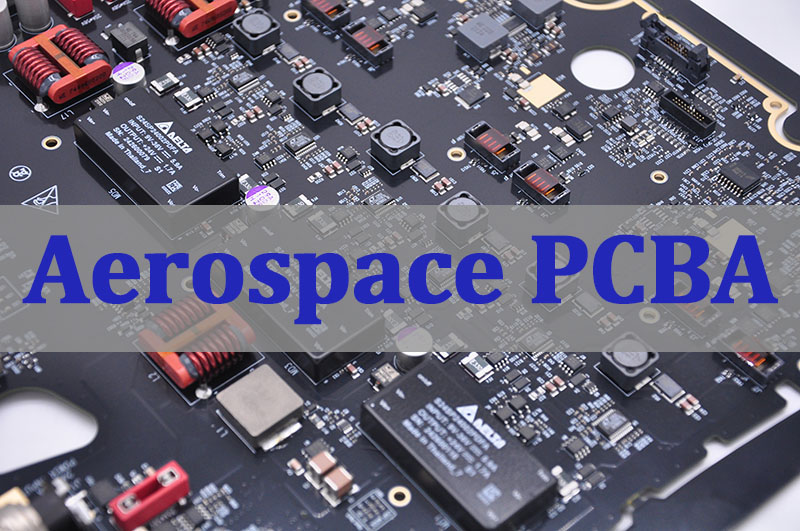

Aerospace PCBA plays a decisive role in avionics, satellite communication, and flight-control electronics where failure is not an option. This guide explains aerospace PCBA design, aerospace PCBA assembly processes, and how aerospace PCB manufacturers meet strict industry requirements through engineering-driven manufacturing.

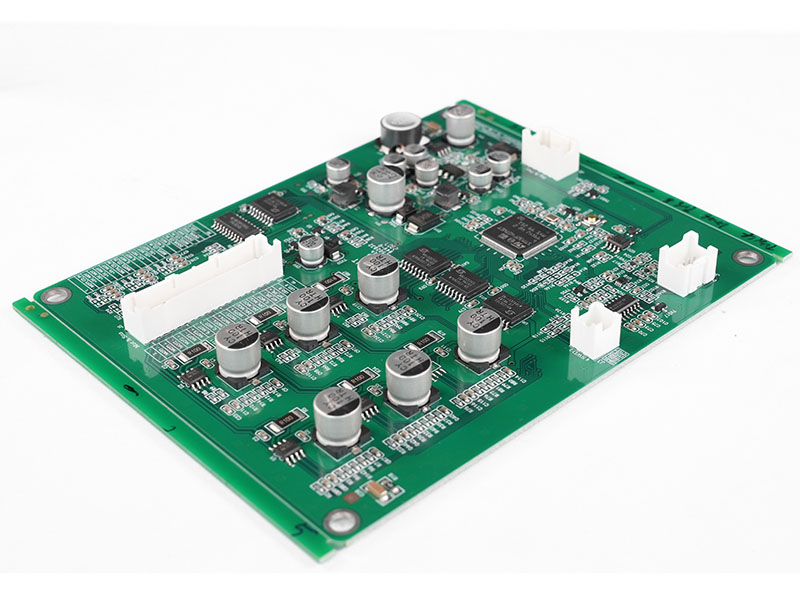

EBest Circuit (Best Technology) is a professional Aerospace PCB and PCBA manufacturer specializing in high-reliability electronics for mission-critical applications. All of our products including HDI board PCBA, heavy copper PCBA, high-speed PCBA, high-frequency PCBA, ceramic PCB assembly, and rigid-flex PCBA are built to aerospace-grade quality standards. Every project is fully customizable, with no minimum order quantity required.

To ensure smooth execution and on-time delivery, each project is assigned a dedicated project coordinator, so you never have to worry about schedule gaps or communication delays. As a fully integrated PCB and PCBA manufacturer with our own in-house facilities, we eliminate intermediaries and typically achieve a lead time of around 1.5 weeks. If you have any Aerospace PCB or SMT PCBA project requiring DFM analysis or a quotation, please contact us at sales@bestpcbs.com. Our pre-sales support team will respond within 12 hours.

What Is Aerospace PCBA?

Aerospace PCBA refers to circuit board assembly designed for aircraft, spacecraft, UAVs, and defense electronics. These assemblies operate under vibration, radiation exposure, extreme temperature cycling, and long mission lifetimes.

Why aerospace electronics demand higher standards

- Extended operating temperature ranges

- Zero-tolerance reliability expectations

- Strict lifecycle documentation

- High-mix, low-volume manufacturing

Unlike commercial electronics, aerospace PCBA prioritizes robustness over cost efficiency. Design decisions often emphasize redundant circuitry and conservative current margins.

Typical aerospace applications

- Flight control modules

- Navigation systems

- Radar processing boards

- Satellite communication units

- Power distribution assemblies

Aerospace PCBA Assembly vs Standard PCBA Assembly ÔÇö What Makes It Different

Aerospace PCBA assembly requires tighter process control compared to consumer electronics assembly.

