The thermal conductivity of copper is one of its most critical physical properties, making it indispensable in thermal management systems. At 20°C (293K), the thermal conductivity of copper averages 401 W/(m·K), second only to silver but far more cost-effective, which drives its widespread use in electronics, industrial machinery, and energy systems.

What Is the Exact Thermal Conductivity of Copper?

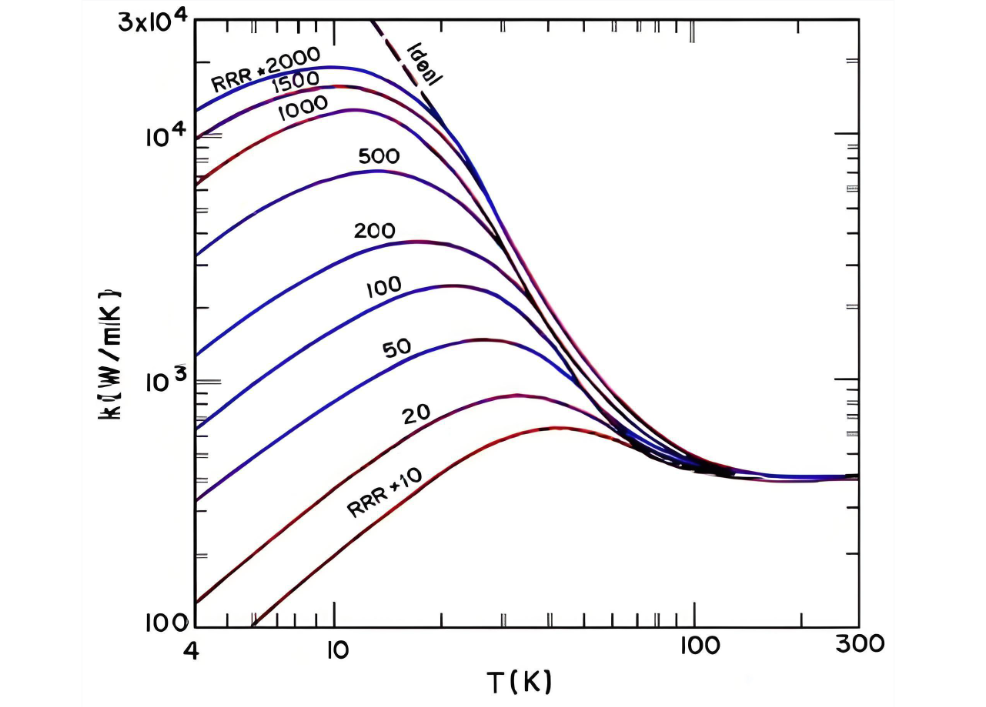

At room temperature (20°C), pure copper has a thermal conductivity of 401 W/(m·K). This value ranges slightly—385 to 426 W/(m·K)—depending on purity, processing methods, and temperature fluctuations. Laser flash analysis is the standard method to verify this parameter for industrial-grade copper.

Why Does Copper Have High Thermal Conductivity?

Copper’s face-centered cubic (FCC) crystal structure enables exceptional heat transfer. Each copper atom bonds with 12 nearest neighbors, creating a dense lattice that allows free electrons to move unimpeded. These electrons act as heat carriers, transferring thermal energy far more efficiently than non-metallic materials.

Thermal Conductivity of Copper vs. Other Metals

| Material | Thermal Conductivity (W/(m·K)) | Key Use Case |

|---|---|---|

| Pure Copper | 401 | High-power electronics cooling |

| Silver | 429 | Specialized aerospace components |

| Aluminum | 237 | Low-cost heat sinks |

| Naval Brass | 120 | Marine hardware (corrosion resistance over conductivity) |

How Does Purity Affect Thermal Conductivity of Copper?

Purity directly impacts performance: 99.99% pure copper (OFHC copper) reaches 401 W/(m·K), while impure copper (95% purity) drops to 350–370 W/(m·K). Zinc, iron, or oxygen impurities disrupt the FCC lattice, scattering electrons and reducing heat transfer efficiency.

