A Copper clad PCB board plays an important part in MCPCB design. In this blog, we will discuss the definition, features, price, layers, and manufacturing process for the copper clad PCB board.

Have you met these headaches?

- Poor heat dissipation shortens LED lifespan?

- Corrosion damage in harsh environments?

- Vibration-induced cracking and structural damage?

- Complex manufacturing processes increase cost and lead time?

Here are the solutions from EBest Circuit (Best Technology) to fully resolve these problems.

- Enhanced Thermal Management: To lower thermal resistance and LED temperatures for longer service life, we adopt the copper-based MCPCB with 1.0â4.0 W/m·K thermal conductivity. Besides, we will consider the copper-filled microvia structure for faster heat transfer.

- Corrosion-Resistant Protection: To protect the metal core PCB from salt spray corrosion, we use the anodized layer or specialized plating. Every board has strictly passed the salt spray test.

- Optimize the structure Design for Vibration: We take the 0.8 mm 5052 aluminum alloy with glass fiber reinforcement when selecting the material, and we will do the vibration test. This material is 0.8mm, which improves anti-vibration performance by 3 times.

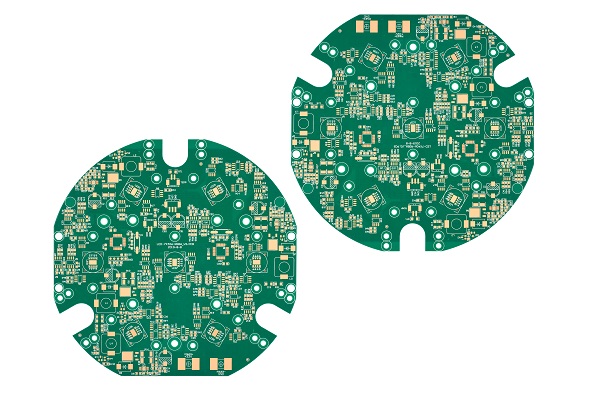

- Advanced Manufacturing Capability: Our solution for complex designs is to get the cutting-edge technology like Microvia, blind via, buried via, etc, which improve the multilayer MCPCB manufacturing efficiency and reliability.

The clad PCB board sits at the heart of many MCPCB designs. EBest Circuit (Best Technology) provides excellent copper clad PCB boards for your MCPCB Design optimization. It would be great if you could give us your specific requirement via sales@bestpcbs.com. We are more than happy to give you our full service from metal core PCB prototype to final delivery.

What is a Copper Clad PCB Board?

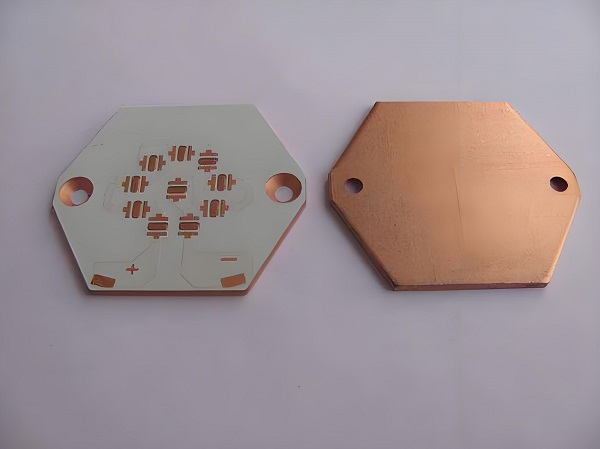

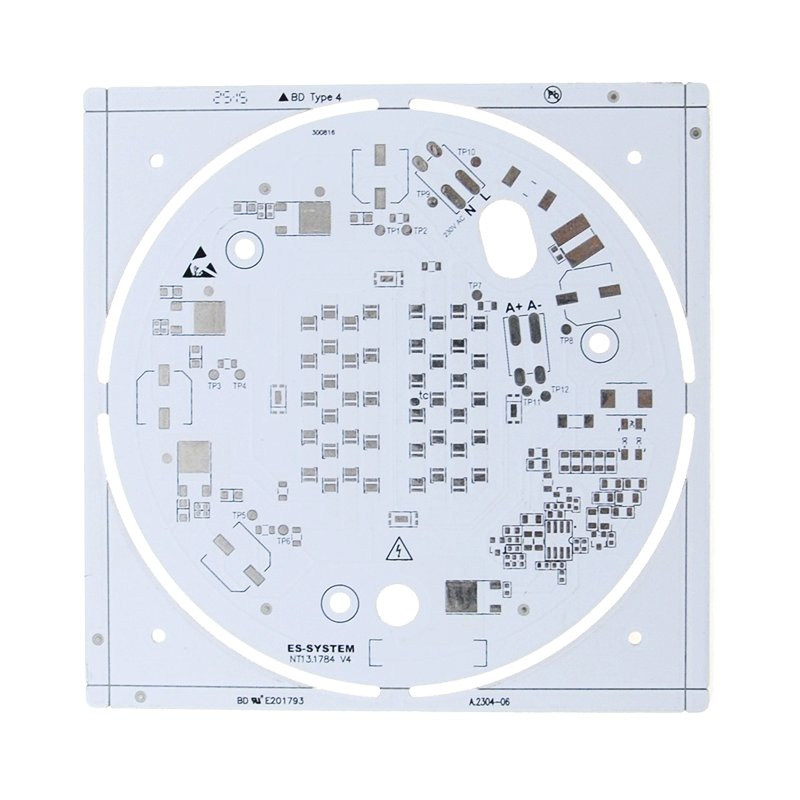

A copper clad PCB board refers to a substrate material laminated with a thin layer of copper foil on its surface. Typically, it consists of an insulating substrate such as FR-4, bonded with copper foil through a lamination process.

