SMD board assembly is the most widely used method for building compact, high-density electronic products today, especially in applications where space utilization, electrical performance, and production efficiency must be tightly controlled. In real production environments, SMD board assembly directly determines electrical reliability, thermal behavior, signal integrity, and long-term field performance, rather than just visual assembly quality.

This article explains how SMD board assembly works in real manufacturing scenarios, what drives its cost, and how engineers and buyers can select a capable SMD board assembly supplier. If you are sourcing SMD board assembly services for prototypes or volume production, EBest Circuit (Best Technology) provides production-ready solutions backed by stable SMT lines and engineering support. For orders or technical discussion, pls feel free to contact us via sales@bestpcbs.com.

What Is SMD Board Assembly and Where Is It Used?

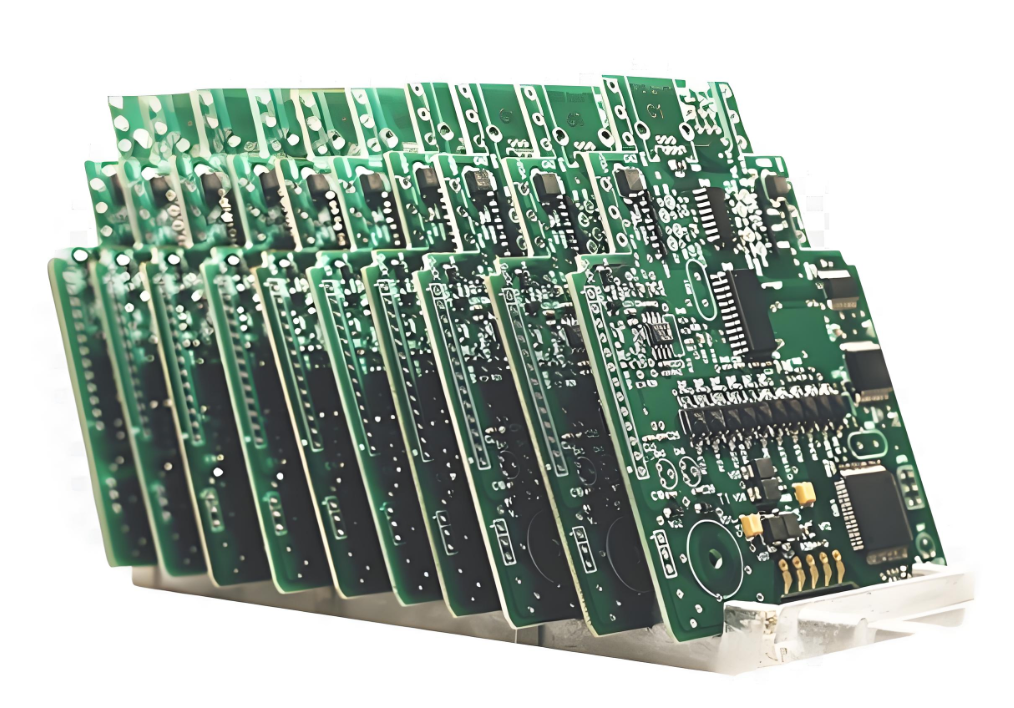

SMD board assembly is the process of mounting surface-mount electronic components directly onto a printed circuit board using automated SMT equipment and controlled soldering processes. It is the dominant assembly method for modern electronics because it enables high component density, repeatable quality, and scalable production.

In practice, SMD board assembly is widely used in:

- Industrial control and automation boards

- LED lighting drivers and modules

- Medical and automotive electronics

- Power supplies, communication, and IoT devices

Compared to through-hole assembly, SMD assembly allows shorter signal paths, better high-frequency performance, and faster production cycles, making it suitable for both prototypes and mass production.

SMD Board Meaning vs SMT Assembly: Are They the Same?

SMD refers to the components themselves, while SMT describes the manufacturing technology used to place and solder those parts onto the PCB. In practical production environments, SMD board assembly brings these two concepts together as a single, well-defined manufacturing workflow. From an engineering perspective, the distinction matters less than the consistency and control of the assembly process.

