Recently, Best Technology faced a huge challenge in a 2oz copper rigid flex PCB manufacturing, this board appeared simple on the drawing but revealed multiple layers of engineering challenges once entering mass production. But finally, we finished this project very well and overcome this challenge, letâs see what are the challenges on this project and how does our team overcome them!

Project Introduction

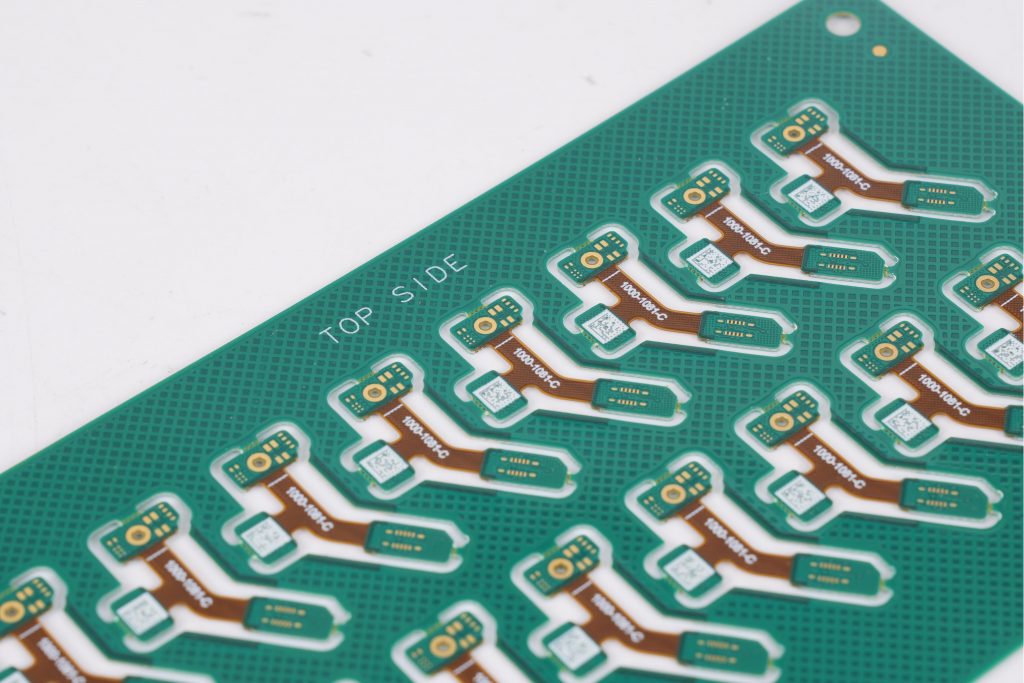

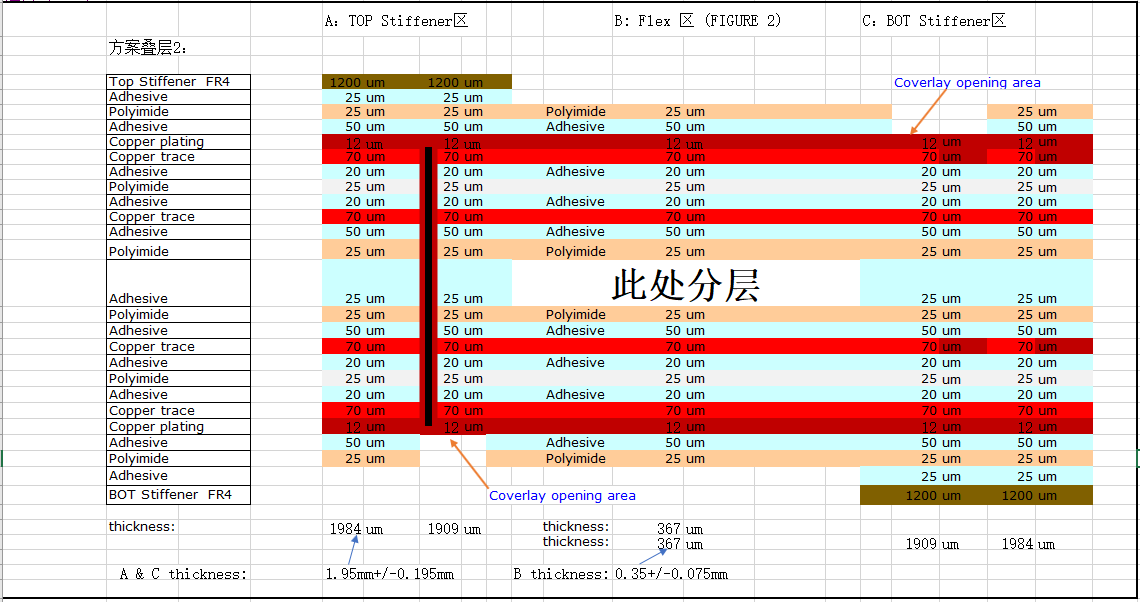

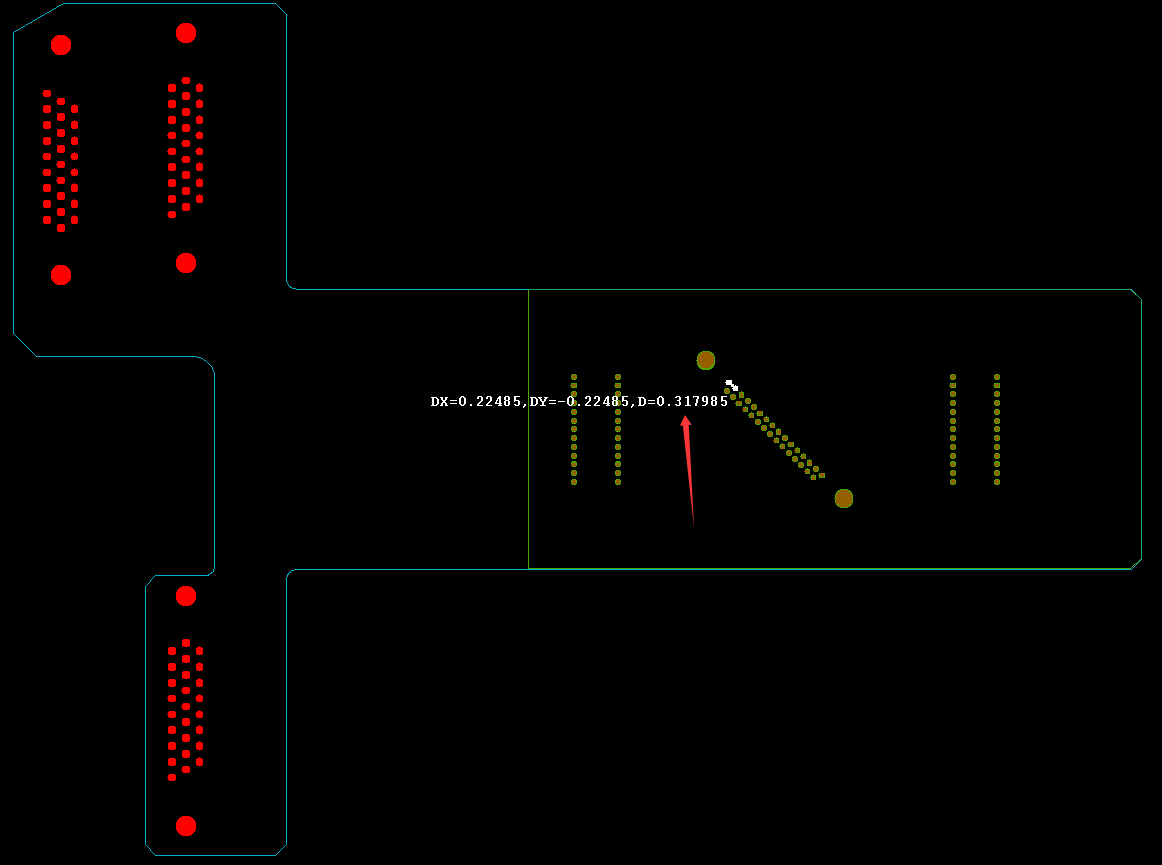

The board used a 70/25 double-sided adhesive ED flexible substrate with PI25/AD50 coverlay, coupled with a 2+2 layers dual access structure that required thick copper, small annular rings, narrow spacings, and FR4 stiffeners with extremely limited clearance. Each of these parameters independently creates difficulty, but combined, they demand precise collaboration between engineering, fabrication, and process control.

This article explains:

- Why the design was inherently difficult

