Chinese PCB manufacturers dominate the global market with their competitive pricing, advanced technology, and fast production capabilities. As one of leading Chinese PCB maker, EBest Circuit (Best Technology) offers a wide range of PCB solutions whether you’re looking for small-batch prototypes or large-scale production. There are numerous cheap Chinese PCB manufacturer available, choosing the right one requires careful evaluation. This article provide you with printed circuit board manufacturers list, to help you find the reliable Chinese PCB manufacturers to suit your project.

Located in Shenzhen, EBest Circuit (Best Technology) provides manufacturing and sale service of various types of printed circuit boards and assembly. During the 18 years, EBest Circuit (Best Technology) focused on oversea market and implemented the professional separation of sales and production. So that we can provide more efficient service to customer and going to be one of the most reliable PCB manufacturers in China. Warmly welcome to contact us at sales@bestpcbs.com for any custom PCB projects of any quantity, from small to large volumes.

Top Chinese PCB Manufacturers

China is home to some of the worldâs leading PCB manufacturers. These companies provide various options, from prototypes to high-volume production. Here are the top 10 PCB manufacturers in China:

- 1. EBest Circuit (Best Technology) Co., Limited: A leader in high-quality PCBs manufacturing includes multilayer FR4 PCB, ceramic PCB, metal core PCBs, PCB assembly. Offers rapid PCB prototyping and assembly services.

- 2. Shenzhen Kinwong Electronic Co., Ltd.: A top supplier known for advanced PCB solutions and reliability.

- 3. Suntak PCB: Offers high-precision circuit boards for industrial and consumer electronics.

- 4. Victory Giant Technology: Well-known for producing high-end PCBs for global customers.

- 5. Aoshikang Technology: Focuses on high-frequency and high-speed PCBs.

- 6. Shennan Circuits: Supplies PCBs to aerospace, medical, and telecommunications industries.

- 7. Jiangxi Copper (JCC): A company in PCB copper materials and circuit board production.

- 8. Wuzhu Technology: Specializes in quick-turn and HDI PCB solutions.

- 9. Sihui Fuji Electronics Technology: Provides a balance of cost and performance in PCB manufacturing.

- 10. Shenzhen Fastprint: Offers PCB, IC substrate, FPC, semiconductor test board products.

How Do I Find the Best Manufacturer in China?

Finding the best manufacturer in China requires a mix of research, due diligence, and relationship-building. Below is a step-by-step guide to streamline your search while ensuring quality and reliability:

â1. Define Your Product Requirementsâ

- Specificationsâ: Materials, dimensions, certifications (e.g., ISO, CE), and compliance standards.

- Volumeâ: Estimate order quantities to target manufacturers that align with your scale.

- Budgetâ: Balance cost with qualityâavoid prioritizing low prices alone.

This clarity helps filter manufacturers that meet your needs and reduces miscommunication later.

â2. Leverage Trusted Sourcing Platformsâ

Use established B2B platforms to shortlist candidates:

- Alibaba.comâ: Filter verified suppliers with âGold Supplierâ or âTrade Assuranceâ badges.

- Global Sourcesâ: Focus on exporters with audited profiles.

- Made-in-Chinaâ: Ideal for niche industries or custom products.

- Exhibition: Attend trade shows like the Canton Fair to meet PCB suppliers face-to-face. Keep regular communication which fosters trust.

It is recommended to Look for suppliers with â„3 years of operation and consistent reviews.

â3. Verify Credibilityâ

- Requesting Business Licensesâ: Legitimate manufacturers will provide a Chinese business license.

- Checking Export Experienceâ: Ask for past client references in your region.

- Third-Party Inspectionsâ: Hire agencies like SGS or Bureau Veritas to audit facilities or test samples.

- Visit Factoriesâ: If feasible, tour facilities to assess equipment, workflows, and working conditions. For remote vetting, schedule a video walkthrough.

â4. Request Samples

- Request Samplesâ: Test functionality, durability, and packaging.

â5. Mitigate Supply Chain Risksâ

- Draft Clear Contractsâ: Include IP protection, penalties for delays, and quality clauses.

- Start Smallâ: Place a trial order before committing to large volumes.

- Use Secure Paymentsâ: Opt for escrow services (e.g., Alibaba Trade Assurance) or letters of credit (L/C).

- Stay Updatedâ: Monitor tariffs, shipping costs, and regulations (e.g., Chinaâs customs policies).

