PCB 8 layer stackup‚Äč is a specific arrangement of copper and insulating layers that provides an optimal balance of performance, density, and signal integrity for complex electronic designs. This article will provide a comprehensive guide to the standard 8 layer PCB stackup, compare it critically with 6-layer alternatives, and explore its key design considerations.

Are you struggling to decide if your high-speed or high-density design truly needs an 8-layer board, or if a 6-layer stackup would suffice?

- ‚ÄčPerformance Anxiety:‚Äč‚Äč Worrying that a 6-layer board might not provide sufficient isolation for sensitive signals, leading to crosstalk and electromagnetic interference (EMI).

- ‚ÄčRouting Congestion:‚Äč‚Äč Facing the frustrating reality of not being able to route all the traces on a 6-layer board, especially with complex components like BGAs.

- ‚ÄčImpedance Mismatch:‚Äč‚Äč Struggling to achieve consistent and controlled impedance for high-speed signals, which is more challenging with fewer layers.

- ‚ÄčPower Integrity Issues:‚Äč‚Äč Experiencing noise on the power plane, which can cause erratic circuit behavior and is harder to manage in a 6-layer stackup.

- ‚ÄčCost vs. Performance Dilemma:‚Äč‚Äč Being caught between the lower cost of a 6-layer board and the superior performance and reliability of an 8-layer PCB, unsure of the right long-term investment.

The good news is that these challenges have clear solutions when you understand the advantages of a well-designed ‚Äč8 layer pcb stackup‚Äč and partner with an experienced manufacturer.

- ‚ÄčEnhanced Signal Integrity:‚Äč‚Äč An 8-layer stackup allows for dedicated signal layers adjacent to solid ground planes, effectively minimizing crosstalk and EMI, which directly addresses performance anxiety.

- ‚ÄčSuperior Routing Capability:‚Äč‚Äč The two additional layers provide much-needed real estate for routing complex designs, effortlessly solving routing congestion.

- ‚ÄčPrecise Impedance Control:‚Äč‚Äč With more layers, achieving a consistent dielectric environment for impedance-controlled traces (like for the ‚Äč8 layer PCB stackup impedance) becomes more straightforward and reliable.

- ‚ÄčStable Power Delivery:‚Äč‚Äč Dedicated power planes in an 8-layer stackup offer low-inductance power distribution, ensuring clean power to all components and eliminating power integrity issues.

- ‚ÄčOptimal Value Proposition:‚Äč‚Äč While the initial cost is higher, the enhanced performance, reliability, and reduced need for re-spins often make the ‚Äč8 layer stackup pcb‚Äč the more cost-effective solution for advanced applications, resolving the cost vs. performance dilemma.

At BEST Technology, we specialize in manufacturing high-quality, high-performance PCBs. As an original 8 layer PCB factory with 19 years of extensive experience in multilayer boards, we understand the intricacies of PCB 8 layer stackup design. We work with you to determine the optimal stackup, whether it’s a ‚Äčstandard 8 layer PCB stackup‚Äč or a more advanced ‚Äč8 layer HDI stackup, ensuring your design is built to the highest standards. A warm welcome to contact us at sales@bestpcbs.com to discuss your PCB 8 layer stackup project requirements.

‚ÄčWhat is the Typical PCB 8 Layer Stackup?‚Äč‚Äč

A typical ‚ÄčPCB 8 layer stackup‚Äč is engineered to maximize performance by carefully alternating signal, plane, and dielectric layers. The arrangement is not random; it is designed to shield high-speed signals and provide stable power.

- ‚Äč1. Standard Arrangement:‚Äč‚Äč A common and effective ‚Äčtypical 8-layer pcb stackup‚Äč follows this sequence from top to bottom: Top Signal -> Ground Plane -> Inner Signal 1 -> Power Plane -> Ground Plane -> Inner Signal 2 -> Power Plane -> Bottom Signal. This “signal-plane-signal” pattern is a cornerstone of good ‚Äč8 layer pcb stackup design guidelines.

- ‚Äč2. Shielding and Isolation:‚Äč‚Äč This configuration provides shielding for the inner signal layers (Inner 1 and Inner 2) by placing them between ground planes. This is crucial for reducing noise and crosstalk.

- ‚Äč3. Impedance Control:‚Äč‚Äč The symmetric structure makes it easier to control the characteristic impedance of traces, which is vital for signal integrity.

