What is electronic manufacturing services? Let’s compare different electronic manufacturers in USA, UK, Canada, France, Australia through this blog.

Are you worried about these problems?

- How to ensure stable delivery amid supply chain fluctuations causing production delays?

- How to reduce costs for small-batch, multi-variety orders?

- How to quickly validate products amid rapid tech iteration and long R&D cycles?

As an electronic manufacturer, EBest Circuit (Best Technology) can provide you service and solutions:

- Rapid Delivery: 20-year supply chain pool + smart scheduling cuts bulk order delivery by 30%, 24-hour rapid prototyping for small batches.

- Cost Optimization: Modular design + flexible line reduces per-unit cost by 15%, seamless scaling from 1 to 10,000+ pieces.

- R&D Acceleration: End-to-end “design-prototype-test” service, 72-hour prototype validation, shrinks time-to-market gap.

Welcome to contact us if you have any request for electronic manufacturing service: sales@bestpcbs.com.

What is Meaning of Electronic Manufacturing Services?

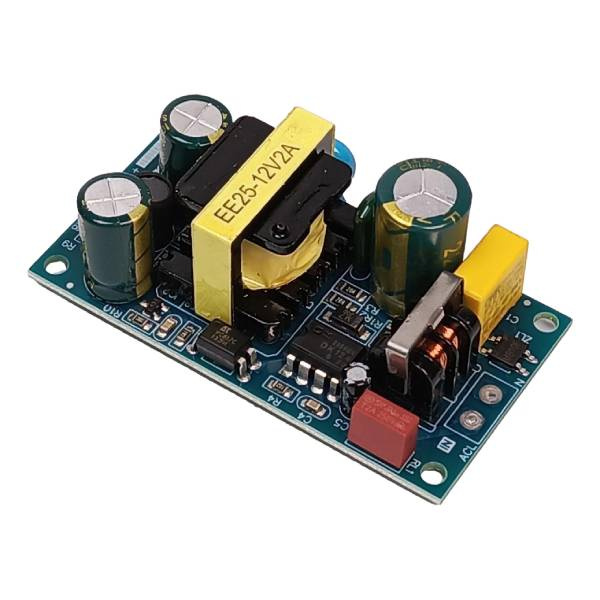

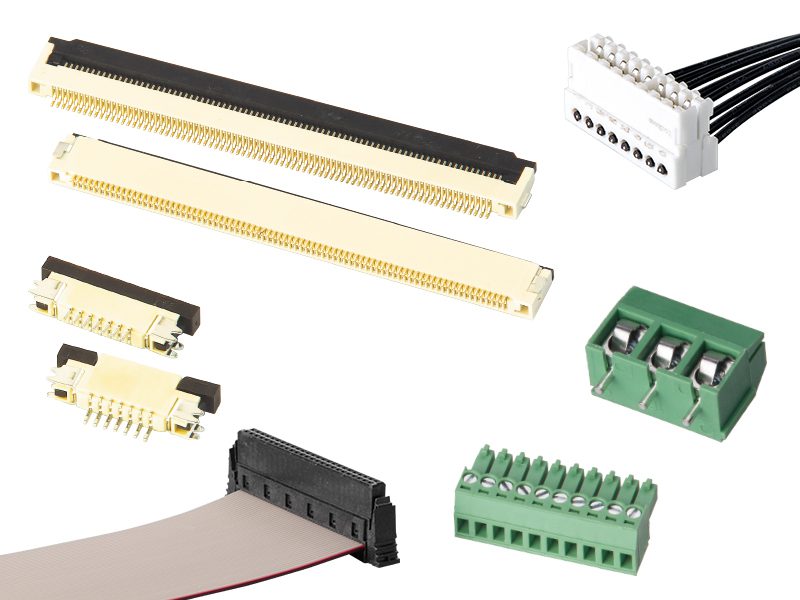

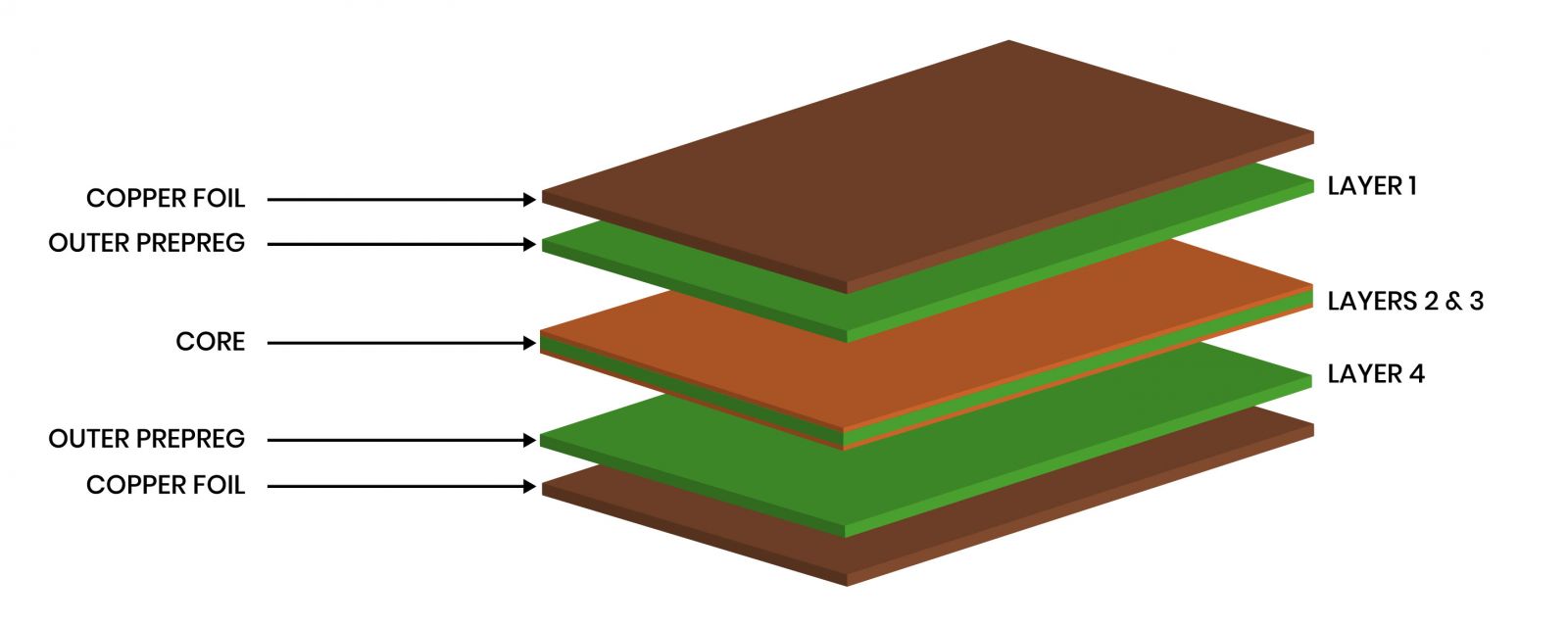

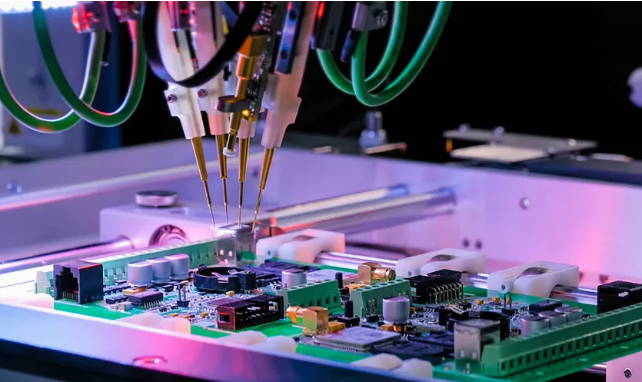

Electronics Manufacturing Services (EMS) refers to an industry dedicated to providing full-process outsourcing solutions for electronic brand owners. It covers the entire process from product design, engineering development, raw material procurement and management, manufacturing (such as PCB assembly and system integration), testing and verification (including circuit, functional, and environmental testing), logistics distribution, to after-sales maintenance.