By combining thorough research with proactive verification, youâll minimize risks and partner with a manufacturer that delivers consistent quality and aligns with your business goals.

Who Makes Fast Turnaround PCBs?

For urgent projects, selecting a China PCB manufacturer that specializes in fast delivery is essential. EBest Circuit (Best Technology) is known for quick turn services.

We always do right things and then do things right, so that we can complete any project quickly & efficiently. We always reply email within 12 hours so that make our customers feeling like doing business with the neighbor. Focusing on electronics & circuit board industry, EBest Circuit (Best Technology) provide one-stop service from designing, DFM, fabrication of all type of printed circuit boards (from MCPCB, ceramic PCB, FR4 PCB, special PCB), to components purchasing, PCBA (SMT) and box assembly, we also provide suitable solution for our customers that help to save time & money of them, and then become the most reliable Chinese PCB manufacturer r of them.

If you need PCB prototype, pls feel free to reach out to EBest Circuit (Best Technology) at sales@bestpcbs.com at any time. EBest Circuit (Best Technology) provides rapid prototypes within 24-48 hours. We have offered more than 1,200 customers in more than 60 countries & areas the fast turnaround PCBs service. We provide both normal delivery service and fast service, and urgent boards can be shipped out within 24 hours!

What Is EBest Circuit (Best Technology) Co., Limited China?

Founded in 2006, EBest Circuit (Best Technology) is one of a direct Chinese PCB manufacturers with in-house production capabilities, own certificate like ISO 9001, ISO 13485, IATF 16949, AS9100D. We specialize in various PCBs, including:

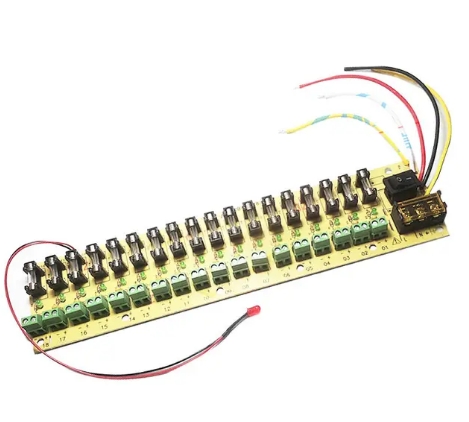

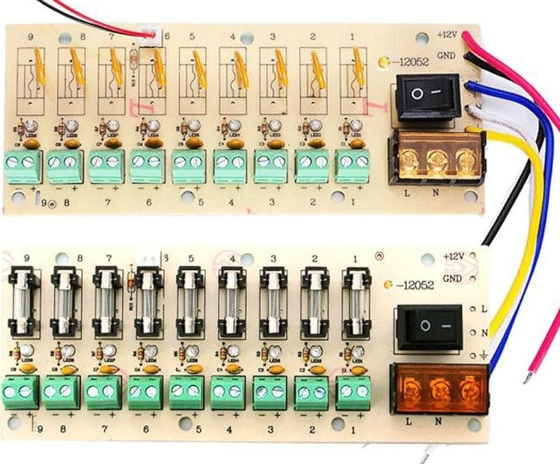

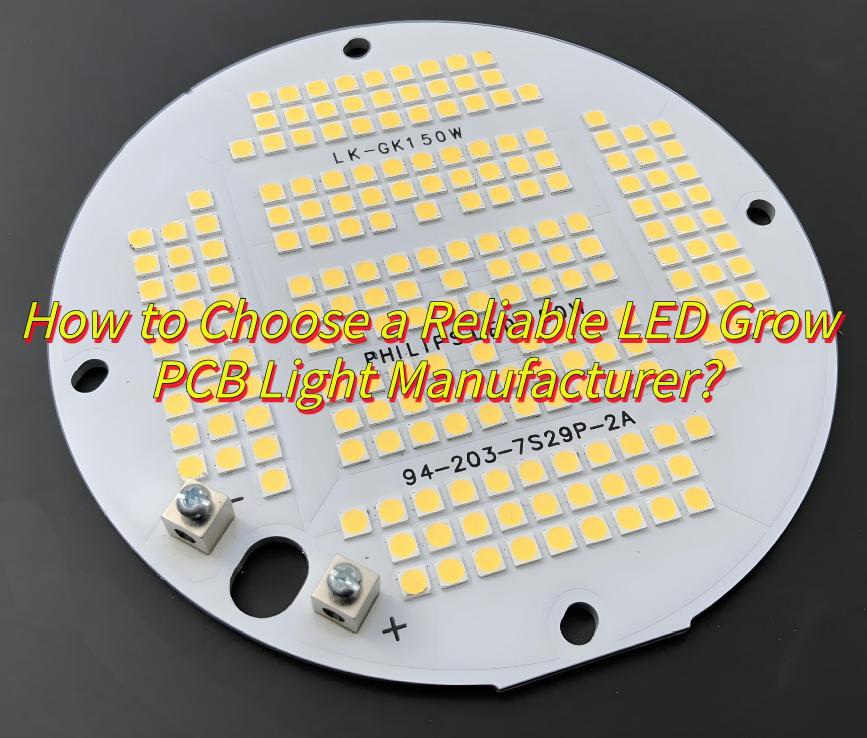

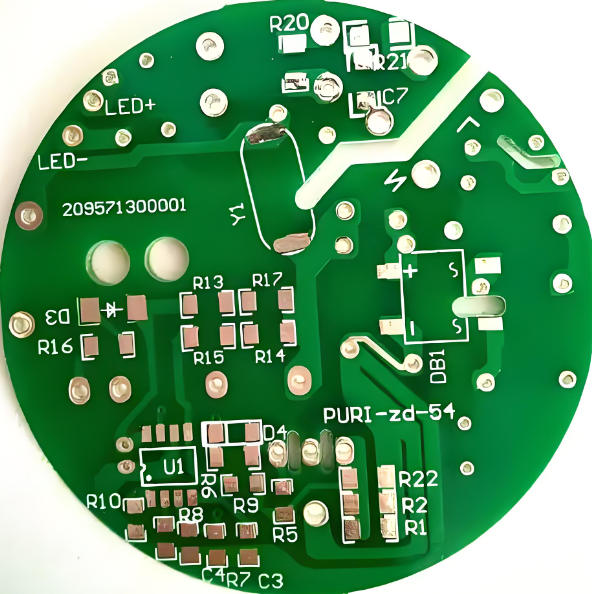

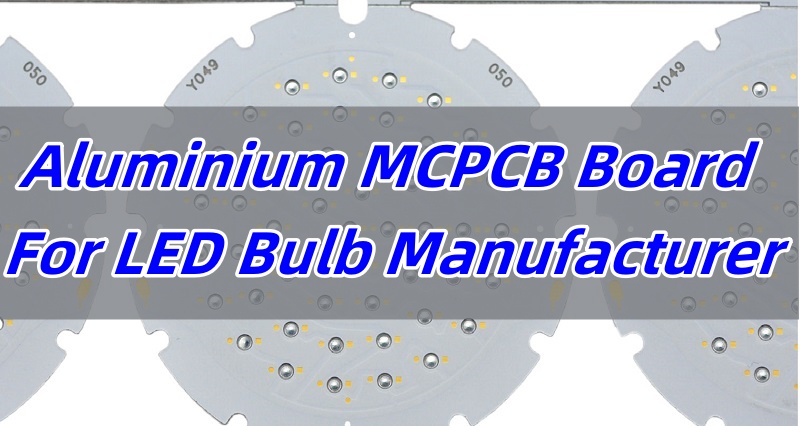

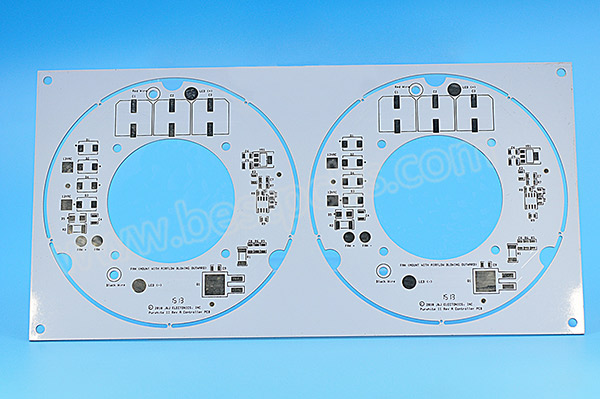

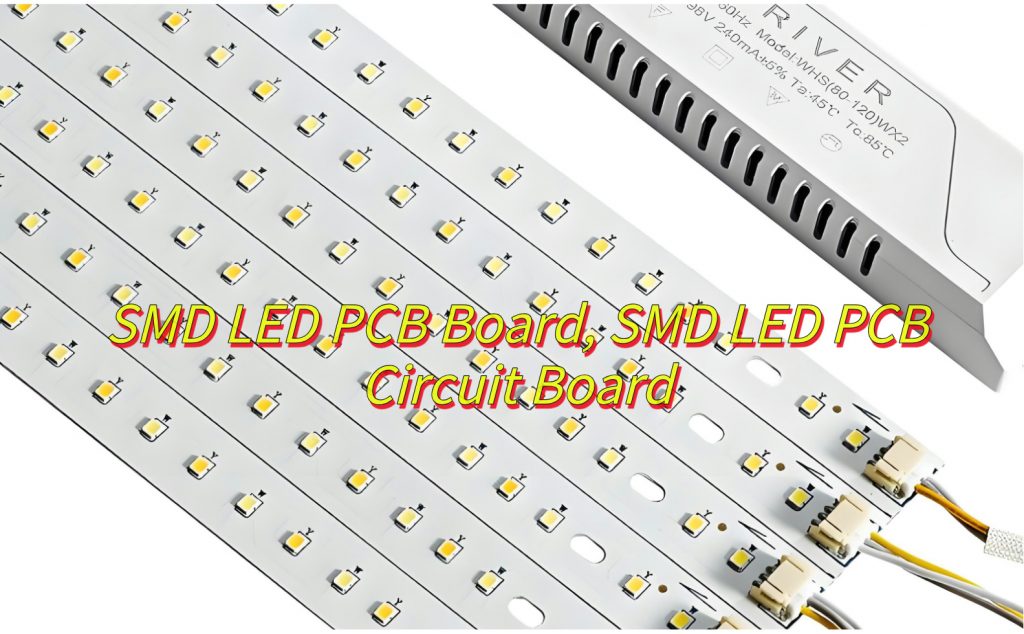

