In today‚Äôs fast-paced tech landscape, finding reliable PCB manufacturers in the USA isn‚Äôt just about checking a list‚ÄĒit‚Äôs about aligning your project‚Äôs unique needs with a partner that delivers on quality, compliance, and speed. Whether you‚Äôre building aerospace components, medical devices, or industrial equipment, the right US-based PCB manufacturer can make or break your product‚Äôs success. This guide breaks down everything you need to know to navigate the top PCB manufacturers in USA and make an informed decision.

Why Choose US-Based PCB Manufacturers? Key Advantages for Your Project

When engineers and product teams debate sourcing options, the shift toward US-based PCB manufacturers continues to gain momentum‚ÄĒand for good reason. Global supply chain disruptions over the past few years have highlighted the risks of offshore production: extended lead times (often 4‚Äď8 weeks), communication barriers, and limited control over quality. US PCB manufacturers address these pain points head-on with 30‚Äď60% faster turnaround times for prototypes and production runs, thanks to local sourcing and streamlined logistics.

Beyond speed, US-based manufacturers offer unparalleled supply chain security. With facilities located within North America, you avoid customs delays, import tariffs, and the risks of geopolitical instability that can derail offshore orders. For industries like defense or aerospace, this local presence isn‚Äôt just convenient‚ÄĒit‚Äôs critical for compliance with ITAR regulations and domestic sourcing requirements. Plus, working with teams in the same time zone eliminates miscommunications and ensures rapid resolution of design or production issues‚ÄĒsomething that‚Äôs nearly impossible with overseas suppliers operating on opposite schedules.

Critical Factors to Evaluate Top PCB Manufacturers in USA

Not all top PCB manufacturers in USA are created equal, so knowing what to look for is essential. Start by defining your project’s non-negotiables: Are you prioritizing speed for a prototype? Quality for a life-saving medical device? Or cost-effectiveness for high-volume production? Once you have clarity, evaluate potential partners against these core criteria.

First, assess their technical capabilities against your design requirements‚ÄĒdo they specialize in HDI, rigid-flex, or RF/microwave circuits? Next, verify their quality control systems: Look for 100% electrical testing, AOI inspection, and traceability protocols that track materials and processes. Customer support is another make-or-break factor‚ÄĒyou need a team that offers proactive DFM feedback and real-time project updates, not just a quote and a deadline. Finally, confirm compliance with industry-specific certifications (more on that next) to avoid costly delays or rework.

Industry-Specific Requirements: Aerospace, Medical & Automotive PCB Needs

The top PCB manufacturers in USA differentiate themselves by catering to industries with strict performance demands. Aerospace and defense projects, for example, require PCBs that withstand extreme temperatures, vibration, and radiation‚ÄĒall while meeting ITAR and AS9100 standards. These applications often call for IPC Class 3 certification, the highest reliability standard that mandates zero defects in critical components like satellite communication systems.

Medical device manufacturers face equally rigorous requirements. PCBs used in implantable devices (e.g., pacemakers) or diagnostic equipment must comply with ISO 13485 and meet biocompatibility standards to ensure patient safety. The automotive industry, meanwhile, demands PCBs that handle high voltage, thermal cycling, and electromagnetic interference (EMI)‚ÄĒkey for electric vehicles and advanced driver-assistance systems (ADAS). When evaluating top PCB manufacturers in USA, ask for case studies in your industry‚ÄĒthis proves they understand your unique challenges.

Essential Certifications: ISO, ITAR, IPC Class 3 & UL Compliance

Certifications aren‚Äôt just logos on a website‚ÄĒthey‚Äôre proof that a manufacturer meets global standards for quality, safety, and compliance. For US-based projects, three certifications stand out as non-negotiable for top PCB manufacturers in USA.

ITAR certification is mandatory for any project involving defense or aerospace components, as it ensures compliance with US export controls and protects sensitive intellectual property. ISO certifications, including ISO 9001 (general quality) and ISO 13485 (medical devices), demonstrate a commitment to consistent processes and customer satisfaction. IPC Class 3 is critical for life-saving or high-reliability applications, with strict requirements for copper thickness, solder mask integrity, and conductor quality.

UL compliance, meanwhile, is essential for consumer and industrial products, as it verifies electrical safety and fire resistance. Don‚Äôt just ask if a manufacturer has these certifications‚ÄĒrequest documentation of their audit history and compliance records to ensure they maintain these standards consistently.