Unlike traditional OEM (focused solely on contract manufacturing) or ODM (combining design and production), EMS achieves vertical integration of supply chain management, quality control, regulatory compliance adaptation, and global logistics networks. This enables brand owners to concentrate on core R&D and market expansion while reducing production costs, shortening time-to-market, and enhancing operational efficiency.

Typical services include end-to-end “design-manufacturing-after-sales” solutions for clients in sectors like communications equipment, medical electronics, and automotive electronics, forming a globally distributed manufacturing network through large-scale production and intelligent management, thereby serving as an indispensable “manufacturing hub” in the electronics industry chain.

Why Choose Electronic Manufacturing Services?

Benefits of electronic manufacturing services:

- Full-Process Design Optimization Support: Through DFM (Design for Manufacturability) analysis, over 80% of manufacturability issues can be identified early, reducing design iteration cycles by 30%. This allows designers to focus on core innovation rather than production adaptation challenges.

- Scalable Cost Control: Centralized procurement and supply chain integration optimize material costs, with bulk purchasing strategies reducing component costs by 15-25%. Automated production lines minimize manual intervention, lowering manufacturing costs by approximately 20%, while lean production reduces waste rates and enhances resource utilization.

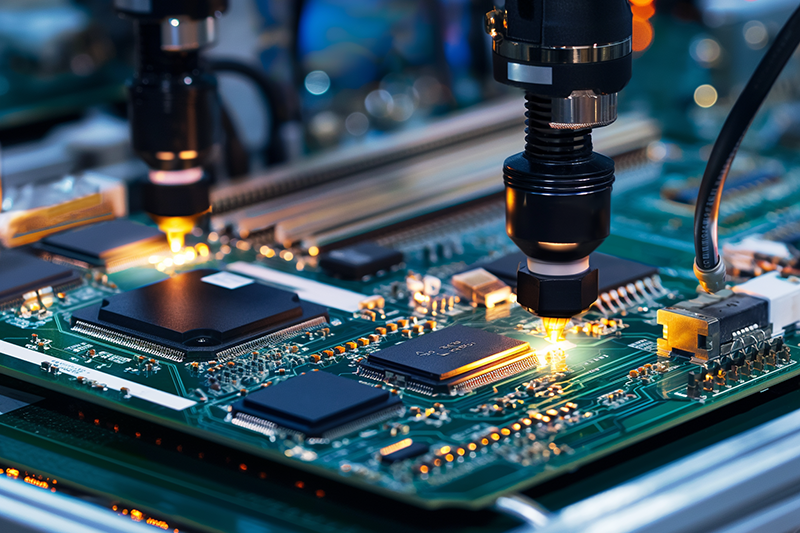

- Multi-Tier Quality Assurance System: Combining AOI (Automated Optical Inspection), X-ray testing, and functional testing ensures PCB reliability. The testing protocol includes six core inspection categories, maintaining defect rates below 0.03%, significantly outperforming industry averages. This reduces post-launch maintenance costs and product recall risks.

- Rapid Time-to-Market & Flexible Production Capacity: Vertical integration of manufacturing resources shortens product launch cycles, reducing prototype-to-mass-production timelines by 40%. Scalable production supports dynamic needs from small-batch prototyping to large-scale manufacturing, eliminating the fixed costs of in-house production lines.

- Supply Chain Risk Mitigation: Global supplier network management provides inventory buffering and logistics optimization. During component shortages, multi-source procurement strategies safeguard critical component supply, preventing project delays. Smart logistics systems minimize transportation damage and delivery time variability.

- Technical Knowledge Sharing: Accumulated industry expertise enhances design optimization. Access to process databases and case libraries helps engineers rapidly identify optimal manufacturing parameters, reducing trial-and-error costs. Shared test data accelerates product iteration cycles and boosts R&D efficiency.

