If you are working on RF or microwave PCB design, the material you choose directly impacts signal loss, phase stability, thermal performance, and overall system reliability. Rogers RO4350B is one of the most widely used high-frequency laminates in telecom, radar, 5G, satellite, and advanced wireless systems. This guide provides a complete breakdown of RO4350B datasheet properties, thickness options, RF advantages, and a comparison against FR4âplus practical manufacturing notes for PCB engineers.

What Is Rogers RO4350B Material?

Rogers RO4350B is a hydrocarbon-ceramic, glass-reinforced laminate engineered for RF and microwave applications from the Rogers RO4000Âź series. Unlike PTFE-based laminates, RO4350B can be fabricated using standard FR4 PCB processesâa huge benefit for cost, lead time, and manufacturabilityâwhile still delivering excellent electrical stability at GHz frequencies.

Key characteristics:

- Dk = 3.48 ± 0.05 (10 GHz, z-axis)

- Df â 0.0037 (low loss)

- High thermal stability

- Low moisture absorption (<0.06%)

- Compatible with FR4 processes

- Excellent for hybrid stack-ups

What Is Rogers RO4350B Material?

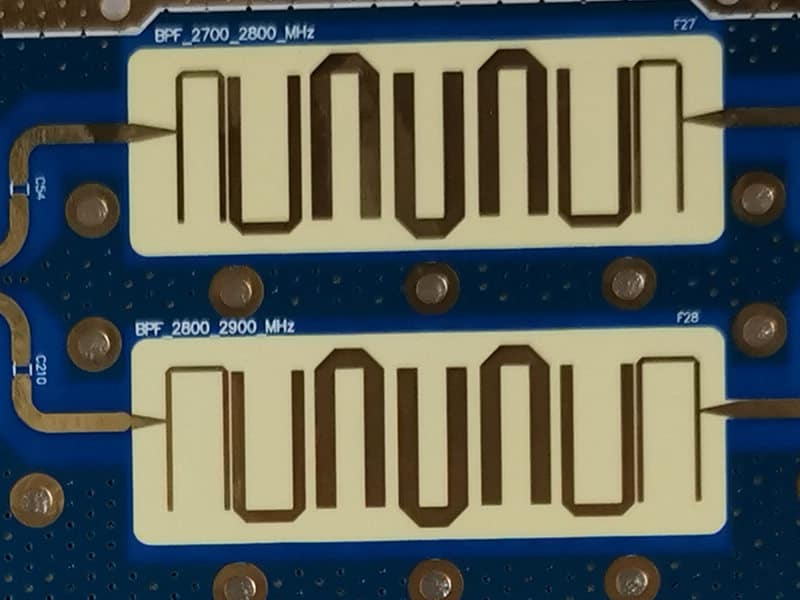

What Is RO4350B Used for in RF PCB Applications?

RO4350B is found in nearly every modern RF system. Typical uses include:

- 5G antennas and base-stations

- Phased-array radar modules

- LNA, PA, and front-end RF chains

- Power amplifiers requiring robust thermal paths

- Filters, couplers, baluns, and RF matching networks

- Automotive ADAS radar

- Satellite communication modules

- High-performance mixed-signal and RF/digital hybrid boards

Because it balances cost and performance, RO4350B is ideal for mid-to-high volume RF production.

Rogers RO4350B Datasheet: Full Material Properties Overview

Below is a consolidated summary of all essential RO4350B datasheet values RF engineers frequently use in simulation, stack-ups, and manufacturing notes.

