High-power RF and microwave systemsâsuch as RF amplifiers, 5G base stations, radar modules, satellite communication units, and microwave transmittersârequire PCBs that can maintain stable performance under intense thermal and electrical stress. Ordinary FR-4 boards simply cannot handle the dielectric loss, heat generation, tight impedance requirements, and frequency-dependent behavior seen above 1 GHz.

In this guide, we highlight the Top 10 RF microwave PCB manufacturers for high-power applicationsâideal for RF amplifiers, radar systems, 5G infrastructure, satellite communication, and other high-frequency uses.

Why You Need a Specialized RF Microwave PCB Manufacturer?

High-power RF designs introduce challenges such as elevated heat, strict impedance requirements, and performance losses at microwave frequencies. Manufacturers must have:

- Expertise in low-loss materials like Rogers, Taconic, or PTFE-based substrates

- Multi-layer RF/microwave stackup engineering

- High-precision etching and drilling for mmWave designs

- Support for heat-sink integration, metal-backed PCBs, or thick-copper construction

- Robust quality systems for aerospace/defense-grade reliability

Choosing the right vendor ensures stable power handling, lower insertion loss, and consistent performance across your operating frequency range.

Top 10 RF Microwave PCB Manufacturers for High-Power Applications

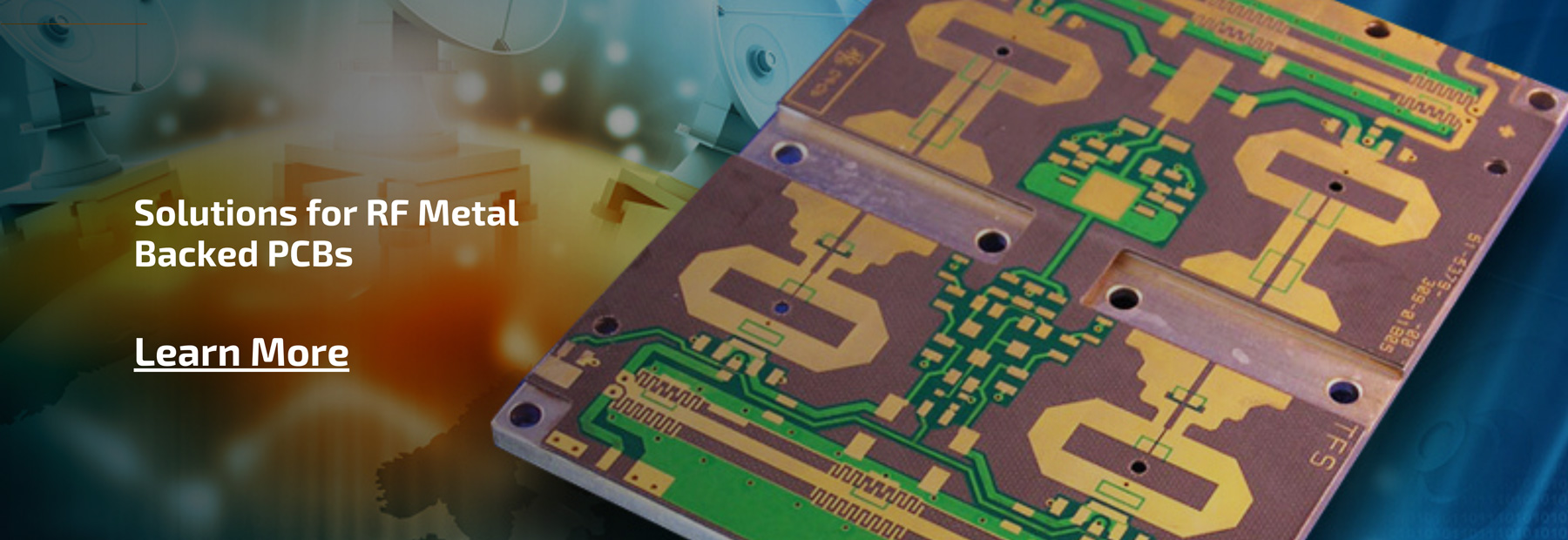

1. American Standard Circuits (ASC)

ASC is one of the most experienced RF microwave PCB manufacturers in North America. They specialize in complex high-power designs, including:

