True double sided aluminum PCB takes center stage in some applications request compact size, high heat dissipation performance, and high flexibility routing. In this blog, we will tell you about the definition, price, manufacturing process, and benefits of a true double sided aluminum PCB.

Are you worried about these issues when doing the project of a true double sided aluminum PCB?

- Geometric accuracy challenge?

- High manufacturing difficulty and cost?

- The thermal management and the heat dissipation issues?

- The poor reliability and the longevity?

EBest Circuit (Best Technology) tackles the above challenges through our fruitful experience.

- Optimizing the manufacturing process and tool path design: For example, we make use of the DSIF strategy and simultaneous machining on both sides to reduce deformation and stress caused by the single-sided manufacturing.

- Material selection and heat treatment process: We will select the high-purity aluminum material, such as 6061 or 7075 aluminum alloy, since it has excellent thermal conductivity and mechanical performance. Meanwhile, we will utilize the heat treatment process to improve the material strength and stability.

- Multi-layer structure design and the connection technology: We will exploit the reliable connection technology to improve the connection strength between layers and the reliability when using the multi-layer structure designs. Meanwhile, we will apply the multi-layer insulation to improve the insulation performance and thermal stability.

- Heat management and the heat dissipation design: We will integrate thermal dissipation structure into the aluminum substrate boards, so as to improve the thermal dissipation efficiency. In the meantime, we will take the low thermal resistance materials and the thermal interface material to improve the heat conductivity efficiency.

- Reliability test and the longevity evaluation: We will evaluate the long-term reliability of the aluminum substrate board through accelerated longevity testing, thermal cycle inspection, mechanical fatigue tests, and others. We use the cutting-edge reliability analysis tool for prediction and optimization.

What is a True Double Sided Aluminum PCB?

A True Double sided aluminum PCB is a metal-core printed circuit board with copper layers on both sides of an aluminum core. It supports the double sided electrical connection compared to the traditional single sided MCPCB. And it can finish more complex circuit design in a limited board surface, and keep the outstanding quality heat dissipation as well. It is widely used in LED systems, power modules, and high-performance automotive electronics.

What is the difference: True Double Sided Aluminum PCB, Pseudo Double Sided Aluminum PCB?

The point is that there is a significant difference in the way of interconnection between layers. A true double sided aluminum PCB uses plated through-holes to connect the top and bottom copper layers directly. Whereas, a pseudo double sided aluminum PCB generally does not get the electrical connection, although both sides have copper. It is necessary to get the connection via a mechanical way or external jumpers. It is worthwhile to note thatĀ a true double sided aluminum PCB can realize more compact and reliable layouts.

What is the Difference between 2 Layer MCPCB and a Double Sided Aluminium PCB?

A 2 layer MCPCB generally refers to two copper layers separated by a dielectric layer over an aluminum base. And its layers can make the electrical connection via a plated through hole. The key is that a double sided aluminium PCB does not have the double sided copper layers in physics. It not only has copper on both sides but also reduces the usage needs of the extra components via direct interconnection between layers. Moreover, it improves the layout efficiency and the integration.

To sum up, both types of boards can improve the routing efficiencyā and integration levelā. But the double sided aluminium PCB is more suitable for the thermally demanding environment for its aluminium base features.

What are the Two Sides of an Aluminium PCB Called?

The two sides are typically called the top copper layer and the bottom copper layer. In a true double sided aluminum PCB, both sides are functional for routing and component placement. And it provides more flexibility in design for the compact equipment.

What is the True Double Sided Aluminum PCB Price?

The true double sided aluminum PCB price is fluctuated by a variety of factors, including material thickness, copper foil weight, hole plating quality, and the manufacturing batch quantity, among others. It significantly reduces the whole project costs via reducing assembly time, improving the PCB longevity, and other aspects, although in the initial stage, the price may be higher than the single sided MCPCB.

When will PCB Double Sided Tape be Used?

PCB double sided tape is used in cases where components or heat sinks need secure attachment without drilling holes. For example, it is generally used in fixing the LED or secondary small boards on the aluminum PCB, especially in the prototyping stage. PCB double sided tap not only provides stable mechanical stability but also avoids the extra steps. Finally, pls pay attention that the specific application may be different for its types, such as the PE foam tape, and the substrate characteristics, such as metal core PCB or glass.

How to Make a Double Sided Aluminium PCB?

- Start with the aluminum core board, which has premium mechanical strength and outstanding thermal dissipation performance.

- Laminate a thin dielectric layer on both sides of the aluminum core. That layer not only guarantees the electrical insulation but also conducts heat more efficiently.

- Bond copper foil layers onto the dielectric layers on both sides. These copper foils will carry the circuit traces.

- Apply photoresist and use a photolithography process to define the precise circuit patterns on both copper sides.

- Etching away the extra copper and saving the designed routing only.

- Drill plated through-holes (PTH) through the board to connect the copper layers on both sides electrically. This involves precise hole drilling and copper plating inside the holes.

- Making the copper plated to the exposed circuit pad and the through holes, to ensure a stable connection and the ease of soldering.

- Making the solder paste layer on both sides to protect against oxidation and the short circuit of circuits. Finally, improve the assembly safety.

- This step is the surface treatments, such as HASL, ENIG, and others, which improve the soldering quality and reliability.

