PCB NFC antenna‚Äč enables seamless near-field communication in smartphones, payment systems, and IoT devices. This article explores their design, differences from RFID antennas, and practical applications.

Why do many struggle with NFC antenna integration? Here are common challenges:

- ‚ÄčComplex impedance matching‚Äč ‚Äď Achieving optimal performance at 13.56MHz is tricky.

- ‚ÄčSize constraints‚Äč ‚Äď Balancing compact designs with adequate inductance (typically <5őľH).

- ‚ÄčMaterial selection‚Äč ‚Äď FR4, flex PCB, or ceramic substrates impact efficiency.

- ‚ÄčInterference issues‚Äč ‚Äď Nearby metal components can disrupt magnetic coupling.

- ‚ÄčManufacturing precision‚Äč ‚Äď Tight tolerances for trace width/spacing (e.g., 0.2mm¬Ī0.02mm).

EBest Circuit (Best Technology) solves these with the following proper solutions:

- ‚ÄčImpedance tuning tools‚Äč ‚Äď HFSS simulations and network analyzer validation.

- ‚ÄčMiniaturization expertise‚Äč ‚Äď Down to 0.15mm thin PCBs with 20oz heavy copper.

- ‚ÄčMaterial guidance‚Äč ‚Äď Recommending optimal substrates (Aluminum, Rogers, or LTCC).

- ‚ÄčShielding solutions‚Äč ‚Äď Ground planes and ferrite layers to reduce interference.

- ‚ÄčHigh-precision production‚Äč ‚Äď 260,000 ft¬≤/month capacity with ¬Ī1mil tolerance.

BEST Technology is an industry-leading PCB manufacturer with 19 years of expertise in advanced circuit solutions, specializing in high-performance ‚ÄčPCB NFC antenna‚Äč designs and innovative flexible circuit applications. As a trusted partner in RF and wireless technologies, we combine precision engineering with cutting-edge manufacturing to deliver optimized ‚ÄčNFC antenna PCBs‚Äč that meet stringent performance requirements.

Our ISO-certified facility supports end-to-end production from rapid prototyping to mass manufacturing, with specialized capabilities in impedance-controlled designs and multi-layer ‚ÄčNFC antenna PCB‚Äč integration. With a 97% on-time delivery rate and dedicated engineering support, we provide tailored solutions for IoT, smart devices, and contactless systems requiring reliable ‚ÄčPCB-based NFC antennas. For customized ‚ÄčNFC antenna PCB‚Äč solutions, pls feel free to contact our technical sales team at sales@bestpcbs.com.

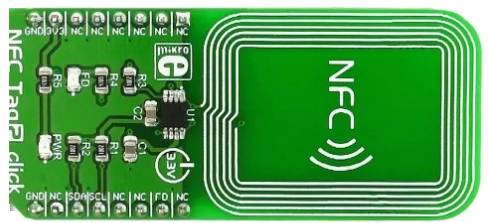

What Is a PCB NFC Antenna?

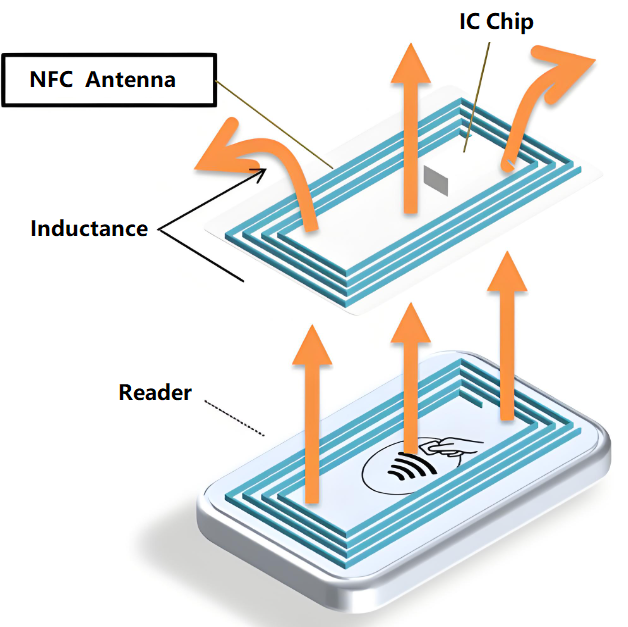

A ‚ÄčPCB NFC antenna‚Äč is a printed circuit board coil enabling 13.56MHz communication within 10cm. It works via magnetic induction, transferring energy and data between devices.