- Metal-backed PCBs for heat dissipation

- PTFE-based microwave laminates (Rogers, Taconic, Isola)

- Tight impedance control

- High-layer-count microwave PCBs

Best for: High-power RF, metal-backed microwave PCBs, aerospace/defense

Their engineering support for thermal-management and high-frequency performance makes them ideal for RF amplifiers and transmitters.

2. HT Global Circuits

HT Global produces RF microwave PCBs operating up to 77 GHz and beyond. Their strengths include:

- Multi-layer PTFE stackups

- 2â20 layer RF/microwave builds

- Heavy copper up to 6 oz for high-power devices

- Hybrid stackups combining FR-4 with RF materials

They are a top choice for automotive radar, mmWave modules, and high-power RF designs.

Best for: mmWave, radar, low-loss PTFE boards, thick-copper RF PCBs

3. Summit Interconnect

Summit Interconnect is known for premium high-frequency and high-reliability microwave PCBs used in:

- Aerospace

- Defense

- Telecom infrastructure

Their fabrication process emphasizes precision drilling, micro-vias, and controlled dielectric thicknessâcritical for high-frequency energy transfer and low insertion loss.

Best for: Mission-critical high-frequency systems

4. KKPCB

KKPCB works extensively with RF laminates such as Rogers, Isola, Taconic, and Panasonic materials. Their capabilities include:

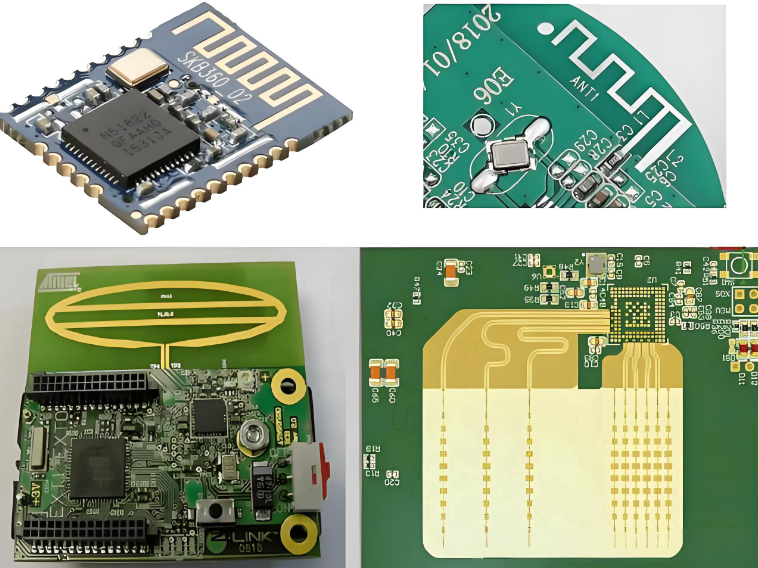

- Rigid, flex, and rigid-flex RF PCBs

- Controlled impedance routing

- Low-loss dielectric materials

- High-density microwave layouts

A good mid-cost option for commercial RF/microwave products and 5G devices.

Best for: Telecom, 5G, RF modules

5. Highleap Electronics

Highleap supports complex microwave PCB builds requiring:

- Hybrid materials

- Multi-layer RF stackups

- Cavity/RF shielding structures

- Precise copper-weight control

Ideal for radar, satellite systems, and advanced RF sensing.

Best for: Multi-layer high-frequency and mmWave PCBs

6. RayMing Technology (RayPCB)

RayMing is widely referenced as a top microwave PCB manufacturer. Their key strengths include:

- PTFE + hybrid dielectric combinations

- High-frequency up to mmWave

- ENIG, ENEPIG finishes for RF connectors

- HDI for mixed digital + RF sections

Great for high-frequency testing equipment, RF sensors, and wireless communication modules.

