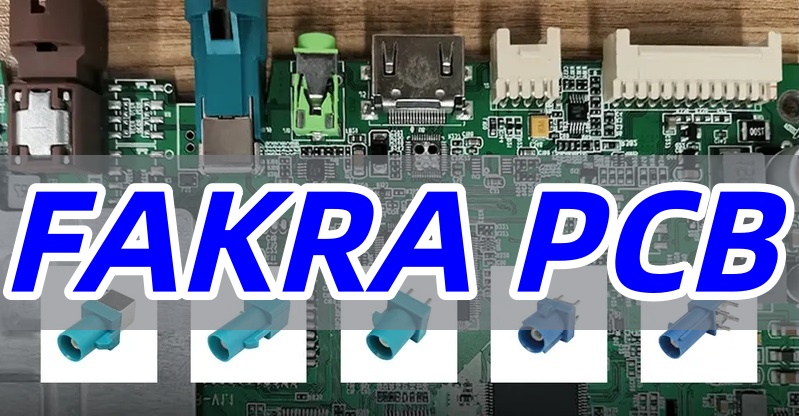

A FAKRA PCBβ is a specialized printed circuit board designed to integrate FAKRA coaxial connectors, serving as the critical RF signal interface in modern vehicles for applications like GPS, infotainment, and ADAS. Are you facing recurring challenges with signal integrity, reliability, or sourcing for your automotive RF modules? This article provides a comprehensive guide to designing, specifying, and manufacturing reliable FAKRA PCBs that meet the stringent quality and performance demands of the automotive industry.

What are the typical pain points engineers face when working with FAKRA PCBs?

- Impedance Mismatch:β Inaccurate PCB trace design or material inconsistency leads to a deviation from the required 50Ξ© impedance, causing signal reflections errors.

- Mechanical Failure in Harsh Environments:β Vibration, temperature cycling, and connector mating cycles can cause the FAKRA PCB mountβ to fail, leading to disconnections in critical systems.

- Unstable High-Frequency Performance:β Understanding and designing for FAKRA connectors PCB frequencyβ limits (up to 6 GHz) is challenging, often resulting in unexpected insertion loss and VSWR.

- Supply Chain Complexity:β Sourcing correct components, like specific HCC FAKRA PCB part numbers, and dealing with long lead times or counterfeit parts can derail production schedules.

- Miniaturization Difficulties:β Integrating miniature FAKRA connectors PCBβ into compact telematics and ADAS modules requires advanced design and manufacturing capabilities to avoid crosstalk and ensure robustness.

At BEST Technology, we address these challenges with rigorous process controls and automotive-grade expertise, ensuring your FAKRA PCB performs flawlessly.

- Controlled Impedance Fabrication:β We utilize high-frequency laminates and precise modeling to guarantee your FAKRA PCB connectorβ footprint translates to a consistent 50Ξ© transmission line, minimizing signal degradation.

- Automotive-Grade Mechanical Design:β Our DFM analysis includes checks for solder joint integrity, reinforced PTH barrels, and optimal FAKRA PCB mountβ design to withstand vibration and thermal stress, ensuring long-term reliability.

- High-Frequency Optimization:β Our expertise with FAKRA connectors PCB frequencyβ requirements ensures stable performance up to 6 GHz through careful material selection and layout guidance.

- Verified Component Supply Chain:β We have partnerships with reputable FAKRA connector manufacturers, guaranteeing access to authentic components like specific HCC FAKRA PCB part numbers, simplifying your logistics.

- Advanced Miniaturization Support:β We provide design rules and precision manufacturing for boards using miniature FAKRA connectors PCB, ensuring reliable performance in the smallest form factors.

BEST Technology is a specialist in high-reliability PCB and assembly manufacturing, with a strong focus on automotive electronics. With IATF 16949 certified production facilities in China and Vietnam, we offer a true one-stop service from FAKRA PCBβ fabrication to full box-build assembly. Contact us at sales@bestpcbs.comβ for a consultation.

What Is a FAKRA PCB?

