Looking for industrial PCB manufacturing service? This guide details our process from stringent design standards to reliable assembly and swift delivery, explaining why we are your ideal partner.

In the fast-evolving PCB manufacturing industry, industrial PCB manufacturing is the backbone of industrial electronics, powering automation systems, measurement devices, and more. Its defining trait is uncompromising durability, as these boards must perform reliably in extreme temperatures, vibration, and corrosion. As a trusted industrial PCB manufacturer with 19 years of experience, EBest Circuit (Best Technology) combine advanced techniques and strict quality checks to deliver solutions that boost your operational efficiency. Choosing the right industrial PCB manufacturer ensures minimal downtime and keeps your projects on track.

What Is Industrial PCB Manufacturing?

Industrial PCB manufacturing refers to the specialized production of printed circuit boards (PCBs) designed exclusively for industrial applications, where failure is not an option. These boards prioritize long-term reliability (10+ year lifespans) and resistance to harsh conditions (extreme temperatures, vibration, corrosion) over consumer-grade priorities like cost-cutting or miniaturization. They power mission-critical equipment such as 24/7 factory control systems, high-load power distribution boards, and automotive/aerospace components, with every production step (material selection, circuit design, testing) tailored to withstand industrial stressors.

Industrial PCB Manufacturing Standards

1. IPC Series: Global Industrial PCB Standards

- Our industrial pcb manufacturing follows IPC-6012 Class 2 (general industrial use) and Class 3 (high-reliability for aerospace/medical). We also adhere to IPC-A-600 for visual inspections, eliminating plating or solder mask defects. These standards ensure global quality compliance.

2. Safety & Insulation Standards

- All boards meet UL 94 V-0 (fire resistance) and IEC 60664-1 (creepage/clearance for high-voltage use). UL 796 certification ensures North American safety compliance, protecting your equipment and team.

3. Industry-Specific Standards

- Our industrial pcb manufacturing aligns with industry norms: IATF 16949 (automotive), ISO 13485 (medical), and AS9100D (aerospace). This ensures seamless supply chain integration.

4. Quality Management Systems

- We hold ISO 9001 (quality), ISO 14001 (environmental), and ISO 45001 (workplace safety) certifications, ensuring consistent, responsible industrial PCB manufacturing.

Industrial PCB Manufacturing Process

1. Design Review and Design for Manufacturability Analysis: including our free Design for Manufacturability (DFM) analysis. Our engineers will identify issues such as insufficient clearances or incorrect solder mask placement within 48 hours, preventing costly rework later in the industrial PCB manufacturing process.

2. Substrate Preparation: We cut FR-4, PI, or metal core substrates to precise dimensions. Each substrate is cleaned to remove contaminants that could affect adhesion in subsequent steps.

3. Circuit Imaging: Photosensitive ink is applied and then exposed using CAD data to outline the circuit pattern. After development, excess copper is etched away with an accuracy of ±0.02mm.

4. Precision Drilling: High-speed CNC drilling machines drill through-holes (minimum 0.1mm) and blind/buried vias. Deburring is then performed to eliminate sharp edges that could cause short circuits.

5. Hole Metallization: Copper (0.8-1.2ÎŒm) is plated onto the hole walls to establish electrical connections between layers, a core requirement for multilayer industrial PCB manufacturing.

6. Lamination: For multilayer boards, we press the layers together with resin-impregnated prepreg at 170°C and 200psi pressure, ensuring a strong bond that can withstand various stresses in industrial environments.

7. Solder Mask and Silkscreen Application: A green or black solder mask is applied to protect the circuit board while exposing the solder pads. Component markings (font height â„0.8mm) are printed for easy assembly, simplifying the next stage after industrial PCB manufacturing.

8. Surface Finish Options: Choose from ENIG (Electroless Nickel Immersion Gold) for precision components, HASL (Hot Air Solder Leveling) for cost-effectiveness, or OSP (Organic Solderability Preservative) for environmentally friendly industrial PCB manufacturing.

9. Rigorous Quality Testing: AOI (Automated Optical Inspection) checks for surface defects, X-ray inspection checks BGA and stacked vias, and flying probe testing ensures electrical connectivity.

10. Final Inspection and Assembly Preparation: Each circuit board undergoes a final visual inspection to confirm compliance with industrial PCB manufacturing standards, and is then packaged to prevent damage during transportation to the assembly site.

Industrial PCB Assembly Process

1. Component Kitting & Verification: Gather all parts (resistors, ICs, connectors) per your BOM, then verify authenticity and specs.