- What manufacturing risks were present

- How our engineering team solved each challenge

- What PCB designers should avoid in similar projects

- Why Best Technology can manufacture such high-reliability rigid-flex PCBs

Material Structure and Key Design Parameters

The board consisted of the following:

- Flexible substrate: 70/25 double-sided adhesive ED copper

- Coverlay: PI 25 µm + Adhesive 50 µm

- Base copper: 2 oz copper

- Layer count: Four-layer rigid-flex structure

- Critical routing: 0.15 mm minimum trace/space

- Plated hole: 0.66 mm with hole spacing of only 0.60 mm

- Annular ring: 0.05 mm on certain pads

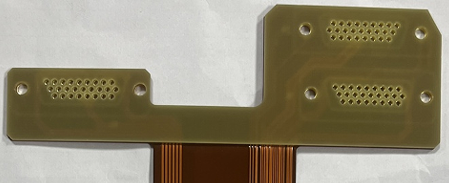

- Stiffener: FR4 stiffener with 0.95 mm stiffener hole and 0.31 mm ribs

This combination is common in advanced HDI rigid-flex PCB manufacturing, yet its manufacturability depends heavily on copper behavior, adhesive flow, and drilling tolerances.

Why This Rigid-Flex PCB Was Inherently Difficult?

1. Thick copper increases side-etching risk

With 2 oz copper, the etching rate is higher and lateral etchâoften called side-etchâis harder to control. In this case, the side-etching amount reached: 0.0070 ± 0.003 mm. For ultra-fine traces in a rigid-flex PCB design, this will eat into the design margin.

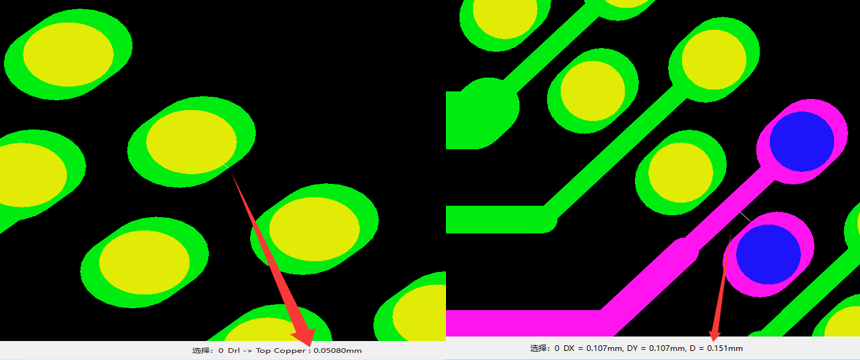

2. Small annular rings compromise via reliability

Pads with 0.05 mm annular ring severely restrict drilling tolerance. In flex-rigid PCB fabrication, annular rings below 0.10 mm are classified as high-risk features.

3. Extremely tight stiffener clearance

The stiffener needed:

- ±0.20 mm placement tolerance

- ±0.05 mm drilling tolerance

But the designer only left 0.15 mm clearance, causing a mismatch between rigid-flex PCB stiffener alignment tolerance and actual manufacturing capability.

4. Thin FR4 stiffener ribs cause glue overflow

Ribs only 0.31 mm wide cannot allow adhesive to retreat during bonding, causing pure glue to overflow and block the stiffener holes.

