If youâve ever stared at a PCB prototype covered in misplaced components or wasted weeks reworking a design because the resistors didnât fit, you know the frustration. smd resistor dimensions arenât just arbitrary numbersâtheyâre the backbone of reliable electronics design. Understanding smd resistor dimensions ensures your components integrate seamlessly with PCBs, perform as expected under load, and avoid costly manufacturing delays. Whether youâre a hobbyist building a DIY project or an engineer designing industrial equipment, getting the dimensions right is non-negotiable. Letâs break down everything you need to know to stop guessing and start choosing with confidence.

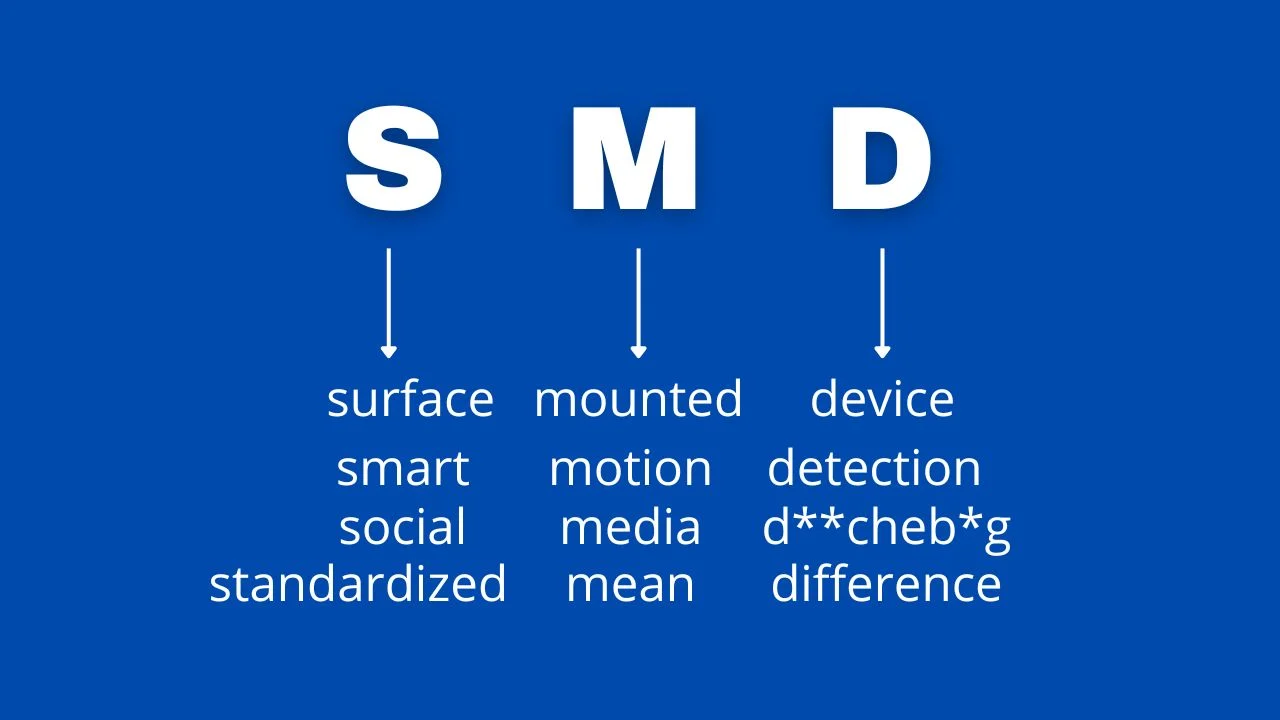

2. What Are SMD Resistors? A Quick Primer for Beginners

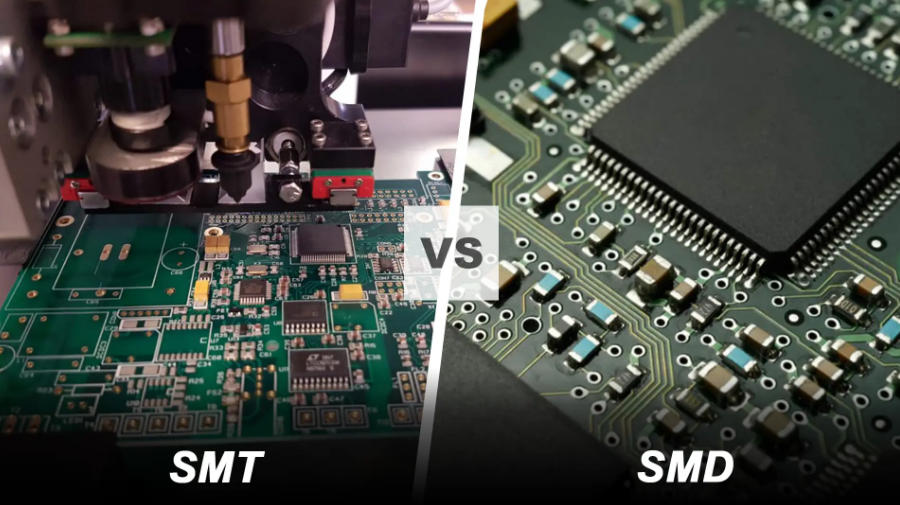

SMD resistors (Surface Mount Device resistors) are the compact, lead-free workhorses of modern electronics. Unlike traditional through-hole resistors that require drilled holes in PCBs, SMD resistors mount directly onto the boardâs surface, saving valuable space and enabling faster assembly. Their key advantages over through-hole alternatives include a 50% smaller footprint, better high-frequency performance, and compatibility with automated pick-and-place machinesâcritical for mass production. But hereâs the catch: their small size means smd resistor dimensions directly dictate what they can do. A tiny 0201 resistor might fit in a smartwatch, but it canât handle the power demands of an industrial power supply. Size isnât just about spaceâitâs about functionality.

3. Understanding SMD Resistor Dimension Codes (Imperial vs. Metric)

One of the most common headaches with SMD resistors is decoding their size codesâand itâs easy to see why. Two global systems dominate: imperial (used primarily in North America and Europe) and metric (favored in Asia). The 4-digit codes look similar, but they mean entirely different things. Letâs demystify them:

- Imperial codes: The first two digits = length (in 1/100 of an inch), the last two = width (in 1/100 of an inch). For example, 0402 = 0.04â (length) x 0.02â (width), and 1206 = 0.12â x 0.06â.