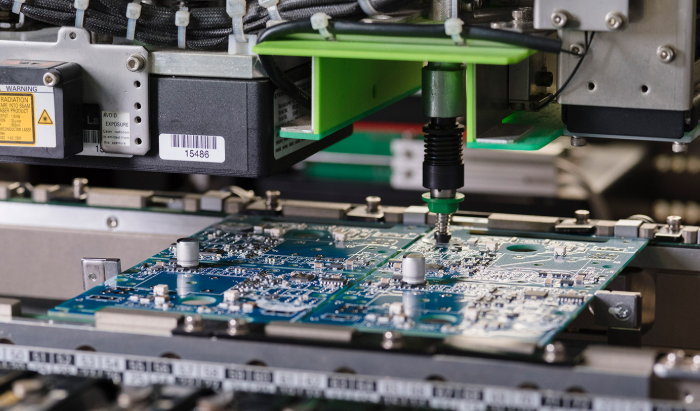

2. SMT Placement: High-speed machines place surface-mount components with ±0.01mm precision, handling both tiny chips and large power modules efficiently.â

3. Reflow Soldering: Boards pass through a temperature-controlled oven to melt solder paste, creating strong, reliable joints. We use lead-free solder for environmental compliance.â

4. DIP Insertion: Manual or automated insertion of through-hole components (e.g., transformers) for mechanical stability in industrial use.â

5. Wave Soldering: Through-hole components are soldered via a molten solder wave, ensuring uniform, durable connections for high-stress applications.â

6. Cleaning: Remove flux residues with eco-friendly cleaners to prevent corrosion, vital for boards in humid or chemical industrial environments.â

7. Conformal Coating (Optional): Apply protective coating for boards exposed to dust, moisture, or vibration, extending service life.â

8. Functional Testing: Test boards under real industrial conditions (voltage, temperature, load) to confirm they meet your performance requirements.â

9. Defect Inspection & Repair: AOI and manual checks identify soldering issues (cold joints, bridging), with immediate repairs to ensure quality.â

10. Packaging: Anti-static packaging protects finished boards during shipping, keeping them ready for your production line.

Why Choose EBest Circuit (Best Technology) for Industrial PCB Manufacturer?

10 Reasons why choose EBest Circuit (Best Technology) for industrial PCB manufacturer:

- Direct Factory Pricing for Industrial PCB Manufacturing: We eliminate intermediaries, offering prices 15-20% lower than distributors while guaranteeing the exceptional quality required for your industrial PCB manufacturing projects.

- 19 Years of Industrial PCB Manufacturing Experience: Our team possesses extensive expertise in all aspects of industrial PCB manufacturing, enabling us to quickly resolve complex challenges â we have served over 5000 customers in the PCB manufacturing industry.

- Fast and Reliable Industrial PCB Manufacturing Delivery: Standard industrial PCB orders (1-12 layers) ship in 7-10 days; prototypes are completed within 24 hours, and small batch orders are delivered in 3-5 days â ensuring your project stays on schedule.

- Free and Comprehensive Industrial PCB Manufacturing Design for Manufacturability (DFM) Service: Our senior engineers will review your design for manufacturability, reducing rework rates by 80%, saving you time and costs.

- One-Stop Industrial PCB Manufacturing and Assembly Service: We offer a one-stop service from design support to industrial PCB manufacturing, assembly, testing, and coating â eliminating the hassle of managing multiple suppliers.

- Rigorous Industrial PCB Manufacturing Quality Control: 7 inspection stages (from raw materials to final testing), utilizing AOI, X-ray, and flying probe testing, ensure a first-pass yield rate of up to 99.8% for your industrial PCB orders.

- High-Reliability Industrial PCB Manufacturing Materials: We only use certified substrates (Shengyi S1000-2V, Isola FR408) and components from authorized distributors â crucial for ensuring the durability of your industrial PCBs.

- Custom Industrial PCB Manufacturing Capabilities: We support 1-32 layer boards, metal core boards, rigid-flex boards, and special surface treatments (ENIG, immersion silver) to meet your unique industrial PCB manufacturing needs.

- Dedicated Industrial PCB Manufacturing Account Manager: You will receive one-on-one English or Chinese support with a response time of no more than 2 hours â ensuring smooth communication throughout your industrial PCB manufacturing project.

- Comprehensive Industrial PCB Manufacturing Regulatory Compliance: Our industrial PCB manufacturing complies with IPC, UL, ISO, and IATF 1649 standards â ensuring your boards pass industry audits and integrate seamlessly.