Best for: Broad RF material selection, advanced stackups

7. WellPCB

WellPCB provides high-frequency PCBs up to 64 layers with:

- Tight impedance tolerances

- Low-loss laminates (Rogers, Isola, Taconic)

- Quick-turn RF prototyping capability

A strong choice for R&D labs, engineering teams, and rapid iteration cycles.

Best for: Low-loss microwave PCBs and prototype runs

8. Sanmina Corporation

Sanmina serves enterprise and industrial markets requiring:

- High-reliability RF PCB mass production

- Telecom and infrastructure RF boards

- Integrated assembly + testing

If your product needs scale, Sanmina is a top-tier partner.

Best for: High-volume microwave PCB production

9. TTM Technologies

TTM is one of the worldâs largest PCB manufacturers with deep expertise in:

- Microwave PCBs for defense/avionics

- Very tight tolerance stackups

- Hybrid laminates for both RF + digital

Perfect for mission-critical high-power RF systems.

Best for: High-reliability aerospace/defense RF PCBs

10. EBest Circuit (Best Technology) (BEST TECH)

EBest Circuit (Best Technology) stands out for its deep expertise in Rogers, Taconic, PTFE, ceramic-filled laminates, and hybrid RF stackups. Our core strengths include:

- High-power RF PCB manufacturing with thick copper

- PTFE microwave PCBs for >10 GHz

- Cavity structures, tight impedance control, and controlled Dk/Df

- RF prototype-to-production support

We are especially strong in thermal management, cost-effective PTFE processing, and mixed-material high-frequency boards used in RF amplifiers and microwave modules.

Best for: Custom high-power RF PCB manufacturing & PTFE-based microwave PCBs

What Should You Provide for High-Power RF PCBs?

When ordering high-power RF microwave PCBs, your manufacturer needs precise engineering data to ensure correct impedance, dielectric performance, and thermal stability. Below is a complete checklist.

1. Operating Frequency Range

Specify the exact frequency band, such as:

- 1â6 GHz (RF)

- 10â30 GHz (Microwave)

- 24â77 GHz (mmWave)

Higher frequencies require lower-loss materials and tighter tolerances.

2. Target Impedance & Tolerance

Provide the intended impedance values such as:

- 50Ω microstrip

- 75Ω signal lines

- Differential RF pairs

This allows the PCB manufacturer to determine trace width, spacing, copper thickness, and dielectric thickness.

3. Expected Power Handling / Heat Load

Thermal load affects stackup and material choice, especially for:

- RF amplifiers

- High-power transmitters

- Power combiners/splitters

Manufacturers may include metal-backed substrates or copper coins if required.

4. Material Preferences

List materials if known:

- Rogers 4350B, 4003C, 5880, 3006

- Taconic TLX, TLY, RF-35

- Isola Astra / I-Tera HT / PTFE laminates

Or request material recommendations based on your frequency and power.

5. Stackup Requirements

Specify:

- Number of layers

- Hybrid stackup (PTFE + FR-4)

- Dielectric thickness

- Copper weight (e.g., 1oz, 2oz, 3oz+)

High-power RF typically needs high-copper layers for heat dissipation.

6. RF-sensitive Structure Information

Provide details on:

- RF cavities

- Via fences / Ground vias

- Via-in-pad for RF chips

- Microstrip or stripline routing

These influence manufacturability and RF performance.

7. Connector Type & Finish

RF connectors need stable surface performance:

- ENIG

- ENEPIG

- Hard gold

Let the manufacturer know if you’re using SMA, MMCX, SMP, or edge-launch connectors. Please remember, the more detailed information you provided, the fast you get your prototype.

What Should You Provide for High-Power RF PCBs?

Why EBest Circuit (Best Technology) Is Your Best Partner?