RO4350B Electrical Properties

| Property | Typical Value | Test Condition / Notes |

| Dielectric Constant (Dk) | 3.48 | Measured at 10 GHz |

| Dielectric Constant Stability | ±0.05 | Across thickness range |

| Dk Temperature Coefficient | +50 ppm/°C | â50°C to +150°C |

| Dissipation Factor (Df) | 0.0037 | @ 10 GHz |

| Volume Resistivity | 1Ă10â· MΩ·cm | ASTM D257 |

| Surface Resistivity | 1Ă10â· MΩ | ASTM D257 |

| Dielectric Strength | 40 kV/mm | Typical |

| Electrical Loss Stability | Excellent | Wideband RF use |

RO4350B Thermal Properties

| Property | Typical Value | Notes |

| Thermal Conductivity | 0.69 W/m·K | Supports heat-spreading features |

| Tg (Glass Transition Temperature) | >280°C | Very stable for lead-free |

| Td (Decomposition Temperature) | â390°C | Rogers method |

| CTE (X-axis) | 11 ppm/°C | Strong dimensional stability |

| CTE (Y-axis) | 14 ppm/°C | Good panel reliability |

| CTE (Z-axis) | 32 ppm/°C | Supports plated through-hole reliability |

| T260 Time | >60 min | Anti-delamination performance |

| T288 Time | >20 min | High thermal endurance |

RO4350B Copper Options

| Copper Type | Thickness | Notes |

| Rolled Copper | œ oz, 1 oz | Better for low-loss RF lines |

| Electrolytic Copper | œ oz, 1 oz, 2 oz | Standard PCB production |

| Reverse-Treated Copper | Available | Improved adhesion in hybrid stack-ups |

For more details about Rogers RO4350B, click here: Rogers RO4350B Datasheet Download

RO4350B Thermal Conductivity

RO4350Bâs thermal conductivity of 0.69 W/m·K is significantly higher than typical FR4 (~0.3 W/m·K).

This means:

- Better heat spreading

- Higher reliability under RF power loads

- Improved board life during thermal cycles

- Lower risk of delamination

This makes RO4350B a strong candidate for RF power amplifiers and modules with high current density.

RO4350B Thickness Options & Common Stack-Up Selections

RO4350B thickness availability is wide, giving designers flexibility.

Common RO4350B Thicknesses

- 0.101 mm / 0.004â

- 0.203 mm / 0.008â

- 0.254 mm / 0.010â

- 0.3048 mm / 0.012â

- 0.406 mm / 0.016â

- 0.508 mm / 0.020â

- 0.813 mm / 0.032â

- 1.524 mm / 0.060â

Copper options: œ oz, 1 oz, 2 oz.

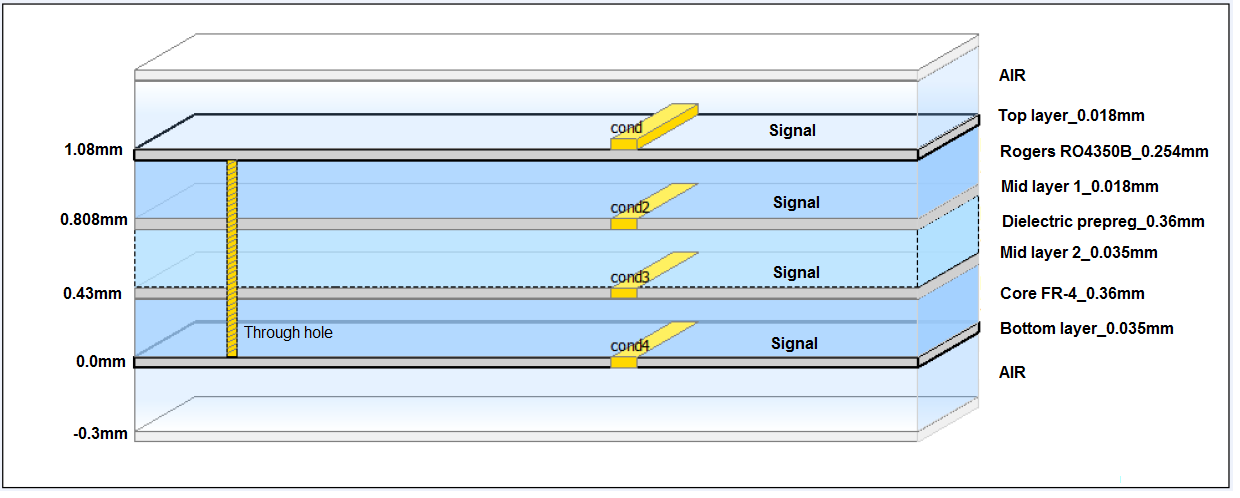

Common Stack-up Approaches

1. RF-only board:

Single RO4350B core for antennas, filters, or couplers.

