The PCB manufacturer in Slovakia plays a crucial role in Europe’s electronic supply chain, offering diverse solutions for industrial, automotive and medical sectors. With mature industrial foundations and proximity to European markets, PCB manufacturer in Slovakia continues to expand their service scope, while facing fierce global competition. This blog covers top players, pain points, selection guides and future trends of Slovakia PCB, providing practical value for relevant businesses seeking reliable Slovakia PCB manufacturer.

Top 10 PCB Manufacturer in Slovakia

| Company Name | Main Business | Core Advantages | Process Capabilities | Lead Time |

| EBest Circuit Co., Limited( Best Technology) | Multilayer/HDI/rigid-flex PCB | Global supply chain, EU compliance | 1-32 layers, 3mil/3mil, blind vias | 2-7 days |

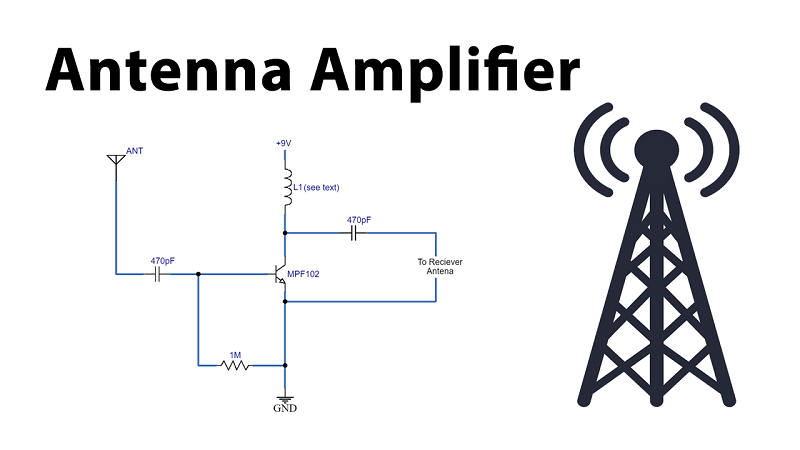

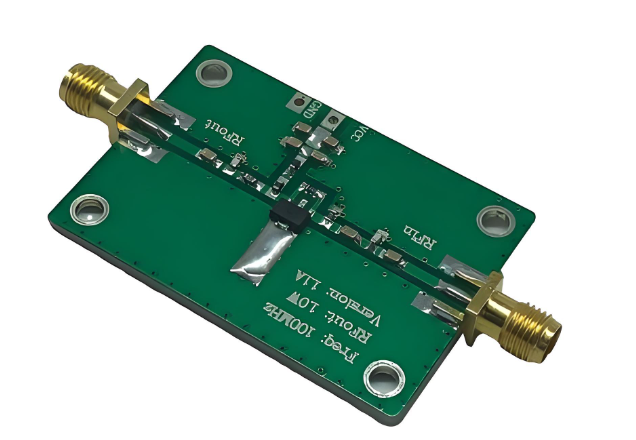

| SQP International s.r.o | Multilayer/RF/turnkey PCB | 30+ years, ISO 9001/14001, defense/medical | ‚ȧ12 layers, <100¬Ķm lines, filled vias | 2-5 days |

| UET PCB s.r.o | PCB fabrication/PCBA | 99.99% yield, IATF16949/ISO13485 | 1-16 layers, Rogers/Isola, impedance | 3-8 days |

| SVI Slovakia s.r.o | PCBA/box build/EMS | 11,400„é° facility, EU near-shoring | SMT/THT, 01005, vapor phase | 4-10 days |

| GPV Electronics SK (H) s.r.o | PCBA/ODM/box build | Bratislava/Vienna logistics, lean | SMT/THT, burn-in, volume production | 5-12 days |

| GPV Electronics SK (N) s.r.o | Prototyping/NPI/testing | 17,000„é° plant, 720 staff (since 1967) | High-volume SMT, system assembly | 3-9 days |

| CRT Electronic s.r.o | Industrial PCBA | 13+ years EU expertise, tailored | SMT/THT, small-batch, testing | 3-8 days |

| Elcom s.r.o | Contract EMS/PCBA | R&D capability, cash register focus | Custom assembly, functional testing | 4-10 days |

| Elpro s.r.o | SMT/THT assembly | In-house equipment, small-volume | Vacuum manipulators, reflow oven | 3-7 days |

| SMT-Innovation s.r.o | SMT/assembly/equipment | 20+ years EU experience, global | High-precision SMT, process optimization | 2-8 days |

