How to make silkscreen for PCB? Let’s discover thickness, size chart, colors selection guide, material and font, production process, removal methods for PCB silkscreen.

Are you troubled these questions about PCB silkscreen?

- Blurry screen printing? “Why is my board’s screen printing always blurry and broken, significantly reducing repair and inspection efficiency?”

- Incomplete information labeling? “How can I clearly label polarity and reference numerals in a limited space to avoid incorrect parts and rework due to unclear labeling?”

- High communication costs? “Does insufficient screen printing precision require repeated confirmation of details with the factory, delaying project timelines?”

As a professional PCB manufacturer, EBest Circuit (Best Technology) can provide you services and solutions:

- Precise Imaging: We use a combination of LPI+LDI high-precision processes, ensuring sharp, engraved character edges and perfect rendering even for ultra-fine 0.15mm line widths, greatly improving subsequent production efficiency.

- Mastering Space Layout: We provide professional screen printing layout optimization services, even in areas densely populated with 0402/0201 micro-components, we can plan a clear, non-overlapping labeling scheme for you.

- One-Stop Service: From the moment you provide your design files, we initiate a manufacturability review, proactively identifying screen printing design risks to ensure production is completed on the first attempt, accelerating your product launch.

Welcome to contact us if you have any request for PCB silkscreen: sales@bestpcbs.com.

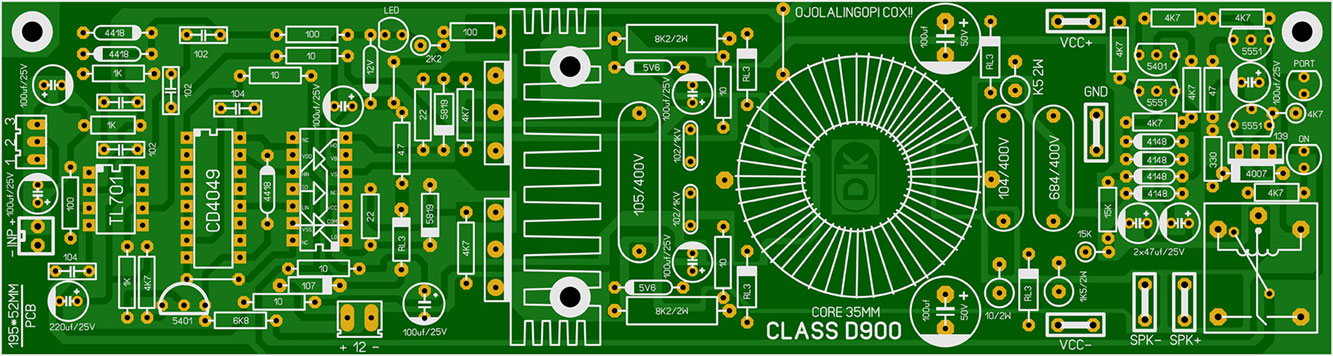

What Is PCB Silkscreen?

The PCB silkscreen layer is an ink marking layer on the surface of a printed circuit board (PCB), typically located above the solder mask layer. Using silkscreen or inkjet printing technology, it directly prints key information such as component identification (e.g., reference numerals R1, C2), polarity symbols (+/-), pin markings, company logos, version numbers, and security certification icons onto the board surface. This provides a visual basis for positioning and identification during assembly, debugging, and repair; it is the PCB’s “information label layer.”

