Finding the right 24 hour PCB manufacturer can be a game-changer, especially when you need fast turnaround times for your projects. Whether youâre in need of quick turn PCB USA services or a 24 hour PCB solution that meets strict deadlines, choosing the right manufacturer is essential. In this article, we will guide you in selecting the best 24 hour PCB manufacturer for your needs.

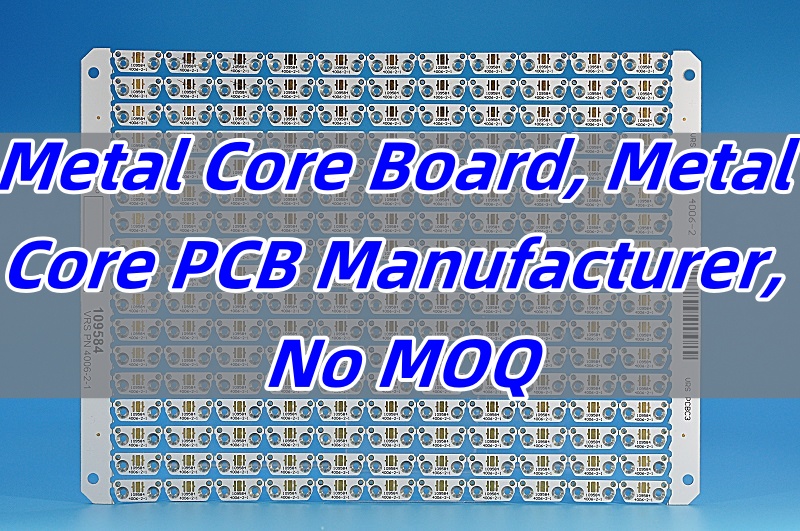

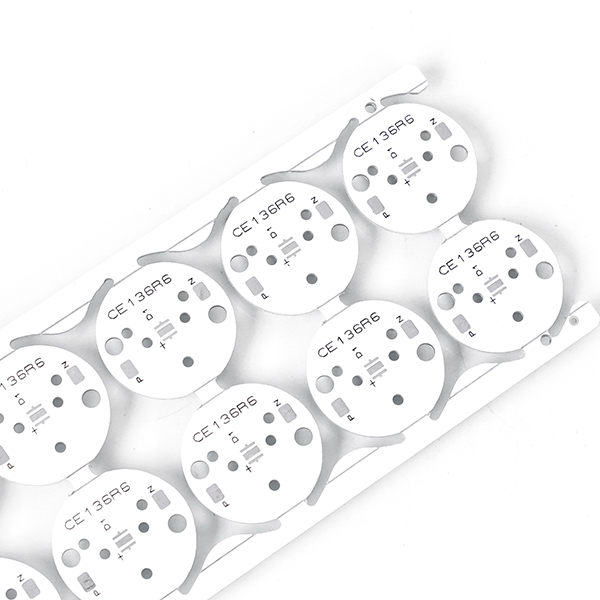

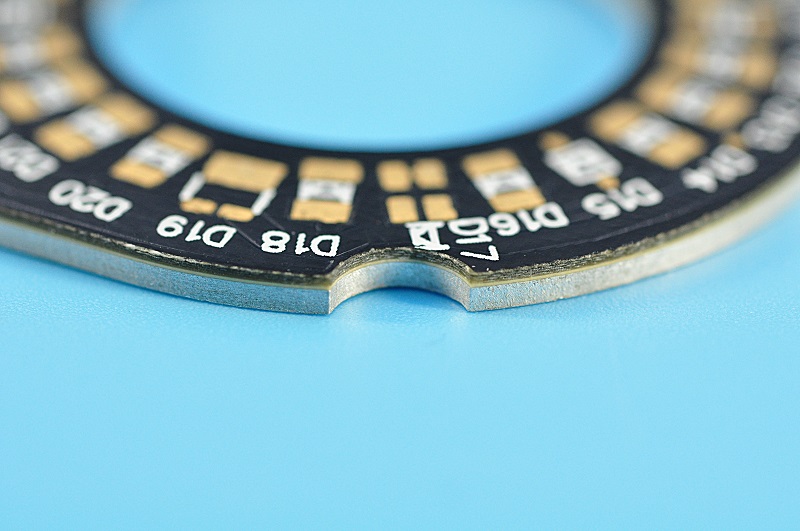

