A footprint PCB, PCB footprint, or land pattern, defines the precise arrangement of copper pads, solder mask openings, and sometimes silkscreen outlines on a printed circuit board where a component will be mounted and soldered. It is the critical physical interface between your schematic symbol and the real-world component, directly impacting solderability, reliability, and performance. This comprehensive guide will delve into the essentials of PCB footprint design, its pivotal role in avoiding manufacturing delays, and best practices for achieving successful, fast-turn PCB fabrication.

Have you ever faced frustrating delays, unexpected costs, or outright failure in your PCB board projects due to seemingly minor design errors? These issues often stem from a fundamental yet overlooked aspect: the PCB footprint. Common pain points include:

- βSolder Bridges and Open Connections:ββ Incorrect pad sizing or spacing leads to short circuits or poor solder joints.

- βComponent Misalignment:ββ Inaccurate courtyard or silkscreen outlines cause parts to be misplaced during assembly.

- βDFM (Design for Manufacturing) Errors:ββ Footprints not optimized for your manufacturer’s processes result in fabrication issues.

- βInconsistent Library Management:ββ Using outdated or unverified footprints from various sources introduces risk.

- βPrototype Re-spins:ββ A single footprint error can force a complete board revision, wasting time and money.

Fortunately, these challenges are entirely preventable with a disciplined approach. The solution lies in:

- βAdhering to IPC Standards:ββ Utilizing industry-standard guidelines for pad geometry.

- βImplementing a Centralized Library:ββ Maintaining a single, verified source for all PCB footprints.

- βConducting Thorough DFM Checks:ββ Collaborating with your fabricator to validate designs.

- βUsing Advanced Design Tools:ββ Leveraging software features for automated footprint generation and validation.

- βPartnering with an Experienced Manufacturer:ββ Choosing a fabricator like BEST Technology with expertise in high-precision footprint PCB production.

At BEST Technology, we specialize in fast-turn, high-precision PCB fabrication and assembly. Our deep understanding of PCB footprint design intricacies allows us to provide expert DFM analysis, ensuring your designs are not only electrically sound but also manufacturable, reliable, and delivered on time. For your next quick turn circuit boards project, pls feel free to contact us at sales@bestpcbs.com.

What is a PCB Footprint?