The key distinction is straightforward:

- SMD (Surface-Mount Device): the component itself, such as resistors, capacitors, ICs, and LEDs

- SMT (Surface-Mount Technology): the assembly process, including solder paste printing, component placement, and reflow soldering

In real-world manufacturing, âSMD board assemblyâ and âSMT board assemblyâ describe the same production workflow from an engineering and procurement perspective. SMD PCB assembly board and SMT PCB assembly board refer to the same type of assembled PCB. SMD describes the component type, while SMT describes the assembly process. In practical manufacturing, both terms are used interchangeably.

How Does SMD Board Assembly Work Step by Step?

board assembly SMT SMD follows a controlled and repeatable sequence designed to minimize defects and ensure consistent solder joint quality. Each step is critical and cannot be treated independently.

A standard SMD assembly flow includes:

- Solder paste printing to define solder volume and joint geometry

- SPI inspection to verify paste height, area, and alignment

- Pick-and-place of SMD components using automated placement machines

- Reflow soldering with a controlled thermal profile

- AOI inspection to detect placement and solder defects

- Functional testing to confirm electrical performance

Small deviations at early stages often lead to yield loss later, which is why process control matters more than visual inspection alone.

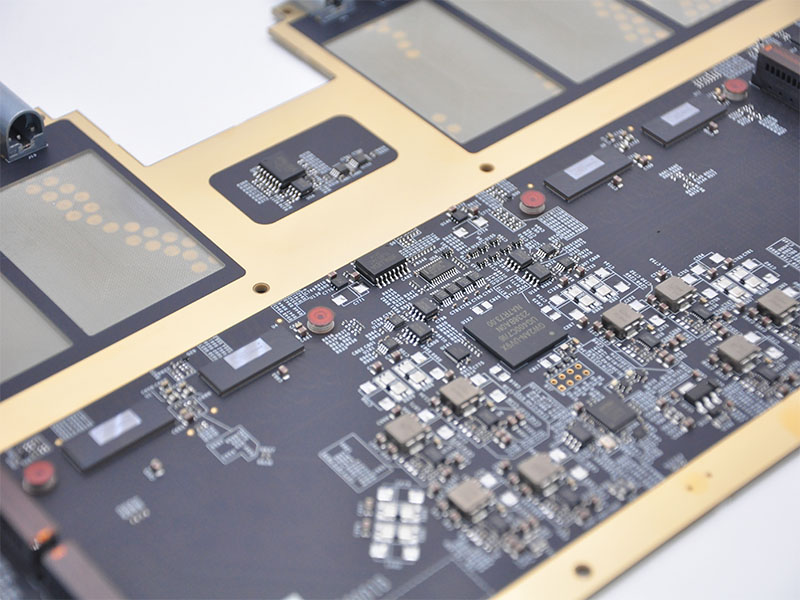

What Components Are Used in SMD Board Assembly?

SMD electronic components are standardized by package size and mounting style, which allows automation and high placement accuracy. Component selection directly affects assembly yield, thermal reliability, and rework difficulty.

Common components used in board assembly SMD include:

- Chip resistors and capacitors (0402, 0603, 0805, and smaller)

- Ceramic and tantalum capacitors

- QFN, QFP, and BGA integrated circuits

- LEDs, power MOSFETs, and regulators

From an assembly standpoint, pad design, package type, and moisture sensitivity must be considered together rather than independently.

SMD Board Assembly for LED and Power Applications

LED and power-related boards place higher demands on SMD board assembly due to thermal and electrical stress. In these applications, solder joints are part of the thermal path, not just electrical connections.

Key assembly considerations include:

- Thicker copper PCBs to improve current carrying and heat spreading

- Precisely controlled reflow profiles to avoid LED damage

- Void control on thermal pads to reduce junction temperature

- Optical, electrical, and aging tests after assembly

Poor assembly control in LED boards often results in early measuring drift or premature failure, even when components are qualified.