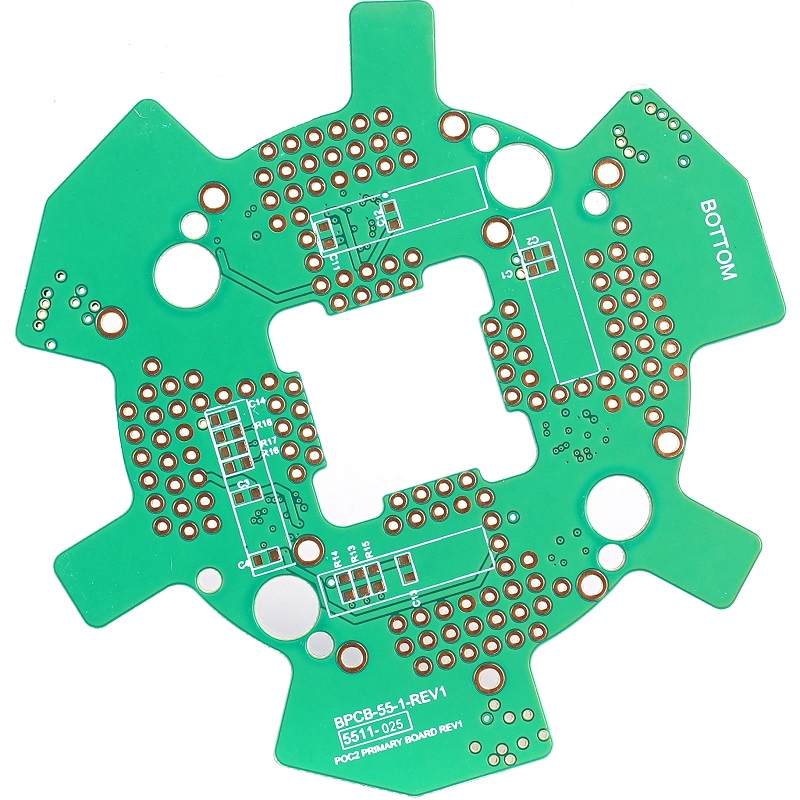

As a small and Medium-sized Enterprise, EBest Circuit (Best Technology) provides a diverse PCB portfolio without MOQ requirements. We mainly specialize in 24-hour PCB manufacturing, PCB Design, and PCBA. The geographic distribution of our customers varies from global. By the way, Israel, Germany, and the United States were the countries with the highest export volumes in our company last year. With aerospace quality, our products can be used in extreme temperatures or environments.

