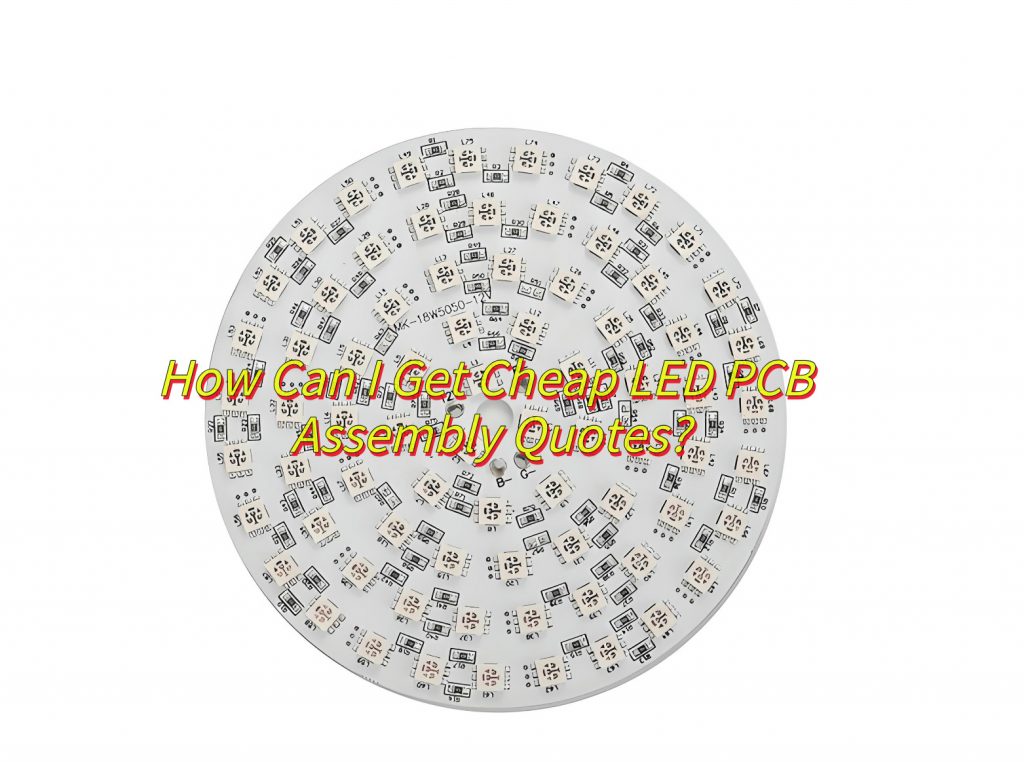

Are you looking for a good LED PCB Mount service? In this blog, Let’s learn the types, infrared benefits, automated solutions of LED PCB Mount, and tips for choosing LED PCB Mount manufacturers.

Choose EBest Circuit (Best Technology) for your LED PCB mount needs. We excel in premium material selection, offering thermally optimized solutions tailored to your requirements. Our state-of-the-art engineering ensures ±0.05mm tolerances, guaranteeing seamless LED integration and superior heat dissipation. Rigorous thermal testing and simulations validate every design, ensuring peak performance. Compliant with UL, CE, and RoHS standards, our solutions meet global safety and environmental benchmarks. Plus, our scalable production and responsive support make us the ideal partner for projects of any size. Contact us today for a quote: sales@bestpcbs.com