In summary, the ‚Äčtypical pcb 8 layer stackup‚Äč is a balanced structure that prioritizes signal integrity, EMI control, and power stability, making it a versatile choice for many demanding applications.

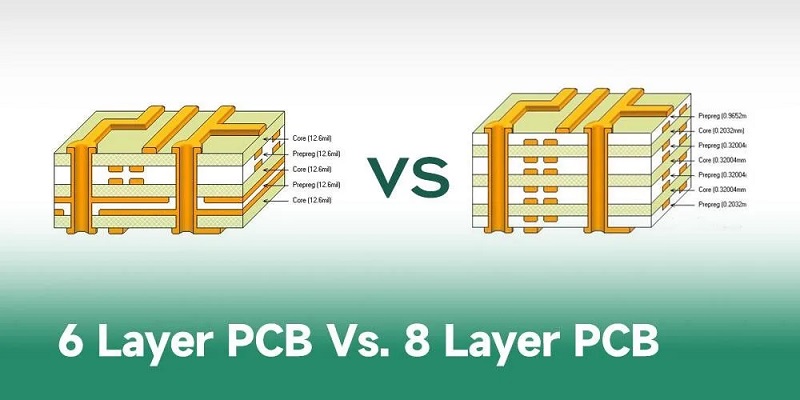

‚ÄčWhat are the Differences: 8 Layer PCB vs 6 Layer PCB?‚Äč‚Äč

The core difference in the “‚Äč8 layer PCB vs 6‚Äč” debate lies in the available resources for routing, shielding, and power distribution. The two extra layers in an 8-layer board provide a significant functional advantage.

- ‚Äč1. Layer Configuration:‚Äč‚Äč A standard 6-layer stackup might be: Signal – Ground – Signal – Signal – Power – Signal. This often forces high-speed signals to be routed on layers adjacent to other signal layers, increasing the risk of crosstalk. In contrast, the ‚ÄčPCB 8 layer stackup‚Äč provides dedicated internal routing layers between ground planes.

- ‚Äč2. Performance:‚Äč‚Äč The 8-layer board offers superior performance for high-speed designs due to better isolation and the ability to have dedicated power and ground planes. This leads to fewer signal integrity issues.

- ‚Äč3. Cost and Complexity:‚Äč‚Äč The ‚Äč6 layer PCB stackup‚Äč is less expensive and simpler to manufacture. It is an excellent choice for many applications but can become a bottleneck for very high-speed or dense designs.

Ultimately, the choice hinges on the design’s complexity. For applications where signal integrity is paramount, the ‚Äč8 layer PCB motherboard‚Äč or similar complex board is the clear winner.

How Thick is an 8 Layer PCB?‚Äč‚Äč

The ‚Äčstandard thickness of a PCB stackup‚Äč is often, but not always, around 1.6mm (0.063 inches). However, the final ‚Äč8 layer PCB thickness‚Äč is a result of the materials used and the number of layers.

- ‚Äč1. Standard and Custom Thickness:‚Äč‚Äč While 1.6mm is common, the thickness can vary. The ‚Äčstandard 8 layer PCB stackup‚Äč thickness can be designed to be 0.8mm, 1.0mm, 1.6mm, or even thicker based on the application’s mechanical and electrical requirements.

- ‚Äč2. Factors Influencing Thickness:‚Äč‚Äč The ‚Äč8 layer PCB stackup thickness‚Äč is determined by the thickness of the core and prepreg (insulating) materials, as well as the copper weight. For impedance control, the dielectric thickness between a signal layer and its reference plane is critical.

- ‚Äč3. Importance of Specification:‚Äč‚Äč When discussing your ‚ÄčPCB 8 layer stackup‚Äč with a manufacturer, it is essential to specify your desired finished thickness and impedance requirements to ensure the stackup is designed correctly.

Therefore, the thickness of an 8-layer PCB is not a fixed value but a key parameter that is carefully engineered during the stackup design phase.

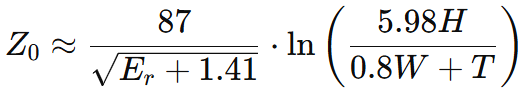

‚ÄčHow to Calculate the 8 Layer PCB Stackup Impedance?‚Äč‚Äč

Calculating the ‚Äč8 layer PCB stackup impedance‚Äč is a critical step for high-speed design, ensuring signals are transmitted without reflection or distortion.

