PCB stencil manufacturer is a key search term for anyone involved in SMT assembly today. In 2025, with shrinking pitch sizes and increasing demand for tighter tolerances, choosing the right stencil partner is more critical than ever. Whether you’re a high-volume EMS company or a small-scale startup, selecting the right SMT stencil manufacturer makes a big difference in your production efficiency. Let‚Äôs explore key aspects of stencil design and production and uncover the top global and Indian manufacturers worth trusting.

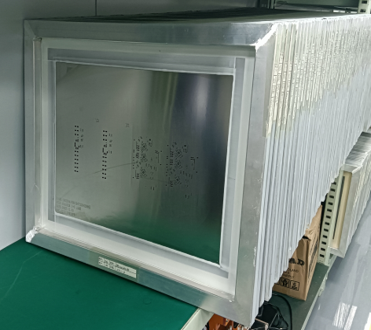

EBest Circuit (Best Technology) is a professional SMT stencil manufacturer. We have our SMT factories in China and Vietnam respectively. We provide SMT stencil, PCB fabrication, and turn-key PCB assembly service. In EBest Circuit (Best Technology), there are standard stencils, step stencils, and nano-coated stencils. Two critical considerations for stencil fabrication are dimensions‚ÄĆ and ‚ÄĆthickness‚ÄĆ. If you have any needs for PCB stencil, just provide us with GTP/GBP, GTO/GBO, Gerber file format (RS-247-x), and Fiducial Mark Data via sales@bestpcbs.com. It‚Äôs our pleasure to cooperate with you.

What is the material of the PCB stencil?

Most stencils are made from stainless steel. It’s the go-to material because of its strength, reusability, and precision. It can handle fine-pitch components and supports repeated solder paste printing without wearing out. For ultra-precise applications, nickel stencils offer smoother apertures and better paste release.

On the other end, polyester (Mylar) stencils are budget-friendly and ideal for quick prototyping. They’re easy to cut manually or with plotters but don’t last long.

Some stencil makers also offer nano-coated stainless steel, which improves solder paste release and reduces bridging‚ÄĒespecially helpful for ultra-fine-pitch or micro BGA designs.

What is the thickness of the PCB stencil?

Stencil thickness plays a big role in paste volume. The standard thickness range is between 0.10 mm to 0.20 mm, depending on the type of components and their pitch.

0.10 mm (4 mil): Best for 0.3 mm BGA or 01005 chips.

0.12 mm (5 mil): Suitable for 0.4 mm BGA and mixed SMT components.

0.15 mm (6 mil): Used for 0.5‚Äď0.65 mm pitch ICs.

0.18‚Äď0.20 mm (7‚Äď8 mil): Ideal for large components with bigger pads.

If you go too thick, you risk bridging and excess paste. Too thin, and you may face cold solder joints. Always match the thickness with your smallest pitch. In EBest Circuit (Best Technology), the common thickness of PCB stencils are 0.06mmÔľĆ0.08mmÔľĆ0.1mmÔľĆ0.12mmÔľĆ0.15mmÔľĆ0.2mm. Just feel free to let us know what is the thickness of the PCB stencil you need.

How much does a PCB stencil cost?

PCB stencil cost depends on size, material, frame type, and cutting method. Basic framed stainless steel stencils usually range from $30 to $100. Frameless stencils are cheaper. In EBest Circuit (Best Technology), For 370*470mm framed, etched stencil, the cost is only $39; laser cutting one need $69. Custom features like step-up/step-down or nano-coating may increase the cost, but they also boost performance and reliability. There is a short lead time for Standard Stencil‚ÄĆ, whose production cycle needs 1 day. But for the nano-coated stencil‚ÄĆ, it will require 3 days to produce.

How do you make a PCB stencil?

Making a stencil involves a series of technical steps that ensure accurate paste deposition.

1.     Design Generation: The Gerber file’s paste layer is used to define the stencil layout.

2.¬†¬†¬†¬† Material Selection: Choose based on project need‚ÄĒstainless steel for production, polyester for quick prototyping.

3.     Laser Cutting: A high-precision laser cuts apertures into the sheet.

4.     Surface Treatment: The stencil undergoes electropolishing or nano-coating to smooth aperture walls.

5.     Framing: Optionally mounted on a metal frame or kept frameless for universal holders.

Each step affects paste volume and application accuracy. That’s why professional suppliers never skip proper surface treatment and post-cutting checks.

PCB Stencil Manufacturer USA

When you’re sourcing stencils in the US, precision and lead time are everything. These five companies are known for reliable production, custom options, and fast delivery.

