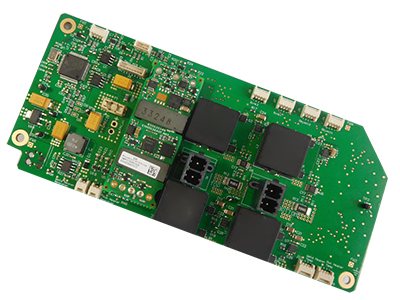

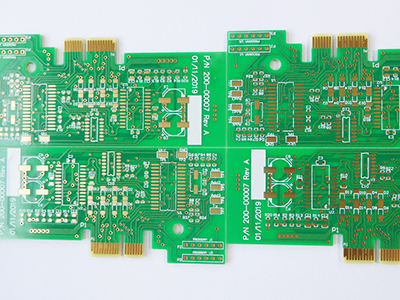

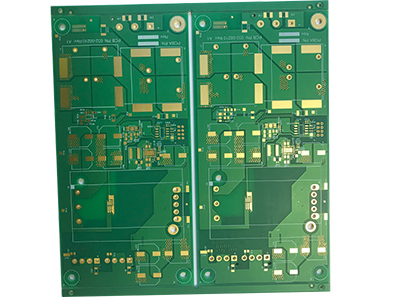

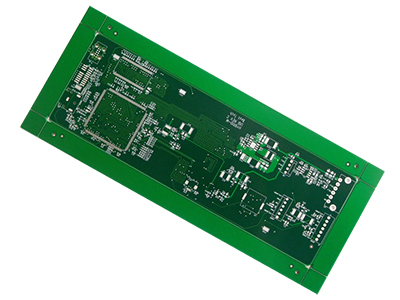

FR4 is the most common material grade that comprises fabricated PCB. FR indicates the material is flame retardant and the 4 indicates woven glass reinforced epoxy resin. Single or double-sided PCB structures consist of an FR4 core and top and bottom copper layers. Multi-layer boards have additional prepreg layers between the center core and top and bottom copper layers. Now, the core consists of a substrate with copper covering, also referred to as a copper clad laminate. The core, laminate, and prepreg may all be FR4 with the copper sheets between the signal and ground layers.

The properties of FR4 may vary slightly depending on the manufacturer; however, it generally has favorable strength and water resistance attributes that support its widespread usage as an insulator for many electrical applications. It serves the same purpose in PCBs, namely to isolate adjacent copper planes and provide overall bending and flexural strength for the structure. FR4 is a good general purpose material for PCB fabrication; however, alternative materials are available.

Alternative PCB Materials

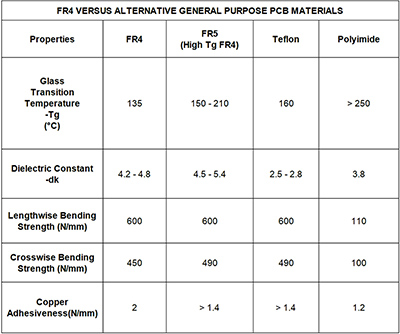

Prior to the explosion of multilayer FR4 PCBs, there were many alternative board materials to FR4. These included FR2, CEM 1, and CEM 3, which were paper-based. However, the strength of FR4, especially for multilayer boards, was a major factor in separating it from alternatives to become the industry standard. Today, there are other materials that are used for single-sided, double-sided, non-plated through-hole (NPTH), and multilayer PCBs, in addition to FR4. These are compared in the table below:

The results above clearly indicate that FR4 is a good general purpose material as its parameters are mostly comparable to the other alternatives. It excels in structural integrity with a 2.0 N/mm copper adhesiveness and matches the alternatives in bending strength.

FR4 is the most widely-used material in PCB construction. Boards made from FR4 are strong, water resistant, and provide good insulation between copper layers that minimizes interference and supports good signal integrity. At EBest Circuit (Best Technology), the industry leader in fast, high-quality PCB prototype and PCB manufacturing, we are capable to meet your board material needs for any case. We will work with you to help you select the materials that will best implement your design intent.

Should you have any queries about FR4 material, contact us anytime, and our sales representative will give you a response at our soonest convenience.