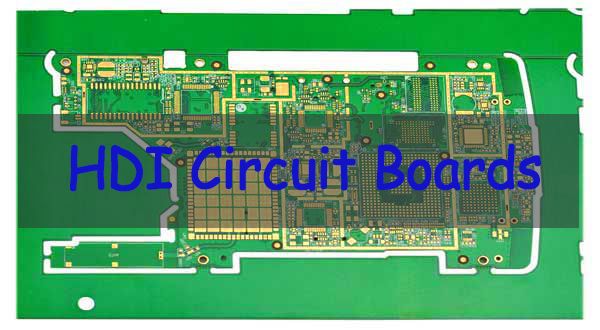

HDI circuit boards‚Äč represent a significant advancement in printed circuit board technology, utilizing high-density interconnect methods to achieve finer lines, smaller vias, and higher connection density than conventional PCBs. This article explores how HDI technology fundamentally enhances the reliability and performance of modern electronic devices, making it a cornerstone for advanced applications.

Many engineers face a critical challenge: standard PCBs often fall short in demanding environments, leading to performance bottlenecks and reliability concerns. Common pain points include:

- Signal Degradation at High Speeds:‚Äč Increased complexity and higher frequencies cause cross-talk, attenuation, and impedance mismatches.

- Limited Real Estate for Advanced Components:‚Äč It’s difficult to route a high pin-count BGA or FPGA on a standard PCB without adding excessive layers and cost.

- Thermal Management Issues:‚Äč Inefficient heat dissipation in dense layouts can lead to premature component failure.

- Mechanical Failure Risks:‚Äč Traditional through-holes and larger vias are more susceptible to stress fractures under thermal cycling or vibration.

- Cost-Performance Trade-offs:‚Äč Achieving higher performance often meant moving to more expensive, exotic materials or complex, less reliable manufacturing processes.

Overcoming these challenges requires a technological shift. The following solutions, inherent to HDI design and manufacturing, directly address these limitations:

- Superior Signal Integrity:‚Äč HDI’s use of microvias and finer traces allows for optimized impedance control and shorter signal paths, reducing loss and EMI.

- Maximum Component Density:‚Äč HDI technology enables the routing of complex ICs in a smaller area, often reducing the total layer count and board size.

- Enhanced Thermal Performance:‚Äč Stacked and staggered microvias can act as thermal vias, improving heat dissipation away from critical components.

- Improved Mechanical Robustness:‚Äč Laser-drilled microvias create less stress in the dielectric material and are more resilient to thermal expansion and mechanical shock than mechanically drilled holes.

- Optimized System Cost:‚Äč By enabling a reduction in layer count and size while improving performance, HDI offers a better overall cost-structure for high-end products.

At BEST Technology, we specialize in the manufacturing of high-reliability HDI printed circuit boards‚Äč that are engineered to meet the rigorous demands of advanced applications. Our expertise in advanced processes like any-layer interconnect and controlled impedance ensures your designs achieve peak performance and longevity. For a partnership built on quality and innovation, contact us at sales@bestpcbs.com.

What Are HDI Circuit Boards?

High-Density Interconnect (HDI) boards are defined by their use of microvias (typically with a diameter of less than 150¬Ķm), fine line widths/spaces (under 100¬Ķm), and higher connection pad density. They represent the evolution of PCB technology to support the miniaturization and performance requirements of modern electronics.

- Core Characteristics:

- Microvias:‚Äč Blind and buried vias drilled by laser, allowing for connections between adjacent layers.

- Fine Features:‚Äč Tighter trace widths and spaces enable more routing in a smaller area.

- Built-up Layers:‚Äč HDI boards are often constructed using sequential lamination processes, building up the layer stackup.

- Advanced Materials:‚Äč While FR4 is common, high-frequency or high-Tg materials are frequently used to enhance performance.

- Key Benefits for Reliability:

- Shorter Signal Paths:‚Äč Reduced signal travel distance minimizes loss and propagation delay.

- Reduced Crosstalk:‚Äč Tighter control over impedance and spacing lowers electromagnetic interference.

- Enhanced Electrical Performance:‚Äč Overall, HDI technology leads to faster signal transmission and better power integrity.

In summary, HDI circuit boards‚Äč are not just smaller PCBs; they are a fundamentally different approach to interconnection that inherently supports greater reliability.

How Do HDI Printed Circuit Boards Enhance Routing Density in Advanced Devices?