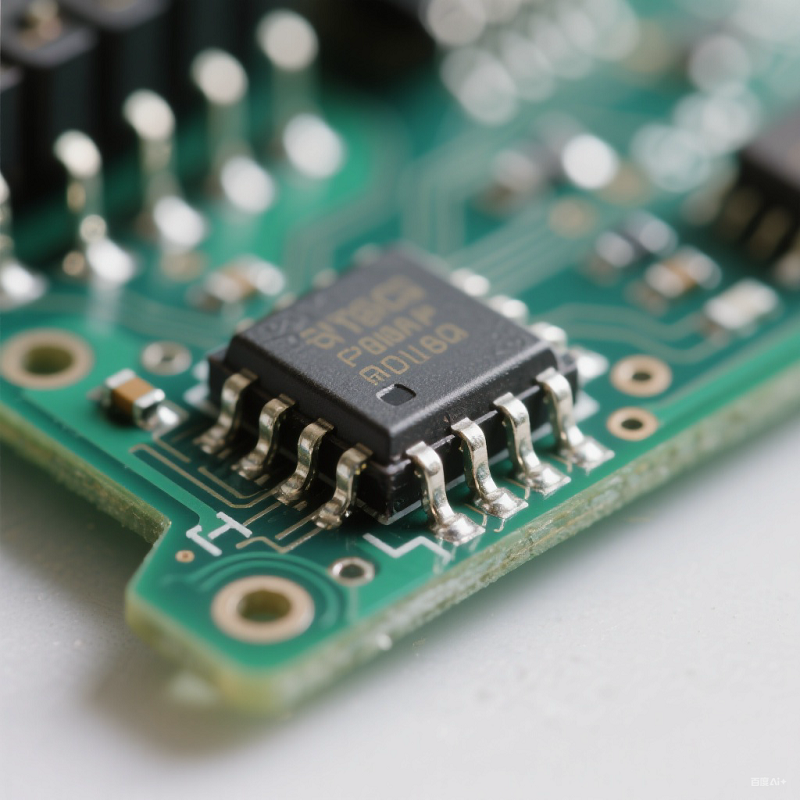

In PCB design, a footprint is the physical representation of an electronic component on the board layout. Think of it as a “footprint” left by the component. It does not define the electrical function but rather the physical connection points and keep-out areas.

- βKey Elements of a Footprint:ββ

- βPads:ββ These are the copper areas where the component’s leads or terminals are soldered. They can be for through-hole (pads with holes) or surface-mount technology (SMT).

- βSolder Mask Opening:ββ This is an opening in the solder mask layer that exposes the copper pad, allowing for soldering. The opening is typically slightly larger than the pad.

- βSilkscreen Outline:ββ This is a non-conductive drawing on the board that shows the approximate shape and orientation of the component, aiding in assembly and debugging.

- βCourtyard:ββ This is a keep-out area that defines the space required for the component itself, ensuring no other parts are placed too close.

- βReference Designator:ββ The unique identifier (e.g., R1, C5, U3) that links the footprint to its schematic symbol.

- βImportance of Accuracy:ββ An incorrect βPCB footprintβ is a primary cause of manufacturing defects. A pad that is too small can lead to a weak solder joint; a pad that is too large can cause solder bridging. Accurate βfootprint designβ is the first step toward βfast turn PCB fabrication.

What is the Carbon Footprint of a PCB?

While “PCB footprint” primarily refers to the land pattern, the term “carbon footprint” relates to the environmental impact of manufacturing a PCB. This encompasses the total greenhouse gas emissions produced throughout the PCB’s lifecycle, from raw material extraction and processing to fabrication, assembly, shipping, and end-of-life disposal.

- βFactors Influencing PCB Carbon Footprint:ββ

- βMaterials:ββ The energy intensity of producing copper foil, laminate substrates, and solder mask.

- βManufacturing Processes:ββ Energy consumption from drilling, plating, etching, and lamination.

- βTransportation:ββ Emissions from shipping raw materials and finished boards globally.

- βWaste Management:ββ The environmental cost of treating and disposing of chemical waste and scrap boards.

- βReducing the Impact:ββ While the primary focus of this article is on the land pattern, choosing a manufacturer committed to sustainable practices, such as efficient energy use and waste reduction, can help minimize the overall βPCB carbon footprint.

Why PCB Footprint Design Guidelines Matter in PCB Design Projects?

Following strict βPCB footprint design guidelinesβ is non-negotiable for the success of any βPCB design project. These guidelines ensure that your design is manufacturable, reliable, and compatible with automated assembly equipment, which is crucial for βquick turn PCB boards.

- βEnsuring Solderability and Reliability:ββ Guidelines provide rules for pad sizes, shapes, and spacing that promote proper solder fillet formation, preventing defects.

- βFacilitating Automated Assembly:ββ Precise footprints allow pick-and-place machines to accurately position components, increasing assembly speed and yield for βfast turn printed circuit board assembly.

- βPreventing Signal Integrity Issues:ββ For βhigh-speed PCB design, proper pad and via design within the footprint is critical to minimize parasitic effects and ensure signal quality.

- βStandardizing Design:ββ Guidelines create consistency across different designers and projects, reducing errors and streamlining the design process for βrapid prototyping circuit boards.

How to Follow IPC Standards for PCB Footprints?

The IPC provides a set of industry-accepted standards that form the foundation of professional βPCB footprint creation. Adhering to βIPC standards for PCB footprintsβ is the most effective way to guarantee compatibility and quality.

- βKey IPC Standards:ββ

- βIPC-7351:ββ This is the most important standard for βPCB footprintβ generation. It provides mathematical models for calculating land pattern geometries based on component dimensions. It defines three density levels (Least, Nominal, Most) to balance solderability and space.

