China PCBA contract manufacturing has reshaped the electronics supply chain. This blog provides a comprehensive guide to China PCBA contract manufacturing, covering industry features, top companies, advantages of choosing Chinese PCBA contract manufacturers, selection tips, and real-world case studies from EBest Circuit (Best Technology).

Are You Struggling With These Common Challenges?

- Unpredictable lead times: Small-batch prototypes or urgent orders often face delays.

- Inconsistent quality: Poor soldering, component errors, or test failures can occur.

- Slow communication: Design changes and technical issues may not be addressed promptly.

- Unstable component supply: Key parts may be delayed or out of stock.

- Limited technical support: Lack of guidance increases risks during design or production.

How Does BEST Technology Solve These Challenges?

- Optimized production planning: Smart scheduling and multi-line SMT ensure fast delivery from prototypes to mass production.

- Strict quality control: DFM reviews, ISO-certified lines, AOI + X-ray inspections guarantee reliable products.

- Dedicated engineering support: Each project has a personal engineer for guidance and real-time updates.

- Stable component sourcing: Global certified channels and strategic inventory prevent shortages.

- Design & production support: Expert advice in development, testing, and mass production ensures consistency and reliability.

EBest Circuit (Best Technology) specializes in high-quality PCB and PCBA contract manufacturing, offering rigid, rigid-flex, and flex PCBs, aluminum Base PCBs, and ceramic base PCB assembly for automotive, medical, aerospace, and industrial applications. Our competitive edge lies in strict quality control, ISO-certified production lines, dedicated engineering support, and full turnkey solutions from prototyping to mass production. To discuss your project or request a quote, contact us at sales@bestpcbs.com.

What is China PCBA Contract Manufacturing?

PCBA contract manufacturing in China means outsourcing printed circuit board assembly to specialized companies. These partners manage each step carefully:

- Component sourcing ‚Äď locating original and certified parts.

- Board fabrication¬†‚Äď producing rigid, flex, or rigid-flex PCBs.

- Assembly ‚Äď automated soldering, placement, and reflow processes.

- Inspection ‚Äď using AOI, ICT, and functional tests.

- Packaging & delivery ‚Äď shipping finished boards with full traceability.

This complete approach reduces risks, saves time, and improves project stability.

What are the Features of PCBA Contract Manufacturing?

The service has several clear features that make it attractive:

- Scalability¬†‚Äď from small-batch prototypes to mass production.

- Flexibility¬†‚Äď handling rigid, rigid-flex, and flex PCB China projects.

- Quality control¬†‚Äď certifications such as ISO 9001, ISO 13485, and IATF16949.

- Automation ‚Äď modern machines reduce human errors.

- Cost balance ‚Äď reasonable pricing without cutting standards.

These features give global customers confidence when working with Chinese PCB contract manufacturers.

Top China PCBA Contract Manufacturing Companies

Many companies appear in searches such as Top 10 PCB manufacturers in China or China PCB manufacturer list. But only a few truly stand out. Their advantages include:

- Fast response time to international clients.

- Strong engineering support with design for manufacturability checks.

- Global shipping channels that cut delays.

- Transparent project communication.

These are the real differences that separate top China PCBA contract manufacturing companies from the rest.

Advantages of Choosing China for PCBA Contract Manufacturing

China has become a preferred hub for PCB and PCBA because of several strong points:

- Cost efficiency ‚Äď high production volume reduces overall expense.

- Technology investment¬†‚Äď factories adopt SMT lines, X-ray inspection, and cleanrooms.

- Supply chain strength ‚Äď easy access to parts, boards, and logistics.

- Fast delivery¬†‚Äď competitive lead times compared to other regions.

These strengths give customers a reliable way to move from design to mass production quickly.

How to Select Reliable PCB Contract Manufacturers?

Not every supplier offers the same level of service. To select a reliable partner, companies should:

- Verify certifications to match industry needs.

- Review inspection systems like AOI, ICT, and flying probe testing.

- Check sourcing channels to avoid counterfeit risks.

- Request project cases that prove capability.

- Evaluate communication, response speed, and engineering support.

These points help companies avoid common problems such as delays or quality failures.

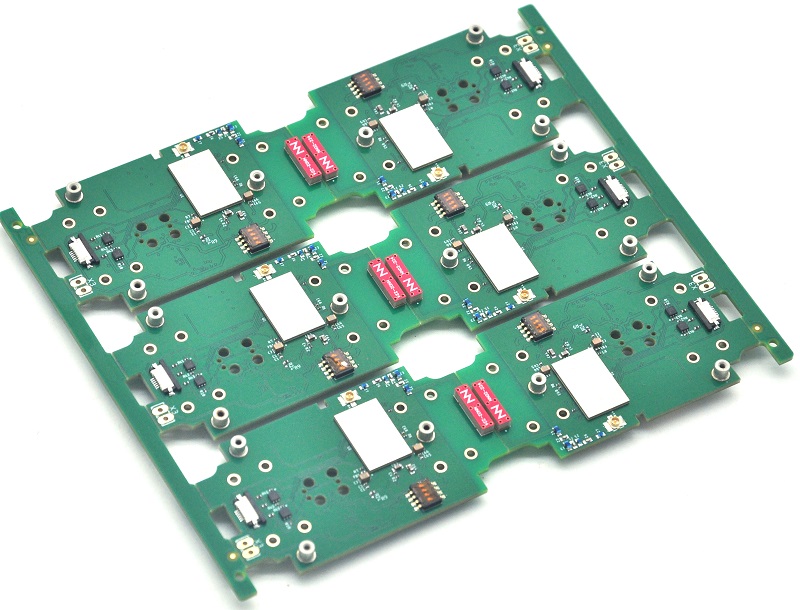

Case of PCBA Contract Manufacturing at EBest Circuit (Best Technology)