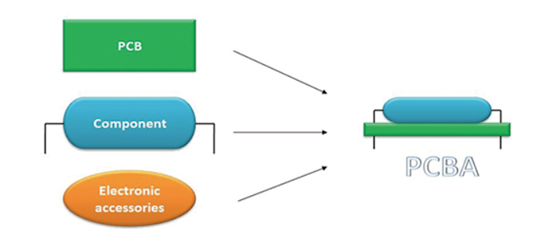

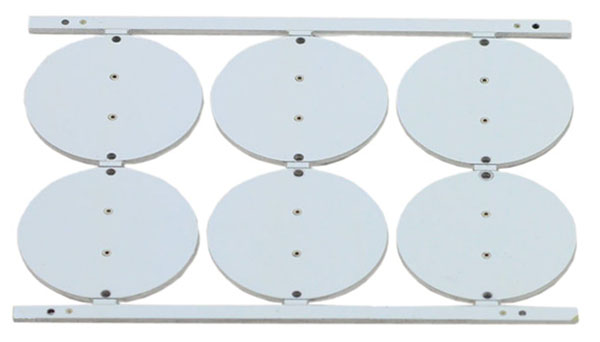

What is LED PCB Mount?

An âLED PCB mountâ refers to a light-emitting diode (LED) designed to be securely attached to a printed circuit board (PCB). These components are integral to modern electronics, combining the LEDâs light-generating capabilities with the PCBâs ability to provide electrical connections, structural support, and thermal management.

What Are the Types of LED PCB Mounting?

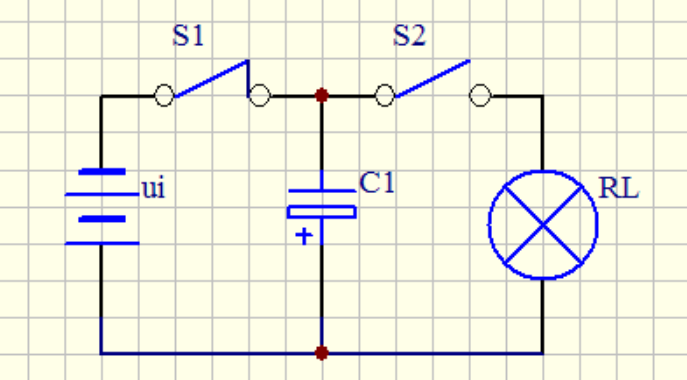

LED PCB mounting methods vary by technical approach, each suited to specific needs:

- Through-Hole (DIP)â-LEDs mounted via pins in drilled PCB holes; manual assembly, low cost, suited for basic indicators.

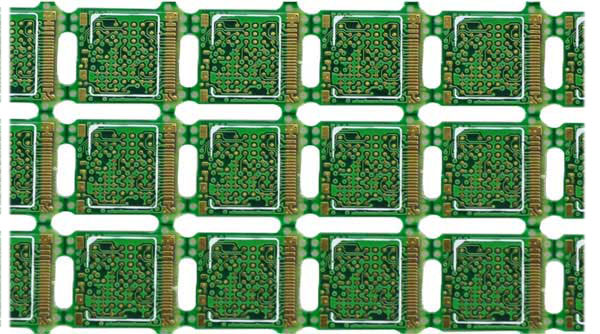

- Surface-Mount (SMT/SMD)â-Automated soldering onto PCB surface; compact, high-density, dominant in electronics/displays.