- βIPC-SM-782:ββ This older standard has been largely superseded by IPC-7351 but is still referenced.

- βUsing a PCB Footprint Calculator:ββ Many ECAD tools and online calculators are built around the IPC-7351 formulas. You input the component’s dimensions from its datasheet, and the calculator generates the compliant pad layout for your β0805 PCB footprint, β0603 PCB footprint, or complex components like a βQFN footprint.

- βCreating a Checklist:ββ Develop a βPCB footprint checklistβ based on IPC standards to verify each footprint before releasing it to your library. This should include checks for pad size, solder mask expansion, and courtyard clearance.

How to Make a Component Footprint in PCB Layout Design?

Creating an accurate footprint PCB is a fundamental skill for any PCB designer. While the process can vary slightly between ECAD tools like Altium Designer, OrCAD, or KiCad, the core principles remain the same. Mastering footprint in PCB design ensures components fit correctly and solder reliably, which is essential for fast turn PCB fabrication.

Gather Component Data: Start with the manufacturerβs datasheet, which contains the critical dimensions needed for PCB footprint creation, such as pin spacing (pitch), pin width and length, and overall package dimensions. This step is crucial for building a PCB component footprint that meets design specifications.

Use ECAD Tool Features:

- Manual Creation: Draw pads and outlines based on datasheet measurements. This method is suitable for custom or unusual components like a potentiometer PCB footprint or LED PCB footprint.

- Component Wizard: Most professional tools have wizards to automate standard packages (resistors, capacitors, SOIC, QFP) creation by prompting for key dimensions. Common examples include 0603 PCB footprint or 0805 PCB footprint.

- IPC-Compliant Footprint Generator: Advanced tools like Altium integrate generators using IPC standards for PCB footprints, creating highly accurate footprints that comply with pcb footprint design guidelines.

Verify the Footprint: After creation, cross-check it against the datasheet. Print at 1:1 scale and place the actual component (e.g., cherry mx PCB footprint, Arduino Nano PCB footprint) to confirm fit. This verification is invaluable for quick turn PCB boards and rapid prototyping circuit boards.

Key Takeaway: This section emphasizes footprint principles, dimensioning, and IPC standards, laying the foundation for reliable PCB designs in PCB board projects.

How to Build a Footprint for PCBβ?

Building a PCB footprint transforms design principles into a practical layout that integrates seamlessly with manufacturing processes. It directly impacts the success of fast turn PCB fabrication, ensuring components fit correctly, solder reliably, and meet PCB footprint standards. A footprint, or land pattern, defines solder pads, silkscreen outlines, and keep-out areas.

1. Setting Up the PCB Library Environment

Create a dedicated PCB footprint library in ECAD tools like Altium Designer. This organizes all footprints for pcb design projects and accelerates fast turn custom PCB production.

- Steps: File β New β PCB Library β save with a descriptive name (e.g., βcypcblib1.pcblibβ).

A well-structured library is key to maintaining consistency in quick turn PCB fabrication workflows.

2. Creating the Footprint Using a Component Wizard

For standard components, wizards simplify footprint creation and ensure adherence to IPC standards for PCB footprints.

Steps:

- Select Package Type: For example, SOP for surface-mount ICs or QFN footprint PCB layout for compact ICs.

- Set Pad Dimensions: Define solder pad sizes from datasheets (e.g., length and width for SOP28).

- Configure Spacing and Outline: Input pad pitch and overall dimensions; set silkscreen line width for clear component outlines.

- Finalize and Name: Assign a unique name following pcb footprint naming convention for easy identification.

This workflow suits 0603 PCB footprint, 0805 PCB footprint, and standard surface-mount packages, reducing errors in fast turn prototype PCB boards.

3. Manual Footprint Design for Custom Components

For unconventional parts:

- Pad Placement: Position pads accurately; specify hole sizes for through-hole components like through hole resistor PCB footprint or screw terminal PCB footprint.