Turnaround Time Comparison: Rapid Prototyping vs High-Volume Production

One of the biggest advantages of working with top PCB manufacturers in USA is faster turnaround times‚ÄĒbut not all speed is created equal. Prototyping and high-volume production have different timelines, and the best manufacturers offer tailored solutions for each.

For prototyping, quick-turn services can deliver functional boards in 3‚Äď5 business days, allowing you to test designs, iterate, and accelerate your NPI cycle. This agility is a game-changer for startups and innovation-driven projects, where speed-to-market can mean the difference between leading the industry or falling behind. For high-volume production, top PCB manufacturers in USA balance speed with scalability‚ÄĒlook for tiered pricing models and automated production lines that handle 10,000+ units without sacrificing quality.

When comparing turnaround times, ask about contingency plans for emergency orders. The best US-based manufacturers offer rush services for critical projects, something offshore suppliers rarely provide. Also, clarify lead times for design revisions‚ÄĒlocal partners can often adjust quickly, while overseas changes can add weeks to your timeline.

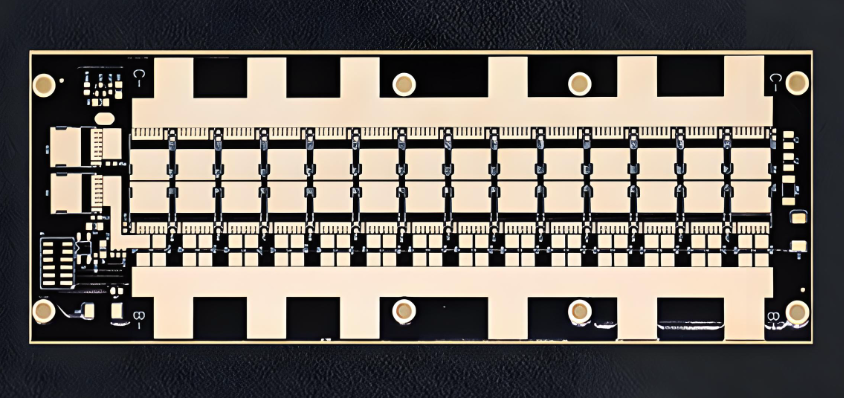

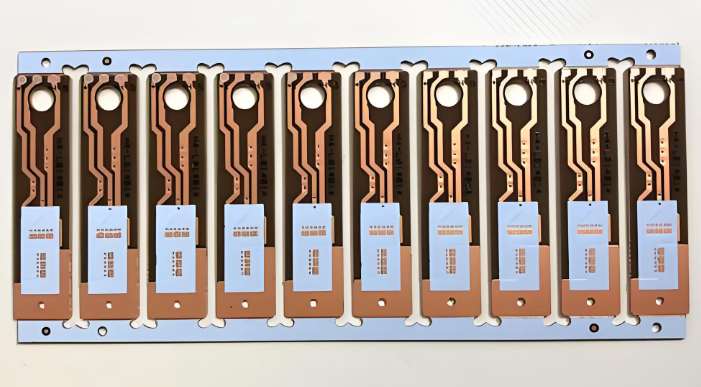

PCB Technology Capabilities: HDI, Rigid-Flex & RF/Microwave Expertise

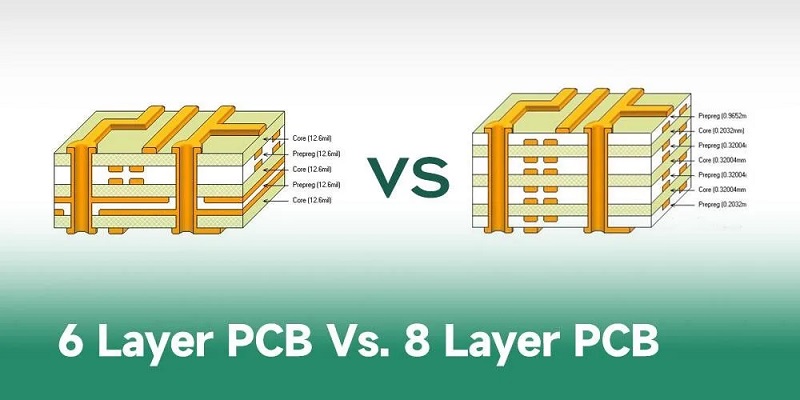

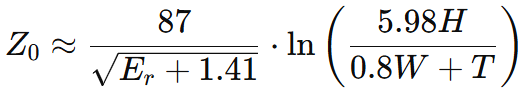

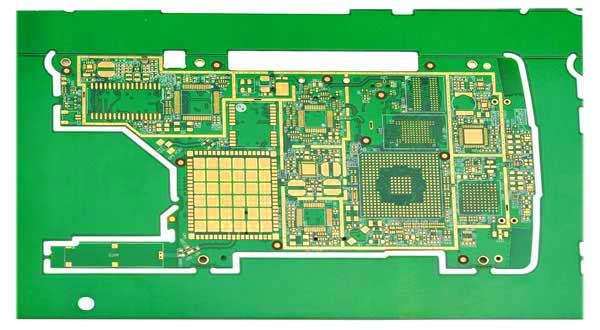

As electronic devices become smaller, more complex, and more powerful, the technical capabilities of your PCB manufacturer matter more than ever. The top PCB manufacturers in USA invest in cutting-edge technology to handle advanced designs that offshore suppliers may struggle with.

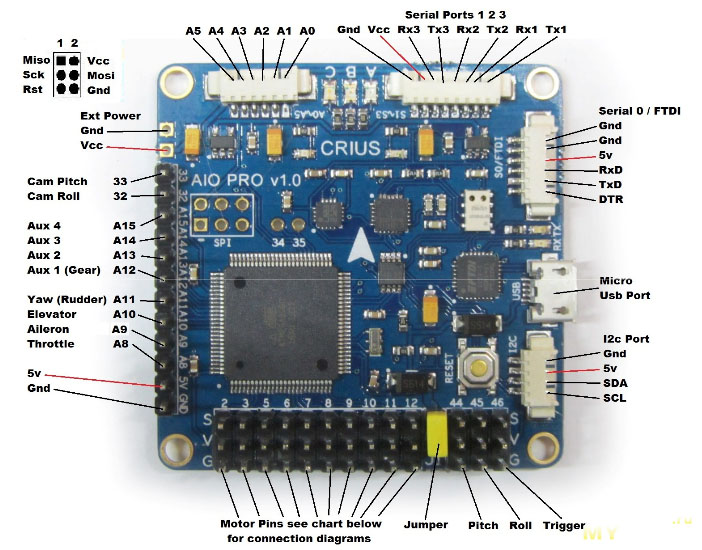

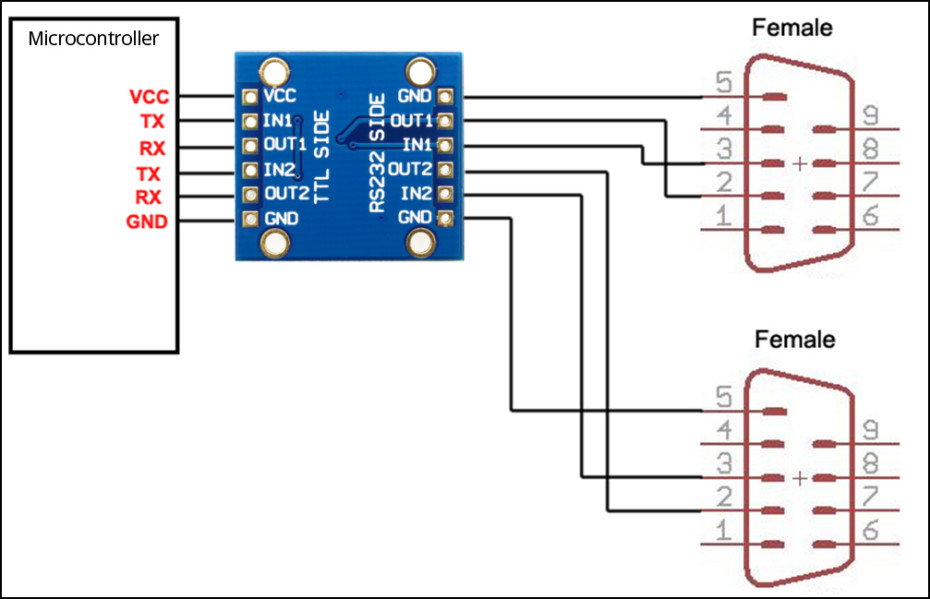

HDI (High-Density Interconnect) PCBs are essential for smartphones, wearables, and medical devices, as they allow for more components in a smaller footprint. Rigid-flex PCBs, which combine rigid and flexible materials, are ideal for aerospace and automotive applications where space is limited. RF/microwave PCBs require specialized materials and manufacturing processes to ensure signal integrity for communication systems, radar, and satellite technology.

