Turnkey Box Build Assembly enables OEMs and system integrators to move from assembled PCBA to fully integrated, tested, and packaged products through a single manufacturing partner. This article explains how turnkey box build assembly works, what UK manufacturers typically provide, how PCBA integration affects quality and lead time, and how to select a reliable partner capable of supporting UK-based projects with consistency and scale.

As a turnkey box build assembly manufacturer with 20 years of PCB and PCBA industry experiences, EBest Circuit (Best Technology) places strong emphasis on inventory management, supported by an MES-enabled production system that ensures full traceability for every PCBA product. This disciplined approach allows materials, components, and assemblies to be tracked accurately from receipt to final delivery. We have also landed ISO 13485 and AS9100D certifications, reflecting our commitment to regulated and high-reliability manufacturing.

With in-house PCB and PCBA factories, we maintain full control over production planning and lead time, enabling us to rebalance schedules internally for urgent orders rather than leaving customers in a passive position. If you are looking for an insightful opinion on a Turnkey Box Build Assembly UK project, including Free DFM and process adaptation suggestions, please feel free to contact us at sales@bestpcbs.com.

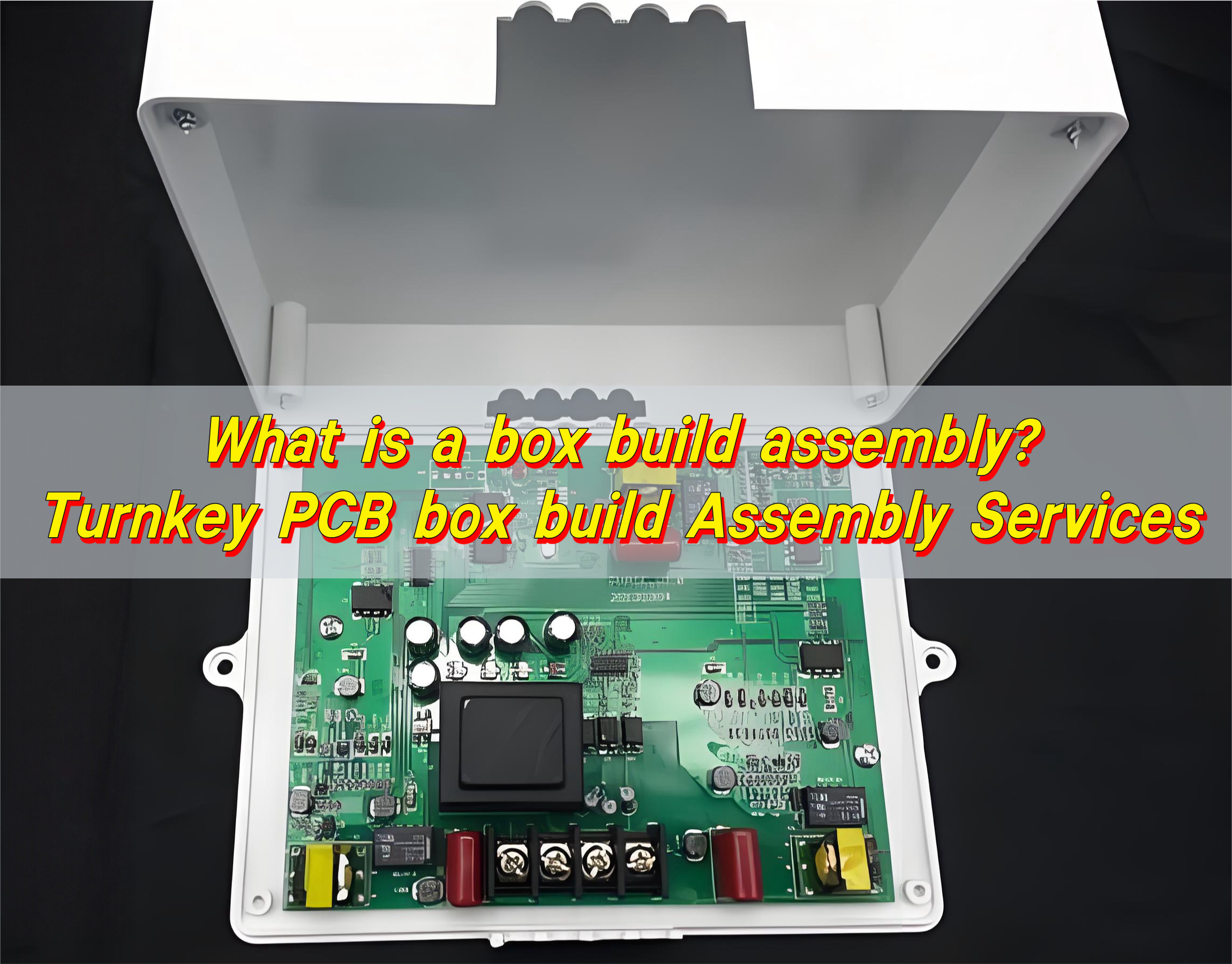

What Is Turnkey Box Build Assembly and How Does It Work?