Pain Points of PCB Manufacturer in Slovakia

- Local Slovakia PCB factory lack ultra-fine line prototype capacity (below 3mil/3mil), relying on cross-border imports that extend lead times by 3-5 working days.‚Äč

- RoHS compliance pre-inspection for custom RF and high-Tg materials lengthens testing cycles, and small-batch prototype costs are 20-30% higher due to limited local scale.‚Äč

- Strict EU environmental regulations and high labor costs raise expenses for Slovakia PCB manufacturer, while mixed-brand equipment cuts efficiency by 10-15%.‚Äč

- Insufficient localized DFM support and specialized tools prolong design iterations for Slovakia PCB design, constrained by miniaturization and production limits.‚Äč

- Severe skilled labor shortage forces Slovakia PCB assembly plants to automate, yet 01005 component assembly still depends on limited skilled staff.‚Äč

- RoHS-compliant component supply disruptions and post-assembly testing add 1-2 working days to lead times, delaying production continuity.

How to Choose A Reliable PCB Manufacturer in Slovakia?

A Selection Guide to PCB Manufacturer in Slovakia:

- Verify Certification Qualifications: Prioritize manufacturers holding ISO 9001 (general quality), IATF 16949 (automotive-grade), and ISO 13485 (medical-grade) certifications‚ÄĒover 90% of leading Slovakia PCB factory possess these. Additionally, confirm UL certification and UL 94V0 flame retardant rating to ensure compliance.

- Evaluate Process Capabilities: Beyond verifying 3mil/3mil line width accuracy and 12+ layer production capacity, check support for high-end materials like Rogers/Isola, blind/buried via technology, and ¬Ī1¬Ķm impedance control to meet precision requirements.

- Control Yield Rate and Inspection: Optimize for manufacturers with a yield rate of ‚Č•99.5%. For instance, UET PCB achieves a 99.99% yield rate through full-process quality inspection including AOI (Automatic Optical Inspection) and flying probe testing, ensuring mass production stability.

- Consider Lead Time and Supply Chain: Confirm capacity for urgent prototypes (2-3 days) and mass production (5-7 days). Meanwhile, check inventory of core materials such as FR-4 and high-Tg substrates, as well as the dedicated processing mechanism for urgent orders.

- Prefer One-Stop Services: Prioritize end-to-end services provided by a Slovakia PCB company, including DFM optimization, component sourcing, PCBA assembly, and after-sales functional testing to reduce collaboration costs.

- Validate Supply Chain Stability: Understand partnerships with leading material suppliers (e.g., Isola, Rogers) to ensure supply of RoHS 3 compliant materials and avoid supply disruption risks.

- Confirm Cost Transparency: Request a detailed quotation breakdown to clarify additional fees for testing, expediting, and customization, avoiding hidden costs that align with local production budget needs in Slovakia.

How to Evaluate the Lead Time of Slovakia PCB Manufacturer?

Evaluation Guide to Lead Time of Slovakia PCB Manufacturer:

- Order priority system: Confirm the manufacturer‚Äôs expedited service levels (e.g., 24/48-hour turnaround) for urgent orders and corresponding cost breakdowns to avoid hidden fees.‚Äč

- Raw material inventory: A reliable Slovakia PCB plant maintains ‚Č•80% stock of core materials (FR-4, Rogers) to shorten material procurement cycles for standard orders.‚Äč

- Production schedule transparency: Require real-time order tracking tools to monitor progress and proactively alert for potential delays.‚Äč

- Equipment maintenance plans: Check scheduled maintenance protocols and target unplanned downtime rate (‚ȧ2% monthly) to minimize production disruptions.‚Äč

- Logistics partnerships: Prioritize manufacturers near Bratislava‚Äôs EU logistics hub, enabling next-day delivery to key European markets.‚Äč

- Batch size adaptability: Verify that lead time scales rationally, small batches should not incur excessive delays vs. mass production.‚Äč

- Quality control efficiency: Ensure in-line QA processes (AOI testing) to reduce rework, as post-production fixes can extend lead times by 1-2 days.

How to Evaluate the Production Capacity of Slovakia PCB Manufacturing Company?