- This next step is doing the inspection and testing strictly, to guarantee the PCBs are in line with technical requirements. We need to double-check the alignment accuracy between layers, through-hole quality, and heat dissipation performance.

- Finally, clean and prepare the boards for shipment or assembly into devices.

Why Use a True Double Sided Aluminum PCB?

The major point to choose this board is for the high thermal dissipation performance, the board size reduction, high flexibility of routing, and stability consistency in the high current designs. For issues such as thermal dissipation shortage and routing limitations, true double-sided aluminum PCBs are stable and reliable solutions.

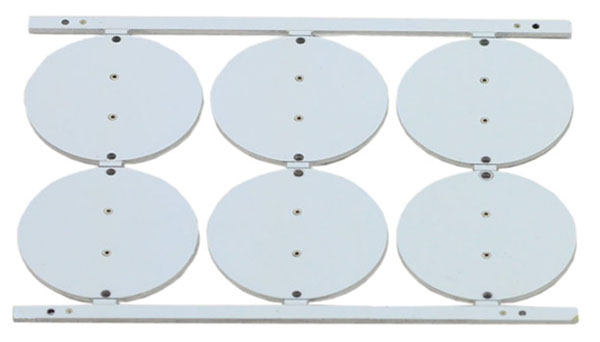

Case about True Double Sided Aluminum PCB

EBest Circuit (Best Technology) has the capability of supporting the true double sided aluminum PCB and the specific solutions for your projects. The following boards have performed well in our customers’ projects.

True Double Sided Aluminum PCB Parameters

- Application: For single high power Cree LED

- Copper: 1 Oz

- Board thicknessZ: 1.6mm

- Thermal conductivity: 2W/m-K

- surface finishing: HAL(LF)

- White Oil

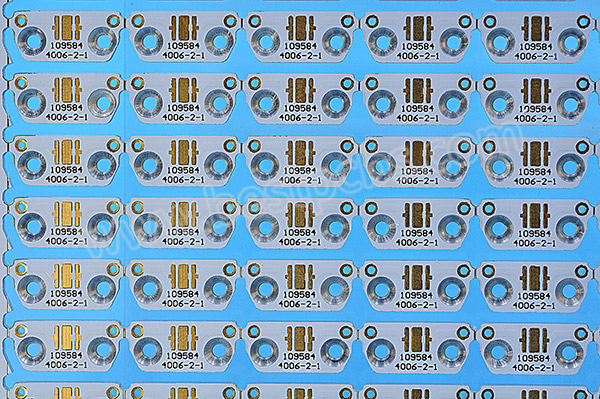

DoubleĀ SidedĀ AluminumĀ Core PCB MCPCB, 1.60mm, 2W, 2Oz

- Board thickness: 1.60mm+/-10%

- Thermal conductivity: 2W/m-K

- Copper thickness: 2Oz

- Solder mask: White

- Silkscreen: Black

- Surface finishing: ENIG 1u”

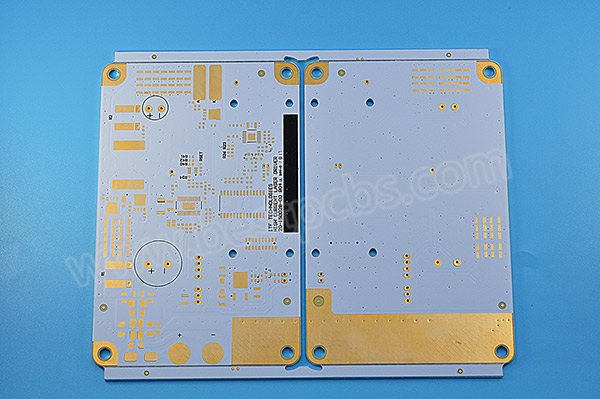

DoubleĀ SidedĀ AluminumĀ Core PCB MCPCB, 1.60mm, 2W, 2Oz

- Board thickness: 1.60mm+/-10%

- Thermal conductivity: 2W/m-K

- Copper thickness: 2Oz

- Solder mask: White

- Silkscreen: Black

- Surface finishing: ENIG 1u”

Why Choose EBest Circuit (Best Technology) for Double Sided PCB Assembly Service?

- Quality Guaranteed: Our true double sided aluminum PCBs are produced under ISO 9001, ISO 13485, IATF 16949, and AS9100D standards. And all our boards have undergone the strict inspection, such as AOI, X-ray, and rigorous QC.

- Full Support: Our factory presents the material procurement, prototype, fabrication, all process inspection, SMT, box build, and the final delivery. You do not need to worry about your order at each stage, since we will make the integrated support to you.

- Fast Delivery: To better suit the market requirements, our company has a lead time policy of 2-3 weeks, no matter how complex the double-side aluminum PCB is.

- High-mix PCB Portfolio: We provide a diverse range of PCBs, such as wholesale double-side aluminum PCBs, copper clad PCB boards, China IMS PCB, star MCPCB, China medical PCBA, and box build service.

In closing, the true double sided aluminum PCB gains a competitive edge in the market for its high heat dissipation performance and compact size, flexible routing design, and high stability in high current design. Getting the knowledge of definition, price, manufacturing process, and benefits will make a great difference for engineers and purchase managers to win the related projects. If you have more questions about the MPCB board, just let us know at sales@bestpcbs.com freely.