After spending two decades in the PCB industry and working on countless circuit boards, Iām stoked to dive deep into Double Layer PCBs. These bad boys are the āSwiss Army knivesā of the electronics manufacturing world! A Double Layer PCB, or double – sided printed circuit board, has conductive traces laid out on both the front and back of an insulating substrate. These two layers are connected by metallized vias, creating a super efficient electrical pathway.

The perks of Double Layer PCBs are off the charts. They offer high – density routing, allowing for complex circuits to be packed in. Theyāre cost – effective, making them perfect for large – scale production. And their electrical performance? Rock solid, ensuring lightning – fast and reliable signal transmission. From the smartphones and laptops we use daily to automotive electronics systems and industrial automation gear, Double Layer PCBs are everywhere, powering the core operations of electronic devices.

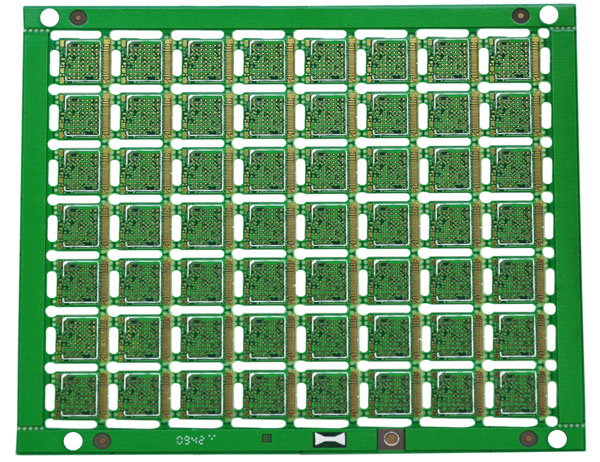

What is a Double Layer PCB?

As an experienced PCB process engineer, double layer PCBs hold a special place in my professional journey. Imagine an insulating substrate serving as the core foundation, with copper foils meticulously applied to both the top and bottom surfaces. These copper foils function as parallel “electronic highways,” facilitating the seamless flow of electric current. The insulating material situated between the layers acts as a robust barrier, effectively preventing signal interference and ensuring optimal performance.

The metallized vias play a crucial role, acting as strategic overpasses that connect these two “highways.” This enables current to traverse between the layers with ease, supporting a wide range of intricate circuit functions. It’s precisely this innovative design that forms the bedrock for enhancing the performance capabilities of electronic devices.

Double Layer PCB Stackup

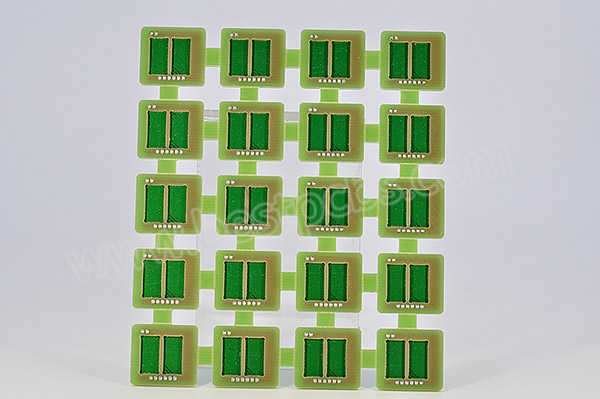

The structure of a Double Layer PCB is both precise and well – thought – out:

- Insulating Substrate: Materials like FR – 4 are commonly used. Theyāre highly resistant to heat and corrosion, providing stable physical support and electrical insulation for the circuit board, much like a strong foundation for a building.

- Top and Bottom Copper Foils: These are the workhorses for current transmission. Their thickness can be flexibly adjusted from 0.5oz to 3oz based on the current – carrying needs of different circuits.

- Metallized Vias: Theyāre the linchpin for connecting the two layers. Without them, the two layers of the circuit simply canāt work together.