Copper clad materials can be broadly categorized based on their substrate type:

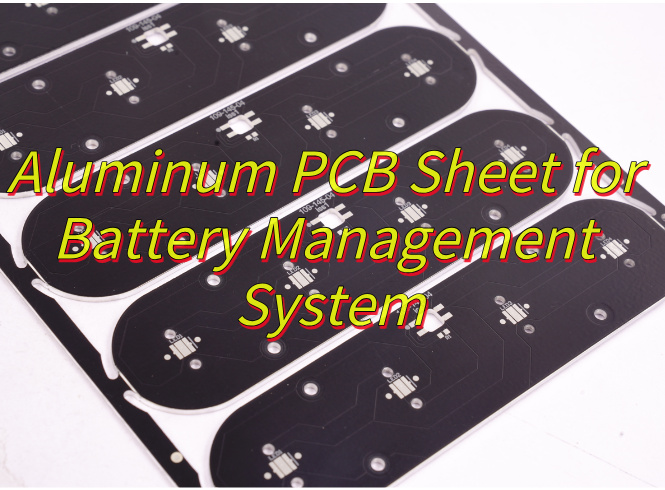

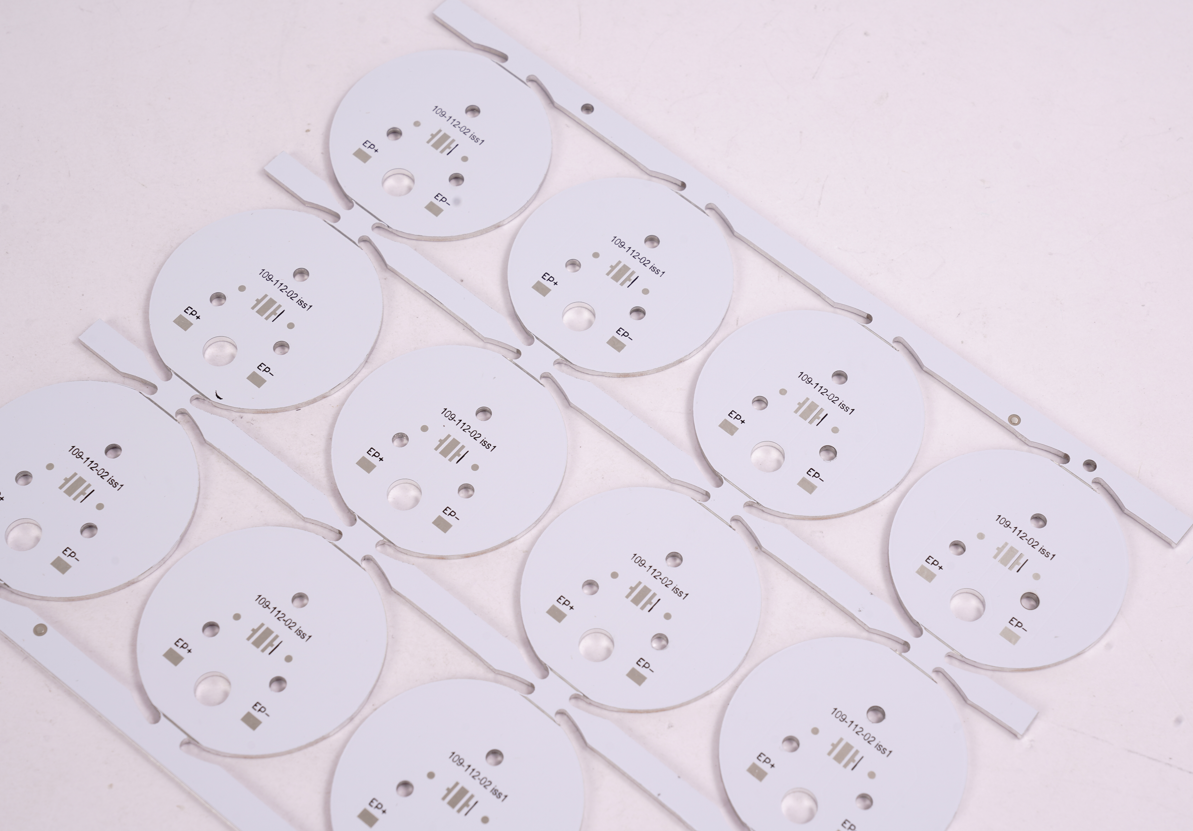

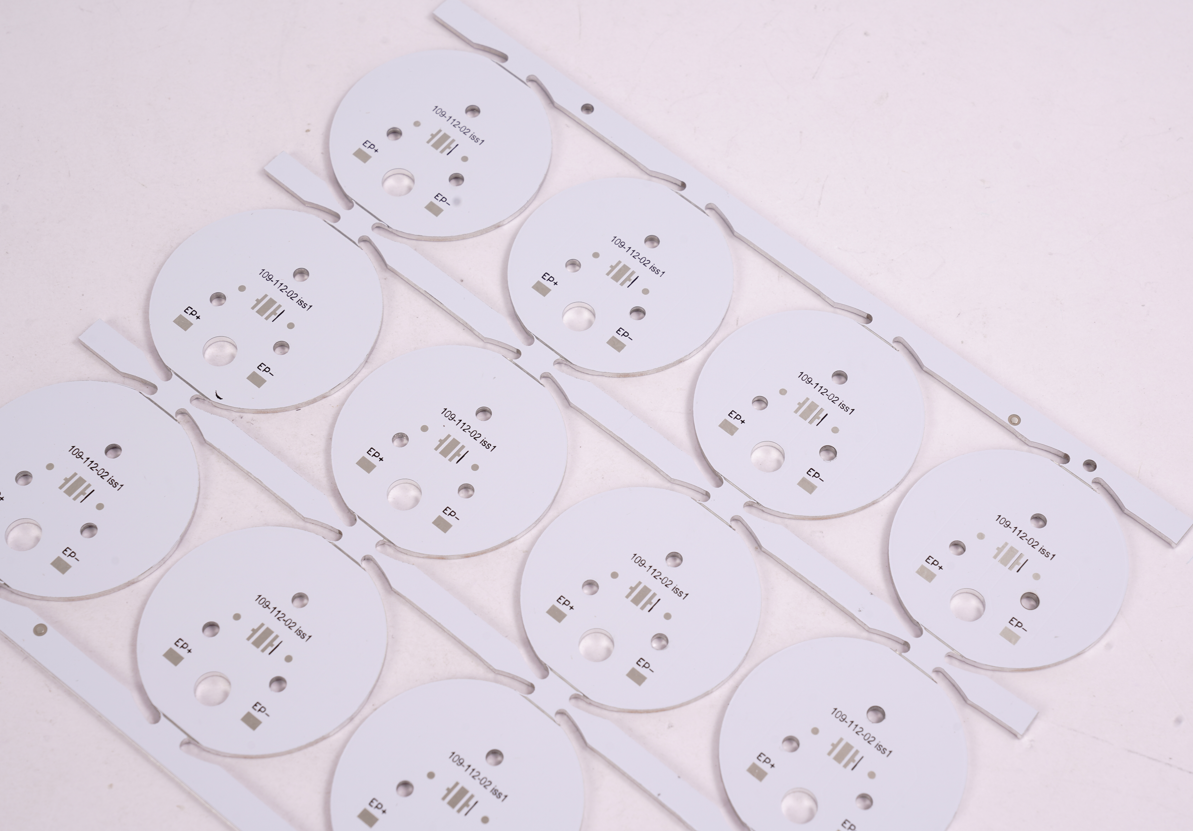

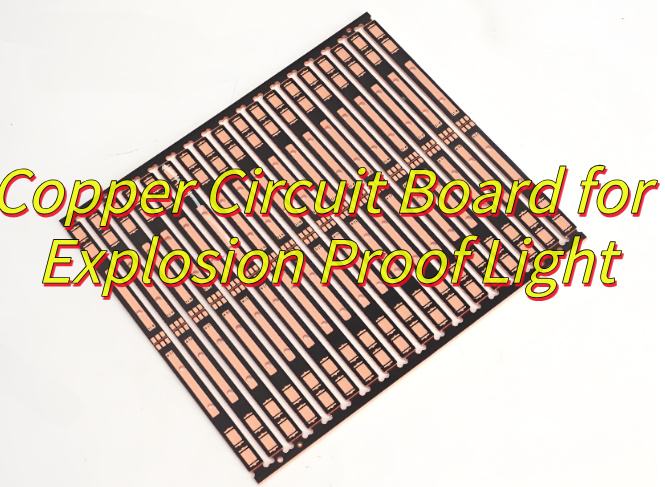