Key features:

- ‚ÄčInductance range: 1‚Äď5őľH for stable resonance.

- ‚ÄčLayers: Single-sided (cost-effective) or double-sided (higher inductance).

- ‚ÄčMaterials: FR4 (standard), flexible PCBs (wearables), or ceramic (high-temperature).

What are the NFC Antenna Types?

Near Field Communication (NFC) antennas are essential components in contactless applications, enabling secure data transfer and wireless power transfer. The design of an NFC antenna significantly impacts performance, influencing factors such as read range, efficiency, and compatibility with different devices. Below are three common NFC antenna types, each with distinct advantages for specific applications:

- ‚ÄčRectangular Spiral‚Äč ‚Äď Simple to design and cost-effective, making it ideal for standard FR4 PCBs in access control and identification systems.

- ‚ÄčCircular Spiral‚Äč ‚Äď Generates a more uniform magnetic field, preferred for payment terminals and industrial applications requiring consistent performance.

- ‚ÄčDouble-Layer Helix‚Äč ‚Äď Maximizes inductance in tight spaces, commonly used in smartphones and wearables where miniaturization is critical.

EBest Circuit (Best Technology)‚Äôs ‚ÄčNFC antenna design tool‚Äč helps select the right type based on your device‚Äôs size and frequency requirements.

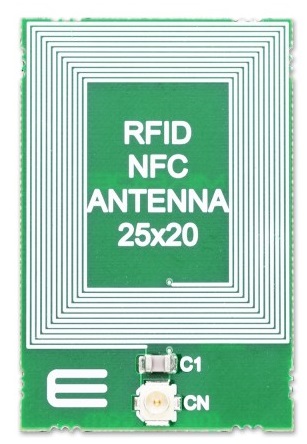

What is Difference: PCB NFC Antenna v.s. PCB RFID Antenna

‚ÄčWhile both NFC (Near Field Communication) and RFID (Radio Frequency Identification) antennas enable wireless communication, they serve distinct purposes in PCB applications. The key differences lie in their operating frequencies, communication ranges, and typical use cases. Below is a comparative breakdown:

| Feature | ‚ÄčPCB NFC Antenna‚Äč | ‚ÄčPCB RFID Antenna‚Äč |

|---|---|---|

| ‚ÄčFrequency‚Äč | 13.56 MHz (fixed) | 125 kHz ‚Äď 2.45 GHz (varies by type) |

| ‚ÄčRange‚Äč | Short-range (<10 cm) | Medium- to long-range (up to 15 m) |

| ‚ÄčApplications‚Äč | Mobile payments, device pairing, smart tags | Inventory tracking, access control, logistics |

‚ÄčDesign Considerations:‚Äč‚Äč

- ‚ÄčNFC Antennas: Optimized for close-proximity interactions, requiring precise impedance matching and compact spiral/helix layouts (e.g., circular spirals for uniform fields).

- ‚ÄčRFID Antennas: Designed for broader frequency adaptability, often using dipole or loop configurations for extended range.

‚ÄčKey Takeaways:

- NFC antennas prioritize proximity and security, while RFID antennas focus on scalability and range.

- Frequency selection dictates antenna geometry‚ÄĒspiral for NFC, dipole/loop for RFID.

- Our engineering team provides application-specific guidance for optimal performance.

‚ÄčEBest Circuit (Best Technology) offers tailored design tools for both technologies, including an ‚ÄčNFC antenna optimizer‚Äč for 13.56 MHz tuning and an ‚ÄčRFID antenna calculator‚Äč for UHF/HF band trace patterns. For custom antenna designs, prototypes, fabrication, assembly, or box build, pls contact us at ‚Äčsales@bestpcbs.com.

How is NFC Antenna Size?

