What is quick turn PCB fabrication? Let’s discover its technical spec, design strategies, production process, recommended manufacturer.

Are you worried about these issues?

- Delays stalling R&D?

- Low-cost quality risks?

- Hidden costs inflating budgets?

EBest Circuit (Best Technology) can provide service:

- 48-hour full-cycle delivery.

- 98%+ first board pass rate.

- All-inclusive pricing.

Welcome to contact us if you have any request for quick turn PCB: sales@bestpcbs.com.

What Is Quick Turn PCB Fabrication?

Quick Turn PCB Fabrication is a highly efficient printed circuit board (PCB) production service. Through optimized processes, automated design checks, and synchronized production management, it completes the entire process from design to delivery within 24 hours to 5 days, significantly shortening product development cycles.

This service is designed to rapidly respond to the electronics industry’s needs for prototype verification and urgent production, allowing for flexible design adjustments. While the unit price is higher, it improves overall efficiency by saving time and costs. This service is widely used in consumer electronics prototypes (such as IoT devices), emergency medical and automotive parts, and rapid verification for startups.

Technical Specifications for Quick Turn PCB Fabrication

| Parameter Category | Technical Specifications |

| Layer Count | 1-16 layers (standard) |

| 18-32 layers (advanced) | |

| Substrate Types | FR-4 (standard) / High-Tg FR-4 / Polyimide / PTFE (RF) / Aluminum-backed |

| Copper Thickness | 0.5oz(17ÎŒm)/1oz(35ÎŒm)/2oz(70ÎŒm)/3oz(105ÎŒm) (outer layers) |

| 0.5oz-2oz (inner layers) | |

| Min Trace/Space | 3mil(0.075mm)/4mil(0.1mm)/5mil(0.125mm) (standard) |

| 2mil(0.05mm) (laser drilling) | |

| Via Technology | Through-hole(PTH)/Blind(BVH)/Buried(BVH) |

| Microvia(â€0.15mm) | |

| Surface Finishes | HASL(Leaded/Lead-free)/ENIG/OSP/Immersion Silver/Immersion Tin |

| Solder Mask Coverage | Green(standard)/Blue/Red/White/Black/Clear (LPI) |

| Dimensional Tolerance | Board edges: ±0.15mm |

| Hole diameters: ±0.05mm | |

| Outline: ±0.2mm (laser cutting) | |

| Special Processes | Gold fingers/Carbon ink printing/Embedded resistors/Rigid-flex/Selective gold plating |

| Lead Time | Single/double-sided: 24 hours |

| 4-8 layers: 48-72 hours | |

| 10+ layers: 5-7 business days |

How to Design Fast Turn PCBs to Reduce Production Cost?

1. Modular Pre-layout

- Decompose complex circuits into independent functional modules (e.g., power modules, signal processing modules), develop standardized libraries for cross-project reuse. Universal power module packaging reduced layout time by 30%.

2. Structured Constraint Management

- Import mechanical structure data (STEP format), define keep-out zones and height restrictions. Use 25mil sub-grid for critical components (BGA) and 50mil main grid for general layout to align with automated SMT machine precision.

3. Layer Count Dynamic Balancing

- Determine minimum viable layer count through signal integrity simulation. Replace traditional through-holes with buried/blind via hybrid structures for high-speed signals. Reduced an 8-layer industrial control board to 6 layers, cutting costs by 18%.

4. Material Standardization Strategy

- Prioritize FR-4 substrate, use localized PTFE hybrid construction for >5GHz signals. Develop enterprise material libraries with â„70% standard component packages. Achieved 40% cost reduction compared to full Rogers 4350B solutions.

5. DFM Rules Embedded Design

- Implement real-time DRC rules: minimum trace width/spacing 6mil, pad diameter via+12mil, solder mask opening trace+4mil. Reduced production defect rates from 2.3% to 0.7%.