A FAKRA PCBβ is a circuit board engineered to host FAKRA (Fachkreis Automobil) connectors, which are standardized coaxial interfaces used primarily in automobiles for transmitting radio frequency signals.

- Core Purpose:β The primary role of a FAKRA PCB is to provide a reliable, impedance-controlled pathway for RF signals from a coaxial cable to the board’s integrated circuits, supporting systems like GPS, satellite radio, and cellular connectivity.

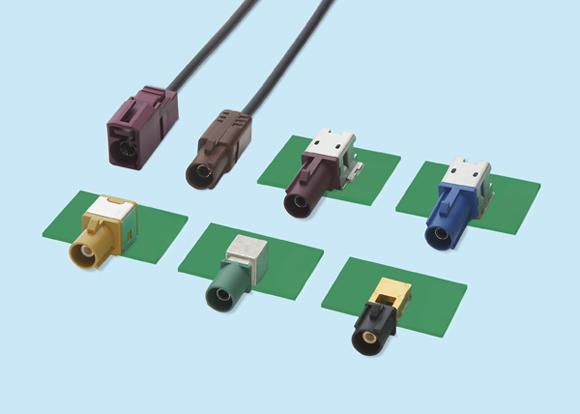

- Key Feature β Color Coding:β A defining feature is the use of color-coded connector housings (e.g., blue for GPS, yellow for USB) on the FAKRA PCB connector, which prevents mis-mating during assembly in the vehicle harness.

FAKRA Connector Color and Coding Guide

| Color | Code Letter | Primary Application | Typical Frequency Range |

|---|---|---|---|

| Blueβ | Aβ | GPS (Global Positioning System) | 1.575 GHz |

| Light Greenβ | Bβ | Reserved / User-Defined | – |

| Grayβ | Cβ | SDARS (Satellite Digital Audio Radio Service) | 2.32 – 2.345 GHz |

| Pinkβ | Dβ | Cellular Phone (2G/3G/4G Telematics) | 800 MHz – 2.7 GHz |

| Blackβ | Eβ | Reserved / User-Defined | – |

| Greenβ | Fβ | CarPlay / Android Auto (LVDS Differential Signals) | – |

| Redβ | Gβ | GPS (Modern de facto standard) | 1.575 GHz |

| Brownβ | Hβ | SDARS (Satellite Radio) | 2.32 – 2.345 GHz |

| Whiteβ | Jβ | Bluetooth / Wi-Fi | 2.4 GHz / 5 GHz |

| Orangeβ | Kβ | Tire Pressure Monitoring System (TPMS) | 433 MHz / 315 MHz |

| Yellowβ | Lβ | Digital Audio Broadcasting (DAB/DAB+) | 174 – 240 MHz |

| Light Blueβ | Mβ | Vehicle TV Tuner | 470 – 862 MHz |

| Violet / Purpleβ | N, P, R, Sβ | V2X / DSRC (Vehicle-to-Everything) | 5.85 – 5.925 GHz |

| Black (4-pin)β | U, V, W, X, Zβ | Automotive Radar (ADAS) | 24 GHz / 76-81 GHz |

In summary, a FAKRA PCB is a fundamental component in modern automotive electronics, ensuring that various RF systems can be connected correctly and perform reliably over the vehicle’s lifetime.

How a FAKRA PCB Connector Enables Stable RF Transmission in Automotive Electronics?

The FAKRA PCB connectorβ is the critical interface that ensures stable RF transmission by maintaining signal integrity from the cable to the PCB. Its design is tailored for the harsh automotive environment.

- Standardized Impedance:β The connector is engineered to maintain a 50-ohm impedance through its interface, providing a smooth transition to the similarly controlled impedance trace on the PCB. This minimizes reflections at the connection point.

- Superior Shielding:β The metal shell of the connector, when soldered to a continuous ground plane on the PCB, creates an excellent shield against electromagnetic interference (EMI), which is abundant in a vehicle.