How Thick Is a PCB Silkscreen?

| Process Type | Average Thickness | Features |

| Traditional Screen Printing | 30–35μm | Obvious ink accumulation, slight edge diffusion |

| LPI (Liquid Photo Imaging) | 15–25μm | Uniform thickness, precision ±3μm |

| Inkjet Printing | 18–22μm | Non-contact, local thickening possible |

| LDI (Laser Direct Imaging) | 15–20μm | Ultra-thin precision, suitable for HDI boards |

PCB Silkscreen Size Chart

| Parameter | Minimum Value | Recommended Value | Applicable Process |

| Character Height | ≥0.8mm | 1.0-1.5mm | All Processes |

| Character Line Width | ≥0.15mm | 0.18-0.2mm | LDI/LPI superior to traditional screen printing |

| Polarity Symbol Diameter | ≥1.0mm | 1.2-1.5mm | All Processes |

| Pin 1 Identification | ≥0.8mm | 1.0mm | LDI precision best |

| LOGO/QR Code | Minimum unit ≥0.3mm | ≥0.4mm | LDI/Inkjet exclusive |

| Solder Mask to Pad Clearance | ≥0.2mm | 0.3mm | All Processes |

What Are the Colors of PCB Silk Screen?

Common standard color systems of PCB silk screen include:

Core Standard Color Systems

- White: Accounts for over 70% usage, suitable for dark substrates like green/black PCBs. Provides 80% high contrast and is the default choice for consumer electronics. White silkscreen on green substrates improves text clarity by 40% under normal lighting, reducing assembly errors by 15%.

- Black: Designed for light substrates like white/yellow PCBs. Black-on-white schemes are common in laboratory-grade PCBs, enhancing readability by 30% in cleanroom environments. Note that black ink may cause glare under strong light.

- Yellow: Preferred for low-light environments, offering 20% higher reflectivity than white. Commonly used in automotive electronics/outdoor devices. Tests show yellow text recognition speed is 0.3 seconds faster than white under 50lux illumination.

Special Color Considerations

- Red/Blue: Often used in military-grade PCBs for color-coded voltage regions. Red marks high-voltage areas, blue denotes signal layers, complying with IPC-A-610 standards.

- Custom colors (e.g., pink/purple): Require 10-30% additional cost and may extend lead time by 3-5 days. A case study revealed pink silkscreen caused 8% yield loss due to ink curing issues in mass production, now mainly used for prototype validation.

Design Rules

- Contrast First: Green substrates must use white/yellow silkscreen; black substrates require white; white substrates need black. Incorrect pairing can double troubleshooting time.

- Font Standards: Recommend sans-serif fonts, character height ≥1.5mm, line width ≥0.18mm. BGA area silkscreen must maintain 0.3mm safety clearance from pads.

- Environmental Adaptation: Industrial control boards recommend matte surface treatment, reducing 90% glare interference. Medical devices require alcohol-resistant UV-cured inks.

What Ink Is Used in PCB Silkscreen?

PCB screen printing mainly uses non-conductive ink materials, and specific types include:

- Epoxy-based ink: A traditional mainstream material, resistant to high temperatures and chemical corrosion, suitable for welding processes.

- Acrylic-based ink: Fast-drying, suitable for high-efficiency production lines, but with slightly weaker heat resistance.

- Polyester-based ink: Excellent adhesion and weather resistance, ensuring long-term marking clarity.

- Polyurethane-based ink: Abrasion-resistant and chemically resistant, suitable for high-reliability environments.

- UV-cured ink: Cures quickly using ultraviolet light, improving production efficiency; commonly white/black.

- Thermosetting ink: Cures by heat, with strong adhesion; mostly used for text marking.

- Special conductive inks (such as carbon ink, silver ink): Used in specific scenarios (such as conductive marking), but the core function of screen printing is non-conductive marking.

How to Make Silkscreen for PCB?

1. Design and Specification Development

- Character design must comply with IPC-SM-840 standards: minimum line width 0.1mm, character height ≥0.6mm, maintain 0.1mm safety clearance from pads/vias. Polar components (e.g., diodes, capacitors) require clear “+”, “C” symbols, with left-to-right/bottom-to-top orientation for readability.

- Output Gerber format design files containing character layers, solder mask layers, and drilling layers, validated through DFM analysis to prevent manufacturing defects.