‚ÄčEBest Circuit (Best Technology) recently established a strategic partnership with a leading Swiss IoT monitoring solutions provider to manufacture high-reliability PCBA boards for their smart building and energy management systems. Our PCBA assemblies are widely used in the client’s ‚Äčenergy collaborative consumption projects (ZEV), ‚ÄčFlat Roof Monitoring System (Dach-Monitoring)‚Äč, and ‚ÄčFilter Monitoring System (Filter-Monitoring)‚Äč, which have been successfully deployed across residential, commercial, and industrial buildings throughout Europe.

Application Scenario 1: Distributed Energy Management System

The PCBA boards designed and assembled by EBest Circuit (Best Technology) are integral to the client’s energy collaborative consumption projects (ZEV), which enables intelligent management of solar energy sharing and metering in multi-tenant residential buildings. Our boards feature multi-channel data acquisition capabilities, support real-time processing of smart meter data, and drive energy visualization and automated billing interfaces through wired or wireless communication.

📌 Key Functions of our PCBA Boards:

- Multi-channel meter data acquisition and transmission

- Energy distribution and consumption logic control

- User-end data visualization support

- Remote communication and alarm functionality

Application Scenario 2: Flat Roof Monitoring System

The same client utilizes our PCBA boards in their ‚ÄčFlat Roof Monitoring System (Dach-Monitoring)‚Äč‚Äč for detecting water leakage and monitoring micro-climate conditions within flat roof structures. Our boards interface precisely with temperature and humidity sensors, transmit data reliably via LoRa networks, and trigger instant alerts through multi-channel notification systems when leaks are detected‚ÄĒeffectively preventing structural damage and significantly reducing maintenance costs.

📌 Technical Highlights:

- Low-power battery design supporting continuous operation for 8+ years

- Multi-protocol communication compatibility for complex building environments

- High-sensitivity water detection with rapid response time

Application Scenario 3: Predictive Filter Maintenance System

We also supplied PCBA boards for the client’s ‚ÄčFilter Monitoring System (Filter-Monitoring)‚Äč, which optimizes HVAC operations through predictive maintenance. The boards incorporate high-precision sensors to collect real-time data on filter pressure, temperature, and humidity, utilize intelligent algorithms for analysis, and automatically notify facility managers when replacements are needed‚ÄĒachieving efficient resource utilization and significant carbon emission reduction.

📌 System Benefits:

- Over 50% reduction in manual inspections and travel costs

- Dynamic maintenance scheduling avoiding unnecessary replacements

- Significant energy savings and CO‚āā emission reduction

Value Delivered by EBest Circuit (Best Technology):

- ‚ÄčHigh-Reliability Design: All PCBA boards comply with ISO 13485 medical device and IATF 16949 automotive electronics standards, suitable for demanding environments

- ‚ÄčFlexible Manufacturing Capabilities: Support for rigid, rigid-flex, and small-batch quick-turn PCB production to accommodate rapid product iterations

- ‚ÄčEnd-to-End Quality Control: Implementation of AOI, X-ray inspection, ICT testing, and multiple quality assurance processes ensuring long-term operational stability

- ‚ÄčSupply Chain Advantages: Leveraging local component supply networks and logistics capabilities to support agile delivery for European markets

Through this collaboration, EBest Circuit (Best Technology) has not only enhanced the functionality and reliability of the client’s IoT systems but also demonstrated our expertise in high-end industrial and building technology PCBA manufacturing, providing comprehensive solutions from design to mass production.

Where to Get China PCBA Contract Manufacturing?

Many global businesses search for PCB contract manufacturers or PCBA contract manufacturing. The challenge is not finding suppliers but finding the right one. EBest Circuit (Best Technology) combines:

- Certifications for automotive, medical, and aerospace projects.

- Engineering guidance at each stage.

- Strict quality control with modern inspection systems.

- Full turnkey EMS solution from PCB prototypes, fabrication, SMT assembly, and box build.

We reduce pain points such as unclear communication or inconsistent quality. Our goal is to build long-term trust with customers.

To sum up, China PCBA contract manufacturing has transformed global supply chains by providing cost-efficient, high-quality, and fast services. While there are many Chinese PCB manufacturers, not all offer the same level of reliability. EBest Circuit (Best Technology) stands out by addressing customer pain points such as delays, inconsistent quality, and lack of engineering guidance. We’re here to partner with you on your PCB and PCBA projects. Contact our sales team at sales@bestpcbs.com.