PCB fabrication china is more than a search term; it is the door to a huge ecosystem that blends speed, skill, and costâeffectiveness. In this guide you will see how Chinese plants turn design ideas into reliable boards, how rapid prototypes cut weeks off a schedule, and how assembly services let you launch products sooner. You will also meet EBest Circuit (Best Technology), a factory that fixes your needs with practical solution.

EBest Circuit (Best Technology) provides PCB fabrication, rapid prototyping, and assembly services in China. High-mix, low-volume, high-quality, fast prototyping, and turnkey assembly service are our core competencies. Our wide PCB range includes FR4 PCBs, ceramic PCBs, and metal core PCBs. Just feel free to contact us via sales@bestpcbs.com for effective solutions for your PCB fabrication projects.

What Is the Best PCB Fabrication China Company?

Every engineer wants the âbest,â yet that word means different things. Some value dense HDI layers, some need medical traceability, and others just want parts shipped fast. In China the list of factories is long, but only a few check every box. The best partner masters three areas at once: production management, technical design help, and delivery quality. Clear planning tools avoid the lastâminute schedule chaos that plagues many shops. A digital MES platform logs every panel and keeps data honest. A customer sees realâtime status and can adjust volumes without fear of hidden delays. That is how EBest Circuit (Best Technology) has built trust. Its engineers run early DFM reviews, spot Mark point gaps, and resize tiny test pads that slow AOI. When boards ship, each has a QR code that links to full trace records. The âbestâ is not just clean copper; it is also calm communication, stable lead times, and data you can show your own clients.

PCB Fabrication Manufacturer in China

China hosts thousands of board shops, yet the market sorts itself into clear tiers:

Tierâ1 Integrated Groups. These giants run multiple plants, own laminate lines, and serve telecom or server farms. They tackle highâlayer counts but may give prototypes low priority.

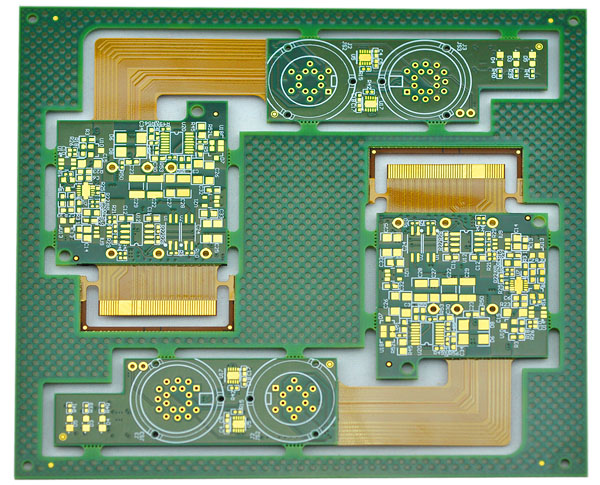

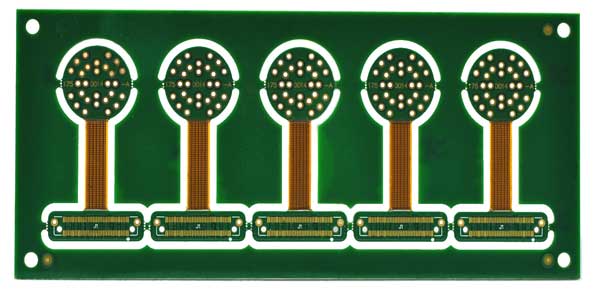

Tierâ2 Specialist Plants. Focus areas include RF, ceramic, or flex. They invest in niche gear and skilled staff. EBest Circuit (Best Technology) sits here, pairing fineâline knowâhow with agile service.

Tierâ3 Mass Producers. They chase large consumer orders. Prices are sharp, yet service is thin and design feedback minimal.