- Solder Mask Layer: This layer acts as a shield, protecting the copper foils from oxidation and short circuits, almost like a suit of armor for the circuit board.

- Silk – Screen Layer: It marks the positions and polarities of components, offering clear instructions for assembly and maintenance down the line.

Our Services

Design

- Our 20+ veteran engineers, each with 19+ years of expertise, tackle complex designs effortlessly. We provide end – to – end services including PI, SI analysis, and EMC testing, plus a complimentary DFM check. Our proactive approach identifies production risks early, streamlining the transition from design to high – quality product and saving you time and costs. [Explore more success stories]

Prototyping

Need samples fast? Our 24-hour rush prototyping service delivers quicker than pizza! Plus, our expert engineers offer free technical supportāask us anything, and we’ll explain it clearly. Special requests? We can use premium materials like Rogers or Dupont and implement unique processes. [Learn more about our prototyping process]

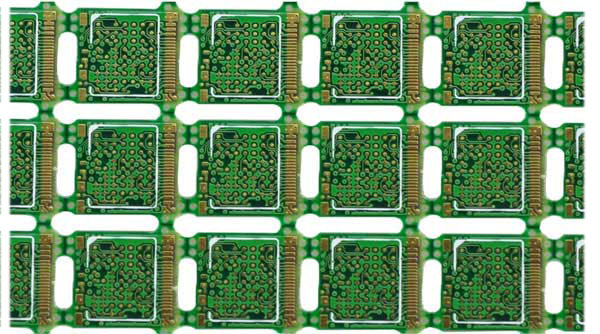

Mass Production

Our 8,000ć” factory, with 18 years of expertise, boasts a 260,000 sq. ft. monthly capacity. Certified by ISO13485 and IATF16949, we ensure top – tier quality for every Double Layer PCB. [Request mass production quote]

Assembly

Our PCB assembly service stands out from the competition. With over 10 SMT production lines in operation and free passive components, it’s a cost – effective solution. Rigorous quality control, including DFM/DFA inspections, functional/ICT tests, X – RAY scans, and dual AOI, ensures top – notch results. We handle SMT, through – hole, BGA, and QFN assembly with ease, and there’s no MOQ. It’s your all – in – one assembly destination. [Learn more about our assembly service perks]

Production Capabilities/Process Capabilities

| Item | Capabilities |

| Layer Count | 1 – 32 Layers |

| Max Board Dimension | 2424″ (610610mm) |

| Min Board Thickness | 0.15mm |

| Max Board Thickness | 6.0mm – 8.0mm |

| Copper Thickness | Outer Layer:1oz~30oz, Inner Layer:0.5oz~30oz |

| Min Line Width/Line Space | Normal: 4/4mil (0.10mm); HDI: 3/3mil (0.076mm) |

| Min Hole Diameter | Normal: 8mil (0.20mm) ; HDI: 4mil (0.10mm) |

| Min Punch Hole Dia | 0.1″ (2.5mm) |

| Min Hole Spacing | 12 mil (0.3mm) |

| Min PAD Ring(Single) | 3mil (0.075mm) |

| PTH Wall Thickness | Normal: 0.59mil (15um); HDI: 0.48mil (12um) |

| Min Solder PAD Dia | Normal: 14mil (0.35mm); HDI: 10mil(0.25mm) |

| Min Soldermask Bridge | Normal: 8mil (0.2mm); HDI: 6mil (0.15mm) |

| Min BAG PAD Margin | 5mil (0.125mm) |

| PTH/NPTH Dia Tolerance | PTH: Ā± 3mil (0.075mm) ; NPTH: Ā±2 mil (0.05mm) |

| Hole Position Deviation | Ā±2 mil (0.05mm) |

| Outline Tolerance | CNC: Ā± 6mil (0.15mm); Die Punch: Ā± 4mil (0.1mm); Precision Die: Ā± 2mil (0.05mm) |

| Impedance Controlled | Value>50ohm: Ā±10%; Valueā¤50ohm: Ā±5 ohm |

| Max Aspect Ratio | 0.334027778 |

| Surface Treatment | ENIG, Flash Gold, Hard Gold Finger, Gold Plating(50mil), Gold finger, Selected Gold plating,ENEPIG, ENIPIG; HAL, HASL(LF), OSP, Silver Imm., Tin Imm |

| Soldermask Color | Green/White/Black/Yellow/Blue/Red |

Why Choose Us?