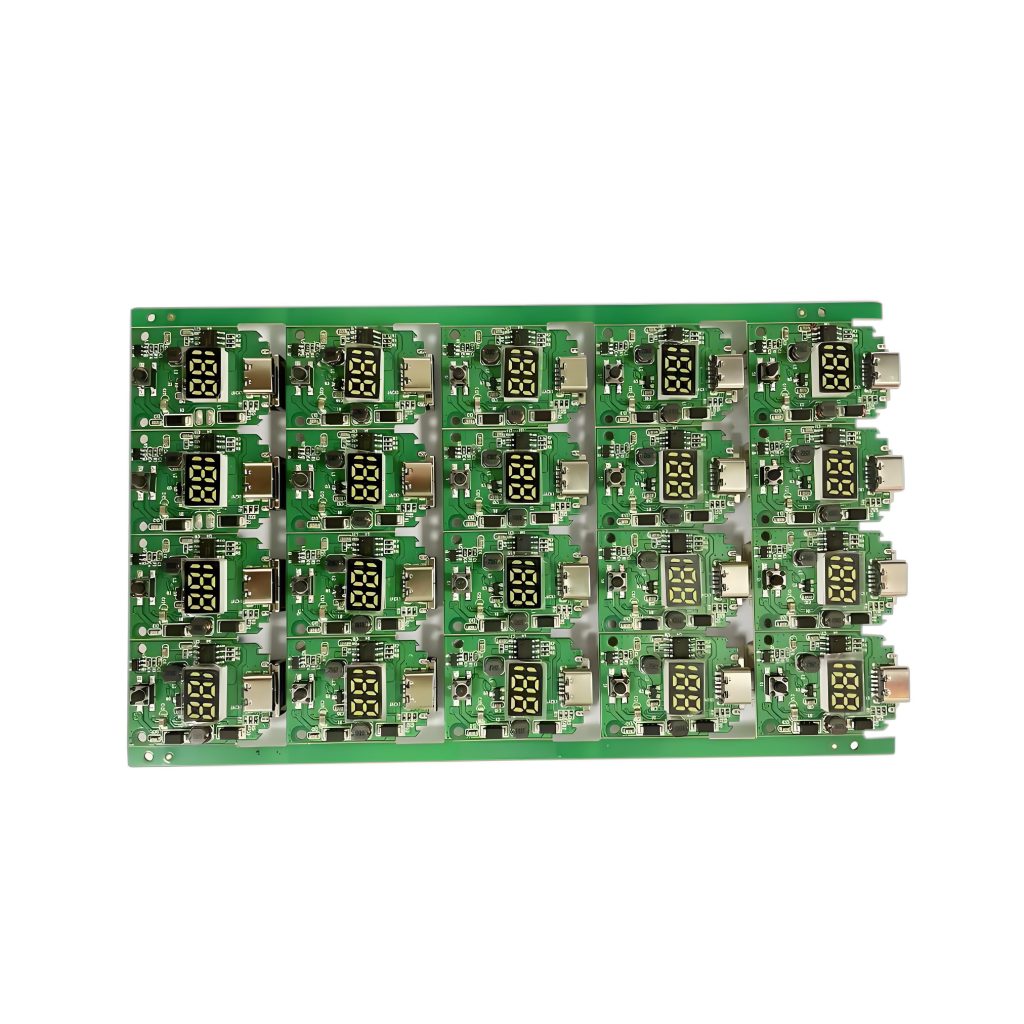

6. Panelization Economic Design

- Use V-cut + stamp hole hybrid panelization with 3mm process margin. Optimal panel count: 5pcs/panel, reducing unit costs by 35% versus single boards.

7. Concurrent Design Process

- Execute parallel tasks during schematic phase: BOM standardization review, ECAD-MCAD mechanical interference checks, and FloTHERM thermal simulations. Shortened design cycles from 15 days to 9 days.

Double Sided PCB Quick Turn Fabrication Processes

1. Material Cutting

- Substrate Preparation: Use automatic shearing machines to cut copper-clad laminates (FR-4/CEM-1) into standard sizes (e.g., 18″Ă24″) with edge tolerance â€0.1mm.

- Pre-Baking Treatment: Bake cut substrates at 120â for 2 hours to eliminate material stress and prevent warpage during subsequent processes.

2. Drilling

- CNC Drilling: Employ 6-axis CNC drills with 0.2mmâ3.2mm diameter bits, operating at 10,000â15,000rpm. Drilling time per panel â€5 minutes.

- Hole Cleaning: Immediately blow debris from holes using high-pressure air to avoid plating defects.

3. Electroless Copper Plating

- Desmearing: Immerse drilled panels in potassium permanganate solution to remove resin residues from holes.

- Copper Deposition: Deposit 0.3â0.5ÎŒm copper layer in alkaline solution for hole wall conductivity, taking ~45 minutes.