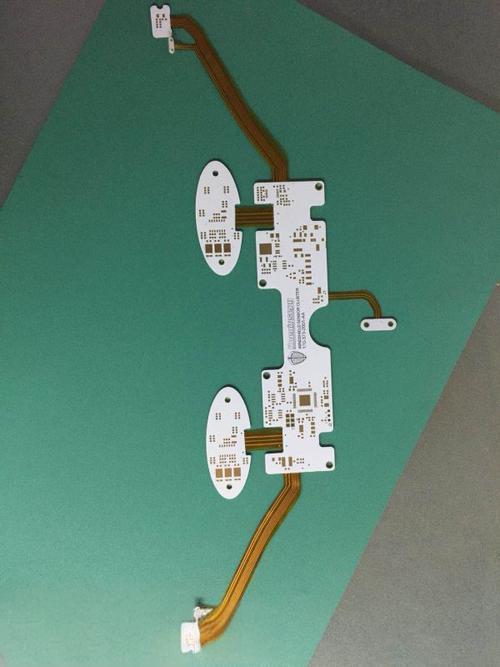

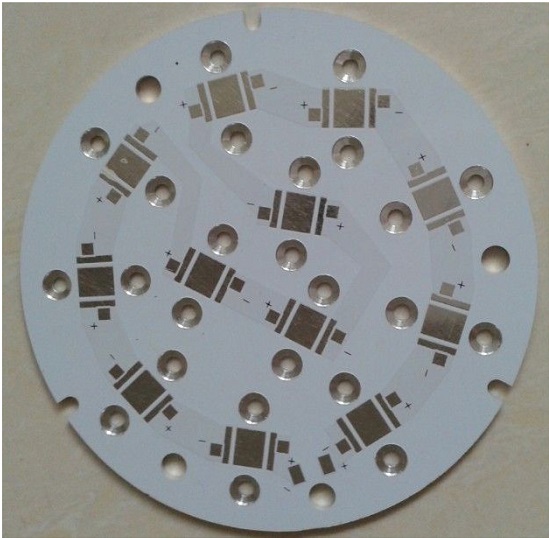

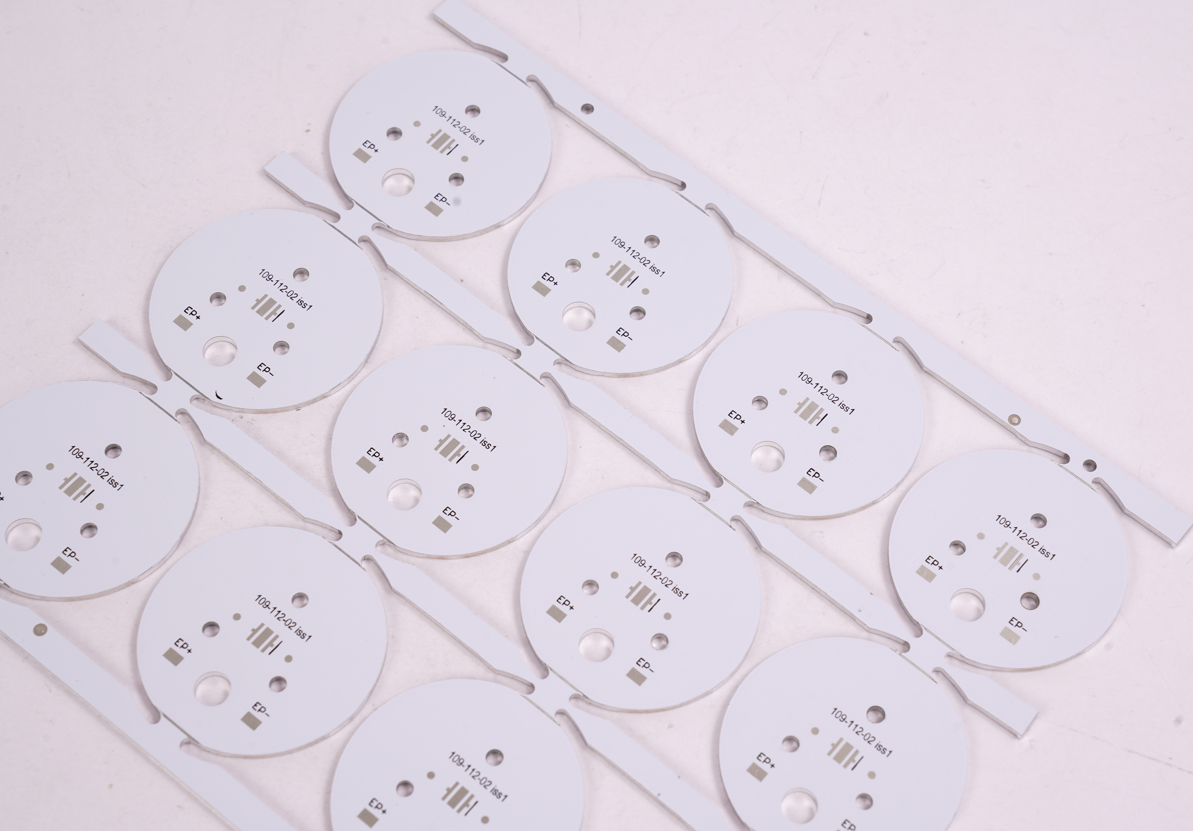

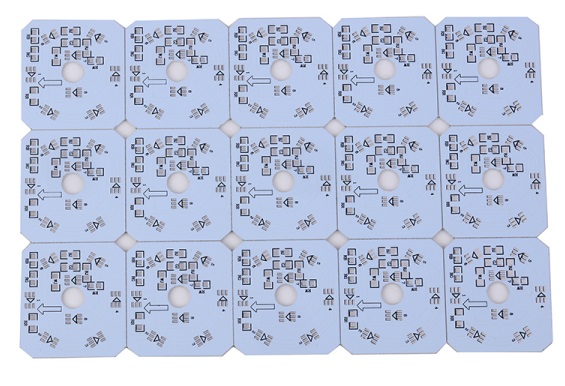

- If the substrate is metallic, such as aluminum or copper, it forms a Metal Core PCB (MCPCB). These PCBs are designed for applications with high thermal demands, where effective heat dissipation is crucial.

- If the substrate is non-metallic, like FR-4 fiberglass, it is known as Copper Clad Laminate (CCL), widely used in general electronic circuit boards.