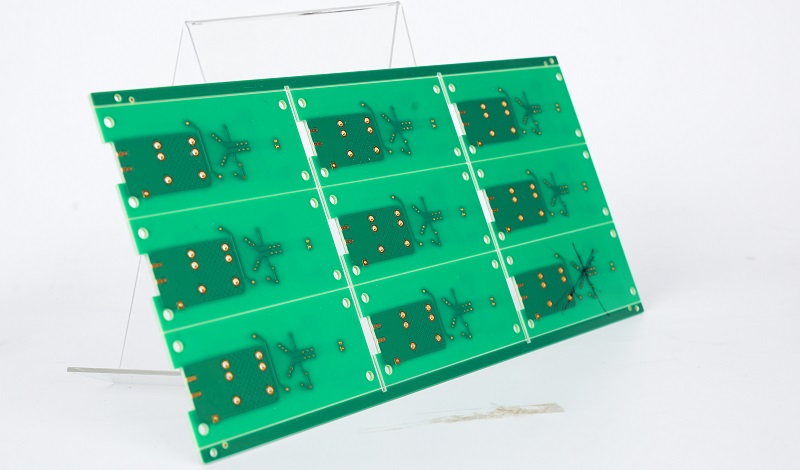

When you need both speed and precision, the specialist tier wins. EBest Circuit (Best Technology) uses smallâbatch parallel lines, so one day it runs a sixâpiece RF sample, the next day a thousand power boards. The team holds ISO 9001, ISO 13485, IATF 16949, and AS9100D certificates. These cover medical, automotive, and aerospace fields, letting customers merge different projects under one roof rather than juggle several vendors.

Who Is the Largest PCB Fabrication China Supplier?

Measured by revenue, the crown often shifts between names such as Wus, Shennan, and DSBJ, each topping billions of dollars in sales. Their size brings depth of process but also layers of approval that can slow tweaks. For small to mid runs you may wait in a queue behind telecom giants. That gap is where agile factories thrive. EBest Circuit (Best Technology) may not be the biggest by floor space, yet its smart line layout and lean cells give response speed that giants cannot match. A focused scope means a project manager can tweak a drill file this morning and still plate copper tonight. Growth is steady but controlled, so each client keeps a direct contact, not a ticket number in a help desk.

Is EBest Circuit (Best Technology) in China?

Yes. EBest Circuit (Best Technology) is headâquartered in Shenzhen. The site sits close to laminate suppliers like Shengyi, logistics hubs in Shenzhen, and the port of Hong Kong. That location drops transit time and lets engineers visit raw material plants the same day an issue appears. For customers abroad this means shorter DHL routes and consistent freight rates. Local teams speak fluent English, which clears cultural hurdles and streamlines calls.

How Much Does PCB Fabrication China Cost?

Cost moves with layer count, copper weight, surface finish, and above all, order volume. A twoâlayer FRâ4 sample under 100Â mmÂČ may cost under USDÂ 30 shipped air. Move to eight layers, blind vias, ENIG finish, and that price rises toward USDÂ 150 for the same outline. Volume orders drive price per piece down fast once panels fill the full 18Â ĂÂ 24Â inch sheet. EBest Circuit (Best Technology) gives sliding scales on each quote, so design teams see breakâeven points between prototype and pilot runs. The quote also lists lead time options if you need: standard and express. Express lifts cost a little but the urgent boards can be finished within 24 hours. All fees appear in one sheetâfabrication, parts, SMT setâupâso buyers avoid hidden extras later.

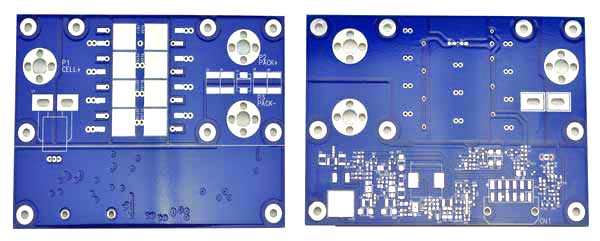

What Is the Most Commonly Used PCB Material in PCB Fabrication China?