Turnkey box build assembly is a manufacturing model where a single supplier takes responsibility for the complete product build, from PCBA integration to final enclosure assembly and shipment. Instead of coordinating multiple vendors, customers work with one accountable partner.

From an engineering perspective, box build assembly typically begins after PCBA completion and extends through mechanical assembly, wiring, system testing, labeling, and packaging. The âturnkeyâ aspect means the supplier manages materials, processes, quality control, and logistics under one program.

In practice, this approach reduces coordination overhead, minimizes interface risks between suppliers, and shortens overall time to marketâparticularly for products with complex electromechanical integration.

Top 5 Turnkey Box Build Assembly Manufacturers in the UK

The UK market includes a number of established manufacturers that support turnkey box build assembly, primarily for industrial, medical, defense, and instrumentation sectors. These companies typically focus on compliance, documentation, and stable delivery rather than ultra-low-cost production.

Representative UK turnkey box build assembly manufacturers include:

- TT Electronics â A well-known EMS provider supporting regulated industries, with strong capabilities in industrial and medical box build.

- ESCATEC â Offers end-to-end electronics manufacturing, including box build and system integration for international OEMs.

- LAC Group â Focuses on low-to-medium volume, high-mix assemblies with strong engineering support.

- JJS Manufacturing â Provides box build and electromechanical assembly for industrial and defense applications.

- UK Circuits / Spirit Electronics (group-level services) â Supports complex assemblies with compliance-driven workflows.

In summary, UK-based providers are strong in documentation, compliance, and proximity to local customers. However, many rely on distributed supply chains or offshore PCB/PCBA sourcing, which can affect flexibility, lead time, and cost control for growing programs.

What Does a Turnkey Box Build Assembly Manufacturer Actually Provide?

A professional turnkey box build assembly manufacturer delivers far more than final assembly labor. The real value lies in integration management and accountability.

Typical services include:

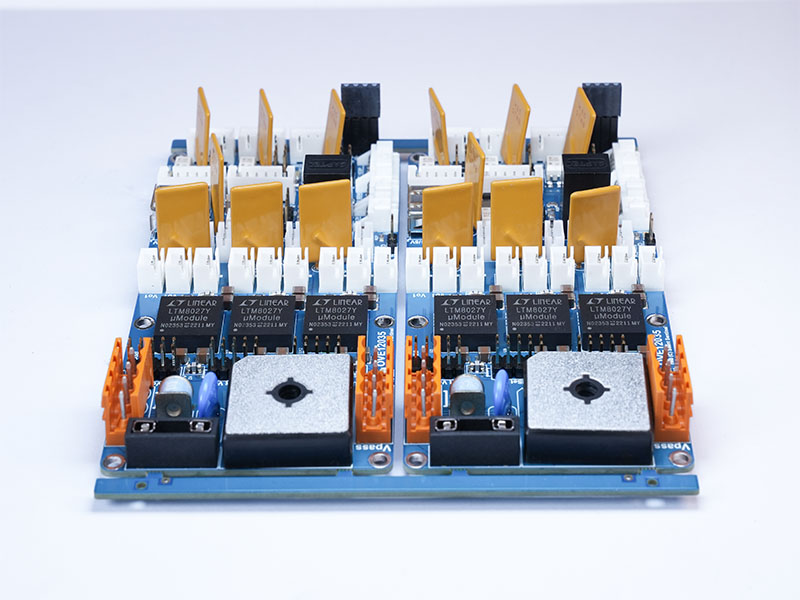

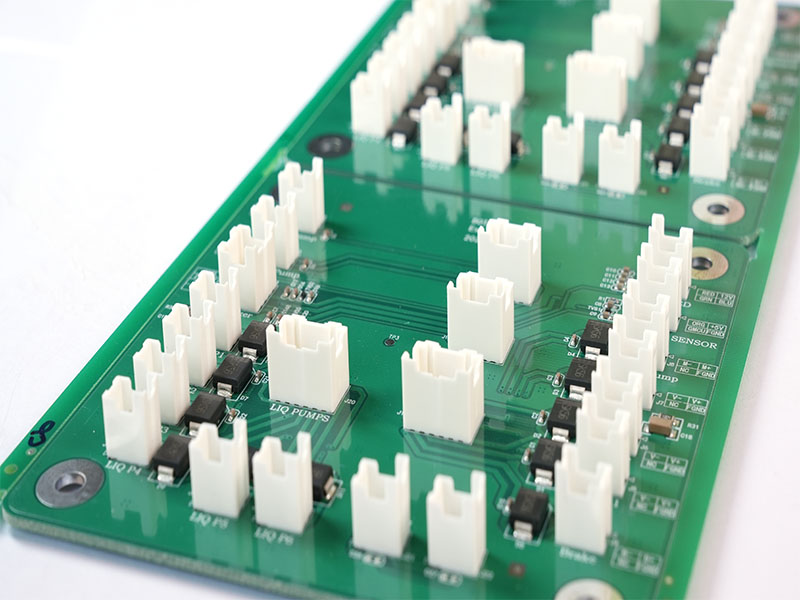

- PCBA integration into enclosures

- Cable and wire harness assembly

- Mechanical subassembly and fastening

- Functional, system-level, and burn-in testing

- Firmware loading and configuration

- Labeling, serialization, and documentation

- Final packaging and logistics coordination

From a customer standpoint, the supplier assumes responsibility for interactions between electronics, mechanics, and testingâremoving ambiguity around failure ownership.

What Is the Standard Box Build Assembly Process in Electronics Manufacturing?