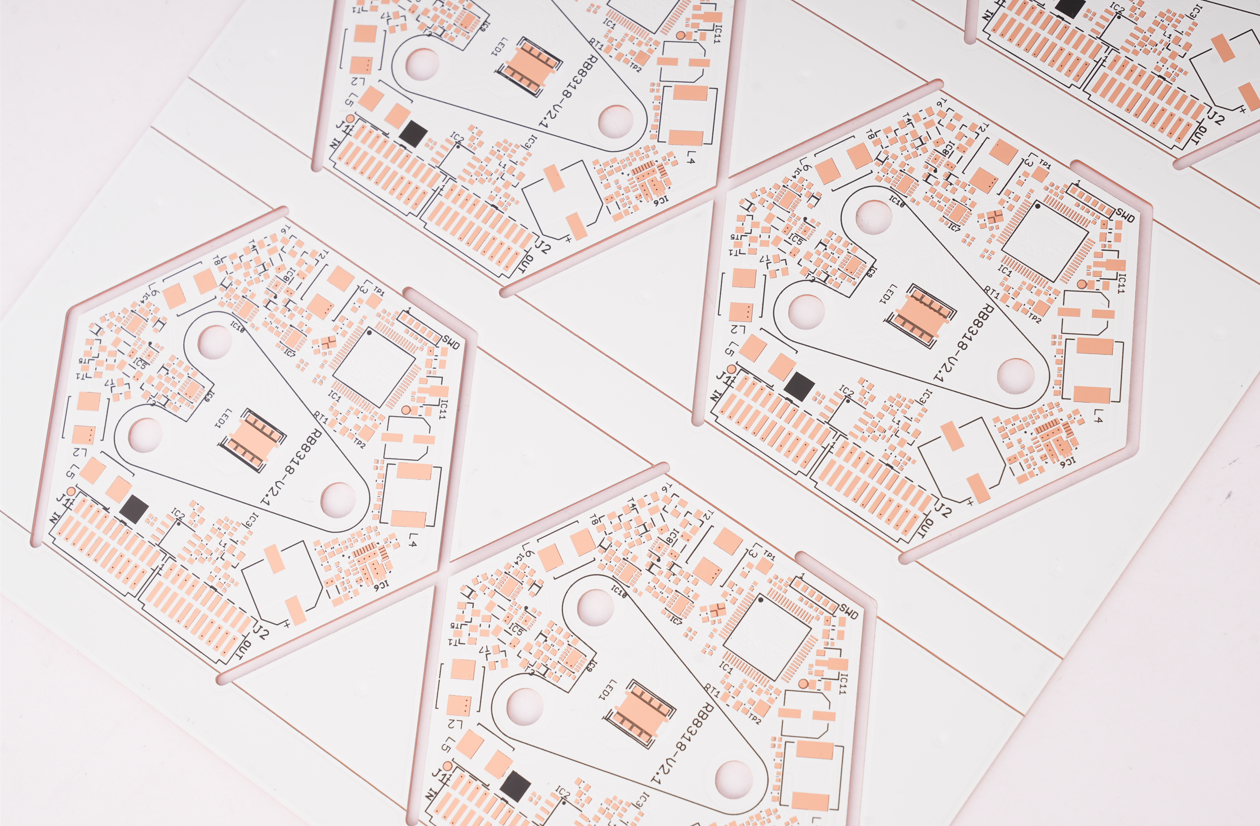

Depending on the specific application, PCB cores can vary from FR-4 fiberglass, metal cores (aluminum, copper), to advanced ceramic substrates. In this discussion, the focus will be on metal core PCBs.

What Does Copper Clad Laminate Mean?

Copper clad laminate is also called CCL, which refers to the raw material. But copper clad PCB board may include the finished PCBs. Copper clad laminate is an essential and basic material in electronic manufacturing, like phones and laptops. That features the circuit conducting in electronic parts. The structure of copper clad laminate is hot-pressed by copper foil, an insulated substrate, such as Resin and glass fiber. It consists of a core insulating material bonded with copper foil on one or both sides.

Difference Between Copper Clad PCB and Photosensitive Copper Clad Board

While a copper clad PCB board is a general base for PCB fabrication, a photosensitive copper clad board has a special coating that reacts to light exposure. It has a great feature that it can form the circuit pattern through exposure and development. No need to process the traditional etching process to form the circuit pattern.

However, the big difference between copper clad PCB and photosensitive copper clad board is that the copper clad PCB should undergo etching, drilling, and other complex processes, then finish the PCB. It is commonly used in consumer electronics and communication devices. So the photosensitive copper clad board simplifies the manufacturing process, and it is mostly perfect for the small batch and the high precision circuit manufacturing, like HDI PCB board.

What is the Copper Clad PCB Board Price?

There are mainly 3 factors for price fluctuation.

- The first factor is the substrate type, such as aluminum core and copper core. The aluminum core price is generally higher 30%-50% than the common FR4. However, the copper core substrate board will be more expensive, whose unit price may increase 50%-100% than the aluminum core board, which depends on the copper purity and the copper thickness.

- Another factor is the complexity of the manufacturing process. The cost will increase 15%-25% if the high thermal metal core board needs special hole drilling, such as laser drilling, and surface treatment, such as immersion gold. Since this process is more complex, it is difficult to do well.

- The final factor is the manufacturing batch quantity. If the quantity is lower than 100 pieces, the prototype unit price may be USD20-50 per piece. However, if above 1000 pieces, the price could be lower to USD5-10 per piece. And the copper core board will increase the cost by more than 20%-30%.

