Printed circuit board assembly manufacturer services are the heart of today’s electronic world. From smartphones to aerospace tech, nearly every modern device relies on quality PCB assembly. If you’re searching for a reliable supplier, understanding the process and key players is a great first step. In this article, weâll walk you through how to pick the right partner, and explain why EBest Circuit (Best Technology) could be your ideal choice.

With extensive technical expertise, EBest Circuit (Best Technology) offers surface-mount and through-hole assembly, testing, prototyping, and final packaging to the global. We offer both PCB manufacturing and assembly under one roof, which ensures rapid turnaround times, less cost, and stable quality. For lead time, standard runs take around 14 days. For urgent prototypes, we can finish in 24â48 hours. We offer global-level quality with professional support, fast responses, and deep engineering insight tailored to custom projects. For any custom PCB manufacturing, or PCB assembly service, kindly contact us at sales@bestpcbs.com at any time. There is no MOQ in EBest Circuit (Best Technology).

What is a printed circuit board assembly?

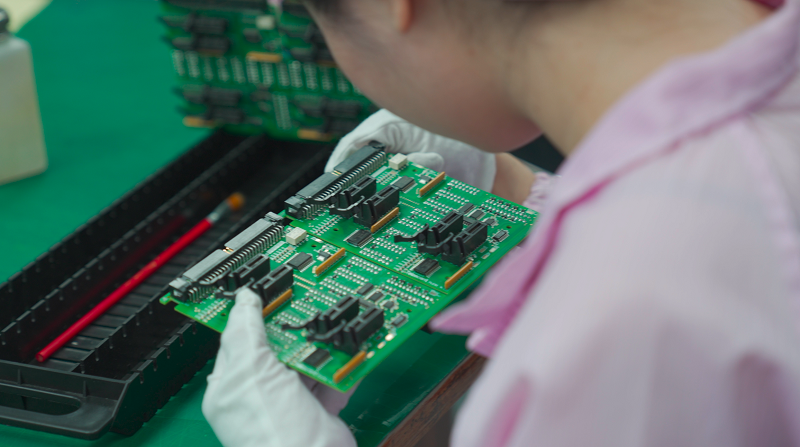

A printed circuit board assembly (PCBA) involves mounting and soldering electronic components onto a bare PCB. The board starts as a flat piece with copper pathways. Then, components like resistors, capacitors, and microchips are placed onto the board, either by hand or automated machines. After soldering, the board is tested to ensure every part works as intended.

Assembly is different from just PCB manufacturing. PCB manufacturing is about making the empty board. Assembly is about adding life to it. Together, they form the full process that brings electronics to life.

Who manufactures printed circuit board assembly?

Many companies around the world specialize in this service. In the USA, there are hundreds of printed circuit board assembly manufacturers, ranging from small custom shops to large factories. Some companies only do assembly, while others handle the full productionâdesign, fabrication, and assembly.

Examples include:

- EBest Circuit (Best Technology)

- Sanmina

- Jabil Circuit

- Advanced Circuits

- TTM Technologies

Each one has its strengths. Some focus on fast prototyping. Others offer high-volume production or special certifications like ISO13485 for medical devices.

What is the best printed circuit board assembly manufacturer?

There is no one-size-fits-all answer. The best printed circuit board assembly manufacturer depends on your needs. Still, you can look for certain traits:

- Quality standards: Look for ISO9001 or IATF16949.

- On-time delivery: A delay in boards can delay your whole project.

- Customer service: You need a team that responds quickly and clearly.

- Engineering support: Helpful when working on a new or custom design.

- MES material tracking: Ensures traceability for each component used.

EBest Circuit (Best Technology) meets all of these standards and more. With a professional engineering team and MES systems in place, they help clients across medical, automotive, and industrial fields.

Who is the largest printed circuit board assembly manufacturer in the world?

The largest printed circuit board assembly manufacturer globally is Foxconn. Known for assembling Apple products, Foxconn handles massive volumes daily. Other giants include Pegatron, Flex, and Jabil.

But for many companies, especially small to mid-sized firms, these giants might not be the right fit. They often prefer flexible manufacturers like EBest Circuit (Best Technology), which focus on quality, service, and custom solutions rather than only volume.

How do I find the printed circuit board assembly manufacturer?