- Robust Keying Mechanism:β The unique plastic keying and color coding of a FAKRA connectorβ prevent incorrect mating, ensuring that the right signal source is always connected to the right receiver, which is vital for system functionality.

The FAKRA PCB connectorβ is more than just a port; it precision-engineered component that guarantees stable RF signal transmission by combining electrical precision, mechanical robustness, and error-proofing.

What are FAKRA Connectors PCB Frequency Limits and Why They Matter in High-Speed Designs?

Understanding the FAKRA connectors PCB frequencyβ limits is crucial for ensuring system performance, as these limits define the maximum data rate the connection can support without significant signal degradation.

- Standard Limit:β Standard FAKRA connectors are typically rated for frequencies up to 6 GHz. This covers most automotive applications like GPS (1.5 GHz), 4G/LTE, and Wi-Fi.

- Importance for High-Speed Designs:β As automotive systems evolve towards 5G and higher-speed data (e.g., for camera modules), operating frequencies increase. If the FAKRA connectors PCB frequencyβ limit is exceeded, insertion loss rises and VSWR increases, leading to a weak or corrupted signal. This makes the 6 GHz limit a key consideration when selecting components for future-proof designs.

Therefore, the FAKRA connectors PCB frequencyβ specification is not just a number; it is a boundary that dictates the suitability of the connector for current and emerging high-bandwidth applications in the vehicle.

Understanding FAKRA PCB Mount Options for Robust RF and GPS/4G/Wi-Fi Modules

The FAKRA PCB mountβ option chosen directly impacts the mechanical stability and long-term reliability of the RF connection in modules that are subject to constant vibration.

- Through-Hole Mounting (TH):β This method involves leads inserted into plated-through holes in the PCB and soldered. It offers the highest mechanical strength and is preferred for applications where the connector might undergo significant mating force or extreme vibration.

- Surface Mount Technology (SMT):β SMT FAKRA PCB mountβ connectors are soldered to pads on the PCB surface. This allows for faster, more automated assembly and is ideal for high-volume production. The mechanical strength is generally lower than THT but sufficient for many applications with proper design.

Selecting the right RA PCB mountβ styleβthrough-hole for maximum robustness or surface-mount for assembly efficiencyβis a critical decision based on the specific mechanical demands and production volume of the automotive module.

Overview of HCC FAKRA PCB Part Numbers and How They Differ Across Connector Families

HCC FAKRA PCB part numbersβ refer to the specific coding system used by a major connector manufacturer (Hirose) to identify different FAKRA connector variants. Understanding these part numbers is key to sourcing the correct component.

- Decoding the Number:β A typical HCC FAKRA PCB part number provides encoded information about the connector’s series, color, keying code, mounting style (right-angle, vertical), and termination type.

- Differences Across Families:β Different series within the HCC catalog may offer variations in size (e.g., miniaturized), performance (e.g., higher frequency), or locking mechanism. For example, a part number for a mini FAKRA PCBβ connector would belong to a different series than a standard-sized one.

Therefore, paying close attention to HCC FAKRA PCB part numbersβ is essential for engineers to ensure the selected connector matches the electrical, mechanical, and spatial requirements of their specific PCB design.

Miniature FAKRA Connectors PCB Design Rules for Compact Automotive and Telematics Devices

Designing with β FAKRA connectors PCBβ components requires adherence to specific rules to maintain signal integrity and mechanical stability in increasingly compact devices.

- Prioritize Grounding:β Even more so than with standard connectors, a solid ground connection is vital. Use an extensive ground plane directly under and around the connector footprint, with multiple vias adjacent to the ground pads to minimize inductance.

- Maintain Impedance Continuity:β The reduced size makes impedance control more challenging. Work closely with your PCB manufacturer to ensure the trace width and spacing as it exits the miniature connector maintains 50Ξ©.

- Manage Crosstalk:β Place other components and high-speed traces a sufficient distance away from the miniature FAKRA connectors PCBβ to prevent unwanted coupling and crosstalk.