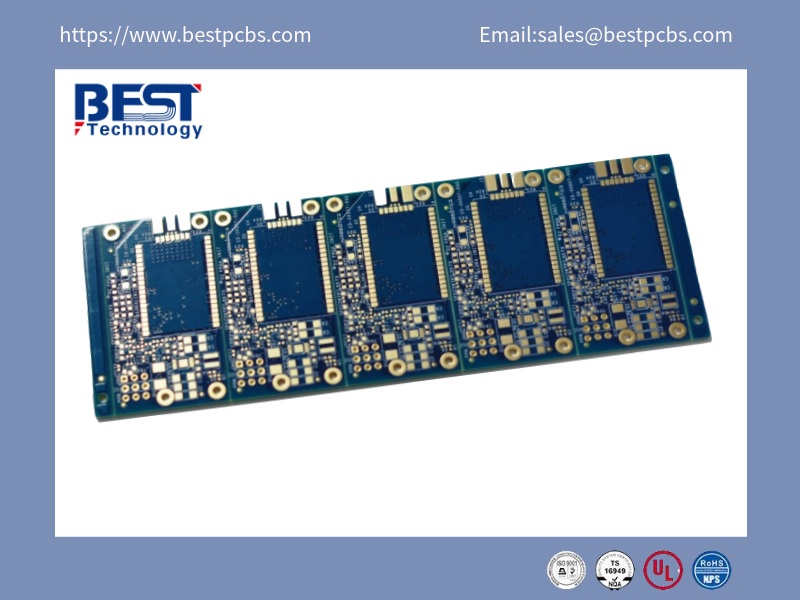

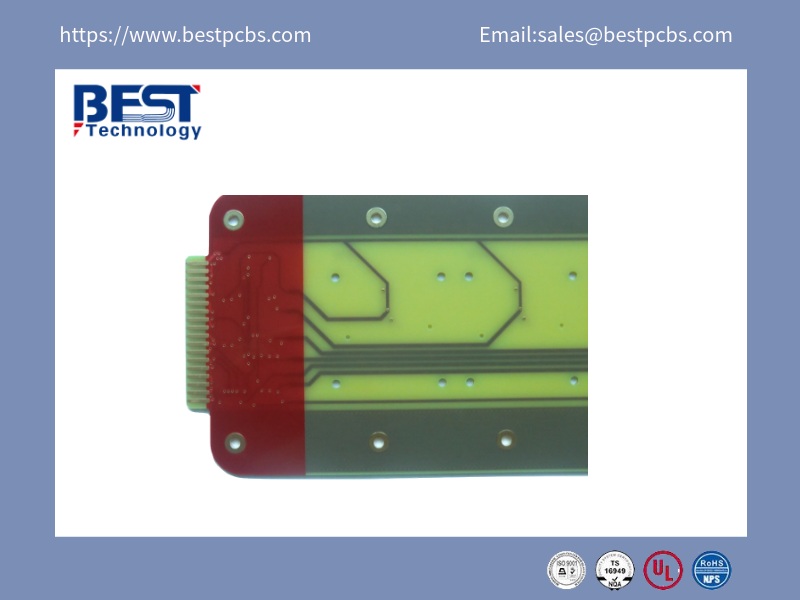

Apart from standard rigid FR4Â PCB, EBest Circuit (Best Technology) supports multi-layer PCB, like 4 Layer PCB, and some customization PCBs, like HDI PCB, and BGA PCB Assembly. We have nearly 2 Decades of expertise in quick Turn PCB manufacturing, if any questions just feel free to contact EBest Circuit (Best Technology) at sales@bestpcbs.com.

Is There a 24 Hour PCB Manufacturer with No MOQ in China?

If you’re looking for 24 hour PCB manufacturing in China, itâs crucial to understand the capabilities and limitations of different manufacturers. Many companies offer rapid turnarounds, but the challenge often lies in minimum order quantities (MOQ). Some Chinese PCB manufacturers still impose MOQs, especially when production is expedited. However, there are a few companies that cater to low or no MOQ requirements for smaller batch runs. For instance:

- EBest Circuit (Best Technology) specializes in fast PCB prototyping with expedited turnaround times. Unlike many manufacturers, we eliminate minimum order quantities (MOQs) for select services, ensuring flexibility for low-volume needs. Our comprehensive PCB solutions include 24-hour lead time options strategically designed to support prototyping phases and small-batch production demands.

- Seeed Studio focuses on PCB prototypes and small batches, with the option for fast delivery, offering a solution for companies that need quick results without large commitments.

China offers competitive pricing and fast manufacturing. Working with Chinese 24-hour PCB manufacturers offers convenience and speed for urgent projects.

Can Quick Turn PCB USA Services Handle Complex Assembly in 24 Hours?