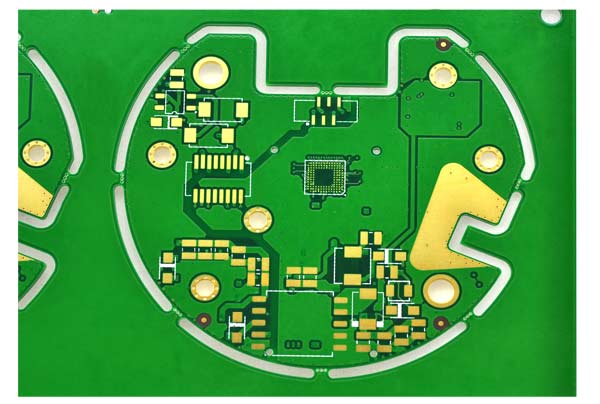

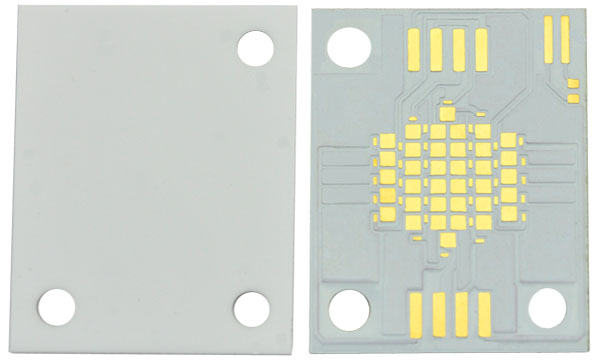

- Chip-on-Board (COB)â-Bare dies bonded to PCB and resin-coated; high brightness, uniform light for commercial/auto lighting.

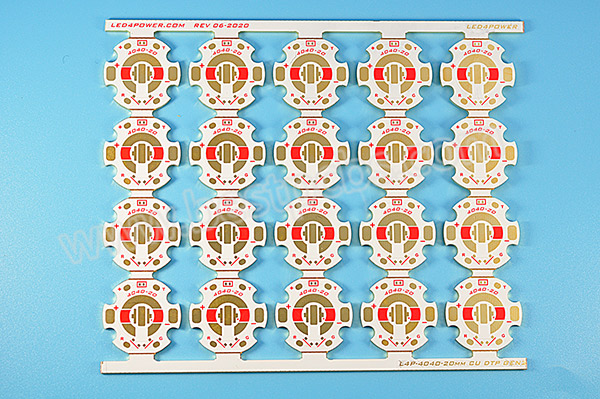

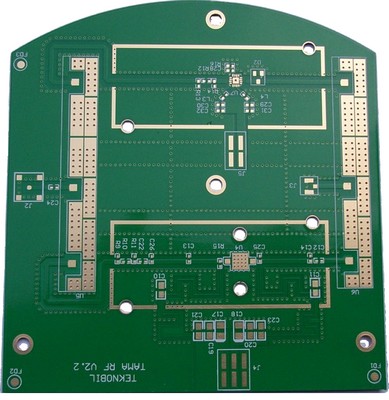

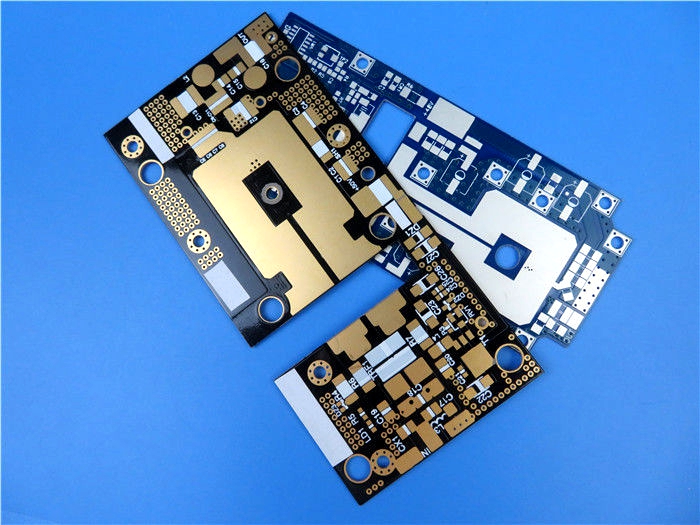

- Metal-Core PCB (MCPCB)â-Aluminum/copper substrates for high-power LEDs; superior heat management in streetlights/auto headlights.

- Flip-Chipâ-Dies mounted upside-down with solder bumps; reduces resistance, improves thermal/electrical performance.

- Integrated Modulesâ-Pre-built units with LEDs, drivers, and optics; plug-and-play for smart lighting/IoT systems.