- Silkscreen and Keep-Outs: Draw outlines and define keep-out areas to prevent interference.

- Validation: Cross-check against datasheets for reliable soldering and DFM analysis in quick turn PCB assembly.

4. Integrating Footprints into a Unified Library

Link footprints with PCB symbols to create a complete library:

- Associate Footprints and Symbols: Ensure pcb footprint Altium integration maintains consistency across PCB library and PCB board projects.

- Verify Integration: Confirm that updates propagate correctly using commands like altium update footprint from library.

Key Takeaway: This section focuses on practical footprint creation, library management, and tool-based integration, enabling efficient fast turn printed circuit boards production while adhering to PCB footprint design guidelines.

How Does a PCB Footprint Library Improve Fast Turn PCB Fabrication?

A well-managed, centralized βPCB footprint libraryβ is a strategic asset that dramatically accelerates the PCB development cycle and enhances quality, directly enabling βfast turn PCB fabrication.

- βEliminates Redundant Work:ββ Engineers don’t waste time recreating the same βPCB symbolsβ and footprints for every new project.

- βEnsures Consistency and Accuracy:ββ A verified library containing all your βPCB footprintsβ (from βcapacitor PCB footprintsβ to βESP32 PCB footprints) prevents the use of incorrect or outdated land patterns.

- βStreamlines DFM Analysis:ββ When a manufacturer receives a design with standardized, IPC-compliant footprints, their βDFM analysisβ is faster and more straightforward, reducing the back-and-forth and speeding up production.

- βFacilitates Team Collaboration:ββ A shared library ensures all team members are working from the same source of truth, reducing errors in complex βpcb board projects.

How to Read a PCB Footprint?

Reading a footprint is essential for debugging and verifying a PCB layout. You need to understand what each element represents.

- βIdentify the Pad Types:ββ Distinguish between SMD pads (flat copper on the surface) and through-hole pads (with a drill hole in the center).

- βCheck the Layers:ββ View the footprint in your ECAD tool across different layers (Top Layer for pads, Top Solder Mask for openings, Top Overlay for silkscreen). Ensure the solder mask opening correctly exposes the pad.

- βUnderstand the Courtyard:ββ This layer defines the physical boundary of the component. No other parts should encroach on this space.

- βVerify the Reference Designator:ββ Confirm it matches the schematic symbol.

Why Choose BEST Technology for High-Precision Footprint PCB Production and Assembly?

When your βPCB design projectsβ demand high precision and quick turnaround, the choice of manufacturer is critical. BEST Technology is the ideal partner for βhigh-speed PCBβ and high-reliability applications.

- βExpertise in DFM:ββ We perform thorough βPCB DFMβ checks, focusing on βfootprint PCBβ accuracy to catch potential issues before they reach production, saving you time and cost.

- βAdvanced Manufacturing Capabilities:ββ Our facilities are equipped to handle the tight tolerances required for modern components, including micro BGAs and fine-pitch devices.

- βCommitment to Fast-Turn Services:ββ We understand the market’s need for speed. Our processes are optimized for βquick turn PCB fabricationβ and βquick turn PCB assemblyβ without compromising on quality.

- βTechnical Support:ββ Our engineering team can provide guidance on βPCB footprint design guidelinesβ and help optimize your design for manufacturability.

βTo sum up, a footprint PCB is the foundational element that bridges electronic design and physical reality, determining the manufacturability, reliability, and success of a circuit board. Mastering its design and management is the key to unlocking efficient and fast-turn PCB fabrication. By understanding its components, adhering to IPC standards, and maintaining a rigorous library, you can avoid common pitfalls and accelerate your time to market. For manufacturers who prioritize precision and speed, partnering with a specialist like BEST Technology ensures that your intricate footprint designs are executed flawlessly. For your next high-precision PCB board projects, pls feel free to reach out to our team at sales@bestpcbs.com.