SMD Prototype Board vs Mass Production Assembly

SMD prototype assembly prioritizes speed and design verification, while mass production emphasizes consistency, yield, and cost optimization. Understanding the difference helps avoid redesigns later.

Typical differences include:

- Prototype assembly: flexible scheduling, low MOQ, manual verification

- Production assembly: automated inspection, stable BOM sourcing, process locking

Designing footprints and layouts with production constraints in mind significantly reduces future revisions and ramp-up risks.

What Equipment Is Required for SMD PCB Assembly?

Professional PCB board SMD SMT assembly relies on a complete set of automated equipment rather than isolated machines. The overall line capability matters more than any single piece of equipment.

Core equipment typically includes:

- Automatic solder paste printers

- High-speed and high-accuracy pick-and-place machines

- Multi-zone reflow ovens

- AOI and X-ray inspection systems

Equipment accuracy and maintenance level directly influence defect rates, especially for fine-pitch and high-density boards.

SMD Board Assembly Machine and Cost Factors

SMD board assembly machines determine placement accuracy, throughput, and achievable defect levels.

More advanced machines reduce long-term cost by improving yield.

Key cost drivers include:

- Total component count per board

- Presence of fine-pitch or BGA devices

- Single-sided vs double-sided assembly

- Inspection depth and test coverage

Higher automation usually increases setup cost but lowers per-unit cost in stable production.

China SMD Board Assembly: Quality and Risk Control

China remains the global center for SMD board assembly due to its mature supply chain and manufacturing infrastructure. However, quality is determined by process control, not location.

Reliable SMD assembly factories typically provide:

- Full material traceability

- Documented assembly and inspection processes

- Stable SMT production lines

- Direct engineering communication

Structured supplier audits and pilot builds are effective ways to control sourcing risk.

How Much Does SMD Board Assembly Cost? (Price Reference)

SMD board assembly pricing is based on structure and complexity rather than a single flat rate.

Understanding the pricing logic helps prevent hidden costs.

Typical reference ranges (excluding components):

- Prototype: USD 0.10â0.30 per pad

- Small batch: USD 8â20 per board

- Volume production: USD 3â8 per board

Actual pricing depends on board size, layer count, component mix, and inspection requirements.

How to Choose a Reliable SMD Board Assembly Manufacturer?

Choosing an SMD board assembly manufacturer should be an engineering decision, not a marketing one.

Capability alignment matters more than advertised capacity.

A practical evaluation checklist includes:

- SMT line configuration and accuracy

- Inspection and testing coverage

- Engineering response speed

- Quotation transparency

- Track record in similar products

A capable SMD board assembly supplier reduces long-term cost by preventing quality escapes and rework.

All in all, this article outlined how SMD board assembly is executed in real manufacturing environments, how cost and quality are managed, and how engineers can evaluate suppliers for both prototype and volume production.

EBest Circuit (Best Technology) provides a one-stop integrated service covering PCB fabrication, component sourcing, PCBA assembly, and testing, while supporting prototypes and small-batch builds to help engineers validate designs and accelerate product launch. With ISO 9001 / ISO 13485 / IATF 16949 / AS9100D certifications, in-house PCB and PCBA factories, and a digital workshop enabling full material and production traceability within seconds, we ensure consistent quality and reliable lead times. If you are planning an SMD board assembly project or need technical consultation, please feel free to contact EBest Circuit (Best Technology) at sales@bestpcbs.com.

FAQ: Common SMD Board Assembly Questions

Q1: Is SMD board assembly suitable for prototypes?

Yes. With proper setup and engineering support, it enables fast iteration and low-volume builds.

Q2: What files are required to start SMD PCB assembly?

Gerber files, BOM, pick-and-place data, and assembly notes are required.

Q3: Can SMD and through-hole components be combined?

Yes. Mixed assembly is common in industrial and power boards.

Q4: What causes most SMD assembly defects?

Incorrect solder paste volume, poor footprint design, and uncontrolled reflow profiles.

Q5: How long does SMD board assembly take?

Prototypes typically take 3â5 days, while volume production takes 7â15 days.