HDI printed circuit boards‚Äč achieve superior routing density through advanced structural elements that bypass the limitations of traditional through-hole vias.

- Microvia Technology:‚Äč Laser-drilled microvias allow for “via-in-pad” designs, placing vias directly on component pads. This eliminates the need for stub traces from the pad to a via, freeing up routing space.

- Any-Layer HDI:‚Äč The most advanced form, where microvias can connect any two layers in the stackup, providing unparalleled routing flexibility and the highest possible density for complex processors and FPGAs.

- Sequential Lamination:‚Äč This process allows for the creation of multiple layers of microvias, effectively building a three-dimensional routing structure within the board.

The enhanced routing density provided by HDI printed circuit boards‚Äč is a primary driver for the miniaturization and increased functionality of devices like smartphones and medical implants, directly contributing to their reliability by enabling more robust and optimized layouts.

What Factors Define a Reliable HDI Printed Circuit Board Supplier for Complex Builds?

Choosing the right HDI printed circuit board supplier‚Äč is critical. A reliable partner possesses specific capabilities that ensure the success of complex builds.

- Advanced Process Control:‚Äč Demonstrated expertise in laser drilling, fine-line imaging, and sequential lamination with tight process controls.

- Material Expertise:‚Äč Experience with a range of materials, from standard FR4 to high-speed and high-Tg laminates, suitable for various HDI printed circuit boards.

- Engineering Support:‚Äč Strong Design for Manufacturability (DFM) feedback to optimize designs for yield and reliability before production begins.

- Robust Quality Assurance:‚Äč Investment in advanced inspection equipment like Automated Optical Inspection (AOI) and micro-sectioning analysis to validate microvia quality and layer registration.

- Proven Track Record:‚Äč Evidence of successfully manufacturing boards of similar complexity, such as any-layer HDI or boards with specific impedance requirements.

A true partner, like BEST Technology, acts as an extension of your engineering team, ensuring that the sophisticated design of your HDI circuit board‚Äč is translated into a physically robust and reliable product.

How Does the HDI Printed Circuit Board Market Evolve With RF and Microwave Demands?

The HDI printed circuit board market‚Äč is increasingly influenced by the stringent requirements of RF and microwave applications, such as 5G infrastructure and automotive radar.

- Demand for Tighter Tolerances:‚Äč RF circuits require extremely precise impedance control, which HDI processes can deliver through consistent dielectric thickness and fine trace geometry.

- Integration of Mixed Materials:‚Äč RF designs often use specialized laminates (e.g., Rogers) combined with FR4 in hybrid stackups‚ÄĒa capability that advanced HDI manufacturers must master.

- Low-Loss Considerations:‚Äč The move towards higher frequencies demands materials and processes that minimize dielectric loss (Df), a key factor in the HDI printed circuit board market‚Äč for RF.

The evolution of the market shows that HDI is no longer just about density; it’s about precision and material science to ensure signal integrity at high frequencies, which is a cornerstone of reliability in RF systems.

Why Do Engineers Compare HDI vs PCB When Optimizing Performance and Miniaturization?

The comparison of HDI vs PCB‚Äč (referring to standard PCBs) is a fundamental step in design optimization, focusing on the trade-offs between performance, size, and cost.

| Feature | Standard PCB | HDI PCB |

|---|---|---|

| Via Type‚Äč | Through-hole vias only | Microvias (blind/buried) |

| Line/Space‚Äč | >100¬Ķm (4 mil) | <100¬Ķm (3 mil and below) |

| Routing Density‚Äč | Lower | Significantly Higher |

| Signal Integrity‚Äč | Good for lower frequencies | Superior for high-speed designs |

| Board Size‚Äč | Larger for equivalent function | Can be substantially smaller |

| Relative Cost‚Äč | Lower for simple designs | Can be cost-effective for complex, miniaturized products |

Engineers choose HDI vs PCB‚Äč when the project’s goals for miniaturization, speed, and reliability outweigh the need for the simplest, lowest-cost board. The choice for HDI is a direct investment in enhanced performance and reliability.

How Does the PCB HDI Stackup Influence Impedance Control and Signal Quality?

The PCB HDI stackup‚ÄĒthe arrangement of copper and dielectric layers‚ÄĒis a critical design factor that dictates impedance control and, consequently, signal quality.

- Precise Dielectric Layers:‚Äč HDI processes allow for the use of thin, consistent dielectric core and prepreg materials, enabling designers to hit target impedance values (e.g., 50ő©, 100ő© differential) with high accuracy.

