, or ceramic behave during machining to prevent delamination or cracking.

- Full-Service Integration:‚Äč Ability to not only fabricate the board with these features but also to handle the subsequent SMT and mechanical assembly, ensuring a perfect fit.

In a nutshell, Counterbore vs countersink‚Äč are essential machining techniques that enable secure, flush fastener installation and component seating in sophisticated PCB assemblies. Mastering their design, symbols, and applications is key to achieving reliable, professional-grade electronics.

For designers seeking a manufacturing partner that treats these critical details with the precision they deserve, EBest Circuit (Best Technology)‚Äč stands ready. We combine extensive experience in complex PCB fabrication‚ÄĒincluding precise counterbore and countersink‚Äč machining‚ÄĒwith comprehensive SMT services‚Äč to deliver fully realized, reliable products. Pls feel free to contact us anytime at sales@bestpcbs.com to discuss your next PCB project.