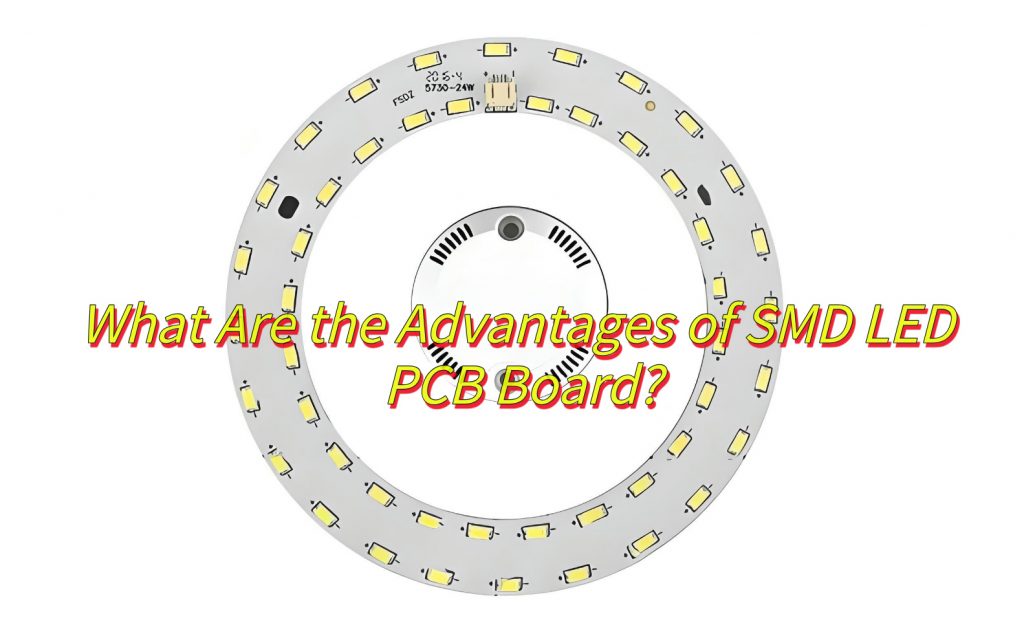

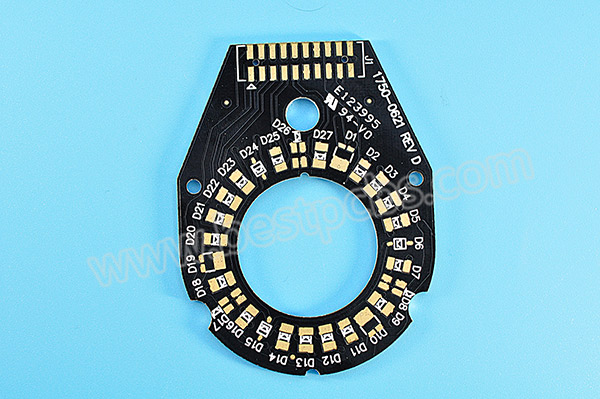

- Metal Core PCBs: Includes single-layer metal core PCB, two-layer aluminum base PCB, multilayer aluminum based PCB, double-sided metal core PCB.

These are ideal for LED applications (e.g., automotive headlights, outdoor displays) due to excellent heat dissipation.