- Reference Plane Management:‚Äč A well-designed PCB HDI stackup‚Äč ensures that high-speed signal layers have uninterrupted reference planes, minimizing impedance discontinuities and return path problems.

- Microvia Impact:‚Äč The structure of microvias has less impact on impedance than through-hole vias, leading to cleaner transitions between layers.

A meticulously planned stackup is non-negotiable for achieving the signal integrity promises of HDI technology, making it a primary tool for ensuring the reliability of high-speed digital and RF circuits.

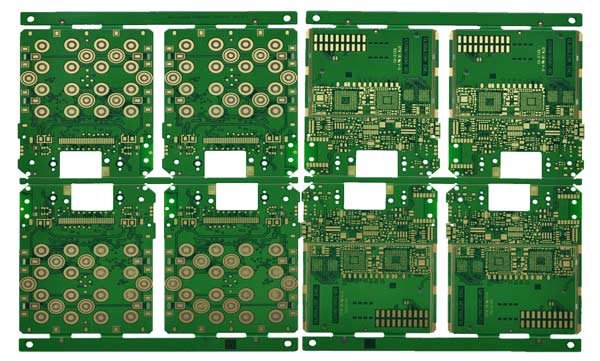

What Steps Define the HDI PCB Manufacturing Process for Multilayer HDI Structures?

The HDI PCB manufacturing process‚Äč for multilayer structures is a sequence of precise, repetitive steps that build up the board layer by layer.

- Core Lamination:‚Äč Starts with a central core material.

- Laser Drilling:‚Äč Microvias are drilled into the dielectric material using lasers.

- Desmear and Plating:‚Äč The microvias are cleaned and metallized to create electrical connections.

- Pattern Plating:‚Äč Copper traces are patterned on the layer.

- Lamination:‚Äč A new dielectric layer is laminated over the previous one.

- Repeat:‚Äč Steps 2-5 are repeated to build the sequential layers.

- Final Lamination and Through-Hole Drilling:‚Äč The entire board is laminated, and any required through-holes are drilled and plated.

- Surface Finish and Testing:‚Äč The board receives a surface finish (e.g., ENIG) and undergoes rigorous electrical and optical testing.

This sophisticated HDI PCB manufacturing process‚Äč allows for the creation of complex, reliable multilayer structures that are impossible to achieve with standard PCB techniques.

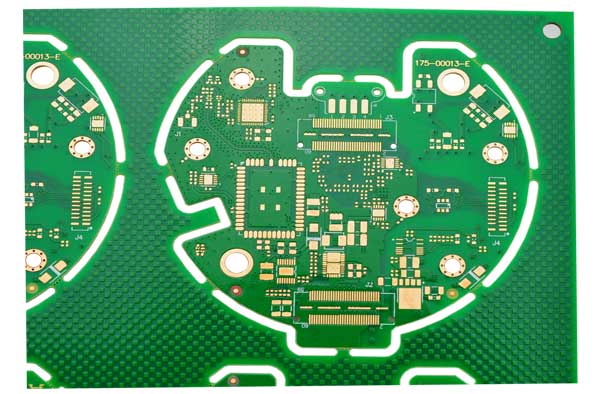

How Does HDI Technology in PCB Enable Any-Layer Interconnect for Next-Generation Products?

HDI technology in PCB‚Äč reaches its pinnacle with any-layer interconnect, where laser-drilled microvias can connect any two adjacent layers in the board stackup.

- Maximum Routing Freedom:‚Äč This approach provides the designer with virtually unlimited routing channels, essential for escaping modern, ultra-fine-pitch BGAs.

- Optimal Signal Paths:‚Äč Signals can take the most direct route possible, minimizing layer transitions and stub lengths, which boosts performance.

- Structural Integrity:‚Äč While complex, the sequential build-up process creates a more homogeneous structure, reducing the risk of delamination under stress.

HDI technology in PCB, particularly any-layer build-up, is the key enabler for the most compact and high-performance products on the market, from advanced servers to cutting-edge wearables, ensuring their reliability through superior design flexibility.

Why Choose EBest Circuit (Best Technology) as Your HDI Circuit Board PCB & PCBA Partner for Advanced Projects?

Selecting EBest Circuit (Best Technology) for your advanced HDI projects means partnering with a specialist that combines deep technical expertise with robust manufacturing capabilities. We are not just a supplier; we are an extension of your engineering team, dedicated to turning complex designs into market-leading products with precision, reliability, and speed.