Competitive Pricing

Weāre all about offering you the best bang for your buck. By streamlining our production processes and building long – term partnerships with top – notch suppliers, we keep costs low without sacrificing an ounce of quality. Youāll get quotes that are hard to beat in the market!

Quality Assurance

Quality isnāt just a buzzword for usāitās our obsession. From the moment raw materials arrive at our factory to the final product inspection, we have strict quality control measures in place. Only products that pass all our rigorous tests make it to your hands. Each Double Layer PCB you receive is a testament to our commitment to excellence.

Turnkey Solutions

Partnering with us means getting the full package. We handle everything from design and prototyping to mass production and assembly. Say goodbye to juggling multiple suppliers and the headache of excessive communication. Weāll cut down your project timeline significantly. Plus, youāll have a dedicated sales assistant by your side throughout the process, ready to assist with anything you need.

On – Time Delivery

We know that in the electronics industry, time is money. Thatās why weāve built a robust production planning and logistics system. With our online production status tracking, you can check on your orderās progress anytime. Rest assured, we always deliver on time, ensuring your projects stay on schedule.

Advantages of Double Layer PCBs

- Design Flexibilityļ¼The double – sided routing opens up a whole new world of circuit layout possibilities. No matter how intricate the circuit design is, we can make it work. Itās also a game – changer for miniaturizing electronic devices, helping pack more functionality into a smaller space.

- Cost – Efficiencyļ¼Compared to multi – layer PCBs, Double Layer PCBs offer a great balance between performance and cost. For most projects, they deliver the performance you need without breaking the bank, making them a smart choice for budget – conscious customers.

- Superior Electrical Performanceļ¼Thanks to smart layout and routing designs, along with reliable metallized via connections, signal interference and crosstalk are minimized. This means signals are transmitted quickly and accurately, keeping your devices running smoothly.

Double Layer PCB Production Process/Manufacturing Flow

- Design Reviewļ¼Our engineering team conducts a meticulous review of your design files. We scrutinize every detail, from circuit routing to component selection, to make sure the design aligns perfectly with our manufacturing processes and avoid any potential rework.

- Material Procurementļ¼Weāre picky when it comes to suppliers. Only the highest – quality insulating substrates, copper foils, and other raw materials make the cut. Each batch undergoes strict testing to ensure they meet our high – performance standards.

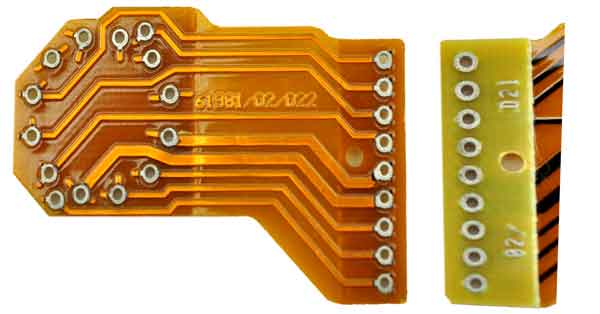

- Pattern Transferļ¼Using photolithography techniques, we transfer the circuit pattern onto the copper foil with pinpoint accuracy. Through processes like exposure and development, we ensure the pattern is sharp and in the right place.

- Etchingļ¼We use etching solutions to remove the unwanted copper, leaving behind the precise conductive traces. Precise control over the etching time and concentration is key to ensuring the tracesā width and spacing match the design specifications.

- Drilling and Metallizationļ¼Holes are drilled through the substrate to connect the two layers, and then metallized to make the hole walls conductive. The position and size of these holes must be spot – on to guarantee a reliable connection between the layers.