Top 5 PCB Stencil Manufacturers in the USA

1.¬†¬†¬†¬† Stencils Unlimited ‚Äď Based in California, this company provides laser-cut stainless steel stencils, including framed, frameless, and step stencils.

2.¬†¬†¬†¬† Metal Etch Services ‚Äď Known for tight tolerance and advanced surface treatment, ideal for HDI boards.

3.¬†¬†¬†¬† Solder Tools ‚Äď Offers fast delivery and specialized stencil holders for frameless designs.

4.¬†¬†¬†¬† Pentalogix ‚Äď Known for integrating Gerber data with stencil production quickly and accurately.

5.¬†¬†¬†¬† OSHA Stencils ‚Äď A good fit for military and aerospace-grade stencil demands.

USA-based stencil manufacturers combine speed, experience, and reliability. Their services are perfect for high-performance electronics requiring short lead times and top-notch quality.

SMT Stencil Manufacturer India

India’s electronics manufacturing sector is booming, and so is the demand for high-precision SMT stencils. These five Indian manufacturers have a strong presence in both domestic and export markets.

Top 5 SMT Stencil Manufacturers in India

1.¬†¬†¬†¬† Fine-Line Circuits Ltd (Mumbai) ‚Äď Offers laser-cut stainless steel stencils and supports high-mix SMT production.

2.¬†¬†¬†¬† Eastek Circuits (Chennai) ‚Äď Delivers consistent stencil quality with a quick turnaround for South India.

3.¬†¬†¬†¬† Ascent Circuits (Bangalore) ‚Äď One of India‚Äôs oldest PCB companies with strong stencil-making capability.

4.¬†¬†¬†¬† Micropack Ltd (Bangalore) ‚Äď Trusted by defense and aerospace customers for stencil accuracy.

5.¬†¬†¬†¬† SMT House India (Delhi NCR) ‚Äď Supplies a wide range of SMT tools, including custom PCB stencils.

Indian SMT stencil manufacturers are catching up fast with global standards. Their value-driven pricing and technical support make them a solid choice, especially for large-scale manufacturing units.

PCB Stencil Manufacturers in Bangalore

Bangalore is the hub for PCB production and stencil making in India. These five manufacturers are trusted for high precision and responsive service.

Top 5 PCB Stencil Manufacturers in Bangalore

1.¬†¬†¬†¬† Micropack Limited ‚Äď A pioneer in high-reliability stencils, especially for defense and aerospace.

2.¬†¬†¬†¬† Ascent Circuits ‚Äď Offers both PCB fabrication and stencil manufacturing under one roof.

3.¬†¬†¬†¬† PCB Power Market ‚Äď Known for online ordering of PCBs and stencils with India-wide shipping.

4.¬†¬†¬†¬† Accel Circuits ‚Äď Offers SMT support services, including stencil production and assembly aids.

5.¬†¬†¬†¬† Vinyas Innovative Technologies ‚Äď Provides integrated electronics services including fine-pitch stencil production.

If you’re operating out of South India or sourcing from Bangalore, these companies offer reliable and timely stencil services that meet international standards.

Why Should You Choose EBest Circuit (Best Technology) as Your SMT Stencil Manufacturer?

With nearly two decades of experience, EBest Circuit (Best Technology) has grown into a trusted name for all things PCB and that includes high-precision SMT stencils.

- Custom Engineered: Every stencil is crafted based on your design specs and pad geometries.

- Fast Delivery: We ship globally with lead times as short as 24‚Äď48 hours.

- Material & Size Choices: Common stainless steel, nano-coated options available. Besides, there are various PCB stencil sizes available, like 37x47cm, 42x52cm, 55x65cm, and 73.6×73.6cm.

- Quality Assurance: All stencils go through multiple QC stages, including aperture inspection and smoothness testing.

- One-Stop Solution: Combine PCB fabrication, SMT assembly, and stencil ordering in one place.

In short, we don‚Äôt just deliver stencils‚ÄĒwe support your PCB projects at every step.

In conclusion, in 2025, the role of a professional PCB stencil manufacturer is more important than ever. Whether you‚Äôre after accuracy, speed, or both, partnering with the right SMT stencil manufacturer can dramatically improve your assembly process. This article offer SMT stencil manufacturer 2025 for your reference. From the best USA-based suppliers to reliable Indian companies and trusted names in Bangalore, the options are plenty. And when you’re looking for a proven partner with consistent performance, EBest Circuit (Best Technology) is always ready to help. Any questions about PCB stencils, just feel free to consult EBest Circuit (Best Technology) at sales@bestpcbs.com. Thanks for allowing us to handle your stencil needs.