- Metric codes: The first two digits = length (in millimeters), the last two = width (in millimeters). So 1608 = 1.6mm x 0.8mm, and 3216 = 3.2mm x 1.6mm.

The biggest mistake? Confusing imperial 0603 with metric 0603. Imperial 0603 = 1.6mm x 0.8mm (metric 1608), while metric 0603 = 0.6mm x 0.3mm (imperial 0201)âa difference that can ruin your entire PCB. Pro tip: Always confirm the code system with your supplier, and keep a conversion chart handy (multiply inches by 25.4 to get millimeters, or pide millimeters by 25.4 for inches).

4. smd resistor package dimensions

Common SMD Resistor Package Sizes (Detailed Specs + Comparative Chart)

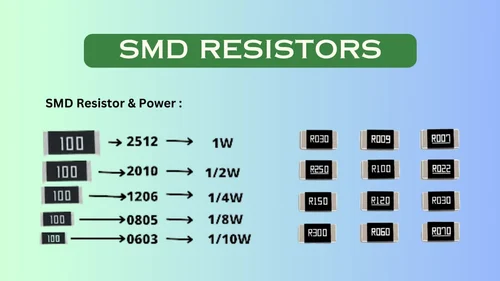

When people talk about smd resistor dimensions, theyâre usually referring to package sizeâthe physical length, width, and height of the component. Here are the most widely used packages, with specs that matter:

| Imperial Code | Metric Code | Dimensions (mm) | Dimensions (inch) | Rated Power (W) | Height (mm) |

|---|---|---|---|---|---|

| 0201 | 0603 | 0.6 x 0.3 | 0.024 x 0.012 | 0.05 | 0.25 |

| 0402 | 1005 | 1.0 x 0.5 | 0.039 x 0.020 | 0.063 | 0.35 |

| 0603 | 1608 | 1.6 x 0.8 | 0.063 x 0.031 | 0.10 | 0.45 |

| 0805 | 2012 | 2.0 x 1.2 | 0.079 x 0.047 | 0.125 | 0.55 |

| 1206 | 3216 | 3.2 x 1.6 | 0.126 x 0.063 | 0.25 | 0.75 |

| 2512 | 6432 | 6.4 x 3.2 | 0.252 x 0.126 | 1.00 | 1.20 |

Notice how power rating scales with size? A 2512 package can handle 1W of power, while a tiny 0201 maxes out at 0.05W. This is because larger packages have more surface area for heat dissipationâcritical for high-power applications.

How Package Dimensions Impact Thermal Dissipation & Assembly

Thermal management is where smd resistor dimensions really shine (or fail). Smaller packages like 0201 and 0402 are great for compact devices (think smartphones or wearables), but they struggle with heat. If you push a 0402 resistor beyond its 0.063W limit, itâll overheat, drift in resistance, or even burn out. Larger packages like 1206 and 2512 spread heat more effectively, making them ideal for power supplies or industrial controls.