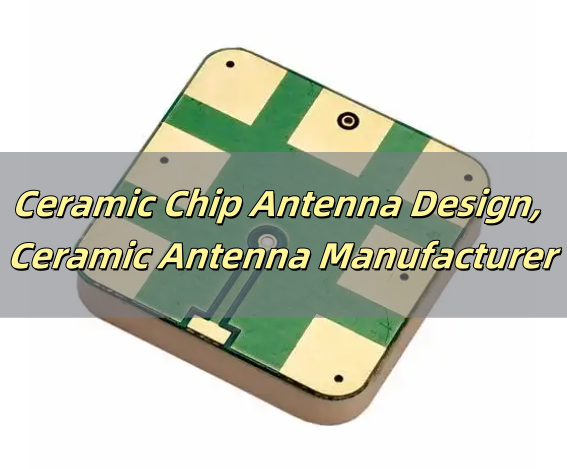

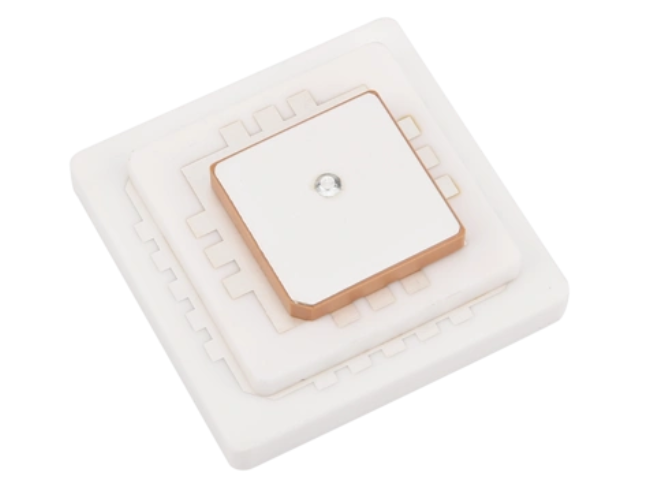

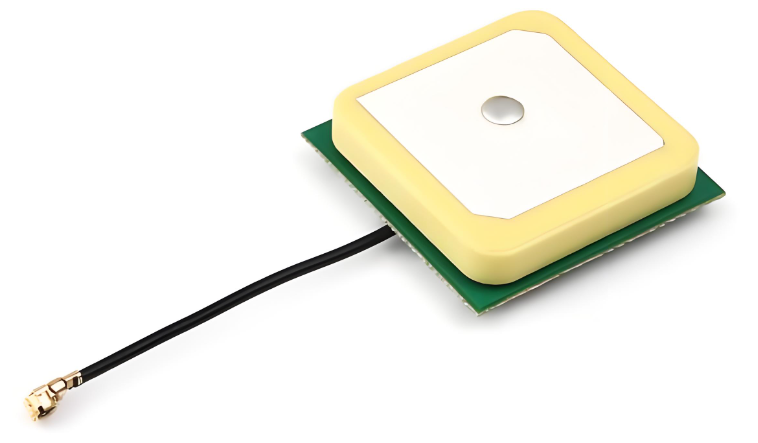

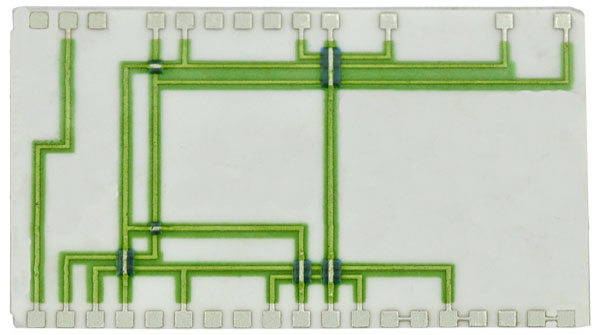

- Ceramic PCBs: Includes thick film PCB, thin film PCB, DPC PCB, DBC/DCB PCB, AMB PCB, LTCC PCB, HTCC PCB.