Applications of Electronic Manufacturing Service

- Communications equipment manufacturing: such as base station equipment and routers, requires high-precision assembly and testing.

- Medical electronics: such as medical imaging equipment and monitors, demand high reliability and compliance.

- Automotive electronics: such as in-car entertainment systems and autonomous driving modules, involve complex supply chains and quality control.

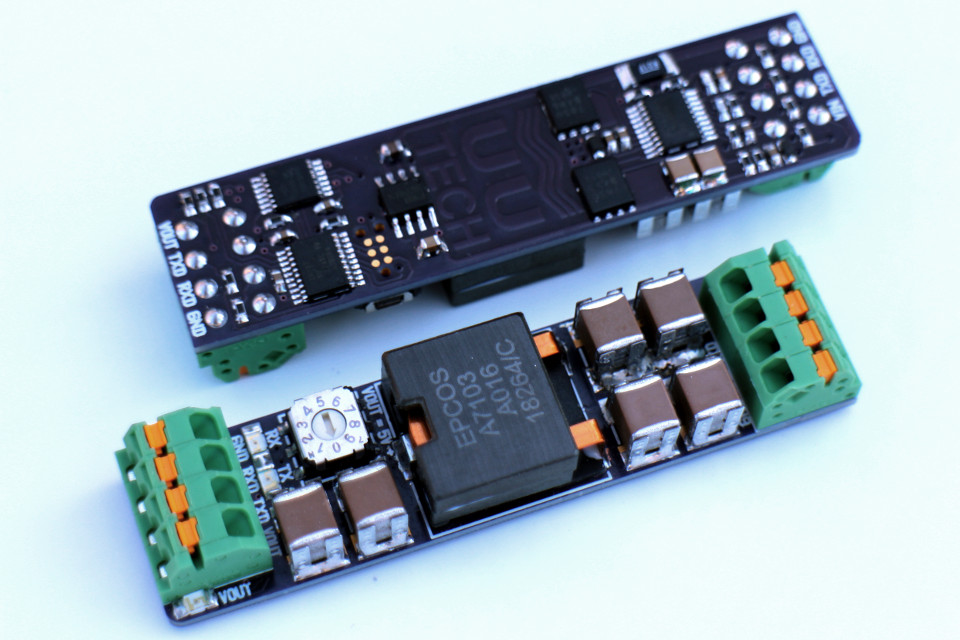

- Industrial control: such as PLCs and sensor modules, require durability and environmental adaptability.

- Consumer electronics: such as smartphones and tablets, require rapid iteration and large-scale production.

Electronic Manufacturing Services USAâ

Below are electronic manufacturer in USA:

- Jabil Inc.: A global leader in electronic manufacturing services (EMS), headquartered in Florida, offering integrated design, manufacturing, and supply chain solutions across medical, automotive, consumer electronics, and other industries.

- Flex Ltd.: Renowned for end-to-end EMS capabilities spanning design engineering to full-scale production, with expertise in medical, automotive, and consumer electronics sectors, backed by a global manufacturing footprint.

- Sanmina Corporation: Based in San Jose, California, this EMS provider specializes in PCB assembly and comprehensive manufacturing services, operating production facilities across the U.S., Europe, and Asia to support multinational clients.

- Plexus Corp.: Headquartered in Neenah, Wisconsin, it delivers tailored electronic manufacturing solutions for diverse industries through production sites in the U.S., Europe, and Asia, emphasizing technical precision and quality control.

- Benchmark Electronics: With its headquarters in Tempe, Arizona, this contract manufacturer supports clients through a distributed production network spanning the U.S., Mexico, and Asia, enabling cost-effective scaling and rapid deployment.

- Celestica Inc.: A supply chain-centric EMS firm that extends its capabilities across the electronics manufacturing value chain, leveraging global resources to optimize client operations.

- TTM Technologies: Focused on advanced PCB technology development and manufacturing, this company excels in high-precision circuit board solutions for demanding applications.

- RUSH PCB Inc.: Located in Silicon Valley, it provides flexible EMS from low-volume prototypes to high-volume production, catering to automotive, industrial, and telecommunications sectors with agile manufacturing processes.