4. Circuit Imaging

- Dry Film Lamination: Attach photosensitive dry film to substrates via thermal rollers at 110â±5â and 1.5m/min speed.

- Laser Exposure: Use LDI (Laser Direct Imaging) to project patterns onto dry film with â€4mil resolution, eliminating film usage and saving 30% time.

5. Etching

- Alkaline Etching: Immerse exposed panels in ammonium chloride-copper solution to remove non-conductive copper, maintaining line width tolerance ±0.05mm.

- Quick Stripping: Rinse residual dry film with high-pressure water jet at 50â±5â for â€2 minutes.

6. Solder Mask Application

- Screen Printing: Apply UV-curable solder mask using 36T mesh, achieving 20â30ÎŒm thickness with automatic alignment accuracy ±0.1mm.

- Pre-Curing: Bake panels at 80â for 10 minutes in infrared tunnel oven to stabilize ink flow.

7. Surface Finish

- Nickel deposition: 3â5ÎŒm thickness, 8â12 minutes

- Gold deposition: 0.05â0.1ÎŒm thickness, 3â5 minutes

- Alternative: HASL (Hot Air Solder Leveling) through tin furnace, taking â€1 minute per panel.

8. Electrical Testing

- Flying Probe Testing: Utilize 4-axis flying probe machines with 50â150g contact force. Single panel testing time â€3 minutes, covering 100% networks.

- Fault Marking: Automatically ink-mark short/open circuit locations for rework.

9. Routing & Depaneling

- CNC Milling: Cut panels using 1mm diameter milling bits with ±0.05mm path accuracy. Single board routing time â€2 minutes.

- V-Cutting: For manual breakaway, score panels to 1/3 thickness at 30°â60° angle.

10. Final Inspection & Packaging

- AOI Inspection: Scan solder pads/traces with 3D cameras to detect defects (e.g., solder balls, misalignment) at 1.2mÂČ/minute speed.

- Vacuum Packaging: Seal panels in aluminum foil bags with desiccant, vacuuming to -0.1MPa for moisture/oxidation protection.

Why Choose EBest Circuit (Best Technology) as Quick Turn PCB Manufacturer?

Reasons why choose us as quick turn PCB manufacturer:

- Ultra-Fast Delivery (24-72 Hours): Accelerates product development cycles by 50%+ compared to standard lead times, enabling rapid prototyping and market validation.