‚Äč1. Key Parameters:‚Äč‚Äč The characteristic impedance of a trace depends on its width (W), the dielectric height (H) to the reference plane, and the dielectric constant (Er) of the insulating material. The copper thickness (T) also has a minor effect.

2. ‚ÄčUse of Formulas and Tools:‚Äč‚Äč While formulas exist, e.g., for microstrip:

Most engineers use impedance calculation tools provided by manufacturers or integrated into PCB design software like ‚Äč8 layer PCB stackup altium. These tools automatically calculate the required trace width for a target impedance (e.g., 50ő© or 100ő© differential) based on the defined stackup.

‚Äč3. Manufacturer Collaboration:‚Äč‚Äč It is best practice to finalize your stackup with your PCB manufacturer. They can provide the most accurate Er values and ensure the fabricated board will meet your impedance targets.

Proper impedance calculation is non-negotiable for reliable high-speed performance and is a fundamental part of the ‚Äč8 layer PCB stackup design guidelines.

‚ÄčHow Many Layers can a PCB Have?‚Äč

PCBs can have a vast number of layers, from 1 to over 50 in extreme cases like advanced servers. The more pertinent question is: do PCB layers matter? The answer is an emphatic yes.

- ‚Äč1. Function of Layers:‚Äč‚Äč The number of ‚ÄčPCB board layers‚Äč directly determines the board’s functionality. More layers allow for more complex circuitry, better separation of analog and digital sections, improved power integrity, and superior signal integrity through proper referencing and shielding.

- ‚Äč2. Choosing the Right Number:‚Äč‚Äč A simple electronic device might only need a ‚ÄčPCB stackup 4 layer, while a smartphone motherboard might require 10 or 12 layers. The decision for a ‚ÄčPCB 8 layer stackup‚Äč is based on the need for a robust design that can handle multiple high-speed signals and multiple power supplies efficiently.

The number of layers is a fundamental architectural decision that impacts the cost, performance, and reliability of the final product.

‚ÄčWhat is the 4 Layer PCB Rule?‚Äč‚Äč

‚ÄčThe “4 layer PCB rule” is a fundamental guideline in PCB design that dictates the optimal arrangement of layers to maximize performance while minimizing cost. It serves as a crucial stepping stone towards understanding more complex stackups like the 8-layer board. While not a rigid law, following this rule is considered a best practice for most 4-layer designs.

- ‚Äč1. The Core Principle: Dedicated Plane Layers‚Äč

The most important aspect of the rule is the allocation of the two internal layers.

Instead of using them for additional signal routing, they are dedicated exclusively as solid, uninterrupted planes‚ÄĒone for ground (GND) and one for power (PWR).

The outer layers (Top and Bottom) are then used for component placement and signal routing. - ‚Äč2. Standard Layer Stackup‚Äč

A typical and effective ‚Äč4 layer board stackup‚Äč follows this sequence:- ‚ÄčLayer 1 (Top):‚Äč‚Äč Components and Signal Routing

- ‚ÄčLayer 2 (Internal):‚Äč‚Äč Ground Plane (GND)

- ‚ÄčLayer 3 (Internal):‚Äč‚Äč Power Plane (PWR)

- ‚ÄčLayer 4 (Bottom):‚Äč‚Äč Components and Signal Routing

- ‚Äč3. Key Benefits of This Rule‚Äč

- ‚ÄčImproved Signal Integrity:‚Äč‚Äč By routing signals on the outer layers adjacent to the solid internal planes, each signal trace has a clear and continuous reference plane.

This controlled environment is essential for managing characteristic impedance and significantly reducing electromagnetic interference (EMI) and crosstalk. - ‚ÄčEnhanced Power Integrity:‚Äč‚Äč The dedicated power plane provides a low-inductance path for distributing power to all components, resulting in a cleaner and more stable voltage supply, which reduces noise.

- ‚ÄčSuperior EMI Performance:‚Äč‚Äč The two internal planes act as shields, containing the electromagnetic fields generated by high-speed signals on the outer layers, making the board less susceptible to emitting and receiving interference.

- ‚ÄčImproved Signal Integrity:‚Äč‚Äč By routing signals on the outer layers adjacent to the solid internal planes, each signal trace has a clear and continuous reference plane.

- ‚Äč4. Comparison to 2-Layer Boards‚Äč

This rule highlights the major leap in performance from a 2-layer to a ‚ÄčPCB stackup 4 layer.

A 2-layer board lacks dedicated planes, forcing signals and power to share routing space, which often leads to noise and reliability issues.