Assembly is another factor. Ultra-small packages (0201) require precision automated equipmentâforget hand-soldering them unless you have steady hands and a microscope. For hobbyists or small-batch projects, 0805 and 1206 are the sweet spot: easy to solder manually while still saving space.

5. smd resistor footprint dimensions

What Is an SMD Resistor Footprint? (Land Pattern Basics)

If smd resistor dimensions are about the component itself, footprint dimensions are about how it connects to the PCB. A footprint (or land pattern) is the layout of copper pads on the PCB where the resistor solders. Think of it as the resistorâs âhomeââif the home is too big or too small, the resistor wonât sit right.

Footprints follow global standards set by IPC (Association Connecting Electronics Industries) and JEDEC (Joint Electron Device Engineering Council). These standards ensure compatibility across manufacturersâso a 0805 resistor from Texas Instruments fits the same footprint as one from Yageo. Ignoring these standards leads to problems: pads too small cause poor solder joints, while pads too large result in solder bridging (short circuits) or the resistor shifting during assembly.

Standard Footprint Dimensions by Package

Here are the IPC-recommended footprint dimensions for the most common SMD resistor packages (pad length x width x gap between pads):

- 0603 (1608): Pad length = 1.2mm, pad width = 0.8mm, gap = 0.4mm

- 0805 (2012): Pad length = 1.5mm, pad width = 1.0mm, gap = 0.5mm

- 1206 (3216): Pad length = 2.0mm, pad width = 1.4mm, gap = 0.6mm

- 2512 (6432): Pad length = 3.0mm, pad width = 2.5mm, gap = 0.8mm

These are starting pointsâadjustments may be needed for high-temperature applications or flexible PCBs. Always cross-check with your resistorâs datasheet and your PCB design software (Altium, KiCad) for manufacturer-specific recommendations.

6. Key Factors to Consider When Choosing SMD Resistor Dimensions

PCB Space Constraints (High-Density vs. Industrial Designs)

The first question to ask: How much space do you have? High-density designs (like wearables or IoT sensors) demand tiny packages (0201, 0402) to fit all components. Industrial equipment or power supplies have more room, so you can opt for larger packages (1206, 2512) that offer better performance and easier assembly. Donât force a small package if space allowsâbigger often means more reliable.

Power Requirements & Performance Tradeoffs

Power rating is non-negotiable. Calculate the maximum power your resistor will handle (using Ohmâs Law: P = VÂČ/R or P = IÂČR) and choose a package that exceeds that by 20-30% for safety. For example, if your circuit requires 0.1W, a 0603 (0.1W) works, but a 0805 (0.125W) gives extra headroom for heat spikes.

Assembly Method (Automated vs. Hand Soldering)

Automated pick-and-place machines handle tiny packages (0201, 0402) with ease, but hand soldering them is frustrating (and error-prone). If youâre building prototypes or small batches, stick to 0805 or 1206. For mass production, automated assembly opens up smaller package options.

Global Supply Chain Compatibility

Not all packages are equally available worldwide. Ultra-small packages (0201) may be harder to source in some regions, or more expensive. Stick to common packages (0402, 0603, 0805, 1206) for easier procurement and consistent quality across suppliers.

7. Common Mistakes in SMD Resistor Dimension Selection (And Fixes)

Even experienced engineers mess up smd resistor dimensionsâhere are the top mistakes and how to avoid them:

- Mistake 1: Ignoring thermal limits. Solution: Always derate resistors (use a higher power rating than needed) and check datasheets for temperature vs. power curves.

- Mistake 2: Confusing imperial and metric codes. Solution: Label your BOM (Bill of Materials) with both codes (e.g., 0603 / 1608) and confirm with suppliers.

- Mistake 3: Choosing a package too small for hand soldering. Solution: For manual assembly, avoid anything smaller than 0805 unless you have specialized tools.

- Mistake 4: Mismatched footprints. Solution: Use PCB design softwareâs built-in footprint libraries (Altium, KiCad) or download from the resistor manufacturerâs website.

8. SMD Resistor Dimensions for Specific Applications

Consumer Electronics (Smartphones, Wearables)

Space is at a premium hereâso packages like 0201 and 0402 are standard. These tiny SMD resistors fit in tight spaces while handling low power (0.05-0.1W). Examples: A smartphoneâs display driver might use 0402 resistors, while a fitness tracker uses 0201s.

Industrial Equipment (Power Supplies, Controls)

Industrial gear needs durability and heat resistance. Packages like 1206 and 2512 are common, as they handle higher power (0.25-1W) and dissipate heat better. A factoryâs motor controller, for example, might use 2512 resistors to handle power spikes.