Our Quality Standards and Certifications

- ISO9001:2015

- ISO13485:2016

- REACH

- RoHS

- IATF16949

Case Studies of High-Reliability Industrial Robot Control PCB

Project Requirements

A leading industrial automation client required a PCB for their next-gen robotic arm control system operating in harsh factory environments. Specs included:

- Thermal Stability: -40°C to 125°C continuous operation with <5% signal drift

- Vibration Resistance: IEC 60068-2-64 compliant (10-500Hz, 5G RMS)

- Signal Integrity: 10GHz bandwidth with â€1% insertion loss variation

- Reliability: 1,000-hour DHHT (Damp Heat High Temp) test pass rate â„99.8%

- Compliance: IPC-6012 Class 3, RoHS/REACH certified

Our Solution:

Material & Layer Design:

- Selected Panasonic M6 high-Tg (170°C) substrate with hybrid copper-invar-copper (CIC) core for thermal expansion matching.

- Implemented 12-layer stackup with blind/buried vias to reduce signal path length by 30%.

- Embedded 0.3mm microvia arrays for high-density interconnect (HDI) in motor control section.

Signal Integrity Optimization

- Designed impedance-controlled traces (50±2Ω for digital, 100±3Ω for analog) with 3D EM simulation validation.

- Applied plasma-enhanced ALD (Atomic Layer Deposition) coating on critical lines to reduce surface roughness to <0.1”m.

- Integrated EMI shielding via embedded ground planes and stitching vias, achieving 25dB cross-talk reduction.

Manufacturing Process Enhancements

- Utilized laser direct imaging (LDI) for 15”m line/space resolution.

- Implemented vacuum-assisted thermal cycling during lamination to minimize warpage (<0.2%).

- Conducted 100% AOI + flying probe testing with custom-built 20GHz test fixtures.

Output Results

- Thermal Management: CIC core enabled 40% better thermal conductivity vs. standard FR4

- Durability: Passed 1,000-cycle thermal shock (-55°C to 150°C) with zero delamination

- Signal Performance: 3D EM modeling reduced crosstalk by 18dB at 5GHz, ensuring error-free 10Gbps data transmission

- Quality Control: Real-time SPC (Statistical Process Control) during lamination reduced defect density by 60%

- Cost Efficiency: HDI design reduced board size by 20%, saving $1.2M/year in material costs for the client

How to Get Started with Our Industrial PCB Manufacturing Services?

1. Initial Consultation & Requirement Communication

- Contact Us: Reach out via website, email, or phone to discuss project background, application scenarios (e.g., industrial control, medical devices), and core requirements (e.g., layer count, dimensions, special process needs).

- Requirement Confirmation: Engineers provide tailored solutions including material selection advice, cost estimation, and lead time planning.

2. Design File Submission & Review

- Submit Design Files: Provide complete engineering files such as Gerber files, BOM lists, and PCB design drawings (compatible with Altium, Eagle, PADS, etc.).

- Design Review: Technical team performs Design for Manufacturability (DFM) analysis to check layout rationality, impedance matching, pad design, etc., ensuring no production risks.

3. Material Selection & Specification Finalization

- Substrate Selection: Choose base materials based on performance needs (e.g., FR4, high-frequency materials like Rogers, metal-core substrates).

- Process Confirmation: Define key parameters including surface finish (HASL, ENIG, OSP), copper thickness, hole tolerance, impedance control, etc.

- Sample Validation: Prototype small batches to verify design feasibility, optimize, and proceed to mass production.

4. Transparent Production Process

- Process Transparency: From cutting, drilling, plating to screen printing and testing, automated equipment + manual quality checks ensure progress feedback at critical steps.

- Environmental Standards: Compliant with international regulations like RoHS and REACH for eco-friendly manufacturing.

5. Rigorous Quality Control

- Multi-Stage Inspection: AOI optical inspection, flying probe testing, X-ray solder joint checks, impedance testing, and aging tests ensure each batch meets IPC standards.

- Traceability: Each PCB is assigned a unique code with full production data archived for traceability.

6. Delivery & Logistics Assurance

- Protective Packaging: Anti-static packaging + vacuum sealing tailored for sea, air, or land transport needs.

- Logistics Tracking: Real-time tracking information ensures on-time delivery to specified addresses.

7. After-Sales Support & Technical Response

- Technical Consultation: Post-production support includes technical documentation, test reports, and installation guidance.

- Issue Resolution: 24/7 after-sales response to address quality concerns or technical queries promptly, ensuring uninterrupted production for clients.

Welcome to contact us if you have any request for industrial PCB manufacturing: sales@bestpcbs.com.