2. Screen Material Selection and Tensioning

- Choose screen material based on precision needs: high precision (line width ≤ 0.15mm) recommends 305 mesh stainless steel mesh (tension 28-30N/cm); ordinary precision can use 200-250 mesh nylon mesh. The mesh frame must be made of aluminum alloy (dimensional accuracy ±0.1mm), anodized for corrosion resistance.

- Screen Stretching Process: A pneumatic screen stretching machine is used to stretch the screen, controlling the tension uniformity within ±1N/cm. After allowing it to stand for 24 hours to release stress, epoxy resin is used to fix the frame and screen. The resin layer thickness is ≤0.5mm, ensuring no air bubbles remain.

3. Photolithography and Exposure Development

- Coating the photosensitive emulsion: After pre-coating the base coat on the screen, evenly coat the photosensitive emulsion (10-20μm thickness) using a squeegee. For high precision requirements, 2-3 layers are needed. After each layer dries, inspect for pinhole defects.

- Exposure parameters: Use a UV exposure machine (energy 80-120mJ/cm²), with film positioning (accuracy ±0.05mm), and an exposure time of 10-20 seconds. Develop using a 1% sodium carbonate solution at a water temperature of 25-30℃ for 30-60 seconds, forming clear openings (open area ≥90%) with an edge jaggedness depth ≤0.01mm.

4. Ink Formulation and Performance Adaptation

- Base Ink Selection: Formulate according to the substrate material (e.g., FR-4, PI) and application (high temperature resistance/flexibility). Epoxy inks are resistant to 260℃ wave soldering (curing conditions 150℃/30 minutes), while polyurethane inks meet the bending requirements of flexible PCBs (1000 bends at 180° without cracking).

- Viscosity Control: Monitor with a rotational viscometer. 300-mesh screen requires 1500-2500 cP, 400-mesh requires 1000-2000 cP. Thinner addition should be ≤10%, and stirring speed 500-800 rpm should be used to ensure uniformity and avoid bubble formation. Colors should be formulated according to the Pantone color chart, with a color difference ΔE ≤1. The contrast between white ink and green solder resist should be ≥85%.

5. Precision Printing Parameter Control

- Equipment Selection: Fully automatic printing machines have an accuracy of ±0.03mm (suitable for large batches); semi-automatic machines with CCD positioning (accuracy ±0.05mm) are suitable for small to medium batches. Manual printing requires a high-precision squeegee (hardness 70-80 Shore), angle 45°-60°, pressure 0.2-0.3MPa, speed 50-100mm/s, and screen distance 1-2mm.

- Real-time Monitoring: Every 10 PCBs are sampled for character clarity and positional deviation (≤0.05mm). Adhesion is tested with 3M tape (residual area ≥95%), and edges are observed with a 200x magnifying glass to ensure no jagged edges. High-precision characters require a 400-mesh stainless steel mesh to avoid ligatures and missing strokes.

6. Curing Process and Quality Inspection

- Curing conditions: Acrylic inks cure at 120-130℃ for 20-30 minutes; epoxy inks cure at 150-160℃ for 30-40 minutes. Staged heating (10 minutes per stage) is used to prevent cracking. The ink thickness deviation after curing should be ≤±10%.

- Quality inspection: AOI automatic detection of character defects (recognition rate ≥99.8%), solvent resistance test (no fading after 100 wipes with 75% alcohol), and temperature resistance test (no color change at 260℃/10 seconds). Defective products are cleaned with a special ink remover and reprinted to ensure a yield rate ≥99%.

7. Environmental Control and Safety Standards

- Production Environment: Temperature 22-25℃, humidity 40-60%, cleanroom class ≥ Class 10000. Operators must wear anti-static gloves to avoid fingerprint contamination. Waste ink and solvents must be recycled separately, complying with RoHS/REACH environmental standards.

- Equipment Maintenance: Regularly calibrate the printing press accuracy (once a month), clean the screen (ultrasonic cleaning after every 500 prints), and replace worn doctor blades (when hardness decreases by more than 10%). Record all process parameters (such as tension, viscosity, curing temperature) to create a traceable production record.