Process differences engineers notice immediately

- IPC Class 3 workmanship standards

- Controlled solder joint inspection

- Full traceability for materials and operators

- Advanced X-ray and functional testing

| Aspect | Aerospace PCBA Assembly | Standard Assembly |

|---|---|---|

| Quality Level | IPC Class 3 | IPC Class 2 |

| Documentation | Full lifecycle traceability | Basic records |

| Testing | Functional + environmental | Functional only |

| Materials | High-reliability components | Commercial grade |

Aerospace PCB Design Standards Engineers Must Follow

Design rules are stricter because aerospace electronics operate in high-risk environments.

Core aerospace PCB design standards

- AS9100 quality management

- IPC-6012DS for rigid boards

- IPC-A-610 Class 3 assembly

- MIL-PRF performance specifications

Design considerations

- Controlled impedance routing

- Redundant power paths

- Thermal stress management

- Via reliability under vibration

Engineers designing aerospace PCB layouts often adopt conservative copper spacing and thicker plating to improve long-term durability.

What Certifications Should Aerospace PCB Manufacturers Hold

Not every PCBA supplier qualifies as an aerospace SMT assembly manufacturer. Certifications signal process maturity and risk control capability.

Key certifications to evaluate

- AS9100D aerospace quality system

- ISO9001 quality management

- IPC Class 3 manufacturing capability

- Material traceability systems

Reliable aerospace PCB manufacturers maintain complete batch records, enabling rapid root-cause analysis when issues arise.

Materials Used in Aerospace PCBA for Extreme Environments

Material selection directly affects reliability in aerospace applications.

Common aerospace substrate choices

- High-Tg FR-4 for standard avionics

- Polyimide for thermal stability

- Rogers RF laminates for communication systems

- Ceramic substrates for power modules

Why material selection matters

- Thermal expansion control

- Radiation resistance

- Mechanical durability

- Signal integrity at high frequency

Choosing aerospace-grade laminates reduces delamination risks during temperature cycling.

Aerospace PCBA Testing Methods for Mission-Critical Electronics

Testing is one of the most expensive but essential stages in aerospace PCBA assembly.

Typical aerospace testing workflow

- Automated optical inspection (AOI)

- X-ray inspection for BGA joints

- In-circuit testing (ICT)

- Functional testing

- Environmental stress screening

Burn-in and reliability validation

Burn-in testing exposes early component failures before deployment. Aerospace programs often require extended burn-in durations to verify long-term stability.

Common Failure Risks in Aerospace Electronics and How to Prevent Them

Even well-designed boards can fail if environmental stress is underestimated.

Major aerospace PCBA failure risks

- Solder joint fatigue from vibration

- Thermal cycling cracks

- Component obsolescence

- Moisture ingress

Prevention strategies engineers apply

- Underfill for large BGAs

- Conformal coating

- Redundant circuitry

- Lifecycle component sourcing

Proactive design review reduces redesign costs later in the program lifecycle.

Cost Factors Behind Aerospace PCBA Assembly Projects

Aerospace PCBA assembly pricing differs significantly from commercial electronics manufacturing.

Primary cost drivers

- Low production volumes

- Specialized inspection requirements

- Engineering documentation

- Certified material sourcing

| Cost Element | Impact Level |

|---|---|

| Engineering review | High |

| Testing procedures | High |

| Materials | Medium |

| Assembly labor | Medium |

Higher upfront engineering investment often lowers long-term maintenance costs.

Prototype vs Production Aerospace PCBA ÔÇö What Engineers Should Know

Prototype aerospace boards focus on validation, while production boards emphasize repeatability.

Prototype stage priorities

- Fast iteration cycles

- DFM optimization

- Electrical validation

Production stage priorities

- Process stability

- Documentation control

- Supply chain continuity

Working with aerospace PCB manufacturers capable of supporting both phases reduces communication gaps.

How to Choose Reliable Aerospace PCB Manufacturers

Supplier selection is one of the most critical decisions in aerospace electronics projects.

Evaluation checklist

- Proven aerospace project experience

- AS9100D certification

- Advanced testing capability

- Transparent traceability system

Engineering support quality often matters more than the lowest quoted price.

Future Trends in Aerospace PCBA Manufacturing and Miniaturization

Aerospace electronics continue evolving toward lighter, smaller, and more power-efficient designs.

Emerging trends

- HDI and microvia structures

- Embedded components

- High-frequency RF integration

- Digital traceability systems

Miniaturization drives tighter design rules and advanced manufacturing techniques.

In summary, aerospace PCBA demands strict design standards, certified manufacturing processes, and advanced testing to ensure mission-critical reliability in harsh environments.

We provide aerospace PCBA solutions supported by experienced engineering teams and integrated manufacturing capabilities. With advantages such as a professional technical team full-process service, AS9100D-aligned quality management, and one-stop PCB fabrication plus aerospace PCBA assembly, we help engineers move from prototype to production with confidence. For project inquiries or orders, contact us at sales@bestpcbs.com.

FAQs About Aerospace PCBA

What makes aerospace PCBA assembly more expensive?

Higher inspection standards, certified materials, and detailed documentation increase overall cost but significantly improve reliability.

Do aerospace PCB manufacturers require AS9100 certification?

Most aviation projects require AS9100D compliance to ensure manufacturing consistency and traceability.

Which materials are best for aerospace PCB design standards?

Polyimide laminates, high-Tg FR4, and RF substrates are commonly used depending on thermal and signal requirements.

Can aerospace PCBA be prototyped quickly?

Yes, but rapid builds still require Class 3 inspection and engineering validation to meet reliability expectations.