2. Hybrid stack-up (RO4350B + FR4):

- RF layers on RO4350B

- Digital/Power layers on FR4

- Best cost-performance balance

3. Multilayer RO4350B stack-up:

For radar, high-power, or mmWave systems requiring uniform RF behavior.

RO4350B vs FR-4: Differences in RF Performance

FR-4 is a good general-purpose material but struggles at higher RF bands. Its dielectric constant shifts with humidity, temperature, and frequency. Loss levels rise significantly above 1â2 GHz, which affects range, efficiency, and signal clarity.

RO4350B addresses these issues with stable electrical behavior, low loss, and stronger control of impedance.

| Feature | RO4350B | FR-4 |

| Dk Stability | Very stable | Unstable at high frequency |

| Loss (Df) | Low | High |

| High-frequency use | Excellent | Limited |

| Thermal stability | Strong | Moderate |

| RF performance | Consistent | Varies widely |

| Typical use | RF, microwave, antennas | General electronics |

For RF paths, RO4350B is nearly always the better choice.

Rogers 4000 Series Materials Overview

The RO4000Âź series includes hydrocarbon-ceramic laminates designed for RF and microwave work. The series offers stable dielectric values, low moisture absorption, and predictable performance across frequency ranges. These materials support antennas, filters, couplers, radar units, medical sensors, and industrial communication systems. RO4003C and RO4350B are the most common choices, though other variants exist for special electrical or mechanical needs. Here are some other RO4000Âź series materials:

Which Rogers Materials Can Be Used for RF & Microwave PCB?

Common Rogers RF materials include:

- RO4350B â balanced performance, processable like FR4

- RO4003C â lower loss, great for 10+ GHz

- RO4835 â improved oxidation resistance and stability

- RT/duroidÂź series â PTFE-based ultra-low-loss materials for mmWave

- TMMÂź series â ceramic thermoset laminates for precision high-power RF

Choose based on frequency, thermal load, and tolerance requirements.

RO4350B PCB Manufacturing Considerations

Although RO4350B is easier to manufacture than PTFE materials, achieving consistent RF performance requires following specific process guidelines. Here are the key considerations for PCB fabrication:

RO4350B PCB Manufacturing Considerations

1. FR4-compatible processing, but with controlled parameters

RO4350B supports standard PCB processes, but drill speeds, lamination pressure, bake profiles, and final copper thickness must be carefully controlled to ensure stable impedance and dielectric consistency.

2. Hybrid stack-ups require expert lamination control

When combining RO4350B with FR4, differences in CTE (coefficient of thermal expansion) must be managed to avoid warpage, resin starvation, or delamination. Precise prepreg selection and lamination cycles are essential.

3. Accurate impedance control is critical

RF designs often require ±5% or tighter impedance tolerance. Manufacturers must account for:

- dielectric thickness tolerance

- copper roughness

- resin-filled vias or back-drilling

- line-width compensation

Providing simulation models or stack-up notes (Dk/Df @ frequency) helps ensure fabrication accuracy.

4. Drilling & plating demands tighter control

RO4350Bâs ceramic-filled structure requires optimized drill parameters to prevent smear and maintain high hole-wall quality, ensuring reliable via plating for multilayer RF PCBs.

5. Proper material storage and handling

To prevent moisture absorption and dimensional shift, the material should be kept in a dry, controlled environment and baked before lamination when necessary.