In summary, the ‚Äč4 layer PCB rule‚Äč is a foundational concept that prioritizes a clean and stable electrical environment. It establishes the core principles of using dedicated power and ground planes, which are then scaled up and refined in more advanced stackups like the ‚Äč8 layer PCB stackup.

‚Äč8 Layer PCB Stackup Design Guidelines

‚ÄčAdhering to proven ‚Äč8 layer PCB stackup design guidelines‚Äč is fundamental to achieving optimal signal integrity, power integrity, and EMC performance. While the previous section outlined four key principles, a deeper understanding requires grounding these rules in the fundamental goals of all stackup design.

Before delving into specifics, all stackup design aims to satisfy two primary rules:

- ‚ÄčA Reference Plane for Every Signal Layer:‚Äč‚Äč Every high-speed signal routing layer must be adjacent to a solid reference plane (power or ground). This provides a controlled impedance path and a clear, low-inductance return path for signals.

- ‚ÄčTight Power-Ground Coupling:‚Äč‚Äč Closely spaced power and ground planes are crucial. The minimal spacing between them creates a natural, high-frequency decoupling capacitor that enhances power integrity and reduces EMI.

‚ÄčUnderstanding the limitations of simpler boards highlights the necessity of a well-designed 8-layer stackup.

- ‚ÄčSingle/Double-Sided Boards:‚Äč‚Äč These lack dedicated planes, leading to large signal loop areas which are major sources of EMI and susceptibility. The primary mitigation is to route critical signals (like clocks) with an adjacent ground trace to minimize the loop area.

- ‚ÄčFour-Layer Boards:‚Äč‚Äč While a significant improvement, the standard 1.6mm board thickness creates a large separation between layers, weakening power-ground coupling and making impedance control challenging. The best 4-layer stackup for EMI (GND-SIG/PWR-SIG/PWR-GND) uses outer layers as ground planes for shielding.

- ‚ÄčSix-Layer Boards:‚Äč‚Äč These offer a better balance. A common good stackup is SIG-GND-SIG-PWR-GND-SIG. It provides a reference plane for each signal layer and pairs the power and ground layers. However, achieving tight power-ground coupling within a standard board thickness remains difficult.

‚ÄčAn 8-layer board provides the canvas to implement near-ideal stackup design. Here are critical guidelines, moving beyond the basics.

- ‚ÄčPrioritize Shielding and Symmetry to Prevent Warping‚Äč

The simplest 8-layer stackup (e.g., SIG-SIG-GND-SIG-SIG-PWR-SIG-SIG) is inherently poor. It has multiple consecutive signal layers without reference planes, leading to poor SI and EMI. A superior approach uses symmetry and multiple ground planes. A ‚Äčhighly recommended 8 layer stackup‚Äč is:- Top Signal (Microstrip)

- Ground Plane

- Internal Signal 1 (Stripline)

- Power Plane

- Ground Plane

- Internal Signal 2 (Stripline)

- Power Plane

- Bottom Signal (Microstrip)

This arrangement is symmetrical, preventing warping. The internal signal layers are shielded between planes, and the ground planes act as excellent EMI shields.

- ‚ÄčMaximize Interplane Capacitance for Power Integrity‚Äč

Following the core rule of tight coupling, place the power and ground planes that require the best noise immunity (e.g., the core voltage for an FPGA) as adjacent layers (e.g., L4/L5 or L6/L7 in the stackup above). The thin dielectric between them creates a large, low-inductance distributed capacitor that effectively suppresses high-frequency noise on the power rail. - ‚ÄčSelect the Optimal Stackup for Your EMC and SI Goals‚Äč

The provided material describes three common 8-layer configurations. The best choice depends on your priority:- ‚ÄčGood SI, Poor EMI (Example 1):‚Äč‚Äč Features many signal layers but lacks sufficient shielding, making it susceptible to radiating.

- ‚ÄčGood SI, Better EMI (Example 2):‚Äč‚Äč This is a strong, common choice. It uses outer ground planes for shielding and has a tightly coupled power-ground plane pair in the center. It offers an excellent balance for most applications.

- ‚ÄčBest SI and EMI (Example 3):‚Äč‚Äč This is the premium configuration, utilizing four ground planes. It provides the highest level of shielding and the cleanest possible return paths for all signals, making it ideal for extremely noise-sensitive or high-radiation applications.