Evaluation Guide to Lead Time of Slovakia PCB Manufacturing Company:

- Facility scale: Assess production area by tiers, small (‚Č•2,000„é°) for batches, medium (‚Č•8,000„é°) for stable mass output, and large (‚Č•15,000„é°, e.g., GPV Electronics‚Äô 17,000„é° plant) for high volume. Top Slovakia PCB factory achieve ‚Č•60% automation for core processes.

- Machine precision: Confirm equipment supports fine-line fabrication (high-end 50¬Ķm, mainstream <100¬Ķm like SQP International), ¬Ī1¬Ķm LDI accuracy, and blind/buried via compatibility for Slovakia PCB.

- Monthly output: A capable PCB manufacturer in Slovakia hits 30,000-50,000„é°/month (medium scale) and 50,000+„é°/month (large scale) to match local demand.

- Quality control system: Require 100% AOI/X-ray testing for high-precision orders, target defect rate ‚ȧ0.3% (industry avg: 0.5-0.8%), and prioritize manufacturers like UET PCB with 99.99% yield rate.

- Material sourcing network: Validate Isola/Rogers partnerships with 48-hour emergency replenishment, and ensure 100% RoHS 3 compliant suppliers.

- Staff expertise: For medium facilities, require ‚Č•50 skilled workers (80%+ IPC-A-610 certified) and ‚Č•40 annual training hours per staff.

- Certification scope: Confirm IPC Class 2/3 compliance (85% of top Slovakia PCB company meet this), plus IATF 16949 (automotive) and ISO 13485 (medical).

Future Challenges for Slovakia PCB Manufacturer

- Rising labor costs in Slovakia, narrowing price gaps with Asian manufacturers.

- Increased R&D investment pressure for advanced technologies (HDI, flexible PCB).

- Stricter EU environmental regulations (RoHS 3 updates) raising production costs.

- Shortage of high-tech talent for complex PCB manufacturing and design.

- Supply chain volatility due to global component shortages and geopolitical risks.

- Competition from neighboring EU countries (Austria, Germany) with mature PCB industries.

- Demand for miniaturization pushing equipment upgrade costs for ultra-fine line production.

- Shift to green manufacturing requiring eco-friendly materials and processes.

FAQs of Slovakia PCB Manufacturing

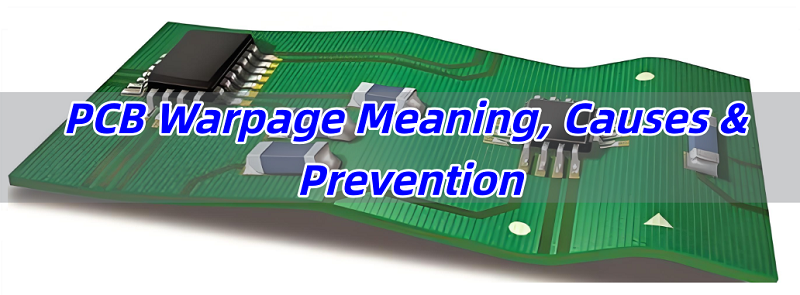

Q1: How to resolve microcracks in PCB substrates during production?

A1: Microcracks stem from thermal stress and inferior materials. A professional PCB manufacturer in Slovakia uses high-grade substrates (Isola, Rogers) with stable thermal expansion and controls soldering temperature swings within ¬Ī5¬įC, plus thermal cycling (-40¬įC to 85¬įC) in prototype testing to eliminate defects.

Q2: Why do PCB prototypes have inconsistent impedance values, and how to fix it?

A2: Inconsistency comes from imprecise line width and material variations. Slovakia PCB manufacturing adopts laser direct imaging (LDI) for ¬Ī1¬Ķm accuracy, pre-tests substrate batches, and provides DFM feedback to achieve 99.8% accuracy for impedance-controlled prototypes.

Q3: How to reduce delamination issues in multilayer PCB production?

A3: Delamination is caused by moisture absorption and improper lamination pressure. An ISO 14001-certified Slovakia PCB plant conducts pre-baking (120¬įC for 4 hours), uses 35-40 psi vacuum lamination, and maintains humidity levels <45%.

Q4: What causes solder bridging in PCBA, and how to prevent it?