Technical Challenge #1: Thick Copper Etching with Narrow Spacing

A 2 oz thick copper PCB combined with:

- 0.15 mm trace/space

- 0.05 mm annular ring

- 0.66 mm PTH

creates a situation where compensation is unavoidable.

However, after compensation (~0.007 mm), the remaining trace width would drop to:

0.08 mm (0.15 â 0.07 mm)

This is below the safe manufacturability range of most rigid-flex PCB suppliers.

Best Technology’s solution

- Eliminated compensation on 0.15 mm traces

- Implemented fine-tuned etching control

- Maintained ~0.10 mm final copper width

- Ensured full electrical reliability

This is a proven strategy in advanced rigid-flex PCB manufacturing for thick-copper builds.

Technical Challenge #2: Annular Ring Integrity in Plated Through Holes

Annular rings <0.10 mm are extremely vulnerable to:

- Drill wander

- Etching undershoot

- Copper thinning

This is especially critical in high-reliability rigid-flex PCBs, where via integrity is essential.

Best Technology’s solution

- Applied rigid-board-level PTH plating process

- Improved copper thickness inside the via barrel

- Adjusted drilling control to 0.65 ± 0.075 mm

- Customer accepted partial ring breakage as long as electrical integrity remained intact

This ensured consistent via performance even in ultra-dense rigid-flex PCB layouts.

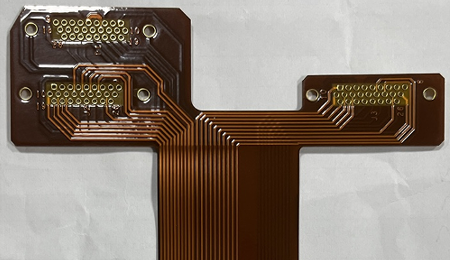

Technical Challenge #3: Stiffener Bonding, Alignment, and Adhesive Overflow

1. Why stiffener tolerance was problematic

In rigid-flex PCB assembly, stiffeners are critical for mechanical reinforcement. However:

- Hole spacing was only 0.60 mm

- Stiffener clearance only 0.15 mm per side

- Combined tolerance ±0.25 mm

This inevitably leads to the stiffener covering the pads unless advanced alignment controls are used.

2. Why glue overflow occurs

Thin ribs (0.31 mm) cannot provide an escape path for adhesive. During lamination:

- The glue squeezes into the holes

- Holes become blocked

- Boards fail inspection

3. Best Technologyâs engineered solution

- Pre-laminated pure adhesive onto FR4 stiffener

- Re-drilled stiffener holes after bonding

- Greatly reduced glue overflow

- Added 100% AOI + manual inspection for hole clearing

- Rejected defective boards, shipped only fully passing units

This is a common best practice in flex PCB stiffener processing when tolerances are tight.

DFM Guidelines for Rigid-Flex PCB Designers

- Avoid annular rings under 0.15 mm, especially in 2 oz copper flex-rigid PCB design.

- Avoid combining thick copper with fine lines, this will increase manufacturing risk.

- Ensure stiffener clearance > total tolerance stack-up. If your clearance is smaller than the alignment tolerance, the stiffener will inevitably shift.

- Keep stiffener ribs â¥0.5 mm

- Send your design for DFM review before finalizing. A good rigid-flex PCB manufacturer will help adjust the stack-up, drill size, and stiffener layout to avoid expensive redesigns.

This case demonstrates how a complex rigid-flex PCBâwith 2 oz copper, ultra-fine traces, small annular rings, and extreme stiffener constraintsâcan be successfully manufactured through detailed engineering, advanced process control, and disciplined quality screening.

Best Technology combines strong fabrication capability with practical DFM insight, enabling customers to produce compact, reliable, and manufacturable rigid-flex PCB designs that perform consistently under demanding conditions.

If you need support with your next rigid-flex or flex PCB project, our engineering team is ready to assist with stack-up review, DFM checks, or trial builds.