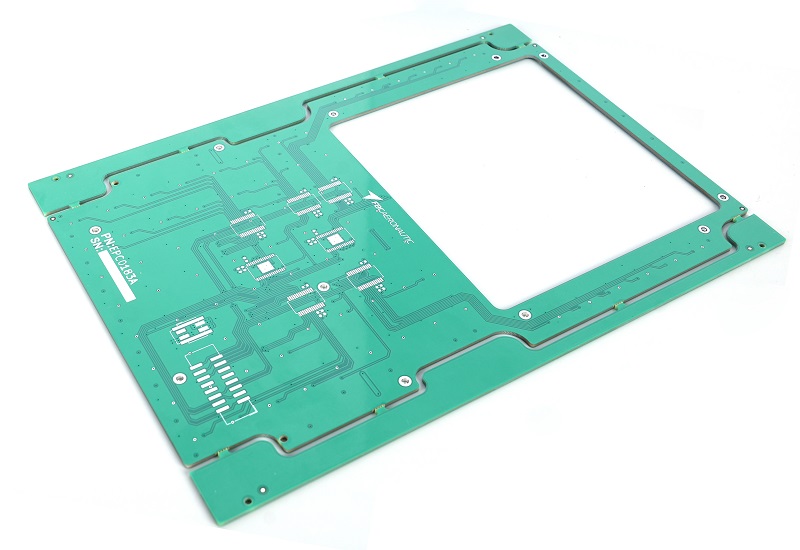

A key question many clients have is whether U.S.-based quick-turn PCB services can handle complex assemblies within 24 hours. The answer depends on design complexity, materials, and assembly type. While advanced 24-hour PCB manufacturers in the USA can manage many complex projects, highly intricate designs (e.g., 20+ layers, HDI with blind/buried vias, or specialized substrates) may require extended timelines.

For example, high-speed, high-frequency boards like flexible or multi-layer PCBs often need additional setup. However, 24-hour assembly services can still meet tight deadlines if the manufacturer utilizes advanced automation and robust supply chains, âprovided component availability and design readiness are confirmed upfrontâ.

What is the Cost of a 24-Hour PCB Manufacturing Service?

The cost of 24-hour PCB manufacturing services varies significantly based on factors such as PCB type (single-sided, double-sided, multi-layer), materials, design complexity, and order quantity. Prototyping costs typically range from 30 to 200+ per boardâ, depending on specifications like layer count (e.g., 4-layer vs. 20-layer) or specialized materials (e.g., high-frequency substrates). Key considerations include:

- âDesign complexityâ: Multi-layer boards, HDI designs with blind/buried vias, or high-frequency materials increase costs.

- âSpeedâ: Automated processes and supplier partnerships reduce costs, but advanced designs (e.g., ultra-thin traces) may still require manual adjustments.

- âShippingâ: Express fees for rush orders add to the total cost.

While manufacturers increasingly offer competitive pricing for rapid prototyping, costs remain tied to technical requirements and supply chain efficiency.

24 Hour PCB Manufacturer California

California is home to some of the top 24 hour PCB manufacturers in the USA. These manufacturers are well-equipped to handle urgent orders and can meet the needs of industries ranging from aerospace to medical electronics. Some of the best-known 24 hour PCB manufacturers in California include:

- Advanced Circuits: Known for offering rapid PCB manufacturing with an emphasis on quality control and customer support. They cater to both small and large-scale projects, ensuring that your PCB is delivered on time without compromising on quality.

- PCB Unlimited: A leading provider of quick turn PCB assembly and 24 hour PCB services. They focus on delivering highly customizable PCB solutions with quick turnarounds.

- Sunstone Circuits: Offers a range of PCB manufacturing services, including quick-turn options, to meet the needs of their customers in California and beyond.

California-based manufacturers are particularly beneficial due to their proximity to the tech industry, offering quick turnaround times for critical components.

Where Can I Find Quick-Turn PCB Manufacturing in the USA?

If youâre hunting for quick-turn PCB manufacturers but prefer to explore independently, here are practical channels to streamline your search:

â1. Industry-Specific Online Platformsâ

Websites like Thomasnet, Alibaba, or MakerVerse connect businesses with verified PCB suppliers. Use filters like location, certifications, or turnaround time to narrow options.