When evaluating top PCB manufacturers in USA, ask about their equipment (e.g., laser drilling machines, automated assembly lines) and their experience with your specific technology. A manufacturer that specializes in simple rigid PCBs may not have the expertise to handle your HDI or rigid-flex design‚ÄĒleading to costly errors or compromised performance.

Quality Control Systems: FPY Rates, AOI Testing & Traceability

Quality is non-negotiable when it comes to PCBs‚ÄĒeven a tiny defect can cause system failure, safety risks, or expensive rework. The top PCB manufacturers in USA prioritize quality control (QC) through rigorous processes and advanced testing.

First, look at their First Pass Yield (FPY) rate‚ÄĒa high FPY (ideally 98% or higher) indicates consistent production quality and reduces the risk of delays. Next, confirm their testing protocols: 100% electrical testing (to check for shorts and opens), AOI (Automated Optical Inspection) for surface defects, and microsection analysis for verifying internal structures like copper thickness. Traceability is another critical QC component‚ÄĒeach PCB should be traceable to its material batch, production date, and test results, allowing you to identify and resolve issues quickly.

Don’t hesitate to ask for a tour of their facility (in-person or virtual) to see their QC processes firsthand. The best manufacturers are transparent about their quality systems and happy to share data on their performance.

Pricing Models: How to Balance Cost & Value with US PCB Suppliers

A common misconception is that US-based PCB manufacturers are more expensive than offshore options‚ÄĒbut when you factor in hidden costs, the gap narrows significantly. The top PCB manufacturers in USA offer transparent pricing models that help you balance cost and value.

Offshore suppliers may offer lower per-unit pricing, but you’ll likely pay more in shipping, customs fees, and tariffs. Plus, delays from communication gaps or quality issues can lead to lost revenue from missed deadlines. US-based manufacturers eliminate these hidden costs with local logistics, faster turnaround, and fewer reworks.

When evaluating pricing, look for flat-rate pricing for prototypes and tiered pricing for high-volume production. Some manufacturers offer hybrid sourcing models‚ÄĒcombining US-based prototyping (for speed and quality) with overseas production (for high-volume cost savings). Be wary of manufacturers that offer unusually low prices‚ÄĒthis often indicates cutting corners on quality or materials, which will cost you more in the long run.

DFM Support: Why Design-for-Manufacturability Matters for US Manufacturers

Design-for-Manufacturability (DFM) is the secret to smooth production, on-time delivery, and cost savings‚ÄĒand the top PCB manufacturers in USA excel at providing proactive DFM support. DFM involves optimizing your PCB design for the manufacturing process, reducing the risk of defects, and minimizing production costs.

A good US-based manufacturer will review your design files early in the process, identifying issues like incompatible materials, tight tolerances, or inefficient layouts. They may suggest changes like adjusting trace widths, adding test points, or selecting alternative materials that are easier to manufacture without compromising performance. This collaborative approach saves time by reducing design iterations and ensures your PCB is production-ready from day one.

Some top PCB manufacturers in USA offer free DFM tools or online portals where you can upload your design files for instant feedback. Take advantage of these resources‚ÄĒthey‚Äôre a sign of a manufacturer that values your success as much as their own.

Supply Chain Resilience: Local Sourcing & Emergency Order Capabilities

The past few years have taught us the importance of supply chain resilience‚ÄĒand the top PCB manufacturers in USA have invested heavily in building robust, local supply chains. Unlike offshore suppliers that rely on global materials and logistics, US-based manufacturers source most components locally, reducing the risk of delays from port congestion, shipping shortages, or geopolitical issues.

Emergency order capabilities are another key aspect of supply chain resilience. If your project hits a snag (e.g., a design change, a defective batch, or a tight deadline), the best US-based manufacturers can accelerate production to meet your needs. They have dedicated prototype lines and flexible production schedules that allow them to prioritize urgent orders without sacrificing quality.

When evaluating top PCB manufacturers in USA, ask about their inventory management systems and backup suppliers. A manufacturer with multiple local material sources and safety stock for critical components is far more reliable than one that relies on a single overseas supplier.

Customer Support & Technical Assistance: 24/7 Response & Account Management

Technical issues and questions are inevitable during PCB production‚ÄĒand the level of customer support can make all the difference. The top PCB manufacturers in USA distinguish themselves by offering responsive, knowledgeable support that goes beyond basic order tracking.

Look for manufacturers that assign a dedicated account manager to your project‚ÄĒthis person will be your single point of contact for design reviews, production updates, and problem-solving. 24/7 technical support is a must for time-sensitive projects, as it ensures you can get help whenever you need it‚ÄĒwhether it‚Äôs a late-night design question or an urgent production issue.