‚ÄčThe size of an NFC antenna is a critical design parameter that directly impacts its performance, efficiency, and suitability for specific applications. Proper sizing ensures optimal inductance, read range, and compatibility with device constraints. Below, we break down the key considerations for NFC antenna sizing, supported by technical guidelines and empirical data.

‚Äč1. Size Guidelines for Common Applications‚Äč

NFC antenna dimensions vary based on device type and functional requirements:

- ‚ÄčSmartphones:

- ‚ÄčRecommended size: 25√ó15mm

- ‚ÄčDesign: 5 turns with 0.3mm trace width to balance inductance (~1‚Äď2 ¬ĶH) and space efficiency.

- ‚ÄčRationale: Larger coils enhance magnetic coupling but must fit within compact device layouts.

- ‚ÄčWearables:

- ‚ÄčRecommended size: 15√ó10mm (flexible PCB compatible)

- ‚ÄčDesign: 3 turns to maintain adequate inductance (~0.5‚Äď1 ¬ĶH) while minimizing footprint.

- ‚ÄčRationale: Smaller form factors require trade-offs between turns and trace width to avoid excessive resistance.

‚Äč2. Key Factors Influencing Antenna Size‚Äč

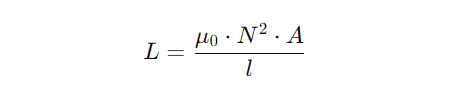

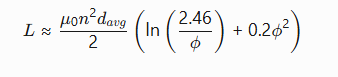

‚Äča. Inductance (L) Requirements‚Äč

The antenna‚Äôs inductance must match the NFC chip‚Äôs tuning capacitance (typically 27‚Äď33 pF for 13.56 MHz). Use the simplified formula for spiral coil inductance:

Where:

- őľ0‚Äč: Permeability of free space (4ŌÄ√ó10‚ąí7 H/m)

- n: Number of turns

- davg‚Äč: Average coil diameter

- Ōē: Fill factor (trace width/spacing ratio).

‚ÄčExample: A 25√ó15mm antenna with 5 turns yields ~1.5 ¬ĶH, suitable for most NFC ICs.

‚Äčb. Trace Width and Spacing‚Äč

- ‚ÄčNarrow traces (0.2‚Äď0.3mm)‚Äč: Reduce parasitic capacitance but increase resistance.

- ‚ÄčWider traces (>0.5mm)‚Äč: Lower resistance but risk eddy currents and size inflation.

‚Äčc. Device Integration Constraints‚Äč

- ‚ÄčGround plane proximity: Keep >1mm clearance beneath coils to avoid Q-factor degradation.

- ‚ÄčBending radius (flex PCBs)‚Äč: Minimum 3√ó trace width to prevent cracking.

‚Äč3. Layout Optimization Techniques‚Äč

- ‚ÄčAvoid 90¬į corners: Use 45¬į miters to minimize impedance discontinuities and EMI.

- ‚ÄčParallel trace alignment: Maintain ¬Ī5¬į skew tolerance for uniform current distribution.

- ‚ÄčSymmetry: Ensure balanced coil geometry to prevent field distortion.

‚ÄčNFC antenna sizing is a trade-off between electrical performance (inductance, Q-factor) and physical constraints (device size, integration).

Designers must:

- ‚ÄčMatch inductance‚Äč to the NFC chip‚Äôs requirements using empirical formulas.

- ‚ÄčOptimize trace geometry‚Äč for minimal resistance and EMI.

- ‚ÄčValidate prototypes‚Äč with network analyzers to ensure resonant frequency alignment.

‚ÄčKey Takeaways:

- Smartphones: 25√ó15mm (5 turns) balances performance and space.

- Wearables: 15√ó10mm (3 turns) prioritizes miniaturization.

- Layout precision (trace width, symmetry) is as critical as size.

For tailored NFC antenna solutions, consult ‚ÄčEBest Circuit (Best Technology)‚Äôs‚Äč engineering team at sales@bestpcbs.com.