â2. Electronics Trade Shows/Exposâ

Events like IPC APEX EXPO or DesignCon gather PCB manufacturers under one roof. Attendees often get early access to new technologies or limited-time offers.

â3. Engineering Forums & Communitiesâ

Platforms like EEVblog, Redditâs r/PrintedCircuitBoard, or LinkedIn groups feature candid discussions where engineers share vetted manufacturer recommendations.

â4. Local Industry Associationsâ

Groups like IPC (Association Connecting Electronics Industries) or regional manufacturing alliances publish directories of certified PCB fabricators.

â5. Custom Google Searchesâ

Try targeted search terms like â24-hour PCB fabrication USAâ + âISO 9001 certifiedâ or âquick-turn prototype PCBâ + âITAR compliantâ to filter results by specific needs.

â6. Supplier Referral Programsâ

Ask existing partners (e.g., component distributors or assembly houses) for trusted PCB fabrication referralsâthey often have pre-vetted networks.

â7. Social Media Outreachâ

Post a detailed RFQ (Request for Quote) on LinkedIn or Twitter, tagging hashtags like #PCBDesign or #ElectronicsManufacturing to attract niche suppliers.

Always verify manufacturers through sample orders or third-party reviews. Check for transparency in pricing, communication responsiveness, and willingness to provide design feedbackâthese traits often signal a reliable partner for urgent projects.

How to Choose a Reliable 24 Hour PCB Manufacturer?

Choosing the right 24 hour PCB manufacturer is crucial for any project that requires fast delivery. Here are some tips to help you select the best manufacturer for your needs:

- Quality Assurance: Ensure that the manufacturer follows strict quality control processes to guarantee the performance and durability of your PCBs.

- Experience and Track Record: Look for manufacturers with a proven track record of successfully delivering quick turn PCB USA services, especially for projects similar to yours.

- Customer Support: Choose a company that provides clear communication and excellent customer service. This ensures that you get the help you need at every stage of the manufacturing process.

- Flexibility: Ensure that the manufacturer can handle varying order sizes and complexities while still meeting your deadline.

- Certifications: Look for manufacturers with relevant industry certifications, such as ISO 9001, which demonstrate a commitment to quality and best practices.

What Are EBest Circuit (Best Technology)’s Advantages as a 24 Hour PCB Manufacturer?

EBest Circuit (Best Technology) is a leading 24 hour PCB manufacturer offering rapid prototyping and quick turn PCB assembly services to customers across the USA. Their competitive advantages include:

- No MOQ: EBest Circuit (Best Technology) understands that some projects require small-scale production, offering no MOQ for prototyping and low-volume orders.

- Fast Turnaround Times: With their advanced manufacturing processes and efficient supply chain management, EBest Circuit (Best Technology) can meet the most urgent deadlines.

- Comprehensive Services: From PCB design to assembly, EBest Circuit (Best Technology) provides end-to-end solutions, ensuring that all your requirements are met under one roof.

- Global Reach: While based in the USA, EBest Circuit (Best Technology) has strong relationships with international suppliers, offering competitive pricing without compromising on quality.

For businesses that require 24 hour PCB manufacturing with no MOQ and fast delivery, EBest Circuit (Best Technology) offers the perfect combination of expertise, speed, and flexibility.

All in all, in today’s fast-paced tech world, having access to 24 hour PCB manufacturers can make a significant difference in meeting your deadlines and staying competitive. Whether you’re in the USA, China, or California, the right manufacturer can help you deliver quality PCBs quickly and efficiently. By understanding factors such as cost, assembly capabilities, and choosing a reliable manufacturer, you can ensure your project is completed on time. EBest Circuit (Best Technology) offers a unique combination of speed, flexibility, and expertise, making it a trusted partner for all your 24 hour PCB needs. Don’t hesitate to contact us at sales@bestpcbs.com.