What Is the Best Font for PCB Silkscreen?

Sans-serif Font Priority

- Recommended sans-serif fonts include Arial, Helvetica, Calibri, etc., offering higher readability at small sizes for international clients.

- Chinese characters require TrueType fonts supporting Chinese character sets (e.g., Microsoft YaHei, SimSun), avoiding decorative or serif fonts.

Character Size Specifications

- Standard character height: 1.0mm-1.5mm (40mil-60mil), minimum not less than 0.8mm (32mil), subject to manufacturer process limits.

- Line width recommended 0.15mm-0.2mm (6mil-8mil), maintaining a height-to-width ratio of 1:6 to 1:7; high-density boards may reduce to 0.8mm height.

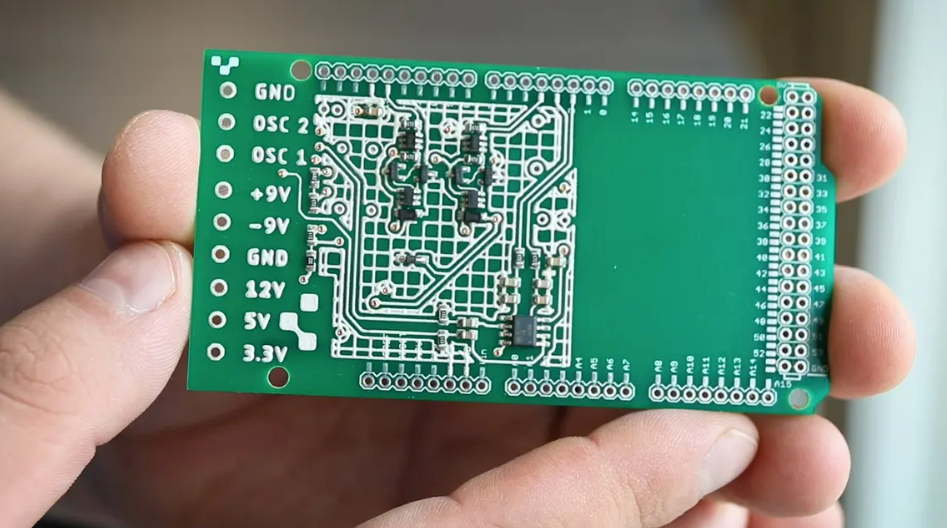

Layout and Positioning Rules

- Silkscreen should be close to corresponding components, avoiding coverage of pads, vias, or test points; reference numbers placed within or near component outlines.

- Reading direction standardized to horizontal or 90° rotation, avoiding arbitrary angles for quick manual identification; connecting lines must clearly point to components.

Safety Spacing Standards

- Silkscreen maintains ≥0.2mm (8mil) safety spacing from pads, copper traces, and vias; high-density boards may reduce to 0.15mm (6mil).

- Inter-silkscreen spacing ≥0.15mm to prevent printing adhesion; avoid covering high-speed signal lines or test points to prevent electrical performance impact.

Multilingual and Internationalization Support

- Fonts must support English, Chinese, and special symbols; Chinese silkscreen height ≥1.0mm, using TrueType fonts to ensure complete character display.

- Version numbers, company logos, etc., uniformly placed at board corners with high-contrast ink (e.g., white ink on dark substrates).

Manufacturer Process Collaboration

- Confirm minimum character height, line width, and spacing capabilities with manufacturers before panelization; verify silkscreen clarity post-Gerber output.

- Ensure Chinese characters remain free of garbled text during editing, output, and production; high-density designs require pre-communication of size limits.

Special Component Identification Standards

- Polar components (e.g., electrolytic capacitors, diodes) require clear polarity markings (e.g., “+” symbols, arrows); integrated circuits indicate Pin 1 position (dots, notches, or “1” digits).