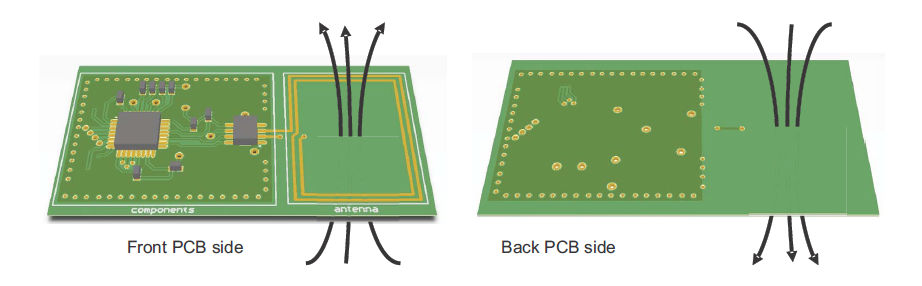

How is the NFC Antenna PCB Layout?

The layout of an NFC antenna on a PCB is crucial for achieving optimal performance in wireless communication systems. A well-designed NFC antenna PCB ensures efficient energy transfer, minimal interference, and reliable operation. This section explores key considerations and best practices for NFC antenna PCB layout, supported by technical insights and empirical data.

‚Äč1. Ground Plane Management‚Äč

Proper ground plane design is essential to prevent performance degradation in NFC antennas:

- ‚ÄčAvoid Ground Planes Under Coils:

Placing ground planes directly beneath the antenna coils can induce ‚Äčeddy currents, which weaken the magnetic field and reduce read range. Maintain a clearance of ‚Äčat least 1mm‚Äč between the coil and any ground layer. - ‚ÄčUse Split Ground Planes:

For multilayer PCBs, consider splitting the ground plane around the antenna area to minimize parasitic capacitance and maintain a high ‚Äčquality factor (Q)‚Äč.

‚Äč2. Trace Design and Geometry‚Äč

The geometry of the antenna traces significantly impacts performance:

- ‚ÄčTrace Width and Spacing:

- ‚ÄčWidth: 0.2‚Äď0.5mm (balance between resistance and parasitic capacitance).

- ‚ÄčSpacing: ‚Č•0.2mm to avoid arcing and ensure manufacturability.

- ‚ÄčCorner Design:

- Use ‚Äč45¬į miters‚Äč instead of 90¬į bends to reduce ‚Äčelectromagnetic interference (EMI)‚Äč‚Äč and impedance mismatches.

- The inductance of a corner can be approximated by: L corner‚Äč‚Čą0.2√óL straight‚Äč

- Where L straight‚Äč is the inductance of a straight trace segment.

- ‚ÄčParallel Traces:

Maintain alignment within ‚Äč‚Äč¬Ī5¬į skew‚Äč to ensure uniform current distribution and consistent inductance.

‚Äč3. Antenna Symmetry and Balance‚Äč

A symmetrical layout is critical for generating a uniform magnetic field:

- ‚ÄčDifferential Feed Design:

For balanced NFC antennas, ensure equal trace lengths and impedance matching (¬Ī10% tolerance) between differential pairs to prevent signal distortion. - ‚ÄčCoil Shape:

- ‚ÄčCircular spirals‚Äč provide the most uniform field distribution but require precise manufacturing.

- ‚ÄčRectangular spirals‚Äč are easier to fabricate but may exhibit slight field asymmetry.

‚Äč4. Material and Layer Stackup‚Äč

The choice of PCB materials and layer configuration affects antenna performance:

- ‚ÄčSubstrate Material:

- ‚ÄčFR4: Cost-effective but with higher dielectric losses (~0.02 at 13.56 MHz).

- ‚ÄčPolyimide (Flex PCBs)‚Äč: Lower loss tangent (~0.005) and better for bendable designs.

- ‚ÄčLayer Stackup:

- ‚Äč2-Layer PCBs: Place the antenna on the top layer with a partial ground plane underneath.

- ‚Äč4-Layer PCBs: Use Layer 2 as a ground reference and avoid routing critical signals near the antenna area.

‚Äč5. EMI and Crosstalk Mitigation‚Äč

To minimize interference:

- ‚ÄčShielding:

Add a ‚ÄčFaraday cage‚Äč or conductive tape around the antenna if nearby components emit noise. - ‚ÄčIsolation:

Keep high-speed digital traces (e.g., USB, HDMI) ‚Äč**‚Č•10mm**‚Äč away from the antenna to prevent coupling.