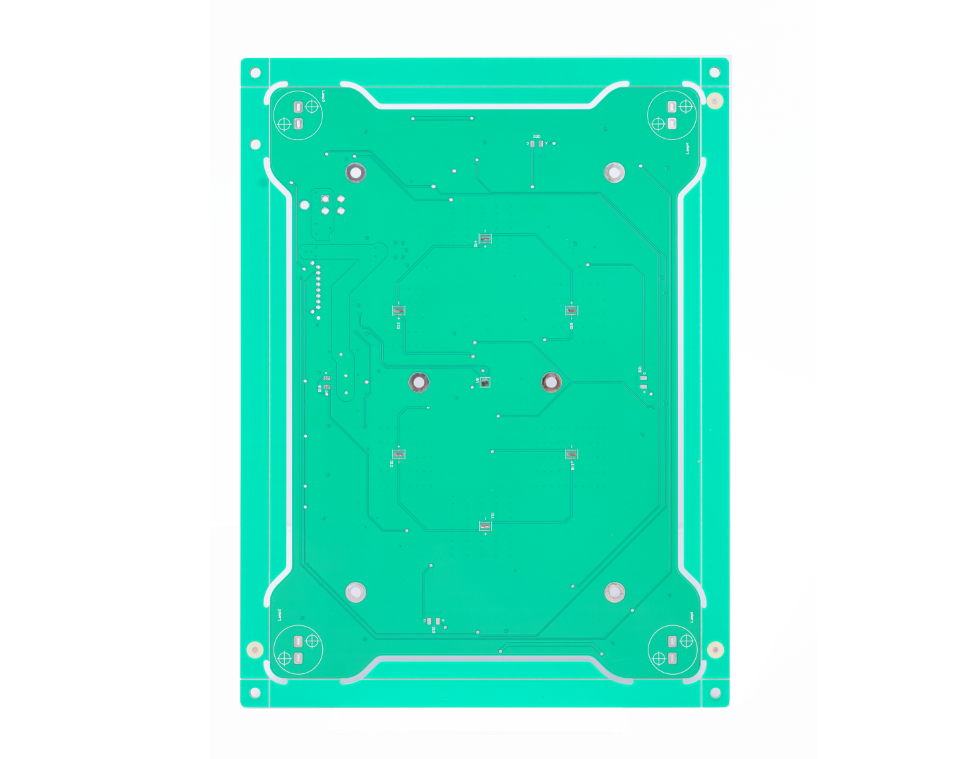

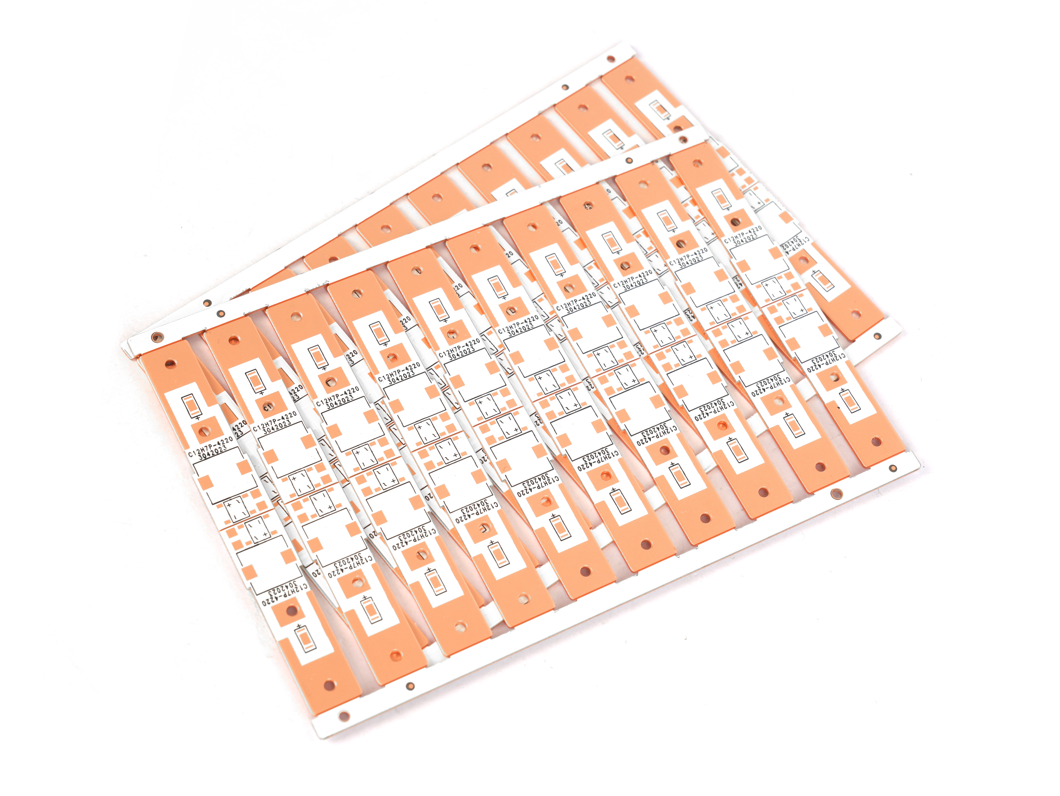

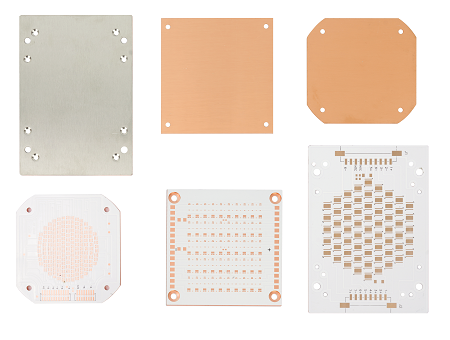

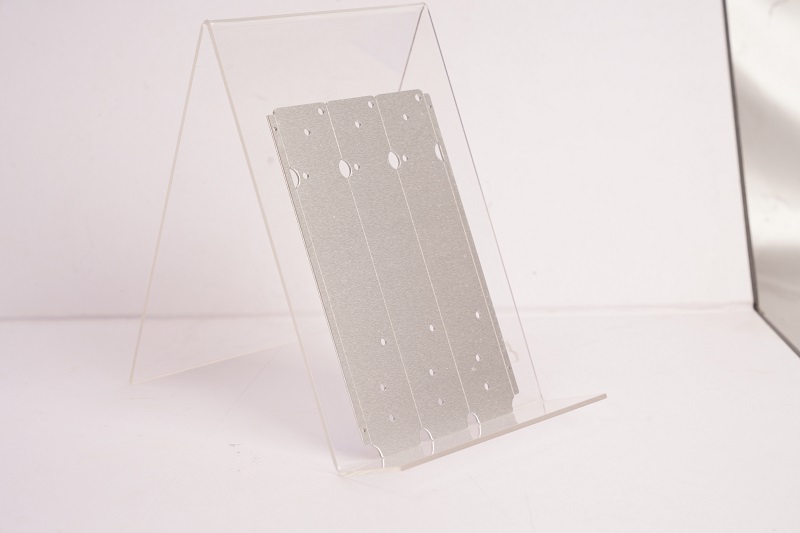

Layers of Copper Clad Board Double Sided

A double sided copper clad board has three material layers: copper foil on the top, insulating substrate in the middle, and copper foil at the bottom. A double sided copper clad board means there are laminated with copper foil on both substrate sides. That is suitable for the electronic equipment that needs both sides to have the circuits. It is applicable for medium complexity circuit design.

Double sided circuits are making the electricity connection through vias. The standard layer of double-sided copper-clad board is only 2 layer copper foil, which is a double-layer routing layer, without an inner layer of copper foil. If the double-sided copper-clad board has an inner layer, it needs to be specified like this: 4-layer copper clad board, which has 2 inner layers.

Manufacturing Process of Single Sided Copper Clad PCB Board

Manufacturing a single sided copper clad board involves several steps:

- Material Preparation: Cutting copper clad laminate to required size.

- Cleaning: Removing contaminants for better adhesion.

- Pattern Transfer: Applying a resist to define circuit patterns.

- Etching: Removing unwanted copper to reveal conductive traces.

- Finishing: Applying surface finishes for solderability and corrosion protection.

This straightforward process makes single sided copper clad boards a cost-effective choice for simpler MCPCB designs.

Difference Between Copper Clad PCB Board, Copper Plated PCB Board, and Copper Coated PCB Board

These terms sound similar but have distinct meanings.

- A copper clad PCB board refers to the base material with copper laminated on one or both sides.

- A copper plated PCB board describes a board that has undergone plating during manufacturing, such as adding copper to through-hole walls.

- Copper coated PCB board is a non-standard term, sometimes used to mean boards with a copper surface layer, but it lacks precision in professional contexts.