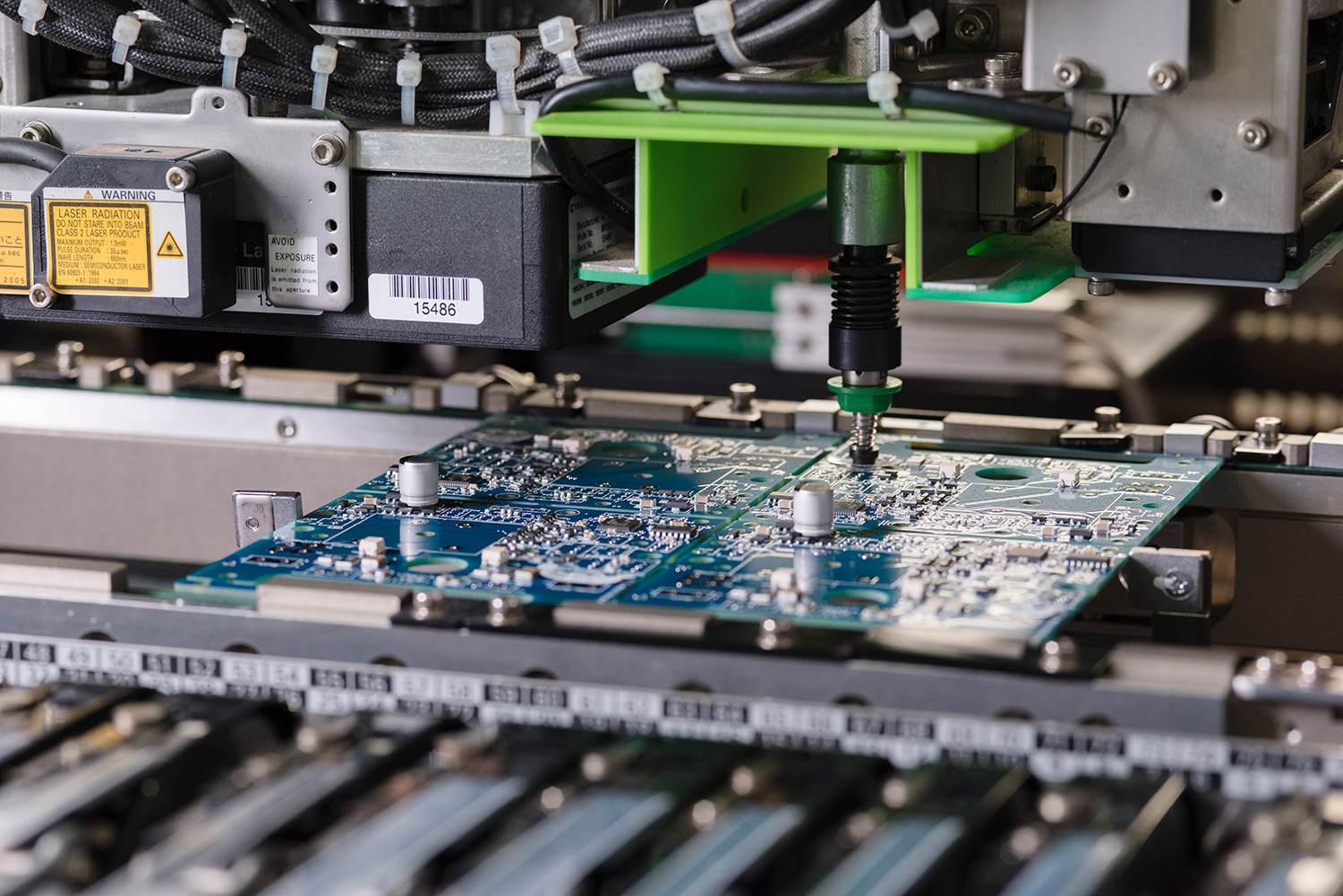

A4: Solder bridging results from faulty stencil design and component placement. Automated SMT lines (10,500 components/hour) with optical centering, laser-cut stencils (0.1mm precision), and post-soldering AOI testing prevent this issue.

Q5: How to shorten lead time for custom high-Tg PCB orders in Slovakia?

A5: Long lead times arise from material shortages and poor scheduling. A reliable PCB manufacturer in Slovakia stocks high-Tg materials (Tg 170¬įC+) and uses in-house production to offer 2-3 day prototype lead times for custom orders.