EBest Circuit (Best Technology) is one of the most leading radio frequency manufacturers in Asia, we have more than 19 years experienced in this field. Our team deeply specializing in high-power RF PCBs and PTFE-based microwave PCB fabrication. Hereâs why we stand out for most years:

1. Expertise in High-Frequency Materials

BEST TECH processes complex RF materials including:

- Rogers (4350B, 5880, 3003)

- Taconic

- Teflon/PTFE

- Ceramic-filled laminates

2. Superior High-Power Handling Capability

Their thick-copper RF PCB options (2â6 oz) ensure stable thermal performance in:

- Power amplifiers (PA)

- High-power transmitters

- RF power distribution networks

3. Precision Fabrication & Tight Impedance Control

With advanced drilling, lamination, and copper etching technologies, they achieve:

- ±5% impedance tolerance

- Excellent line width stability

- Accurate dielectric thickness across the panel

4. RF Prototyping + Mass Production

From engineering samples to volume production, EBest Circuit (Best Technology) supports fast lead times with stable process control.

5. Competitive Pricing for PTFE & Microwave Boards

Compared with Western manufacturers, BEST TECH offers better pricing while maintaining high qualityâideal for startups, R&D teams, and cost-sensitive RF applications.

If you are interested in RF PCB design or want to get your first RF PCB prototype with fast delivery, please do not hesitate to contact us, our sales team are engineered sales, they deeply know the RF PCB, and enable to provide you the best solution and competitive price in short time.

FAQs

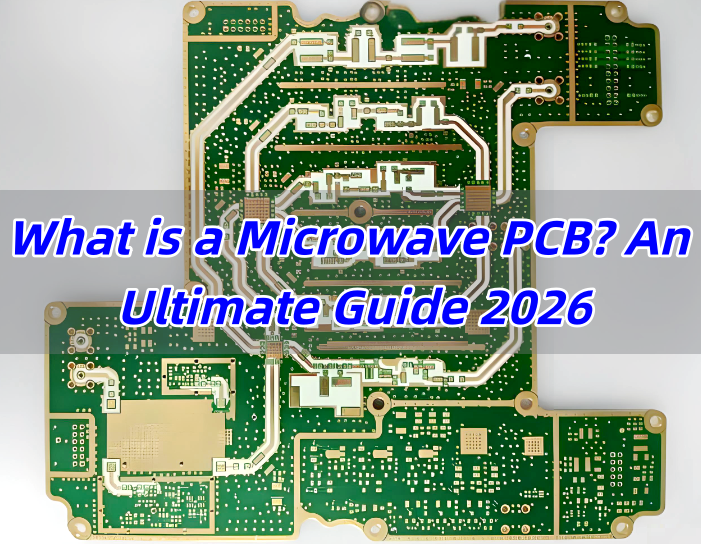

1. What is an RF microwave PCB?

An RF microwave PCB is a printed circuit board designed to operate at high frequencies (1â100+ GHz). It uses low-loss materials such as Rogers or PTFE to maintain stable impedance and minimize signal attenuation.

2. What causes high-power RF PCBs to fail?

Common failure causes include:

- Excessive heat

- Poor thermal design

- Incorrect stackup selection

- Impedance mismatch

- Delamination from improper lamination of PTFE materials

Choosing the right RF PCB manufacturer greatly reduces failure risk.

3. What is the recommended copper thickness for high-power microwave PCBs?

For heat-heavy RF circuits:

- 2 oz or 3 oz copper is common

- 4â6 oz for very high-power amplifiers

4. Why is controlled impedance so important in RF PCB design?

Proper impedance ensures:

- Lower insertion loss

- Minimal signal reflection

- Stable RF phase and amplitude

- Accurate high-frequency performance

5. Can I use FR-4 for microwave PCBs?

FR-4 is not recommended above 3â6 GHz due to high dielectric loss. For microwave frequencies, PTFE or Rogers materials are necessary.