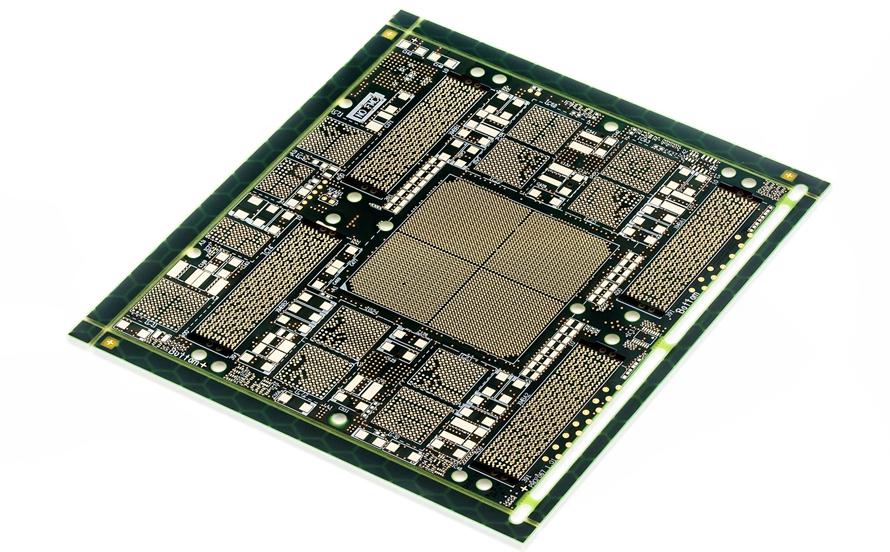

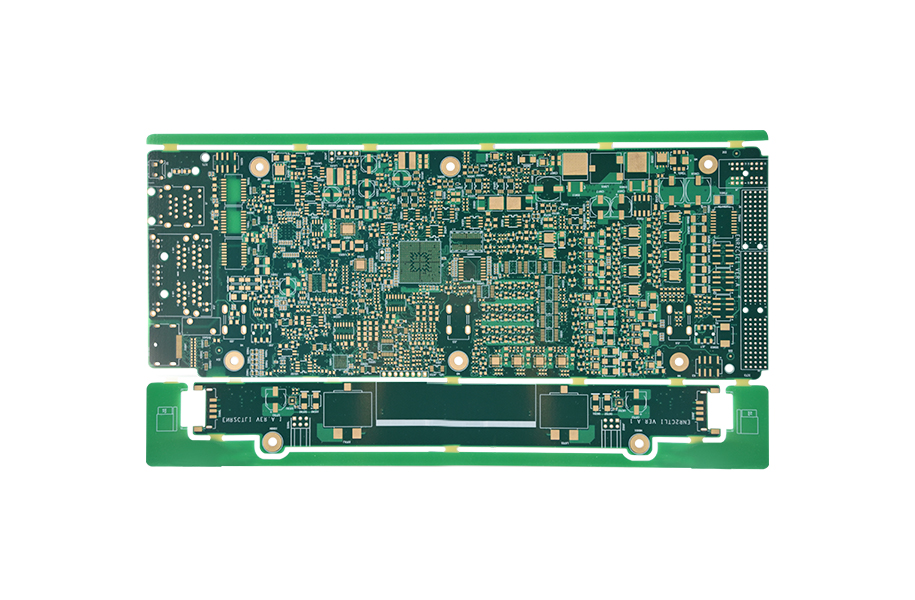

- Advanced Technical Capabilities: Supports 1-16 layer boards with 0.1mm mechanical drilling and 0.1mm laser microvias. Minimum 3.5mil/4mil trace/space (1mil/1mil for HDI). Enables complex designs for IoT, wearables, and high-speed applications.

- Automated DFM Checks: Reduces design errors by 30%+ through pre-production validation, minimizing rework costs.

- Transparent Pricing Model: Eliminates hidden costs, with small-batch discounts for prototypes <50pcs.

- 24/7 Engineering Support: Real-time technical assistance during design phase prevents costly production delays.

- ISO-Certified Quality Control: Ensures reliability for medical/automotive applications with zero-defect tolerance.

- Surface Finish Flexibility: HASL, ENIG, OSP options with 2ÎŒm gold thickness control.