In conclusion‚Äč, an optimized NFC antenna PCB layout requires:

- ‚ÄčStrategic ground plane design‚Äč to avoid eddy currents.

- ‚ÄčPrecise trace geometry‚Äč (width, spacing, corners) for consistent inductance.

- ‚ÄčSymmetrical coil patterns‚Äč to ensure uniform magnetic fields.

- ‚ÄčMaterial selection‚Äč tailored to application needs (rigid vs. flex PCBs).

- ‚ÄčEMI mitigation‚Äč through shielding and isolation.

For performance-critical applications, prototype testing with a ‚Äčnetwork analyzer‚Äč is recommended to validate resonant frequency and Q-factor.

‚ÄčKey Takeaways:

- Ground plane clearance ‚Č•1mm prevents field degradation.

- 45¬į corners and parallel traces enhance signal integrity.

- Differential feed designs improve balance in high-performance systems.

How to Design a PCB NFC Antenna?

NFC (Near Field Communication) is a short-range wireless communication technology operating at 13.56 MHz, designed for secure communication within a few centimeters. NFC antennas are essential components in mobile devices, contactless payments, and access control systems. Designing a PCB NFC antenna requires understanding both antenna theory and practical PCB layout considerations to achieve optimal performance, compact size, and reliable communication.

Key Antenna Parameters and NFC Working Principle

The performance of an NFC system depends heavily on the antenna, which determines parameters such as input impedance, efficiency, gain, polarization, and inductive coupling.

- Input Impedance

Input impedance is the ratio of voltage to current at the antenna terminals:Zin = V / IIt consists of a real part (radiation and loss resistance) and an imaginary part (reactive energy storage). Return loss describes matching:RL = -20 * log10(|őď|)where őď is the reflection coefficient. For mobile NFC antennas, a return loss of -5 dB or lower is generally acceptable. - Antenna Efficiency

Efficiency is the ratio of radiated power to input power:ő∑A = Prad / PinLosses may include conductor resistance, dielectric loss, and reflection from impedance mismatch. - Gain and Directivity

Gain (G) relates to directivity (D) and efficiency:G = ő∑A * DMobile antennas are usually omnidirectional to avoid blind spots. - Polarization and Inductive Field

NFC antennas typically use linear polarization. The reactive near-field region of the antenna, important for NFC coupling, is approximately:r < D^2 / őĽwhere D is the largest antenna dimension, and őĽ is the wavelength. - NFC Communication Modes

NFC supports active and passive modes for peer-to-peer and card-reader communication, typically at 106, 212, or 424 kbps.

Steps to Design a PCB NFC Antenna

1. Select the Antenna Type

Common PCB NFC antenna types include:

- Single-sided rectangular coil

- Single-sided rounded rectangular coil

- Double-sided helical coil

Design choice depends on:

- Available PCB space

- Required inductance

- Miniaturization needs

2. Calculate Key Parameters

Inductance Calculation:

For a coil antenna, the inductance L is:

L = Im(Z) / (2 * ŌÄ * f)

where Im(Z) is the imaginary part of impedance, and f is frequency (13.56 MHz for NFC). The resonant frequency of the LC circuit is:

f = 1 / (2 * ŌÄ * ‚ąö(L * C))

The inductance should generally be below 5 őľH for ease of impedance matching with capacitors.

3. Design the PCB Layout

- Determine line width (w), spacing (s), and number of turns (n).

- Keep coil area maximized while maintaining spacing for manufacturability.

- Avoid placing metal components under or near the coil, as they reduce coupling.

- For multilayer boards, consider double-sided or stacked coil designs to increase inductance without enlarging footprint.

4. Impedance Matching

Impedance matching minimizes return loss and maximizes power transfer:

- Connect a series or parallel capacitor to tune resonance.

- Optional: add a resistor for fine adjustment of Q factor.

- Iteratively simulate and measure until return loss is acceptable at 13.56 MHz.

5. Simulation and Verification

- Use electromagnetic simulation tools (e.g., HFSS) to model the antenna and optimize parameters.