Finding the right manufacturer starts with research. Here’s a quick process:

- Define your needs: Quantity, lead time, board type.

- Check directories: Use online directories for printed circuit board assembly manufacturers USA or global lists.

- Ask for samples: A real sample shows quality better than words.

- Review certifications: Make sure they meet industry standards.

- Talk to the team: Communication style tells you a lot about future service.

Also, pay attention to reviews, turnaround times, and available services. If you’re in the USA, searching for “PCB assembly USA” or “printed circuit board assembly manufacturer California” can lead you to local options.

What is the difference between printed circuit board assembly and PCB manufacturing?

PCB manufacturing is the first step. It involves creating the boardâcutting the shape, printing the circuit layers, and adding holes or vias. PCB assembly is what comes next. This stage involves placing and soldering components onto the manufactured board. In short:

- PCB manufacturing = creating the board

- PCB assembly = adding components to the board

Some companies do both. Others specialize in one area. It helps to know what you need before you contact a supplier.

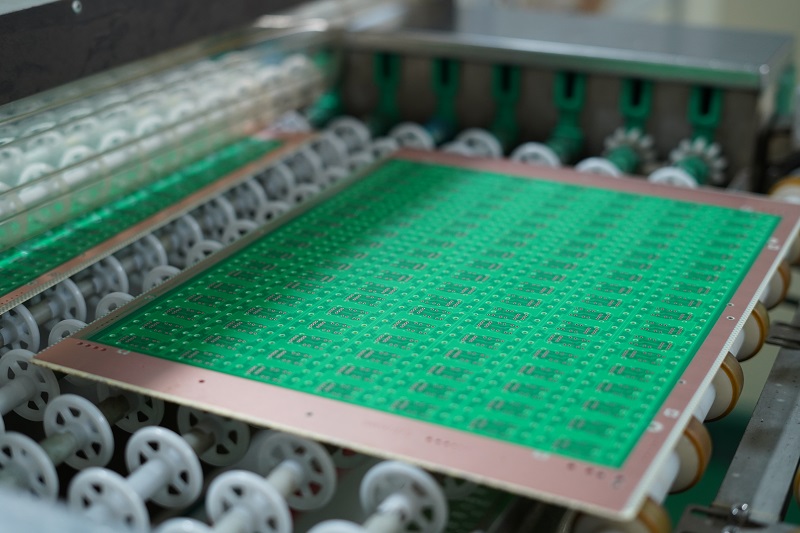

How are printed circuit board assemblies manufactured in industry?

The process is highly automated, especially for large runs. Here’s a simplified version of the process:

- Stencil printing: Solder paste is applied to the board using a stencil.

- Component placement: Pick-and-place machines put parts on the board.

- Reflow soldering: Boards go through an oven that melts the solder paste.

- Inspection: Optical machines and X-rays inspect for issues.

- Testing: Functionality tests ensure the board works as intended.

- Final cleaning and packing: Boards are cleaned and packed for shipping.

Advanced printed circuit board assembly manufacturers use MES systems to track every board from start to finish.

Why should you choose EBest Circuit (Best Technology) as your trusted printed circuit board assembly manufacturer?

EBest Circuit (Best Technology) stands out for many reasons:

- Certifications that matter: ISO9001, ISO13485, AS9100D, and IATF16949. These cover aerospace, automotive, and medical needs.

- MES Material System: Our MES system tracks each component through every process.

- Experienced engineers: We help refine your design before production.

- Fast response times: Quotes, updates, and support are always prompt.

- One-stop service: From design and PCB manufacturing to full assembly and testing.

Clients around the world trust EBest Circuit (Best Technology) for quality, service, and results. Whether you’re a startup or an OEM, we have the skills and tools to support your project.

To put it simply, working with a reliable printed circuit board assembly manufacturer can make a big difference. While many options exist globally and in the USA, not all can meet todayâs speed and quality demands. EBest Circuit (Best Technology) offers an ideal blend of modern systems, expert support, and dependable delivery.

Whether you need low-volume prototypes or high-volume runs, EBest Circuit (Best Technology) offers the services to match. Our 18 years of experience, combined with strict quality control and responsive service, make us a reliable choice for customers worldwide. If you’re searching for the best printed circuit board assembly manufacturer, itâs time to discuss with EBest Circuit (Best Technology) at the trade show or via email at sales@bestpcbs.com.