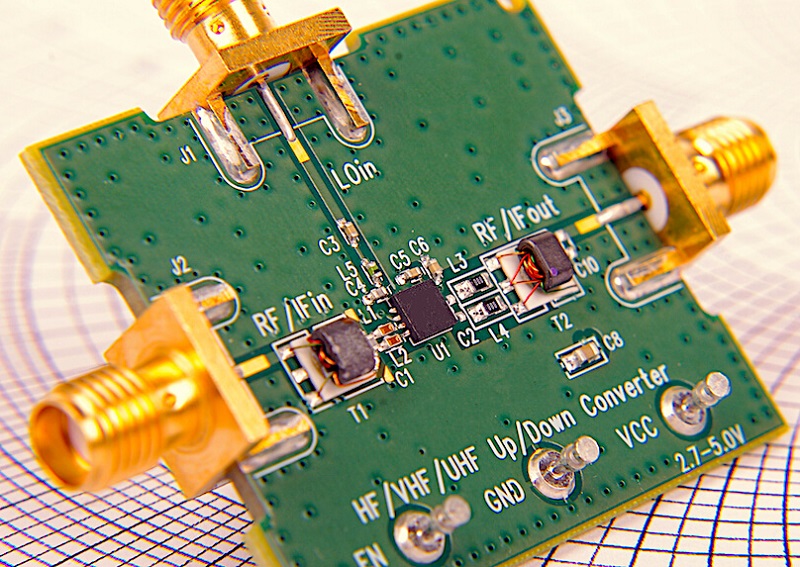

What Are the Benefits of Infrared LED PCB Mounts?

- Superior Heat Dissipationâ: Metal-core PCBs (e.g., aluminum) manage high heat from IR LEDs, ensuring stable performance and extended lifespan in thermal-sensitive applications.

- Robust Performance in Harsh Environmentsâ: Durable mounting (e.g., SMT/COB) and corrosion-resistant materials withstand vibrations, humidity, and extreme temperatures for industrial/outdoor use.

- Miniaturized Design & Scalabilityâ: SMT enables compact, high-density layouts for space-constrained devices, while automated production cuts costs for mass-market adoption.

- High Signal Consistencyâ: Precision mounting minimizes electrical noise, ensuring reliable IR output for communication (e.g., remote controls, LiDAR).

- Customizable Optical Outputâ: Tailored PCB designs optimize wavelength focus (e.g., 850nm/940nm) for biometrics, surveillance, or medical systems.

What Are Removable LED PCB Mount Connectors For?

- Modular Maintenance & Upgrades-Replace or upgrade LED modules without soldering, drastically reducing system downtime.

- Flexible System Design-Reconfigure LED layouts (color, brightness) by swapping modules, adapting to dynamic needs.

- Hot-Swappable Reliability-Replace faulty units during operation, ensuring continuous performance in critical applications.

- Simplified Inventory-Standardize connectors across products to minimize stock complexity and costs.

- Cost-Efficient Repairs-Fix issues by replacing only damaged modules, avoiding waste of entire PCBs.