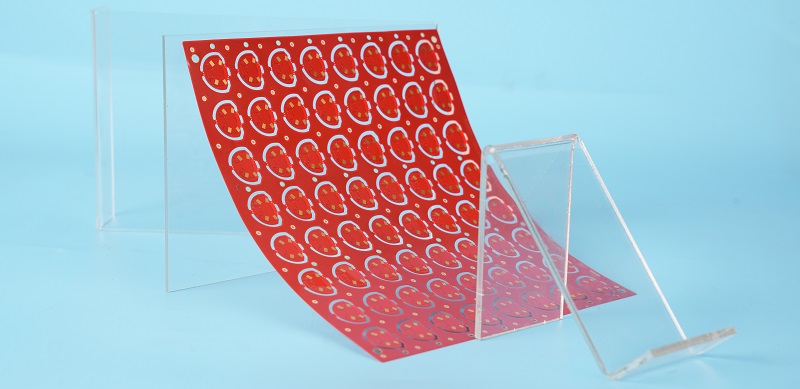

Standard FRâ4 remains the workhorse due to balanced strength, thermal limits, and price. For flex layers, PI (polyimide) is top. Highâfrequency lines move toward lowâloss Rogers 4350B or Shengyi S1000-2. Ceramic boards use alumina or aluminum nitride for LED cooling. EBest Circuit (Best Technology) stocks key grades from local and global brands. A buffer stock policy keeps two weeks of common cores and coppers on hand, which shields your schedule from sudden laminate shortages.

Why Should You Choose EBest Circuit (Best Technology) as Your PCB Fabrication China Partner?

1. It clears design snags fast. Mark points off the grid? Vâscore too deep? Inâhouse CAM engineers spot the glitch, send a marked Gerber back within two hours, and jump to drill only after you approve.

2. It tracks every board. A laser QR at final AOI links drill bits, plating bath ID, and solder mask batch. If a field failure occurs, you view root data at once. That cuts RMA cycles and builds endâcustomer trust.

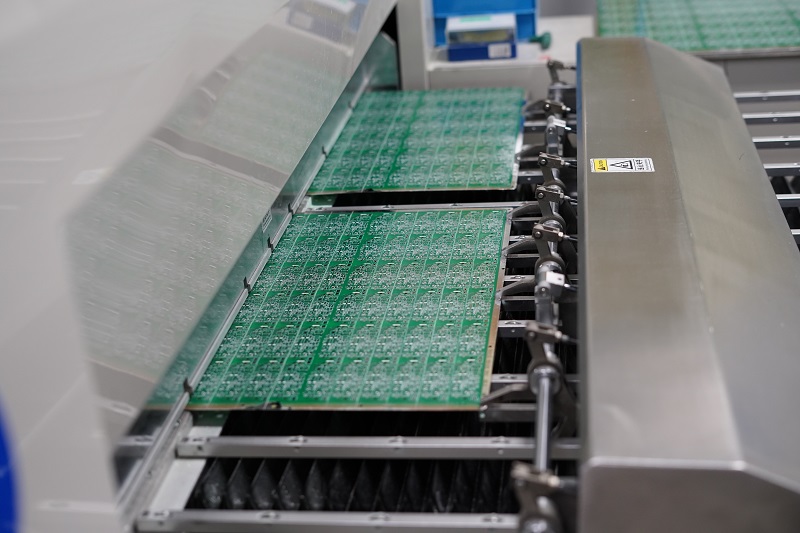

3. It levels up assembly. Fabrication and SMT share one floor, so panels stay indoors. Parts pass Xâray, then SPI, then reflow in a nitrogen oven. Mixedâtech builds place BGA on side A, then throughâhole on side B, soldered by selective wave. A final functional jig runs powerâup and boundary scan.

4. It guards quality. Certifications cover ISO 9001, ISO 13485, IATF 16949, and AS9100D. Audits by medical and aerospace clients verify processes each year.

In summary, choosing a PCB fabrication china partner is no longer a game of rockâbottom price. True value lies in smart planning, reliable quality, and rapid prototyping that keep your design moving. EBest Circuit (Best Technology) answers each of your demandsâplan shifts, design hurdles, and traceabilityâthrough an MES backbone, onâsite assembly, and a culture of open talks. Offering high-quality PCBs is the prerequisite for us to gain the trust of both potential clients and regular customers. And good and prompt service is our soft skill. Reach out to us and share your Gerbers with us at sales@bestpcbs.com, and feel the difference on your very next project.