How to Choose the Copper Clad PCB Board for MCPCB Design?

Choosing a suitable copper clad PCB board for MCPCB design involves 6 fundamental factors.

- First, you should choose suitable copper foils. There are ECF, RACF, and special copper foil for your selection. The ECF is suitable for the low frequency and the high current applications, which have low cost, but it’s mechanical strength is up to 150-300MPa. But its surface roughness is Ra 0.8-1.2ÎŒm, which may cause the high-frequency signal loss. The RACF is a great option for high-frequency transmission or the flexible MCPCB design. This copper foil has excellent ductility, and the surface is smoother. The third foil is a special type, like the high thermal copper foil or the copper foil, where Rz is lower than 3ÎŒm. It is suitable for high-power heat dissipation or high-speed circuits.

- The second factor is copper thickness and the heat dissipation design. The outer layer commonly used is the 1/2 ounce plated copper. The inner layer is recommended to choose the 1-2 once a solid copper plate, so as to optimize the heat dissipation performance.

- The third factor is to optimize the stacked structure. It is great to utilize the inner circuit to block the high-speed signal, so as to reduce the distraction.

- The fourth factor is the copper laying strategy. The antenna area should avoid copper. The creepage spacing should be reserved for high-voltage circuits.

- The fifth factor is the balance between costs. The FR4 depends on the copper foil and the vias to dissipate the heat. But the metal core substrate has a higher cost than FR4. And it improves the heat dissipation efficiency, making it suitable for the high-power MCPCB.

- The final factor is the manufacturing process match. The 2 once copper foil is expensive, and it is difficult to do the fine circuit, but it has great thermal performance. Hence, the design needs to be weighed according to the requirements. The inner layer should use the negative copper to improve the yield, and the surface copper layer should avoid the dense circuit area.

