OEM PCB manufacturer is the starting point for creating reliable, customized circuit boards for today’s electronics. From Wi-Fi antennas to LED boards, everything starts with a trusted PCB partner. Whether you need a small run or large-scale production, understanding the world of OEM PCB manufacturing helps you pick the right partner for success. Let’s explore the best choices, what to look for, and why EBest Circuit (Best Technology) is one of the top options.

As one of an OEM PCB WIFI antenna manufacturers, EBest Circuit (Best Technology) has a proven track record in 2024. We have solved assorted OEM PCB projects for 1700 customers across 40 countries. Our company promotes team spirit, and we implement a 2-3 weeks lead time policy from the top down in 2025. All of our products can be tailored to suit your needs, like FR4, MCPCB, ceramic PCB, and PCB assembly. If you have any nuts-and-bolts cases needed to support, reach out to us at sales@bestpcbs.com. Our professional talents are always here to provide you with professionalism.

What Is an OEM PCB Manufacturer?

An OEM PCB manufacturer builds circuit boards based on the designs and specifications of another company. “OEM” means Original Equipment Manufacturer. This means they don’t design the product themselves. Instead, they bring other people’s designs to life.

These manufacturers play a key role in tech, automotive, medical, and communication devices. They turn ideas into real working boards that power machines, tools, and everyday electronics. Their job includes prototyping, testing, assembling, and producing boards at scale. Most importantly, they must follow strict quality standards.

Who Manufactures OEM PCBs?

Several companies manufacture OEM PCBs around the world. Many of them are located in China, the USA, Canada, and parts of Europe. These manufacturers work for big brands as well as startups.

EBest Circuit (Best Technology) is one of the trusted OEM PCB manufacturers in China certified with ISO, IATF, and AS9100D.

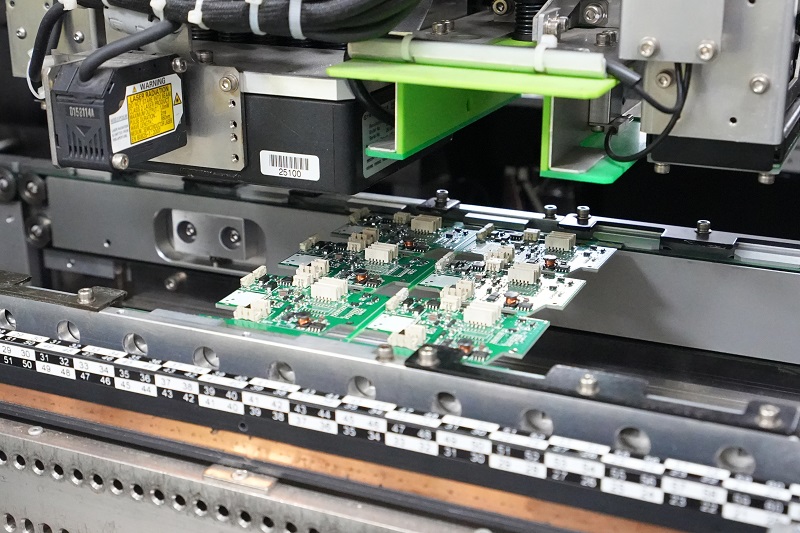

Our engineers are skilled in both PCB fabrication and PCB assembly. Most of them have over 10 years of experience. Our SMT factories are equipped with advanced PCB manufacturing machines. We have SMT plants in China and Vietnam, which give us access to handle multilayer, flex, rigid-flex, and HDI designs from low volume to large volume. It is worth mentioning that there is no MOQ in all of our product portfolio.

Our OEM PCB and PCB assembly are used in all walks of life, Supportive of industries like telecom, defense, LED lighting, consumer electronics, and automotive. If you are interested in our product portfolio, welcome email us via sales@bestpcbs.com to get the product profile and the free quote.

You can also find us on our official website platforms, where you can upload your files and get instant quotes.

Who Is the Largest OEM PCB Manufacturer in the World?