- STAR ENGINEERING, INC: A contract manufacturer specializing in high-reliability circuit board production for aerospace, automotive, marine, and medical markets, adhering to stringent quality and compliance standards.

- Flash PCB: A U.S.-based EMS provider dedicated to PCB design, fabrication, and assembly, serving niche markets such as medical, aerospace, and defense with specialized engineering expertise.

Electronic Manufacturing Services UK

Below are electronic manufacturer in UK:

- TT Electronics plc: Offers specialized electronic manufacturing services including design, testing, surface-mount and through-hole assembly, serving markets in the UK, Europe, North America, and China.

- FermionX: Leading UK South Coast EMS provider with 3 SMT production lines, delivering services from PCB assembly to complete electromechanical integration, holding certifications such as ISO 13485 and ISO 9001.

- Esprit Electronics: With over 30 years of experience, delivers comprehensive EMS solutions including supply chain management, new product introduction, SMT/through-hole processes, and end-to-end packaging/logistics for UK/European markets.

- Electronic Technicians Ltd (ETL): Boasts over 40 years of contract electronics manufacturing expertise, providing full-spectrum contract manufacturing services.

- GB Electronics (UK) Ltd: Specializes in power electronics and complex hybrid assembly for medical, industrial, and scientific instrumentation, with expertise in multi-core cable assembly and electromechanical construction.

- Welwyn Systems Ltd: Part of the TT Electronics Group, focused on professional design and testing services.

- AB Electronic Assemblies: Also under TT Electronics Group, this South Wales-based contract manufacturer delivers tailored electronics solutions.

- Time Electronics Ltd: Since 1967, dedicated to designing and manufacturing calibration, test, and measurement instruments, covering electronic device assembly and production.

Electronic Manufacturing Services Canadaâ

Below are electronic manufacturer in Canada:

- Celestica: A global EMS leader providing design, manufacturing, and supply chain solutions for computing, communications, medical, and aerospace industries. Services span full product lifecycle including prototyping, testing, and global logistics.

- Creation Technologies: Specializes in high-complexity, medium-to-low volume electronics manufacturing serving aerospace, medical, and industrial technology sectors. Operates 13 facilities across Canada, USA, Mexico, and China, delivering end-to-end solutions from design to delivery.

- Vexos: Offers comprehensive EMS and custom material solutions for medical, automotive, communications, and defense markets. With factories in Canada, USA, China, and Vietnam, emphasizes rapid prototyping and new product introduction (NPI).

- Sanmina: Global EMS provider with Ottawa-based design center focused on RF, optical, and microelectronics development. Delivers technology-intensive solutions for communications, medical, and industrial applications.

- Flex: Though headquartered in Singapore, maintains Canadian design hubs supporting client product development through its “Sketch to Scale” program. Services cover communications, consumer electronics, and automotive sectors.

- Jabil: EMS giant with Ottawa operations specializing in optical communications and data center infrastructure manufacturing. Provides full-flow services from design to testing for communications, medical, and industrial clients.

Electronic Manufacturing Services Franceâ

Below are electronic manufacturer in France:

- Asteelflash Group: Headquartered in France, this EMS provider offers end-to-end electronic manufacturing services spanning R&D design, NPI (New Product Introduction), rapid prototyping, material procurement, production, testing, and after-sales support. It serves sectors including aviation, industrial equipment, medical devices, and telecommunications. Notably, the company was acquired by USI (Universal Scientific Industrial) in 2019.

- Ăolane (Yilan): Established in 1975, Ăolane is a French EMS leader with over 40 years of expertise. Specializing in electronics manufacturing and engineering services, it caters to industrial, medical, automotive, and communication sectors. Its longstanding experience ensures reliable solutions for complex technical requirements.

- Cofidur EMS: A French EMS company focused on aviation and industrial electronics, while also extending services to medical, telecommunications, and PC industries. It combines precision engineering with scalable production capabilities to meet diverse client needs.