- Connectors must indicate Pin 1 direction; special packages (e.g., BGA, QFN) require silkscreen dimensions matching actual chip sizes.

Visibility and Maintainability Optimization

- Silkscreen adopts reverse white, bold, or high-contrast designs for clear readability without magnification; board edges include version numbers, manufacturing dates, and company identifiers.

- Test points and interface areas avoid silkscreen coverage to ensure unimpeded flying probe testing or debugging operations.

How to Remove Silkscreen from PCB?

1. Source Control at Design Stage

- Operation Path: Disable silkscreen layer output in PCB design software (e.g., Altium Designer, KiCad). Hide Top/Bottom Silkscreen layers via layer manager, or deselect silkscreen layer file outputs (e.g., .GTO/.GBO files) during Gerber file generation to ensure PCBs are produced without silkscreen.

- Advantages: Zero cost, risk-free, optimal preventive solution that avoids potential PCB damage from physical/chemical removal methods.

2. Physical Scraping Method

- Tool Selection: Use surgical blades, precision carving knives, or professional PCB cleaning tools, paired with fine sandpaper (800+ grit) or grinding erasers.

- Operation Key Points: Scrape at an angle ≤30° to the board surface; only applicable to rigid substrates (e.g., FR4); flexible boards (FPC) prohibited. For sandpaper grinding, use gentle unidirectional motion to avoid scratching the solder mask layer or exposing copper traces.

- Applicable Scenarios: Small-scale, localized silkscreen correction requiring skilled operators to prevent damage to component pads or traces.

3. Chemical Solvent Method

- Solvent Selection: Prioritize dedicated silkscreen removal agents or acetone (high efficiency but may corrode solder mask); alternatives include ethyl acetate or isopropyl alcohol (IPA). Prohibit strong corrosive solvents (e.g., concentrated sulfuric acid, chloroform).

- Operation Process: In ventilated environments, dip a cotton swab in minimal solvent to gently wipe silkscreen areas. Wait 15-30 seconds for ink dissolution, then clean residues with lint-free cloth dipped in IPA.

- Safety Requirements: Wear nitrile gloves, goggles, and N95 masks; keep away from ignition sources; prohibit use on high-frequency boards (e.g., Rogers material) or sensitive component areas.

4. Laser Removal Method

- Technical Principle: Utilize UV laser marking machines for non-contact ablation to precisely remove silkscreen without damaging underlying solder mask or copper layers.

- Advantages: High precision, efficiency, and chemical-free, suitable for high-value PCB repairs or precision circuits.

- Limitations: High equipment cost (requires professional laser systems); requires skilled programming; difficult to implement at general repair shops.

5. Mechanical Grinding Method

- Tool Configuration: Ultra-fine sandpaper (2000+ grit), grinding sponges, or fiber erasers (can be water-dampened to reduce dust).

- Operation Standards: Gentle unidirectional grinding with real-time surface monitoring; stop immediately after silkscreen removal. Avoid over-grinding to prevent solder mask wear or copper exposure.

- Applicability: Recommended only for open non-functional areas; prohibited in component-dense zones to prevent short-circuit risks.

6. Precautions and Risk Control

- Pre-Testing: Conduct small-scale tests in PCB edge non-functional areas to verify solvent compatibility or grinding force.

- Environmental Protection: Treat chemical waste according to regulations; maintain dust-free operation environments to prevent short circuits from dust adhesion.

- Regulatory Compliance: Prohibit removal of certification marks (e.g., UL logo) to avoid regulatory violations; delegate critical boards (e.g., medical/military devices) to professional manufacturers.

- Post-Operation Verification: Perform electrical performance tests (e.g., open/short detection, impedance verification) after silkscreen removal to ensure no functional impairment or hidden faults remain.

- Alternative Solutions: Use alcohol markers for temporary marking; for long-term needs, adjust silkscreen layout via design software or use removable labels for coverage.

Please feel free to contact us if you need any help for silkscreen PCB: sales@bestpcbs.com.