Common Copper Components for Thermal Management

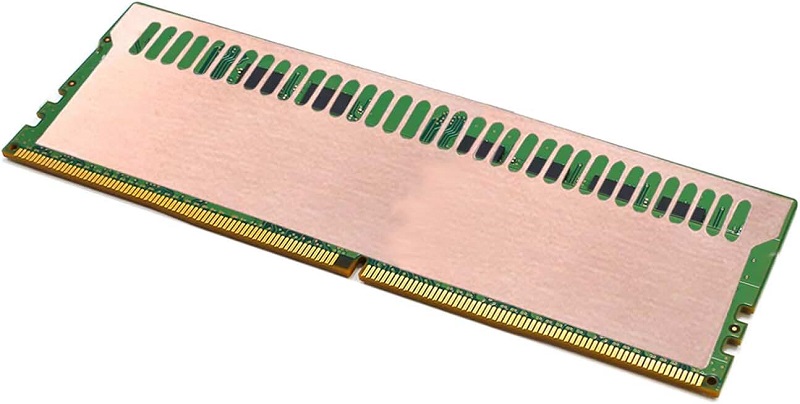

- Copper Heat Pipes: Effective thermal conductivity up to 10,000 W/(m·K), used in laptop and server cooling.

- Copper Cold Plates: Handle heat flux over 100 W/cm² for AI server GPUs via internal microchannels.

- Copper Foil: 0.05–0.3mm thick, ideal for smartphone SoC and flexible PCB heat dissipation.

Processing Techniques to Optimize Thermal Conductivity of Copper

Selective laser melting (SLM) 3D printing creates topology-optimized copper structures with 3x more surface area than traditional designs. Sintering copper powder at 800–900°C enhances lattice density, while electroplating thin copper layers (2–20μm) boosts local conductivity for small components.

Applications of Copper Thermal Conductivity in Electronics

High thermal conductivity of copper is critical for AI servers, where copper cold plates and vapor chambers keep GPUs within safe temperature ranges. Flagship smartphones use copper vapor chambers to reduce SoC junction temperatures by 8–12°C, improving performance and longevity.

Thermal Conductivity of Copper Alloys

Copper alloys have lower conductivity than pure copper due to alloying elements. Yellow brass (67% Cu, 33% Zn) has 109 W/(m·K), while red brass (85% Cu, 15% Zn) reaches 80 W/(m·K). Alloys prioritize strength or corrosion resistance over maximum heat transfer.

FAQ About Thermal Conductivity of Copper

1. Does temperature affect copper’s thermal conductivity?

Yes. Conductivity decreases slightly with temperature—dropping to ~370 W/(m·K) at 100°C—as lattice vibrations scatter electrons. It remains stable below 200°C, suitable for most industrial applications.

2. Can copper’s thermal conductivity be enhanced with coatings?

No, coatings like nickel or tin reduce conductivity. Use copper-graphite composites instead, which maintain 85% of copper’s conductivity while reducing weight by 40%.

3. Is brass a good alternative to copper for heat transfer?

Only for low-heat applications. Brass’s conductivity is 25–37% of pure copper, making it unsuitable for high-power density scenarios like CPU cooling.

4. How to maintain copper’s thermal conductivity over time?

Prevent oxidation with anti-corrosion treatments (e.g., nickel plating). Avoid mechanical deformation that disrupts the crystal lattice, as this degrades conductivity by 5–10%.

5. What’s the difference between thermal conductivity of copper and copper alloys?

Alloying elements (zinc, tin, aluminum) disrupt electron flow. Pure copper’s conductivity is 2–15x higher than alloys, depending on composition.

How to Measure Thermal Conductivity of Copper Accurately?

Laser flash analysis is the gold standard. It heats one side of a copper sample with a laser pulse and measures temperature rise on the opposite side, calculating conductivity via Fourier’s law. This method has a margin of error below 2%.

Factors That Reduce Thermal Conductivity of Copper

- Impurities: Even 0.5% zinc or iron reduces conductivity by 5–8%.

- Porosity: Sintered copper with 50% porosity has 50% lower conductivity.

- Oxidation: Copper oxide layers (CuO/Cu₂O) act as insulators, blocking heat transfer.

We supply high-purity copper components optimized for maximum thermal conductivity of copper, including heat pipes, cold plates, and custom 3D-printed parts. For orders or technical consultations, contact us at sales@bestpcbs.com—our engineering team will tailor solutions to your thermal management needs.