- Practical testing with a network analyzer can validate impedance, inductance, and return loss.

- Adjust coil turns, spacing, or matching components if necessary.

6. Miniaturization Techniques

- Use rounded or spiral coil shapes to save PCB space.

- Consider multi-turn or double-sided coils to maintain inductance in a smaller area.

- Optimize trace width and spacing to maintain inductance while minimizing PCB area.

Comparison of Common Antenna Types

| Antenna Type | Size | Inductance Stability | Integration Ease |

|---|---|---|---|

| Single-sided rounded rectangle | Compact | High | Easy |

| Double-sided rectangular | Larger | Moderate | Medium |

| Double-sided helical | Moderate | Good | Medium |

For mobile devices, the single-sided rounded rectangular antenna often offers the best balance between size, stability, and manufacturability.

Practical Design Tips

- Keep the coil away from metal objects and noisy signals.

- Use appropriate PCB material for low-loss high-frequency performance.

- Adjust trace width and spacing to fine-tune inductance.

- Verify resonance and matching through both simulation and measurement.

- When reducing antenna size, consider multi-layer designs and coil shape optimization.

In a nutshell, designing a PCB NFC antenna requires careful consideration of antenna type, inductance calculation, PCB layout, and impedance matching. By following the steps above and applying miniaturization techniques, designers can achieve efficient, compact NFC antennas suitable for mobile devices and contactless systems. Simulation tools and practical validation ensure reliable performance at 13.56 MHz. Among common designs, the single-sided rounded rectangular antenna generally offers the best combination of stability, size, and ease of integration.

What are the Applications of NFC Antenna PCB?

The ‚ÄčNFC antenna PCB‚Äč is a quiet workhorse in our daily tech. You might not see it, but it’s everywhere. Its applications are vast and growing quickly. This tiny coil on a board makes countless interactions seamless. Let’s look at some of the most common places you’ll find it.

- ‚ÄčContactless Payment Systems:‚Äč‚Äč This is probably the most familiar use. The credit card in your wallet and the terminal at your favorite coffee shop both rely on a ‚ÄčPCB NFC antenna. It makes transactions fast, secure, and simple.

- ‚ÄčSmartphones:‚Äč‚Äč Modern life runs on phones. Every ‚ÄčNFC antenna android‚Äč and ‚ÄčNFC antenna iphone‚Äč has one embedded inside. It enables mobile payments like Google Pay and Apple Pay. It also handles quick pairing with other gadgets.

- ‚ÄčAccess Control:‚Äč‚Äč Forget fumbling with keys. Many offices, hotels, and secure buildings now use NFC keycards. You just tap your card on the reader. The ‚ÄčPCB NFC antenna‚Äč inside the card communicates with the reader to grant access.

- ‚ÄčAsset Tracking:‚Äč‚Äč Businesses need to manage their inventory efficiently. NFC tags with a PCB RFID antenna‚Äč are attached to items in a warehouse or books in a library. A quick scan with a reader updates the system instantly. It saves time and reduces errors.

- ‚ÄčConsumer Electronics:‚Äč‚Äč This area is exploding. Think about pairing your wireless speakers or headphones. Instead of a complicated Bluetooth search, you just tap your phone to the device. This “pairing by tapping” is powered by an NFC antenna PCB. It‚Äôs also common in smart home devices, gaming controllers, and more.

‚ÄčFrom the payment terminal at a store to the smart speaker in your living room, the ‚ÄčNFC antenna PCB‚Äč is a fundamental enabler of modern convenience. Its ability to provide secure, short-range communication and power has unlocked a world of “tap-and-go” applications. As the Internet of Things continues to expand, we will see these clever little antennas integrated into even more aspects of our lives, making our interactions with technology smoother and more intuitive.

Why Choose EBest Circuit (Best Technology) as Your Reliable NFC Antenna PCB Manufacturer?‚Äč

Selecting the right manufacturing partner is as critical as the design itself. A perfect design can be ruined by poor fabrication. This is especially true for a sensitive component like a ‚ÄčPCB NFC antenna, where precision is paramount. EBest Circuit (Best Technology) stands out as a trusted partner for several key reasons.