- Surface Treatmentļ¼Based on your requirements, we choose the right surface treatment process, such as ENIG or HASL. This step enhances the boardās solderability and oxidation resistance, extending its lifespan.

- Solder Mask and Silk – screeningļ¼We apply solder mask ink to protect the circuit traces from short circuits, leaving only the pads for soldering exposed. Then, we silk – screen component markings, polarities, and other essential information, making assembly and maintenance a breeze.

- Assembly and Testingļ¼Electronic components are soldered onto the board, and then we conduct a comprehensive series of functional and quality tests. From basic electrical performance checks to full – scale functionality tests, we leave no stone unturned to ensure the product is up to par.

Problems Solved by Double Layer PCBs

- Space Limitationsļ¼With the trend of miniaturizing electronic devices, space inside is at a premium. The double – sided routing of Double Layer PCBs solves the dilemma of limited space and complex functionality requirements. It enables devices to pack more features into a compact form factor.

- Cost – Performance Trade – offļ¼For projects that need good performance but also have budget constraints, Double Layer PCBs are the perfect fit. They offer a cost – effective way to achieve solid electrical performance, meeting the needs of a wide range of applications.

Double Layer PCB Design Considerations

When designing Double Layer PCBs, keep these key points in mind:

- Circuit Routingļ¼Plan the traces carefully. Isolate high – speed signal lines from potential interference sources and route them separately. Try to separate the power and ground planes as much as possible to reduce power – related signal noise. [Click here for more circuit routing design tips]

- Component Placementļ¼Think about heat dissipation and assembly convenience. Place high – power components in well – ventilated areas and make sure theyāre easy for workers to handle during soldering and inspection.

- Via Designļ¼Be cautious when determining the position and number of vias. Too many can slow down signal transmission, while too few might compromise connection reliability.

- Communicationļ¼Maintain close communication with your manufacturer. Understanding the manufacturing process limitations helps ensure your design can be produced smoothly without a hitch.

Double Layer PCB Thickness

The thickness of Double Layer PCBs should be chosen based on the specific application:

- 0.15mmļ¼ Ideal for ultra – thin devices with strict thickness requirements, like smartwatches or ultra – thin smartphones.

- 0.2mm – 0.8mmļ¼Commonly used in small, portable electronics and some consumer products, striking a balance between thinness and circuit layout needs.

- 1.0mm – 1.6mmļ¼This is the most popular range, widely applied across various electronics. It offers a great compromise between cost and performance and has excellent compatibility.

- 2.0mm – 3.2mmļ¼Suited for devices with high power requirements and more components, providing extra support and better heat dissipation. Itās often used in industrial control and communication equipment.

- 6.0 – 8.0mmļ¼Boasting high strength, it can withstand significant mechanical stress. Itās the go – to choice for applications demanding extreme stability, such as automotive engine control modules.

In practice, consider factors like component size, power consumption, and available installation space to pick the perfect thickness and maximize the boardās performance.

Double Layer PCB Applications

Double Layer PCBs are making waves across multiple industries thanks to their outstanding performance:

- Consumer Electronicsļ¼Theyāre the unsung heroes powering devices like smartphones, tablets, and smartwatches, ensuring smooth operation of all functions. [Discover more consumer electronics success stories]

- Automotive Industryļ¼Crucial for automotive engine control systems, in – car entertainment, and autonomous driving assistance systems, they keep working reliably even in harsh conditions.

- Industrial Fieldļ¼Providing support for PLCs, industrial robots, and automated production lines, they enable precise control and stable operation.

Whether your project is in the design, prototyping stage, or youāre ready for mass production and assembly, our two – decade – long industry experience, professional team, and comprehensive service system have got you covered. We offer customized solutions tailored to your needs. For more information or to start a collaboration, shoot us an email at sales@bestpcbs.com. Letās team up and create amazing electronic products together!