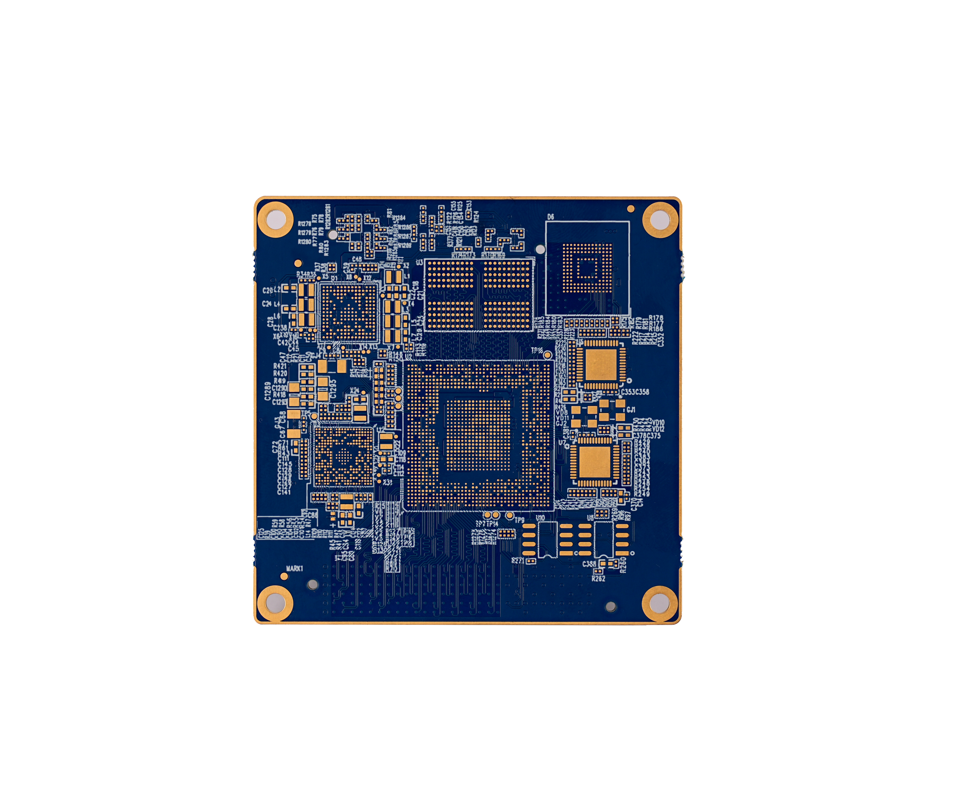

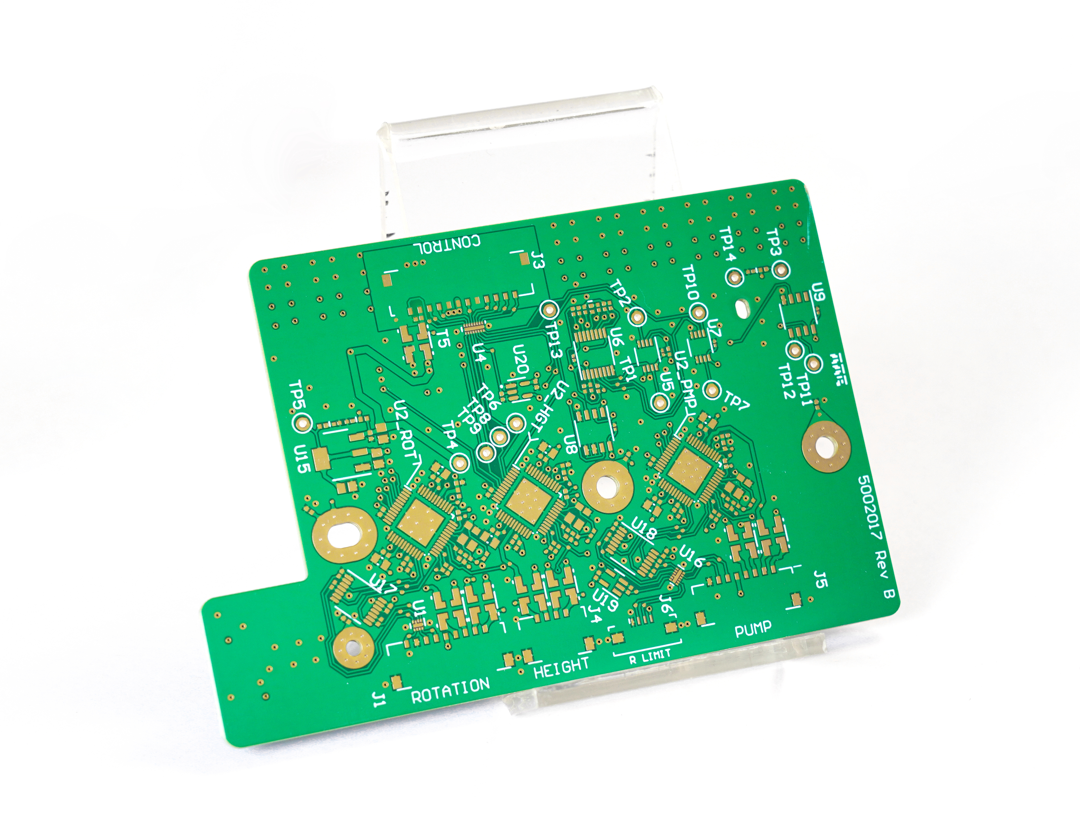

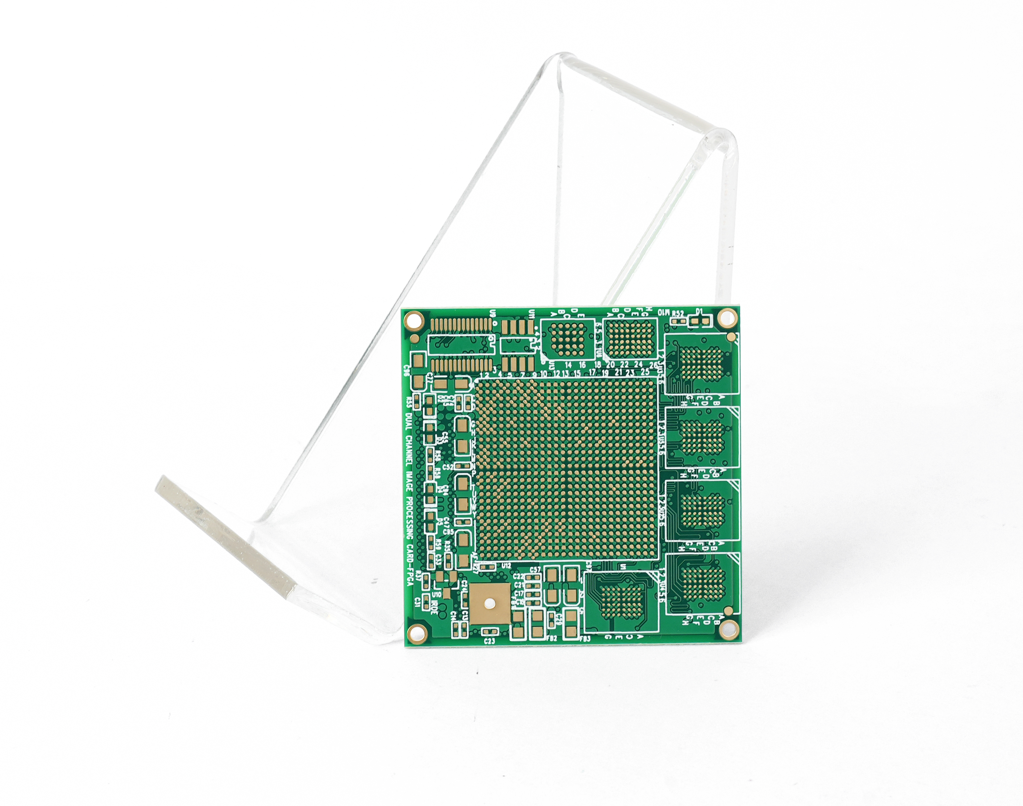

Below is a photo of FR4 PCB board we made before:

Our Quick Turn PCB Prototyping Time

| Layers | Normal Service | Fastest Service |

| 1 | 7 Days | 24 H |

| 2 | 8 Days | 24 H |

| 4 | 10 Days | 48 H |

| 6 | 10 Days | 72 H |

| 8 | 12 Days | 72 H |

| â„10 | TBD | TBD |

Our Quick Turn PCB Options

1. Express Delivery (24-48 Hours)

- Layer Support: 1-6 layers (standard boards).

- Trace Width/Spacing: 3.5mil/4mil (1mil/1mil for advanced processes).

- Drill Size: 0.2mm mechanical drilling (0.1mm laser microvias).

- Suitable For: Urgent prototype verification, exhibition samples.

2. Standard Quick Turn Service (3-5 Days)

- Layer Support: 8-10 layers (complex designs).

- Material Options: FR-4, aluminum substrate, high-frequency materials (Rogers/PTFE).

- Surface Finishes: HASL (leaded/lead-free), ENIG, OSP.

- Suitable For: Small-batch trial production, functional testing.

3. Economy Quick Turn Solution (5-7 Days)

- Copper Thickness: 0.5oz-3oz (standard options).

- Solder Mask Colors: Green, Blue, Red, Black, White, Matte Black.

- Cost Optimization: Volume discounts (50+ panels).

- Suitable For: Pre-production validation, cost-sensitive projects.

How to Get A Quote for Quick Turn PCB Project?

Follow these steps to ensure accurate and efficient quotation:

1. Submit Design Files

- Provide Gerber files (RS-274X format) or PCB design source files (Altium/Eagle/PADS).

- Include assembly drawings if applicable.

2. Specify Technical Requirements

- Layer count (1-16 layers).

- Minimum trace width/spacing (e.g., 3.5mil/4mil).

- Drill size requirements (mechanical/laser).

- Material type (FR-4, aluminum, Rogers/PTFE).

3. Confirm Production Details

- Order quantity (5-5,000+ pieces).

- Surface finish preference (HASL/ENIG/OSP).

- Copper thickness (0.5oz-6oz).

- Solder mask color selection.

4. Indicate Special Requirements

- Impedance control needs.

- Blind/buried vias requirement.

- High-frequency material certification.

- RoHS compliance requirement.

5. Provide Contact Information

- Company name and location.

- Project timeline expectations.

- Preferred communication channel (email/phone).

Welcome to contact us if you have any request for quick turn PCB: sales@bestpcbs.com.