- ‚ÄčCollaborate with Your Manufacturer Early for Impedance Control‚Äč

This guideline cannot be overstated. Once you have a target stackup, you must work with your PCB manufacturer before finalizing the design. Provide them with your target impedances (e.g., 50ő© single-ended, 100ő© differential). They will feedback the precise dielectric thicknesses and trace widths required to hit your targets based on their specific materials and process capabilities. This is a non-negotiable step in the ‚Äč8 layer pcb stackup design guidelines.

In summary, designing an 8-layer stackup is an exercise in careful layer ordering to manage return paths, provide shielding, and ensure stable power. By moving from the basic rules to these advanced guidelines‚ÄĒprioritizing shielded stripline layers, tight power-ground coupling, and selecting a stackup based on EMC needs‚ÄĒyou can fully leverage the capabilities of an 8-layer board to create a robust, high-performance product.

‚ÄčHow is the 8 Layer HDI Stackup?‚Äč‚Äč

‚ÄčAn ‚Äč8 layer HDI stackup‚Äč represents a significant advancement over a standard ‚Äč8 layer PCB stackup‚Äč by incorporating High-Density Interconnect (HDI) technologies. It is designed for the most space-constrained and performance-driven applications where miniaturization and complex routing are paramount.

- ‚Äč1. Core HDI Technologies‚Äč

HDI stackups are defined by their use of advanced manufacturing processes:- ‚ÄčMicrovias:‚Äč‚Äč These are laser-drilled vias with a much smaller diameter (typically less than 150¬Ķm) than mechanically drilled through-hole vias. They allow for connections between adjacent layers (e.g., from Layer 1 to Layer 2) with a minimal footprint.

- ‚ÄčFiner Traces and Spaces:‚Äč‚Äč HDI processes enable the etching of much narrower trace widths and clearances, allowing more circuitry to be packed into a smaller area.

- ‚ÄčAdvanced Build-Up Structures:‚Äč‚Äč HDI boards are often built using a sequential lamination process, creating complex sub-composites that can include stacked microvias, staggered vias, and buried vias.

- ‚Äč2. Design Advantages over Standard 8-Layer Stackups‚Äč

The integration of HDI technology into an ‚Äč8 layer stackup PCB‚Äč offers several critical benefits:- ‚ÄčExtreme Miniaturization:‚Äč‚Äč By using microvias and finer lines, components can be placed closer together, and the overall board size can be drastically reduced. This is essential for devices like modern smartphones, wearables, and IoT sensors.

- ‚ÄčEnhanced Signal Performance:‚Äč‚Äč Shorter pathways and reduced via stubs from microvias lead to better electrical performance at high frequencies, minimizing signal loss and reflection.

- ‚ÄčGreater Routing Density:‚Äč‚Äč HDI allows for escape routing from high-pin-count components like fine-pitch BGAs, which would be impossible to route on a standard ‚Äč8 layer PCB motherboard‚Äč of the same size.

- ‚ÄčImproved Reliability:‚Äč‚Äč The materials and processes used in HDI manufacturing often result in a more robust and reliable board.

- ‚Äč3. Typical Applications‚Äč

An ‚Äč8 layer HDI stackup‚Äč is not for every project due to its higher cost. It is typically reserved for cutting-edge applications, including:- Smartphones and Tablets

- Advanced Medical Implants and Diagnostic Equipment

- High-Performance Computing and Networking Hardware

- Aerospace and Defense Avionics

In conclusion, the ‚Äč8 layer HDI stackup‚Äč is the pinnacle of dense, high-performance PCB design. While a standard ‚Äčtypical 8-layer PCB stackup‚Äč is powerful, the HDI variant pushes the boundaries of what’s possible, enabling the creation of smaller, faster, and more complex electronic devices.

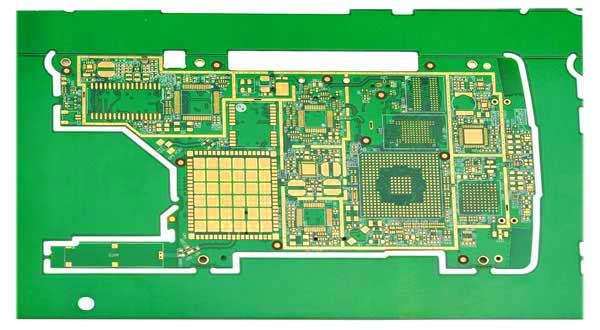

‚ÄčWhat are the Applications of 8 Layer Stackup PCB?‚Äč‚Äč

An 8-layer PCB stackup is widely used in advanced electronic systems where designers need strong signal integrity, stable power delivery, and compact circuit density. These boards support high-speed interfaces, complex processors, and mixed-signal architectures that cannot be achieved with simpler stackups.