Automotive & Medical Devices

These industries demand reliability in harsh conditions (extreme temperatures, vibration). Packages like 0805, 1206, and 1210 are preferredâtheyâre robust enough to withstand automotive underhood temperatures or medical device sterilization cycles. Automotive infotainment systems often use 0805 resistors, while medical monitors use 1206s.

9. How to Measure SMD Resistor Dimensions Accurately

If youâre unsure about a resistorâs size (or suspect a counterfeit), measuring it is simpleâyou just need the right tools:

- Gather tools: Digital calipers (with 0.01mm precision) and a magnifying glass or microscope (for tiny packages).

- Measure length: Place the resistor on a flat surface and measure the longest side (avoid pressing too hardâSMD resistors are fragile).

- Measure width: Measure the shorter side perpendicular to the length.

- Measure height: Measure from the flat surface to the top of the resistor (this affects PCB clearance).

- Verify: Cross-check your measurements with the code on the resistor (e.g., if you measure 1.6mm x 0.8mm, it should be a 0603 / 1608 package).

Pro tip: Counterfeit resistors often have incorrect dimensionsâif your 0805 resistor measures 1.8mm x 0.9mm instead of 2.0mm x 1.2mm, itâs likely fake.

10. SMD Resistor Dimensions vs. Through-Hole Resistors: Comparison

How do smd resistor dimensions stack up against traditional through-hole resistors? Letâs break it down:

- Size: SMD resistors are 50-70% smaller in footprint. A 1206 SMD resistor (3.2mm x 1.6mm) is tiny compared to a through-hole 1/4W resistor (6.3mm x 3.2mm).

- Height: SMD resistors sit 0.25-1.2mm above the PCB, while through-hole resistors stand 8-10mm tallâcritical for low-profile devices.

- Performance: SMD resistors have better high-frequency performance (less parasitic inductance) and faster heat dissipation (direct contact with the PCB).

- Assembly: Through-hole resistors are easier to hand-solder but slower to assemble in bulk. SMD resistors require automation for mass production but save time overall.

When to choose SMD: Most modern electronics (consumer, industrial, automotive) benefit from SMDâs small size and performance. When to choose through-hole: Prototyping (easy to solder), high-power applications (some through-hole resistors handle 5W+), or legacy designs.

11. FAQ: Common Questions About SMD Resistor Dimensions

- Q1: What do the 4 digits in SMD resistor codes represent?A1: For imperial codes (e.g., 0402), the first two digits = length (1/100 inch), last two = width (1/100 inch). For metric codes (e.g., 1608), first two = length (mm), last two = width (mm).

- Q2: Can I replace a 0603 resistor with a 0805 if space allows?A2: Yesâif the power rating is equal or higher. A 0805 (0.125W) can replace a 0603 (0.1W) as long as your PCB has space for the larger footprint.

- Q3: Why do different manufacturers label the same package with slightly different dimensions?A3: Manufacturers have minor tolerances (±0.1mm for length/width). Stick to IPC/JEDEC standards, and the differences wonât affect compatibility.

- Q4: Which SMD resistor size is easiest for hand soldering?A4: 0805 is the sweet spotâlarge enough to handle with tweezers and solder with a standard iron, but small enough to save space.

- Q5: Are there standard footprint dimensions for all SMD resistor packages?

A5: YesâIPC/JEDEC sets global standards. Use your PCB design softwareâs library or download from manufacturers like Yageo or Vishay. - Q6: Does temperature affect SMD resistor dimensions?

A6: Negligibly. SMD resistors are made of ceramic and metal films, which have low thermal expansion. Temperatures up to 150°C wonât change their dimensions enough to cause issues. - Q7: Whatâs the smallest mass-produced SMD resistor size?

A7: 01005 (imperial) or 0402 (metric) = 0.4mm x 0.2mm. Itâs used in ultra-compact devices like smartwatches but requires specialized assembly. - Q8: How do I calculate the right footprint for my PCB?

A8: Use IPC-7351 (the industry standard) or your resistorâs datasheet. Most PCB design software (Altium, KiCad) has built-in calculators to generate footprints based on package size.

12. Final Thoughts: Mastering SMD Resistor Dimensions for Better Designs

smd resistor dimensions might seem intimidating at first, but theyâre just a matter of understanding tradeoffsâspace vs. power, size vs. assembly ease. The key takeaway? Never choose a package based on size aloneâalign it with your applicationâs power needs, assembly method, and PCB constraints. By mastering code translation, footprint standards, and application-specific sizing, youâll eliminate rework, reduce costs, and build more reliable electronics.

Remember: A SMD resistor is only as good as its fitâget the dimensions right, and everything else falls into place. For more details, check out IPC-7351 (the definitive guide to footprint design) or reach out to your resistor supplier for custom recommendations. Whether youâre building a prototype or scaling to mass production, this guide will keep your designs on track.