With 19 years of dedicated PCB expertise, we have the deep industry knowledge needed to get your NFC antenna PCB‚Äč right the first time. Our commitment to excellence is clear in what we deliver:

- ‚ÄčCertified Quality Systems:‚Äč‚Äč We are ISO 9001 and ISO 13485 certified. This means we have robust processes to ensure every board we ship, especially critical ones like a ‚ÄčPCB NFC antenna, meets the highest standards of quality and consistency.

- ‚ÄčComprehensive Turnkey Solutions:‚Äč‚Äč We offer true end-to-end service. Our support covers everything from initial ‚ÄčPCB NFC antenna design‚Äč review and optimization to full box-build assembly. This simplifies your supply chain and ensures seamless integration.

- ‚ÄčRemarkably Fast Lead Times:‚Äč‚Äč We understand the need for speed in development. We offer rapid prototyping, with 6-layer FR4 PCB prototypes available in as little as 24 hours. This allows you to test and iterate faster.

- ‚ÄčExpert Engineering Support:‚Äč‚Äč Our team has deep experience with high-frequency and RF-specific designs. We don’t just build your board; we can help optimize your ‚ÄčNFC antenna PCB layout‚Äč for maximum performance and efficiency, acting as an extension of your engineering team.

- ‚ÄčAdvanced Manufacturing Capabilities:‚Äč‚Äč We use high-quality materials with stable dielectric constants, which is essential for predictable antenna performance. Our controlled manufacturing environment ensures that every ‚ÄčNFC PCB antenna we produce performs identically to your prototype, batch after batch.

‚ÄčIn closing, choosing EBest Circuit (Best Technology) means more than just finding a supplier; it means gaining a partner dedicated to your success. Our combination of proven quality standards, full-service capabilities, rapid turnaround, and specialized technical support makes us the ideal choice for your ‚ÄčNFC antenna PCB needs. We provide the reliability and expertise necessary to transform your innovative designs into high-performing, market-ready products. Let us be the reliable manufacturing foundation that your next great device is built upon.

Case of Supporting Embedded PCB NFC Antenna Project at EBest Circuit (Best Technology)

‚ÄčA client needed high-reliability flex PCB NFC antennas for next-generation fitness trackers, with critical challenges:

- ‚ÄčSpace Constraints: Ultra-compact 12√ó8mm design area

- ‚ÄčDurability Requirements: 100,000+ dynamic bend cycles

‚ÄčOur Solution Leveraged EBest Circuit (Best Technology)‚Äôs Advanced Capabilities:‚Äč‚Äč

✔ ‚Äč2-Layer Polyimide Stackup‚Äč ‚Äď Optimized with 0.1mm (4mil) traces using our 2/2mil line width/spacing technology

✔ ‚ÄčPrecision Laser Cutting‚Äč ‚Äď Achieved ¬Ī0.05mm alignment tolerance (50% tighter than industry standards)

✔ ‚ÄčImpedance-Controlled Design‚Äč ‚Äď 100% tested to ¬Ī5ő© tolerance for 50ő© systems

✔ ‚ÄčMedical-Grade Materials‚Äč ‚Äď DuPont Pyralux AP polyimide with 260¬įC/10s solder resistance

✔ ‚ÄčEndurance Validation‚Äč ‚Äď Exceeded IPC-6013 Class 3 standards for 100k bend cycles

‚ÄčSupported by Our Core Flex PCB Competencies:‚Äč‚Äč

◾ 1-30 layer FPC manufacturing ◾ 28,900„é° monthly capacity

◾ ISO 13485-certified cleanrooms ◾ 98% on-time delivery track record

‚ÄčResult: Delivered 98% on-time with <1% defect rate, enabling seamless integration into mass-produced wearables.

This case highlights how our ‚Äčsub-4mil trace technology, coupled with ‚Äčmedical-grade process controls, solves extreme miniaturization challenges while guaranteeing field reliability.

All in all, PCB NFC antennas‚Äč are vital for secure, short-range communication. Partner with EBest Circuit (Best Technology) for ‚Äčhigh-performance, cost-effective designs. Pls connect with us sales@bestpcbs.com for any multilayer NFC PCB antenna supports.