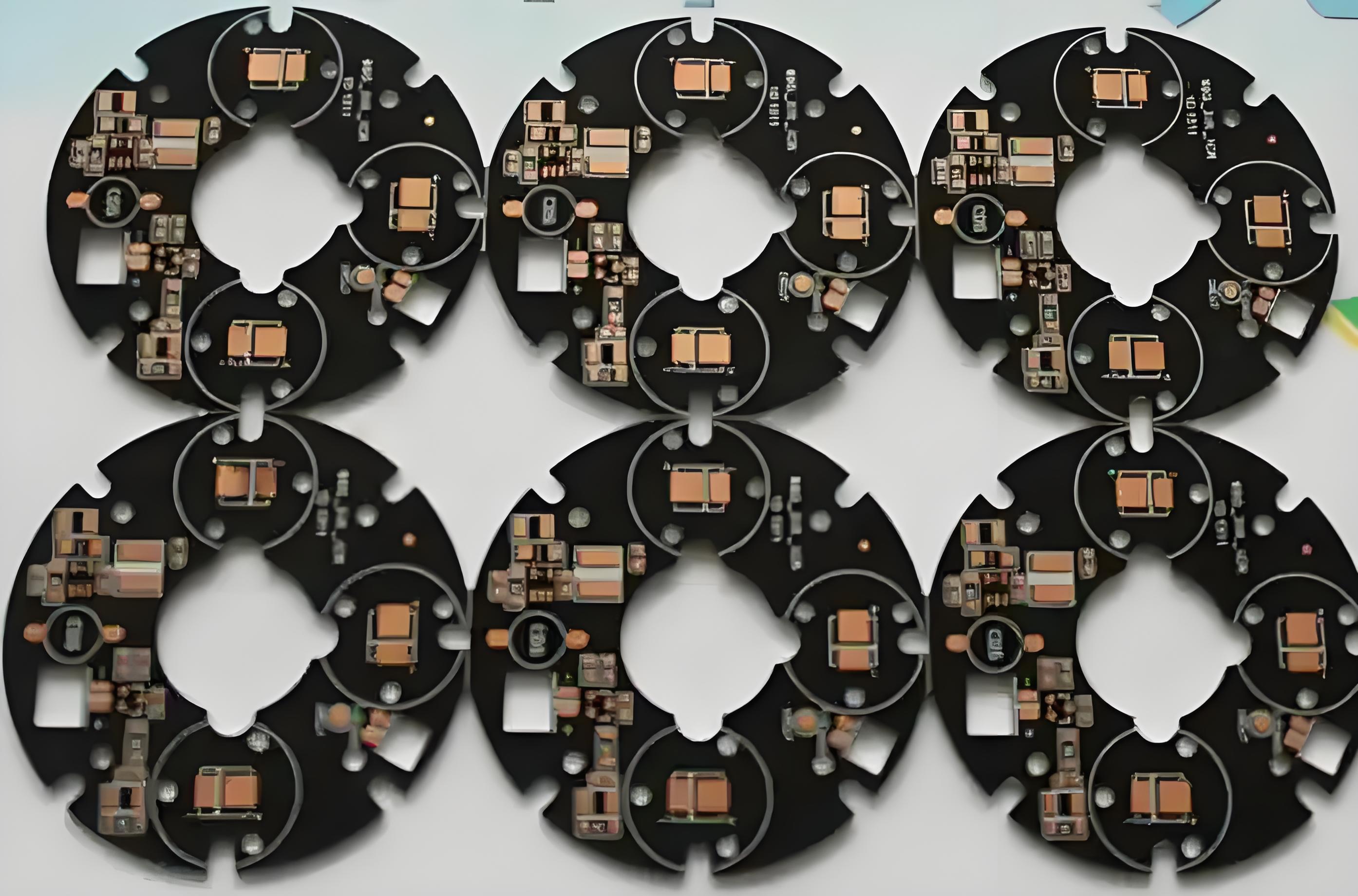

Why Choose EBest Circuit (Best Technology) as One of Your Trusted Copper Clad PCB Board Manufacturers?

EBest Circuit (Best Technology) understands the challenges faced by customers in industries like LED lighting, automotive, and marine electronics. High-power LEDs demand superior heat dissipation. Coastal environments require boards that can resist salt spray corrosion. Vibration-heavy applications need materials that wonât crack under stress.

- EBest Circuit (Best Technology) has the practical experience to address these pain points with thermal solutions, corrosion Resistance, structure design optimization, and advanced manufacturing.

- With certifications including ISO 9001, ISO 13485, IATF 16949, and AS9100D, EBest Circuit (Best Technology) combines quality control with comprehensive quality system to deliver reliable copper clad PCB boards worldwide.

- With over 19 years of experience in the PCB board industry, EBest Circuit (Best Technology) supplies a whole range of boards, like copper clad PCB board, single sided copper clad board, copper clad board double sided, LED automotive aluminum circuit board, copper MCPCB, aluminium core PCB, IMS PCB, and others.

- No matter which board type you want to do with the prototype, fabrication, assembly, or box build. We are the original factory to supply the premium full service for you without wasting a lot of time, money, and energy between a verity of manufacturers.

To conclude, understanding the copper clad PCB board definition, price factors, and manufacturing steps is indispensable in winning specific projects between customers. And EBest Circuit (Best Technology) is one of the leading metal core PCB manufacturers in Shenzhen, supplying you with the EMS turnkey manufacturing services. If you have any inquiries or any technical questions, pls feel free to tell us via sales@bestpcbs.com or +86-755-2909-1601.