The best US-based manufacturers also offer post-delivery support, including troubleshooting assistance and warranty coverage. Don‚Äôt just read reviews‚ÄĒreach out to their customer support team with a few questions to test their responsiveness and expertise. A manufacturer that takes the time to understand your needs is more likely to deliver a successful project.

Sustainability & Environmental Compliance: RoHS & REACH Standards

Sustainability is no longer a nice-to-have‚ÄĒit‚Äôs a requirement for businesses operating in the US and global markets. The top PCB manufacturers in USA prioritize environmental compliance by adhering to strict standards like RoHS and REACH.

RoHS (Restriction of Hazardous Substances) limits the use of lead, mercury, and other toxic materials in electronic devices‚ÄĒcritical for both environmental protection and market access. In the US, California‚Äôs Prop 65 goes even further, requiring warnings for products containing lead or other harmful substances, with fines of up to $25,000 per day for non-compliance. REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) is a European standard that US manufacturers must follow if they export to the EU.

When evaluating top PCB manufacturers in USA, ask about their sustainability practices‚ÄĒdo they use recycled materials? Implement energy-efficient production processes? Offer take-back programs for waste PCBs? Choosing a sustainable manufacturer not only helps you comply with regulations but also enhances your brand reputation among eco-conscious customers.

Case Studies: Success Stories with Top USA PCB Manufacturers

Nothing builds trust like real-world results‚ÄĒand the top PCB manufacturers in USA have a track record of success across industries. For example, a leading aerospace company partnered with a US-based manufacturer to produce HDI PCBs for a satellite project, meeting IPC Class 3 standards and delivering prototypes in 7 days‚ÄĒcutting their NPI cycle by 50%.

Another success story comes from a medical device startup that needed ISO 13485-certified PCBs for a diagnostic tool. By working with a US manufacturer that offered proactive DFM support, they reduced design iterations from 3 to 1, saving 6 weeks of production time and $50,000 in development costs.

These case studies highlight the key benefits of working with top PCB manufacturers in USA: speed, quality, compliance, and collaboration. When researching potential partners, ask for references or case studies in your industry‚ÄĒthis will give you a clear picture of their capabilities and how they can support your project.

Common Mistakes to Avoid When Choosing a US PCB Manufacturer

Even with the best intentions, it‚Äôs easy to make mistakes when selecting a PCB manufacturer‚ÄĒbut the top PCB manufacturers in USA can help you avoid these pitfalls. One of the biggest mistakes is prioritizing price over quality: Choosing the cheapest option may save you money upfront, but it often leads to reworks, delays, and compromised performance.

Another common error is neglecting DFM support. Skipping the design review process can result in unmanufacturable designs or costly changes later in production. Don‚Äôt assume all manufacturers offer the same level of DFM assistance‚ÄĒlook for partners that provide detailed feedback and proactive suggestions.

Failing to verify certifications is also a critical mistake. A manufacturer that claims to be ITAR or ISO certified but can‚Äôt provide documentation is a risk to your project. Finally, don‚Äôt overlook communication‚ÄĒworking with a team that‚Äôs unresponsive or difficult to reach will only lead to frustration and delays. Choose a manufacturer that values transparency and keeps you informed every step of the way.

FAQs: Answers to Your Top Questions About USA PCB Manufacturers

What’s the difference between US-based and offshore PCB manufacturers?

US-based manufacturers offer faster turnaround times (3‚Äď10 days vs. 4‚Äď8 weeks offshore), better communication, stricter quality control, and compliance with US regulations like ITAR. Offshore suppliers may be cheaper for high-volume, simple designs but come with hidden costs like shipping and customs fees.

How do I verify a manufacturer’s IPC Class 3 certification?

Ask for a copy of their IPC certification and audit report. Reputable manufacturers will also provide documentation of their testing processes, including microsection analysis and 100% electrical testing.

What’s the typical turnaround time for prototypes from top PCB manufacturers in USA?

Most US-based manufacturers offer quick-turn prototyping in 3‚Äď5 business days, with rush options available for emergency orders.

Do US PCB manufacturers offer hybrid sourcing models?

Yes‚ÄĒmany top PCB manufacturers in USA combine US-based prototyping with overseas production for high-volume orders, balancing speed and cost-effectiveness.

How important is ITAR certification for my project?

ITAR certification is mandatory for defense, aerospace, or any project involving sensitive US technology. Even if your project doesn’t require ITAR, working with a certified manufacturer ensures stricter quality control and IP protection.