The largest OEM PCB manufacturer in the world today is Zhen Ding Tech Group. They produce massive volumes for global brands in smartphones, wearable devices, and computing. Their advanced equipment and smart factories make them stand out. Following close behind are manufacturers like:

- TTM Technologies

- Nippon Mektron

- Unimicron

These companies have factories in many countries and serve major tech giants. However, their scale is better suited for high-volume, less-custom orders.

Who Is the Largest Manufacturer of OEM PCB in North America?

In North America, TTM Technologies holds the leading spot. Their focus on innovation and high-quality manufacturing makes them a top pick. They serve defense, aerospace, and automotive industries. Besides TTM, you’ll find others in the list of PCB manufacturers in USA like:

- Sanmina

- Advanced Circuits

- Bay Area Circuits

These companies offer PCB manufacturing USA-wide with excellent support and flexibility.

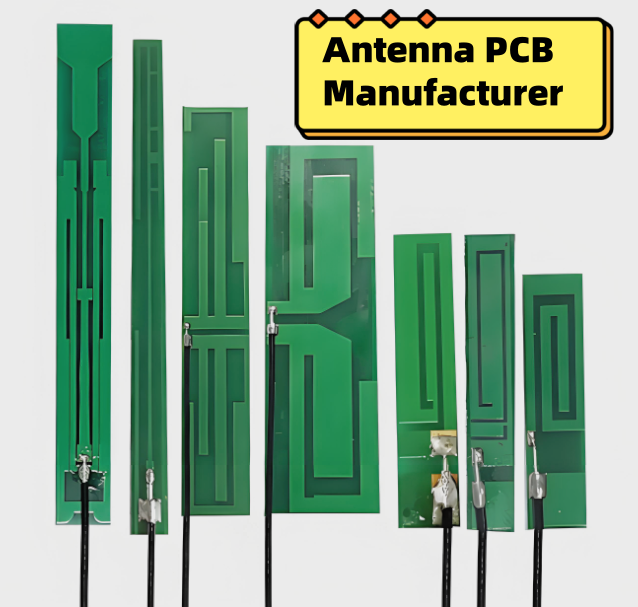

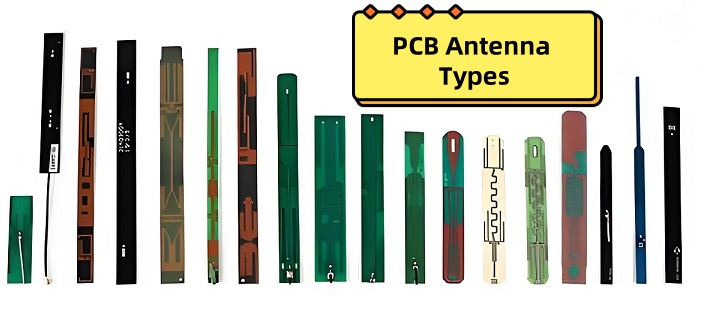

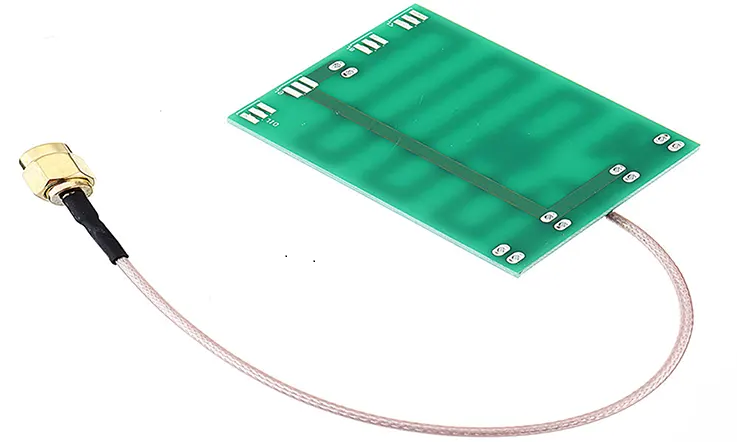

OEM PCB WIFI Antenna Manufacturers

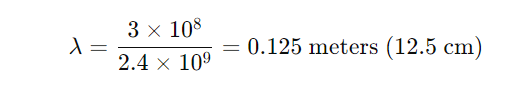

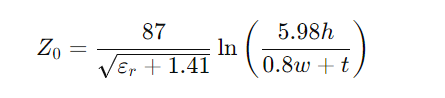

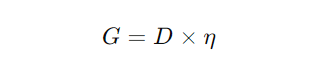

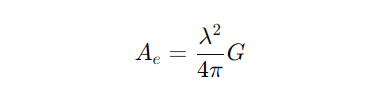

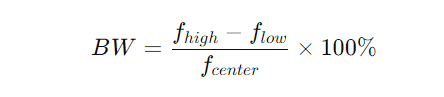

Wi-Fi antenna PCBs are now common in smart home devices, routers, and IoT gadgets. A good OEM PCB WIFI antenna manufacturer needs precise RF knowledge and the ability to work with special materials. They must:

- Handle high-frequency design.

- Use tight impedance control.

- Offer testing for signal strength and stability.

EBest Circuit (Best Technology) is among the few who excel in this area. Their engineers understand RF layout rules and tuning. So, they help companies launch smart, connected devices faster.

OEM WIFI Light Switch PCB Manufacturers

Smart switches use PCBs with both power handling and communication functions. EBest Circuit (Best Technology) is a reliable OEM WiFi light switch PCB manufacturer.

We have the safety certifications, and the capability to manage temperature and power control. Our OEM WIFI light switch PCB uses gold-finished contacts for better durability.

Many OEM immersion gold PCB manufacturers also make light switch PCBs. Immersion gold helps maintain contact quality over time. Look for someone who has done similar projects, especially in smart home or building automation markets.

How to Choose an OEM PCB Manufacturer?

Here’s a checklist for picking a quality OEM PCB manufacturer:

- Check certifications – ISO, IATF16949 (automotive), or ISO13485 (medical).

- Look at capabilities – Can they handle flex, rigid-flex, or high-frequency?

- Test speed – Fast response time and quick prototyping.

- Read reviews – Ask others in your field for feedback.

- Ask for samples – It tells you a lot about the process.

- Review customer service – A good team listens and adapts fast.

Also, if you need something unique like a OEM metal detector PCB or a OEM inverter welding machine PCB, make sure the supplier has done something similar before.

Why Should You Choose EBest Circuit (Best Technology) as Your Trusted OEM PCB Manufacturer?

EBest Circuit (Best Technology) is a well-established OEM PCB manufacturer since 2006. We are your reliable partner that helps your products shine in the market.

Experience across industries: From OEM mobile phone charger PCB board manufacturers to OEM power bank PCB assembly manufacturer, they cover many areas.

- Full support: From quoting to delivery, EBest Circuit (Best Technology) provides updates and solutions.

- Professional team: They offer DFM (design for manufacturing) advice to improve quality.

- Certified and compliant: Their factory is ISO9001, ISO13485, and IATF16949 certified.

- Custom solutions: They even support rare builds like OEM wireless receiver PCB board manufacturers.

- Fast quote and online services: Upload files on our official website for fast feedback.

So whether you need small batch PCB assembly or large orders, they are ready to serve.

In a nutshell, choosing the right OEM PCB manufacturer matters a lot. It affects your cost, timeline, and product reliability. From Wi-Fi antenna PCBs to LED boards, smart switches, and charger PCBs, trusted manufacturers play a key role in your success. Whether you’re working on a new idea or scaling an old one, the right PCB partner will keep you moving. Top PCB manufacturing USA companies offer great service, but companies like EBest Circuit (Best Technology) bring value with global experience, fast response, and full customization.

By implementing a no MOQ policy, EBest Circuit (Best Technology) supports customers for small runs for testing or pilot production. OEM builds to your design. Apart from OEM, EBest Circuit (Best Technology) also supports ODM, providing both design and manufacturing for your project.

Welcome to visit our company website to upload your files and get fast pricing, or contact our sales engineers via sales@bestpcbs.com to get support. It is our pleasure to provide high-quality boards, real support, and fast delivery every time for you.