Typical applications include:

- 8-layer PCB motherboards for industrial and embedded computing

- High-speed network devices such as routers, switches, and 5G baseband units

- Telecommunications infrastructure with dense RF and digital circuits

- Automotive electronics including ADAS domain controllers

- Medical imaging and diagnostic systems

- Industrial automation and rugged control equipment

To show how a real design translates into actual applications, the following example highlights a high-performance 8-layer HDI PCB with engineering features tailored to demanding markets. And the following specific applications are supported by a PCB built to these professional specifications:

- Via Type: Resin-filled buried and blind vias

- Layer Count: 8-Layer

- Material: High-Tg FR-4

- Tg Rating: 180¬įC

- Copper Weight: 1oz outer / 1oz inner

- Surface Finish: ENIG (1őľ‚Ä≥)

- Solder Mask: Green

- Silkscreen: White

- Final Thickness: 1.6mm

- Technology: 3-step HDI

1. Core Networking & Communication Systems

Application: Processing and switching board for 100G/200G/400G network equipment.

Why an 8-layer PCB fits:

The 3-step HDI structure handles fine-pitch BGA components used in high-bandwidth ASICs and FPGAs. Meanwhile, TG180 FR-4 improves thermal stability during long-term, high-load operation. This combination supports multi-lane SerDes signals and tight impedance control for high-speed communication links.

2. Aerospace and Defense Electronics

Application: Signal processing module for airborne radar or mission-critical avionics.

Why an 8-layer PCB fits:

Aircraft electronics experience extreme temperature swings and continuous vibration. 1.6mm finished thickness and TG180 laminate provide strong mechanical strength and thermal endurance. The 1őľ‚Ä≥ ENIG finish offers reliable surface quality for gold-wire bonding and high-frequency interconnects common in RF signal chains.

3. Advanced Medical Imaging Equipment

Application: Core electronic module in portable ultrasound or digital imaging diagnostics.

Why an 8-layer PCB fits:

Medical devices demand both miniaturization and signal clarity. HDI + resin-filled vias help integrate dense components into a compact format while maintaining stable impedance for sensitive analog/digital imaging circuits. The ENIG surface ensures excellent contact reliability for fine-pitch connectors and probe interfaces.

4. Next-Generation Automotive Electronics

Application: Central computing board for ADAS or autonomous driving systems.

Why an 8-layer PCB fits:

ADAS controllers must process multiple high-resolution camera, radar, and LiDAR inputs. An 8-layer stackup provides robust isolation between high-speed differential pairs and noisy power circuits. The 1oz copper thickness supports steady power delivery to high-current SoCs and processing units, ensuring stable performance even at elevated vehicle temperatures.

5. Industrial IoT and Edge Computing Devices

Application: Industrial edge gateway, PLC controller, or machine-vision interface.

Why an 8-layer PCB fits:

Factories require devices that remain stable under dust, humidity, vibration, and electrical noise. The ENIG finish prevents oxidation, and the green solder mask + white silkscreen combination improves maintenance visibility. The rigid 8-layer architecture enhances long-term reliability for 24/7 operation in challenging industrial environments.

In closing, this example makes it clear that an 8-layer PCB stackup is far more than a simple increase in layer count. With the right combination of materials, HDI structures, and controlled-impedance routing, it becomes a powerful platform for mission-critical, high-speed, and high-density electronic systems across multiple industries.

In conclusion‚Äč, PCB 8 layer stackup‚Äč is a sophisticated multilayer board configuration that offers a significant performance upgrade over 6-layer alternatives for demanding electronic applications. This article has explored the structure, advantages, and design considerations that make the 8-layer stackup a preferred choice for high-speed and high-density designs.

For engineers seeking reliable, high-performance PCB 8 layer stackup‚Äč fabrication, partnering with an experienced 8 layer PCB manufacturer is crucial. At BEST Technology, we have the expertise to guide you through the entire process, from selecting the ‚Äčbest 8 layer stackup‚Äč for your needs to ensuring impeccable manufacturing quality. Pls feel free to contact us at sales@bestpcbs.com to get started on your next 8 layer stackup PCB project.