These are High thermal conductivity for RF communicationsâ (5G base stations, radar systems) and power electronics (IGBT modules, new energy vehicle control systems), and âaerospaceâ applications.

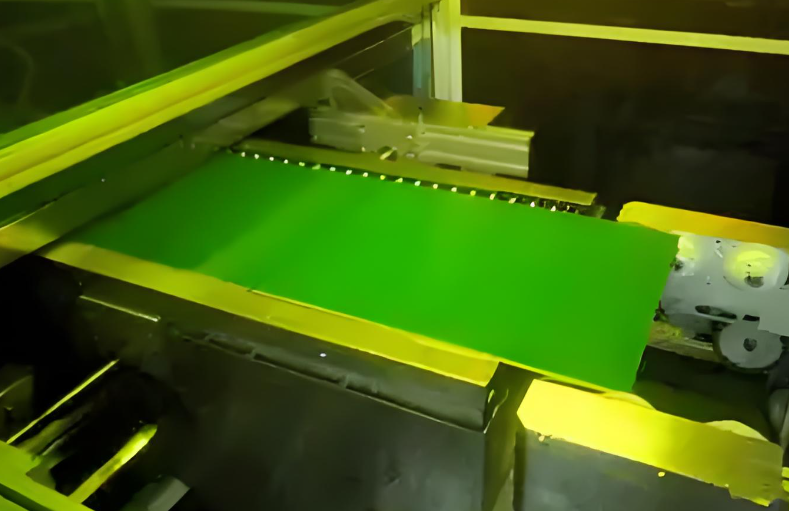

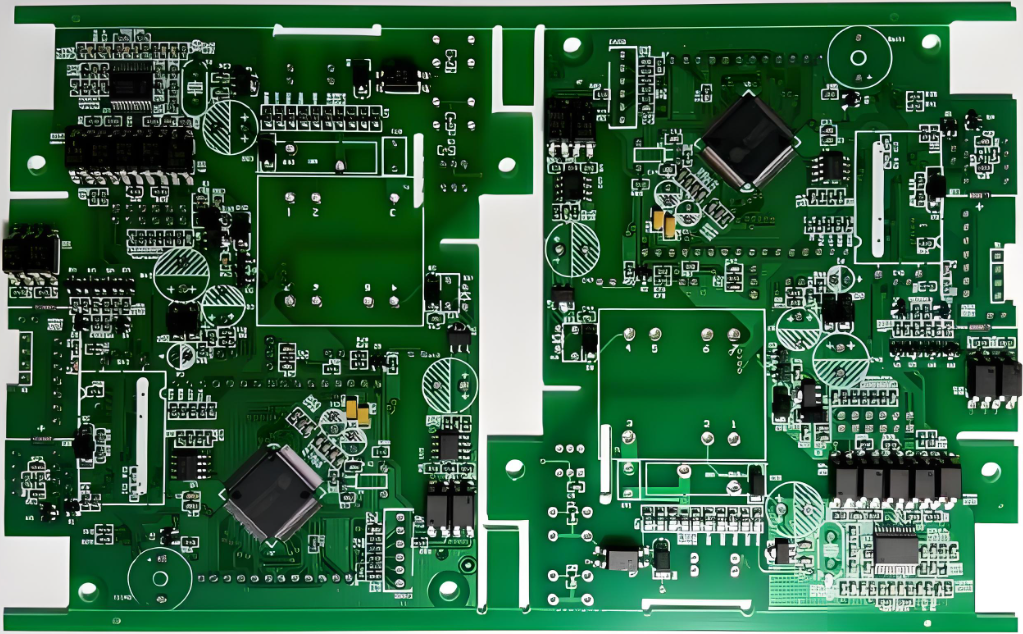

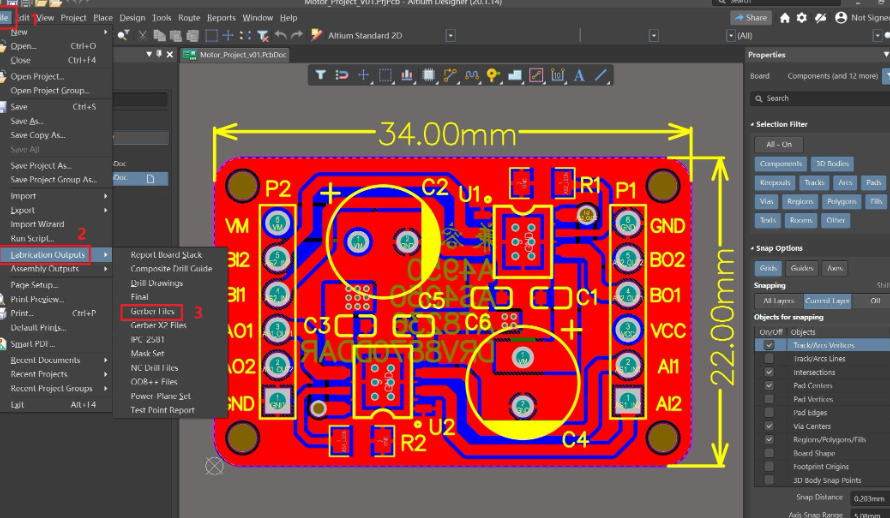

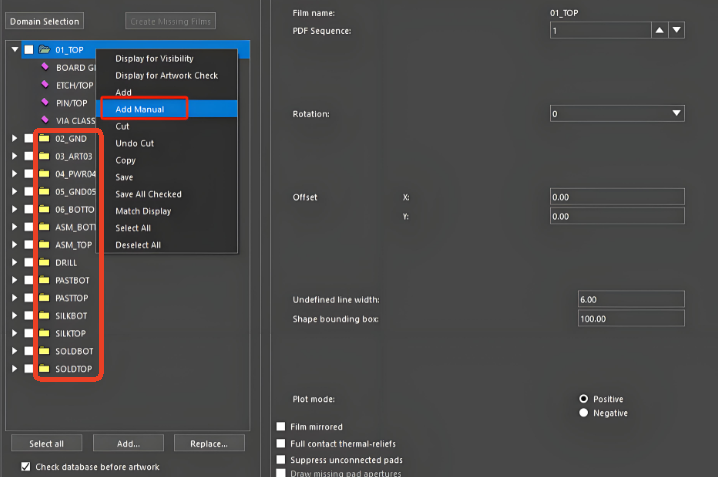

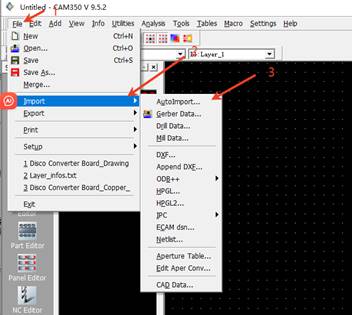

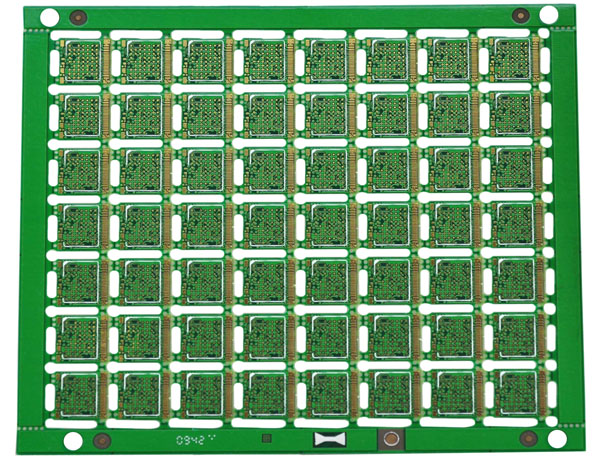

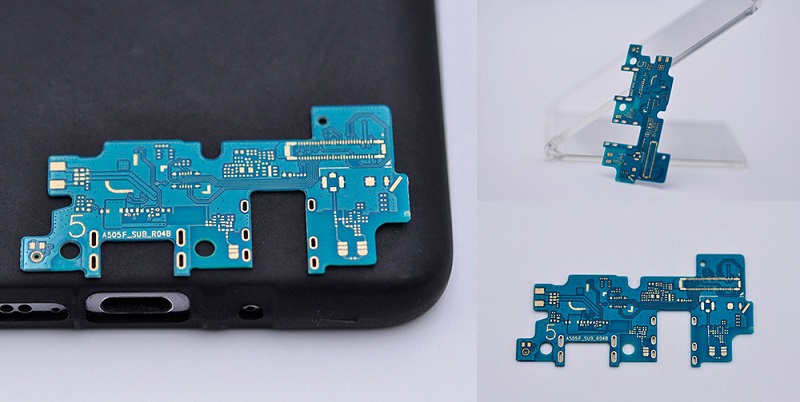

- Printed Circuit Boards: Includes single sided PCB, multi-layer PCB, semi rigid flex PCB, RF PCB.

These are suitable for âconsumer electronicsâ (smart home devices, wearables), âindustrial controlsâ (PLCs, sensors), and âcommunication equipmentâ (routers, switches), balancing cost-effectiveness and performance optimization.

- Special PCBs: Providing custom PCBs like busbar PCB, IC substrate, HDI PCB, extra thin PCB, heavy copper PCB, high Tg PCB, high speed PCB, impedance control PCB.

These meet stringent reliability requirements in âautomotive electronicsâ (ADAS systems, battery management), âmedical devicesâ (imaging diagnostics, portable monitors), and âmilitary equipmentâ (precision guidance, anti-interference systems).

All our above PCB products can be customized to suit your needs, all our PCBs are compliant to REACH, RoHS. Let you no worries about the quality. Currently our mouthy capability is 260,000 square feet (28,900 square meter), more than 1,000 different boards will be completed. EBest Circuit (Best Technology) focus on quality, innovation, and customer satisfaction. We provide fast turnaround service, so that urgent boards can be shipped out within 24 hours.