Following these design rules for mini FAKRA PCBβ integration allows engineers to leverage space savings without compromising the RF performance that is critical for advanced telematics and ADAS modules.

How Do You Integrate a FAKRA Stecker PCB into Automotive Platforms and ADAS Harness Systems?

Integrating a FAKRA Stecker PCBβ (German for “FAK PCB”) involves both electrical and mechanical considerations to ensure a reliable connection within the vehicle’s larger wiring harness system, especially for ADAS.

- Harness Interface Planning:β The FAKRA Stecker PCBβ on a module (e.g., a radar or camera) must be positioned to align correctly with the vehicle’s pre-designed wire harness. This requires close collaboration with the harness supplier early in the design phase.

- In-Line Connector Choice:β The FAKRA Stecker PCBβ (plug) mates with an in-line FAKRA connector (socket) on the harness. Selecting the correct keying and color code for this mating pair is essential to ensure each sensor and antenna is connected in the complex ADAS network.

Successful integration of the FAKRA Stecker PCBβ is a systems-level task that ensures the electronic module becomes a seamless and reliable part of the vehicle’s broader communication infrastructure.

Comparing PCB to PCB Connector Types in RF Applications vs. Standard FAKRA Types

When connecting two PCBs carrying RF signals, engineers must choose between standard PCB to PCB connector typesβ and dedicated FAKRA types, each with distinct advantages.

- Standard PCB-to-PCB Connectors:β These include mezzanine, board-to-board, and stacking connectors. They are versatile for general power and data but are often not optimized for RF potentially introducing significant impedance discontinuities and loss at high frequencies.

- FAKRA Types:β FAKRA connectorsβ are specifically engineered as RF coaxial interfaces. They provide superior shielding and a controlled 50-ohm impedance path, making them the clear choice for high-frequency signals like GPS or cellular. However, they are typically used for cable-to-board connections, not direct PCB-to-PCB links.

The choice boils down to application: use standard PCB to PCB connector typesβ for general purposes, but always specify FAKRA typesβ when the primary function is to carry a clean RF signal between a cable and the board.

Why Automotive Teams Choose EBest Circuit (Best Technology) for FAKRA PCB and Full PCBA Manufacturing Support?

Automotive engineering teams partner with BEST Technology because we deliver the rigorous quality and specialized support mission-critical FAKRA PCBβ applications. Our services are built to meet the high standards of the automotive industry.

- Automotive-Grade Expertise:β We specialize in manufacturing FAKRA PCBβ and high-frequency boards for automotive electronics, including advanced driver-assistance systems (ADAS) modules, camera boards, and antenna modules.

- Global Manufacturing Footprint:β Our IATF 16949 certified PCB and SMT factories in China and Vietnam offer scalable production from quick-turn prototypes to high-volume mass production, ensuring supply chain resilience.

- Comprehensive Engineering Support:β We provide free DFM analysis, impedance control advice, and stack-up recommendations to optimize your design for performance and manufacturability.

- Full-Turnkey PCBA Service:β We manage the entire process from FAKRA PCBβ fabrication and component sourcing (including authentic FAKRA connectorβ procurement) to precise SMT assembly, rigorous testing, and final shipment.

- Rigorous Quality Assurance:β Our compliance with IATF 16949, ISO 13485, ISO 9001, and UL standards, combined with MES traceability, guarantees that every board meets the zero-defect expectations of the automotive sector.

In summary, FAKRA PCBβ technology is a cornerstone of in-vehicle connectivity, demanding precision from design through assembly. This guide has detailed the essential aspects of specifying, designing, and manufacturing robust PCBs with FAKRA connectors to meet the rigorous quality demands of the automotive industry. By choosing BEST Technology as your manufacturing partner, you gain access to specialized automotive-grade expertise, stringent process controls, and a seamless one-stop service that ensures your designs perform reliably in the field.

Ready to get a quote for your automotive-grade FAKRA PCB?β Pls email your Gerber files, BOM, and connector specifications to sales@bestpcbs.comβ for a fast and comprehensive engineering review and quote.