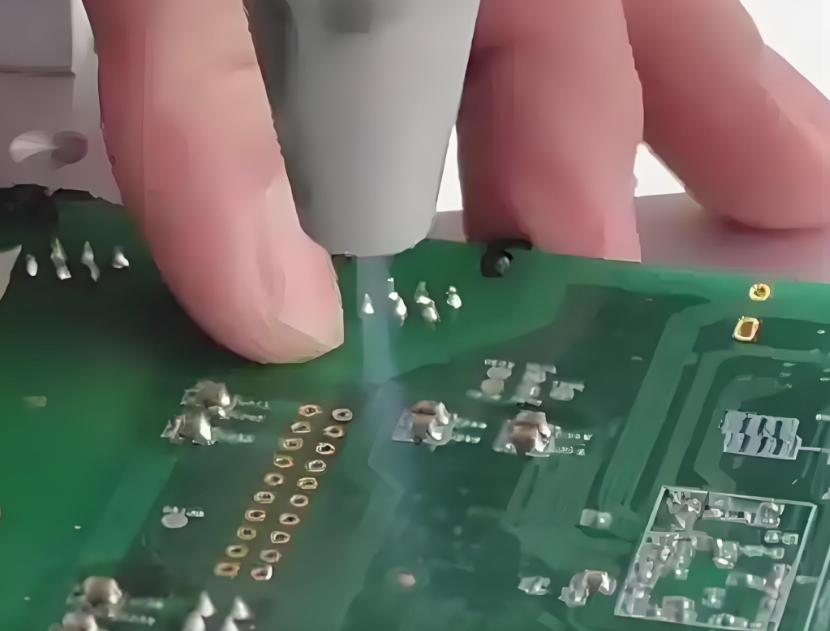

Whatâs the Best Way to Mount LEDs on PCBs?

The optimal method to mount LEDs on PCBs depends on specific application requirements but generally prioritizes these factors:

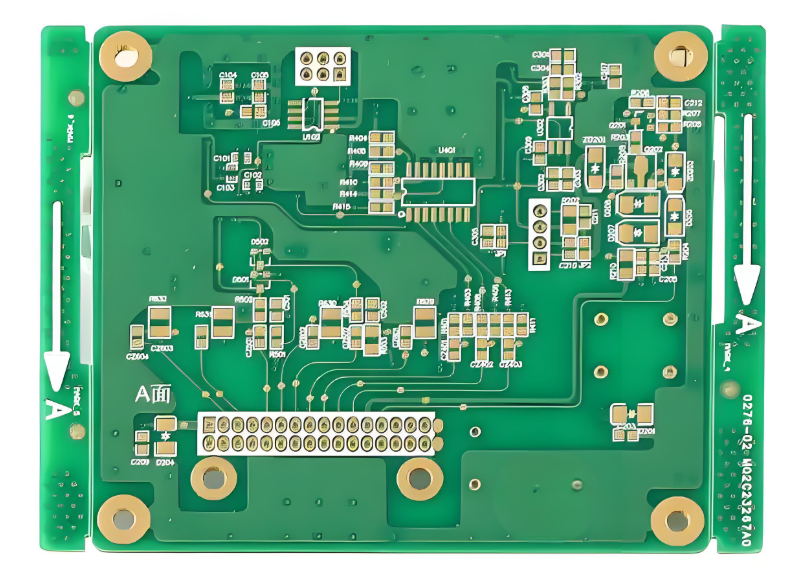

Thermal Management Integration

- Use SMT or THT mounting with thermally conductive pads/vias to channel heat away from LEDs.

- For high-power LEDs, attach external heatsinks via screw mounts or thermal adhesives.

Mechanical Stability

- Employ press-fit connectors to protect against vibration/shock in harsh environments.

- Use underfill epoxy for SMD LEDs on flexible PCBs to prevent solder joint failure.

Serviceability & Upgrades

- Implement modular magnetic or plug-in connectors for tool-free maintenance.

- Design symmetrical layouts with standardized footprints to simplify component swaps.

EMC Compliance

- Isolate LED drivers using grounded shielding cans or dedicated PCB layers.

- Route high-speed traces away from LED power circuits to minimize EMI.

Manufacturing Efficiency

- Opt for SMT for automated assembly lines, reserving THT for heavy-duty components.

- Use pick-and-place fiducial markers to improve placement accuracy during reflow.

Optical Performance

- Angle LEDs strategically using reflective PCB solder masks or integrated lenses.

- Maintain consistent phosphor coating thickness in white LEDs through controlled dispensing.

How Do You Choose LED PCB Mount Manufacturer?

When selecting an LED PCB mount manufacturer, prioritize these five critical factors:

- Material Expertise-Verify they use high-quality, thermally conductive materials (e.g., aluminum, copper alloys) and offer customization for specific thermal requirements.

- Precision Engineering-Ensure their machining/casting processes meet tight tolerances (±0.05mm) to ensure proper LED alignment and heat dissipation.