How to Compare Prices: Chinese vs. Non-Chinese PCB Manufacturers?

Comparing pricing between Chinese PCB manufacturers and global competitors helps in making informed decisions. Hereâs what to consider:

- 1. Material Costs: China often has lower raw material costs, reducing overall expenses.

- 2. Labor Costs: Manufacturing in China is more cost-effective than in Europe or North America.

- 3. Technology & Equipment: Leading Chinese PCB makers use advanced technology while maintaining competitive prices.

- 4. Shipping & Tariffs: Factor in logistics and import duties when comparing global prices.

- 5. Lead Time: Chinese suppliers often have faster production due to efficient supply chains.

In general, China PCB manufacturers offer better pricing without compromising on quality.

What Are the Benefits of Choosing a Chinese PCB Manufacturer?

Selecting a Chinese PCB manufacturer provides several advantages:

- Cost-Effective Production: Lower manufacturing costs lead to competitive pricing.

- Advanced Technology: Many factories use cutting-edge equipment for high precision.

- Scalability: Handles small to mass production with flexibility.

- Fast Prototyping: Quick turnaround times for new product development.

- Global Supply Chain: Strong logistics networks ensure smooth international shipping.

- Customization: Tailored PCB solutions for various industries.

Chinese PCB manufacturers continue to be a preferred choice for companies worldwide.

How to Choose a PCB Manufacturer?

When selecting a Chinese PCB manufacturer, keep these points in mind:

- 1. Industry Experience: Look for companies with a strong track record.

- 2. Quality Standards: Ensure compliance with international certifications.

- 3. Customization Ability: The manufacturer should meet specific design needs.

- 4. Customer Service: A responsive team can resolve issues quickly.

- 5. Production Capacity: Choose a supplier that can scale with your business.

- 6. Pricing & Lead Time: Find a balance between cost and delivery speed.

In conclusion, Chinese PCB manufacturers offer a mix of affordability, quality, and advanced technology. Whether you need good price and quality mix lamination PCB from Chinese manufacturers or a fast-turnaround prototype, there are plenty of options. Research thoroughly, compare suppliers, and choose a manufacturer that aligns with your requirements.

By partnering with the right Chinese PCB manufacturers, you can ensure cost-effective, high-quality solutions for your electronic projects. If youâre looking for reliable PCB production, EBest Circuit (Best Technology) Co., Limited is a strong choice with proven expertise in the industry. Just feel free to contact us at sales@bestpcbs.com for any PCB specification or PCB quotations.