1. Proven Expertise and Manufacturing Scale

- 19+ Years of Experience:‚Äč Established in 2006, we have served over 1,700 satisfied clients‚Äč across 40+ countries, building a reputation as a trusted PCB & PCBA expert in Asia.

- Significant Production Capacity:‚Äč With a monthly capability of 260,000 sq. ft. (28,900 sq. meters), we complete over 1,000 different board types‚Äč monthly, effortlessly scaling from rapid prototypes to mass production.

- Comprehensive Certifications:‚Äč Our commitment to quality is validated by ISO 9001:2015, IATF 16949:2016, and ISO 13485:2016, ensuring compliance with the highest international standards for various industries.

2. Advanced HDI & Specialized PCB Capabilities

We excel in manufacturing complex HDI and specialized circuit boards, as detailed in our capability charts:

- High Layer Count:‚Äč Up to 32 layers‚Äč for standard FR4 PCBs.

- Precision Fine Lines:‚Äč Minimum trace/space capabilities down to 2.5/2.5 mil‚Äč for inner layers and 3/3 mil‚Äč for outer layers (HDI class).

- Advanced Micro-Vias:‚Äč Laser drill capabilities for micro-vias as small as 4 mil (0.1mm)‚Äč in diameter, enabling complex any-layer HDI build-ups.

- Material Expertise:‚Äč Extensive experience with high-frequency materials (Rogers, Taconic), high-TG FR4, and heavy copper boards (up to 20 oz).

- Rigorous Impedance Control:‚Äč Tight impedance tolerance of ¬Ī10% (for values >50ő©) or ¬Ī5ő© (for values ‚ȧ50ő©).

3. True Full Turnkey PCBA Solution

We simplify your supply chain by managing the entire process under one roof:

- Rapid Prototyping:‚Äč Urgent PCB prototypes can be shipped within 24-72 hours.

- Global Component Sourcing:‚Äč We source from authorized distributors (Digikey, Mouser, etc.) to avoid counterfeit parts and offer component warehousing.

- Advanced Assembly:‚Äč Our SMT lines can place 13.2 million chips per day, handle components as small as 01005, and BGAs with a pitch of 0.25mm.

- Comprehensive Testing:‚Äč In-house testing includes AOI, X-Ray, Flying Probe, and functional testing to ensure 100% performance.

4. Commitment to On-Time Delivery and Value

We understand that timelines are critical. With a 97% on-time delivery rate‚Äč and online WIP updates, you always know the status of your order. Our efficient processes and economies of scale allow us to offer competitive pricing without compromising the quality that defines us.

To conclude, HDI circuit boards‚Äč are a foundational technology for achieving superior reliability in modern electronics, enabling higher performance, greater miniaturization, and enhanced robustness. This article has detailed how HDI principles, from stackup design to any-layer interconnect, directly contribute to more reliable end products. BEST Technology possesses the advanced manufacturing expertise and quality-focused processes to be your ideal partner for HDI printed circuit boards. If you have any questions or are ready to proceed any new HDI circuit boards, Pls contact our team at sales@bestpcbs.com.

FAQs

- What is the difference between FR4 and HDI?

FR4 is a type of substrate material, while HDI is a technology and design methodology. A board can be a standard FR4 PCB or an HDI PCB that may also use FR4 material. HDI refers to the use of microvias, finer features, and higher density. - What is the HDI technique?

The HDI technique involves using laser-drilled microvias (blind, buried), sequential lamination, and fine-line tracing to create a higher density of interconnections on a printed circuit board than is possible with conventional methods. - What are the 4 tiers of HDI?

The tiers classify HDI complexity:- Tier 1:‚Äč 1 type of microvia (e.g., all blind vias from surface to layer 2).

- Tier 2:‚Äč 2 or more types of microvias (e.g., blind vias and buried vias).

- Tier 3:‚Äč 3 or more types of microvias, which may include stacked microvias.

- Tier 4 (Any-Layer):‚Äč Microvias can be placed between any adjacent layers, offering the highest density.

- What is ultra HDI PCB?

Ultra HDI refers to PCBs with even finer specifications than standard HDI, typically involving trace/space below 50¬Ķm (2 mil) and microvia diameters below 75¬Ķm (3 mil). It represents the cutting edge of HDI manufacturing.