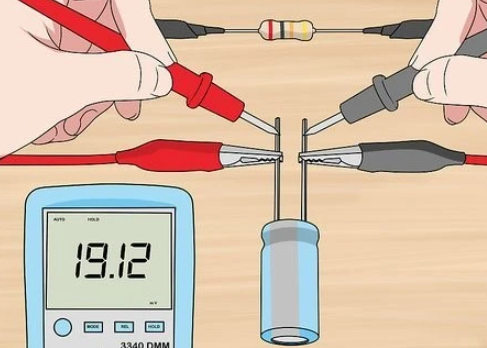

- Thermal Testing Capabilities-Confirm they perform thermal simulations and real-world testing (junction temperature monitoring) to validate designs.

- Compliance Certifications-Check for certifications like UL, CE, and RoHS to ensure adherence to electrical safety and environmental standards.

- Scalability & Support-Choose manufacturers with automated production lines for volume orders and responsive engineering support for custom designs.

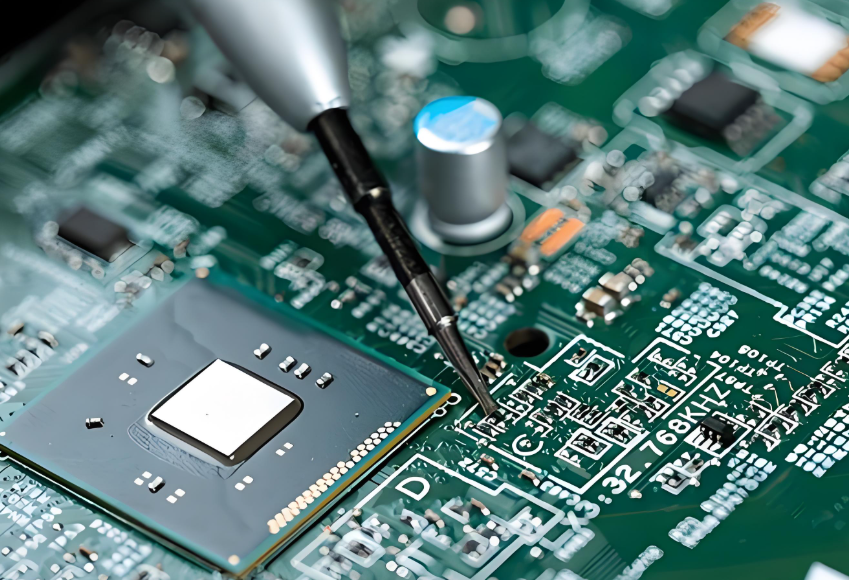

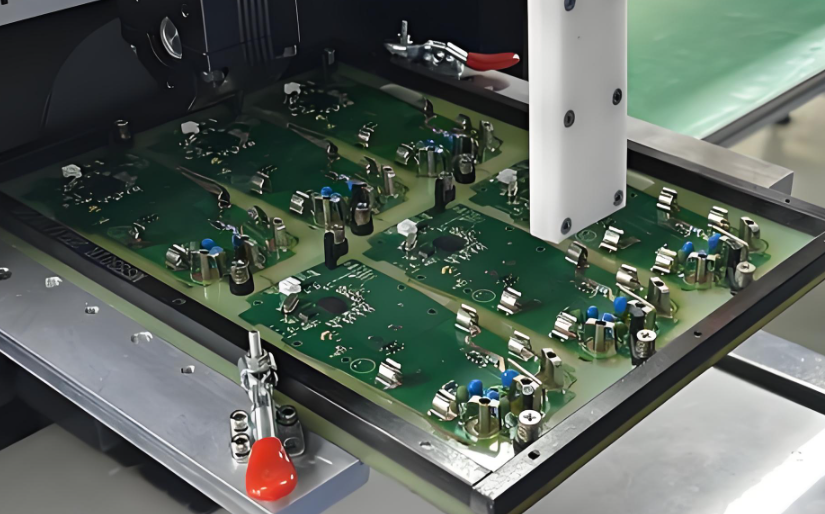

How Do Automated Machines Improve LED PCB Mount?