- Lacroix Electronics: Primarily serving the industrial sector, Lacroix also operates in aviation, medical electronics, and automotive segments. Its services emphasize robust production processes and adherence to stringent quality standards across multiple high-reliability industries.

- ALL CIRCUITS: Recognized as a notable French EMS contract manufacturer, ALL CIRCUITS holds a position in global EMS rankings. It delivers flexible production solutions tailored to various electronics applications, maintaining competitive edge through technical proficiency and responsive supply chain management.

Australian Electronic Manufacturing Servicesâ

Below are electronic manufacturer in Australia:

- Entech Electronics: Established in 1986 and headquartered in Adelaide, South Australia, this Australian-owned contract manufacturer specializes in PCB assembly, electromechanical integration, and HMI solutions. Serving IoT, medical, aerospace, industrial electronics, and mining sectors, with production facilities in Adelaide and Shenzhen, China.

- Wavetronics: Based in Sydney, offering full-spectrum EMS including SMT/through-hole assembly, prototype development, system integration testing, and material procurement. Serves major Australian brands with emphasis on technical training and automated production.

- SRXGlobal: Headquartered in Sydney with operations in Melbourne, Singapore, and Malaysia. Provides electronic design, engineering development, and manufacturing solutions for medical, industrial, defense, and communications sectors. Strengths include cross-border supply chain management and high-standard production processes.

- Circuitwise: Sydney-based PCB assembly specialist holding ISO 13485 medical device manufacturing certification. As a 100% Australian-owned enterprise, profits remain domestically. Primarily serves medical technology innovation needs.

- Microconsultants Pty Ltd: Founded in the 1980s in Frankston, Victoria. Offers contract design and manufacturing services for medium-to-small batch high-quality production. Utilizes a flexible “cottage industry” model integrating experienced technicians.

- GPC Electronics: Former chair of the Australian Electronic Manufacturing & Communications Equipment Association (AEEMA). Specializes in telecom equipment contract manufacturing, leveraging local supply chains (metal/plastic components) and representing early industry cluster development.

- General Power Controls: Established in the 1980s in Penrith, NSW. Assembles computing, communications, amplifiers, and appliance control systems. Emphasizes automation to reduce import dependency while serving local SMEs.

Why Choose EBest Circuit (Best Technology) as Electronic Manufacturer in China?

Reasons why choose us as electronic manufacturer in China:

- Full-link quality control system: Implementing dual ISO 9001/IATF 16949 certified processes from raw material intake to finished product shipment. Equipped with German SMT machines and AOI intelligent inspection systems, defect rates are controlled below 0.3%, significantly outperforming industry averages and ensuring zero-defect delivery.

- Cost optimization through value engineering: Leveraging DFM analysis for design optimization and Yangtze River Delta supply chain cluster advantages, achieving 15-20% material cost reduction while maintaining EU ROHS compliance. This provides clients with cost-effective solutions without compromising quality.

- Flexible manufacturing and rapid response: Supports seamless transition from small-batch prototyping (starting at 500 units) to mass production. Features 7-day rapid prototyping cycles and 21-day standard lead times, with dynamic capacity allocation systems enabling exceptional responsiveness to urgent orders.

- Core technology R&D capabilities: Boasts 32 patents covering precision PCB design and EMC solutions, with proven expertise in 5G communication modules and new energy vehicle BMS systems, positioning at the forefront of industry technical development.

- Production transparency through digital systems: Client-dedicated MES systems provide real-time production data synchronization, enabling 24/7 online monitoring of critical processes. Weekly progress reports ensure transparent supply chain management and reduced client communication overhead.

- Global compliance and regulatory assurance: Products certified to CE, FCC, UL standards with dedicated compliance teams tracking regulatory updates. This mitigates market access risks associated with certification non-compliance for international clients.

- Customized R&D services: Full-process support from concept design to mass production, staffed by 20 senior engineers completing over 50 client customization projects annually. Supports flexible ODM/OEM collaboration models tailored to client needs.

Welcome to contact us if you have any request for electronic manufacturing servicesâ: sales@bestpcbs.com.