With these practices, RO4350B PCBs can achieve repeatable RF performance from prototype to mass production.

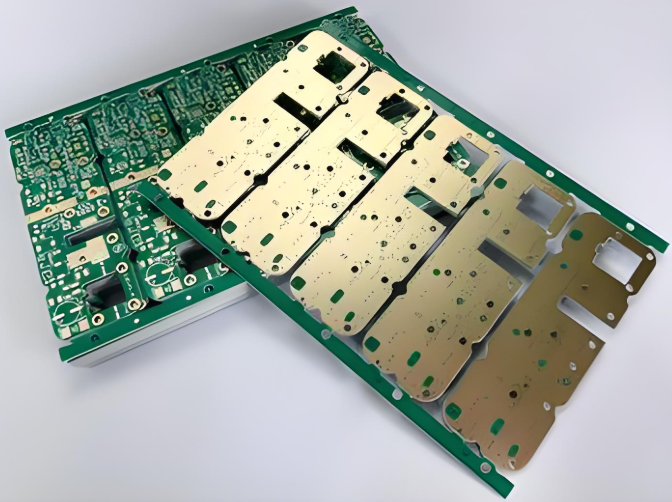

Why EBest Circuit (Best Technology) Is Preferred for RO4350B PCB Fabrication?

When working with RO4350B, choosing the right PCB manufacturer is critical. EBest Circuit (Best Technology) is trusted by RF engineers because:

- They stock RO4350B in multiple thicknesses

- Provide RF stack-up simulation support

- Offer tight impedance control with test coupons

- Perform high-precision routing and controlled-depth milling

- Support hybrid RO4350B + FR4 multilayers

- Provide material certifications and Rogers-lot traceability

If you need consistent RF performance from prototype to mass production, EBest Circuit (Best Technology) is a reliable partner for RO4350B PCB fabrication.

FAQs

1. Does RO4350B support buried or blind vias in multilayer RF boards?

Yes. RO4350B works well in multilayer designs that use blind or buried vias. Its mechanical strength and low z-axis expansion help maintain via reliability during lamination and thermal cycling. When designers use selective RO4350B layers inside a hybrid stack-up, careful lamination scheduling helps control movement and keep impedance stable.

2. Is RO4350B compatible with ENIG, immersion silver, or HASL finishes?

Yes. RO4350B supports common surface finishes, including ENIG, immersion silver, OSP, and certain types of lead-free HASL. Most RF boards use ENIG or immersion silver because these finishes give cleaner surfaces, consistent thickness, and smoother trace edges. A smooth finish helps reduce signal loss at high frequencies. HASL may be less preferred for controlled-impedance lines due to its uneven surface.

3. Can RO4350B be used for power amplifiers that generate heavy heat?

Yes. Many PA modules run on RO4350B because it handles heat better than FR-4 and holds impedance during thermal loads. Designers still need good thermal paths, such as thermal vias under power devices or metal backers for heat spreading. If the PA generates extreme heat, ceramic or metal-backed constructions may be considered. For most communication-grade PAs, RO4350B provides more than enough stability.

4. What stack-up mistakes should designers avoid when using RO4350B?

A common mistake is mixing RO4350B and FR-4 without modeling the transition area. The shift in dielectric constant affects line impedance if the transition is not controlled. Another mistake is routing sensitive RF lines too close to ground via fences, which can create unintended coupling. Over-constraining solder masks around RF traces may also shift the effective dielectric environment.

5. Is RO4350B more expensive than FR-4, and how does it impact project cost?

Yes, RO4350B costs more than FR-4 due to its electrical stability and engineered formulation. The material price is higher, and multilayer stacks may need tighter controls. However, the overall project cost can still drop because fewer design spins occur, RF tuning time is reduced, and system performance becomes more predictable. In many RF designs, the ROI justifies the material cost.