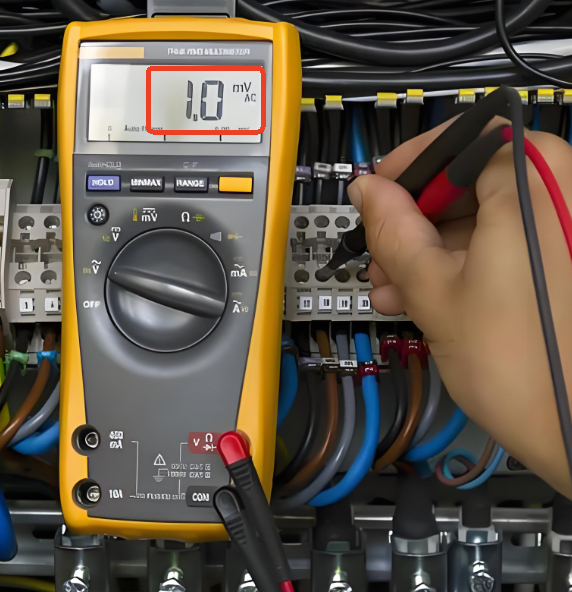

Precision Enhancementâ

- Machine vision systems align components within ±0.01mm tolerance.

- Automated optical inspection (AOI) detects defects like tombstoning or misalignment, reducing manual rework by 90%.

Speed & Efficiencyâ

- High-speed SMT machines place over 25,000 components per hour.

- Integrated UV-LED curing reduces bonding time to under 3 seconds per PCB.

Quality Consistencyâ

- X-ray inspection ensures solder joint integrity for critical applications.

- Programmable controls standardize parameters (solder paste volume, pressure) to eliminate batch variations.

Miniaturization Supportâ

- Robots handle ultra-small components (e.g., 0201/01005 LEDs) for compact designs.

- Multi-axis systems manage complex layouts (double-sided mounting) seamlessly.

Cost & Safety Benefitsâ

- Precision dispensing reduces material waste by 15%.

- Enclosed systems minimize worker exposure to hazards like toxic fumes.

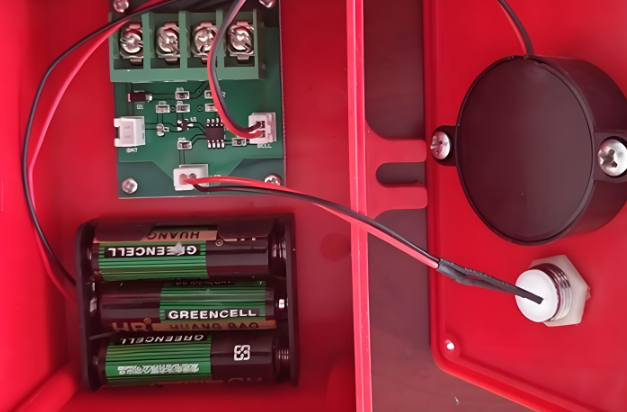

Can 4PDT Red LED PCB Pushbutton Switches Be Mounted on PCB?

Yesâ, 4PDT red LED PCB pushbutton switches are designed for PCB mounting, featuring through-hole solder terminals that align with standard PCB layouts. Ensure compatibility by verifying the pin count/spacing (e.g., 8-pin, 19x13mm hole spacing), LED voltage (e.g., 12V or 5V), and switch ratings (e.g., 250V AC, 8A). Always cross-check the datasheet for mechanical/electrical specifications to match your PCB design.

In conclusion, that’s all about LED PCB mounting. If you have any issues with LED PCB mount, please leave a message below this blog.