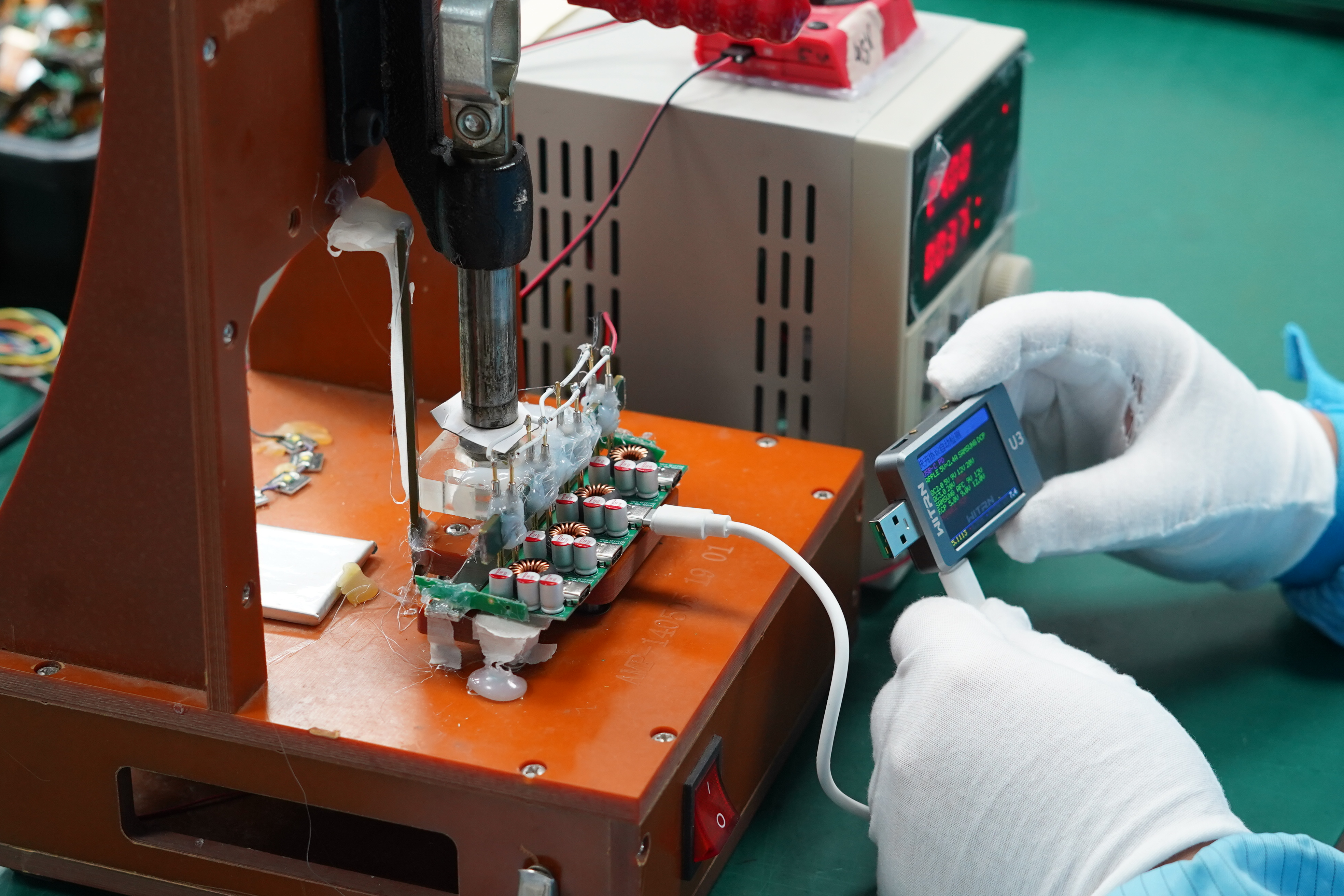

While details vary by product, a standard box build assembly process follows a disciplined sequence to ensure repeatability and quality.

Typical process flow:

- Incoming material inspection (PCBA, mechanical parts, cables)

- Subassembly preparation (harnesses, brackets, modules)

- PCBA installation into enclosure

- Cable routing and interconnection

- Mechanical fastening and torque control

- Functional and system testing

- Final inspection, labeling, and packaging

Under real manufacturing conditions, skipping or reordering steps often leads to latent failures, rework, or shipment delaysâmaking process discipline critical.

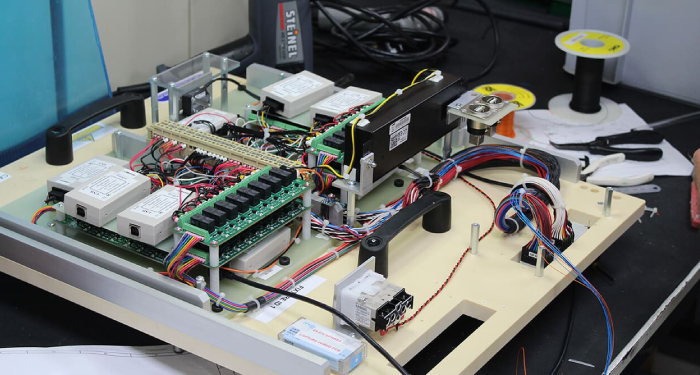

How Does Turnkey Assembly Simplify Complex Multi-Supplier Projects?

Complex products often involve PCBs, enclosures, cables, displays, fasteners, and firmware sourced from different vendors. Managing these independently introduces risk.

Turnkey assembly simplifies this by:

- Centralizing material coordination

- Reducing interface mismatches between suppliers

- Establishing a single build schedule

- Assigning one party accountable for integration issues

As a result, engineering changes and schedule adjustments can be implemented faster and with fewer downstream disruptions.

How Does PCBA Integration Impact Turnkey Box Build Assembly Quality and Lead Time?

PCBA is the technical foundation of any box build product. Poor coordination between PCBA and box build stages is one of the most common root causes of delays and failures.

When PCBA and box build are integrated:

- Connector placement aligns with enclosure constraints

- Cable lengths and routing are validated early

- Thermal and mechanical interactions are tested realistically

- Rework loops are significantly reduced

From a lead-time perspective, in-house or tightly integrated PCBA eliminates handoff delays and accelerates troubleshooting during early builds.

Why Select EBest Circuit (Best Technology) for Supporting Turnkey Box Build Assembly UK Projects?

EBest Circuit (Best Technology) supports UK turnkey box build assembly projects by combining PCB fabrication, PCBA, and system integration under one manufacturing structure. Rather than acting as a final assembler only, we approach box build from the electronics foundation upward.

Key strengths include:

- Integrated PCB fabrication and PCBA before box build

- Engineering-led DFM and system integration review

- Support for low-volume, pilot, and scalable production

- Stable supply chain coordination and material traceability

- Clear communication aligned with UK customer expectations

This model allows UK customers to retain local design and compliance control while leveraging a consolidated manufacturing partner capable of executing complex builds efficiently.

For full-service turnkey pcb assembly project discussions, please contact us via sales@bestpcbs.com.

FAQ About Turnkey Box Build Assembly

What Products Are Suitable for Turnkey Box Build Assembly?

Industrial controllers, medical devices, power systems, communication equipment, and embedded systems with mechanical integration are ideal candidates.

Does Turnkey Box Build Assembly Include Testing and Final Packaging?

Yes. Most turnkey programs include functional testing, system verification, labeling, and packaging as part of the scope.

How Early Should Box Build Assembly Be Considered in Product Design?

Ideally during PCB and enclosure design. Early consideration prevents mechanical conflicts and late-stage redesigns.

Can Turnkey Box Build Assembly Scale From Low Volume to Mass Production?

Yes, when process documentation, test strategy, and supply chain planning are established from the initial builds.