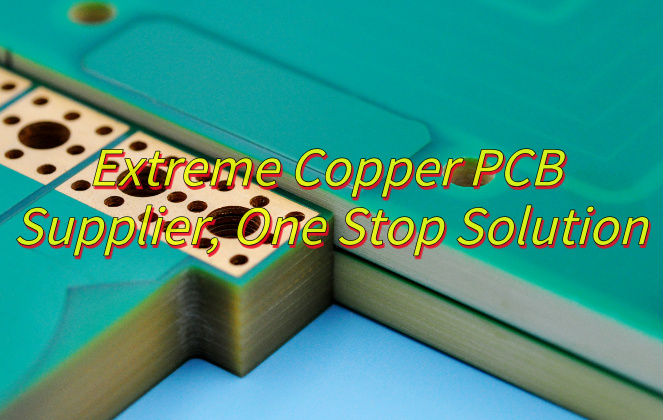

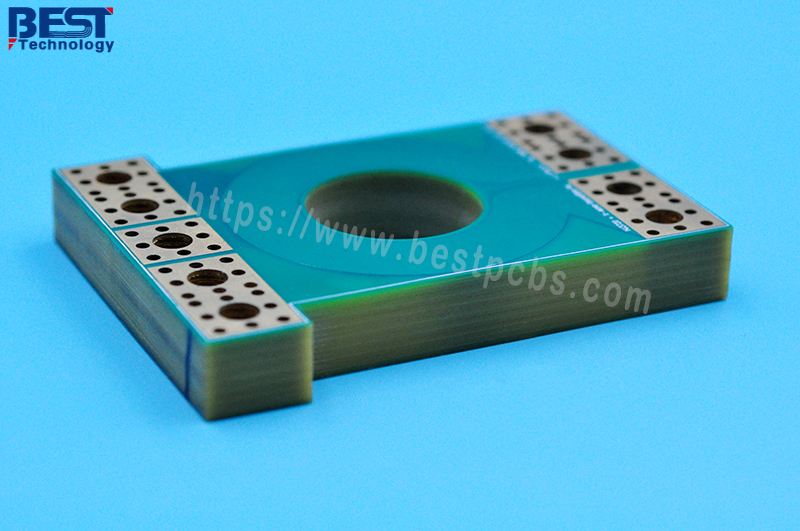

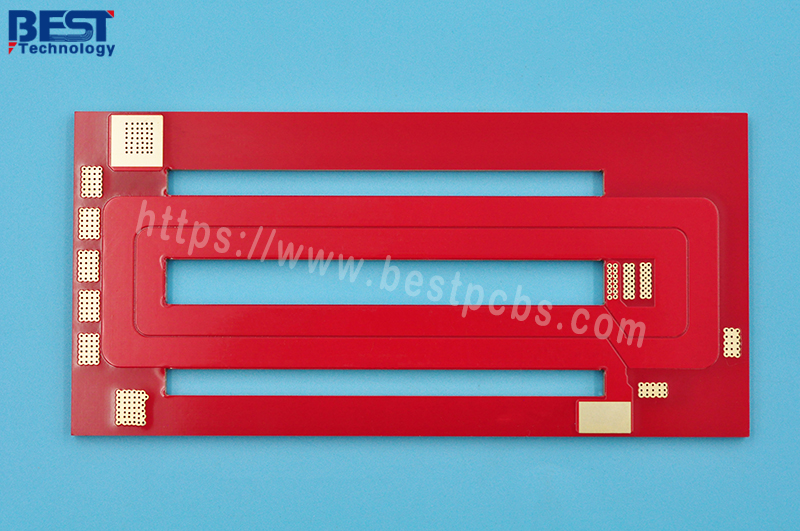

Heavy copper PCB design refers to creating printed circuit boards with much thicker copper layers than standard boards. While a typical PCB uses 1 oz copper (about 35¬Ķm), heavy copper PCBs range from 2 oz to 20 oz per square foot, sometimes even higher for extreme power needs.

Thick copper layers improve current handling, enhance mechanical strength, and allow for compact, high-power layouts without compromising reliability.

What is heavy copper PCB?

Heavy copper PCB uses copper conductors that are much thicker than standard PCBs. While standard boards use 1 oz copper (about 35¬Ķm), heavy copper boards range from 2 oz to 20 oz per square foot. Some extreme designs even go beyond that, which we call extreme copper PCB.

So, why so thick? Because thicker copper carries more current without overheating. It also improves mechanical strength, making the board more robust for harsh environments.

In short, heavy copper PCBs are not ordinary. They are designed for power electronics, automotive, defense, and industrial equipment that demand strength and stability.

Why use thick copper PCB?

Power systems produce heat. A lot of it. If your PCB cannot handle high current, failure is just a matter of time. That’s why thick copper PCBs are vital.

Here’s why industries love them:

- Superior current capacity: Thick copper allows higher amperage without damaging traces.

- Better heat dissipation: No more overheating issues in power circuits.

- Strong mechanical bonding: Ideal for connectors, heavy components, and thermal sinks.

- Design flexibility: Perfect for high-density interconnects and power distribution layers.

When reliability is non-negotiable, heavy copper PCB design is the answer.

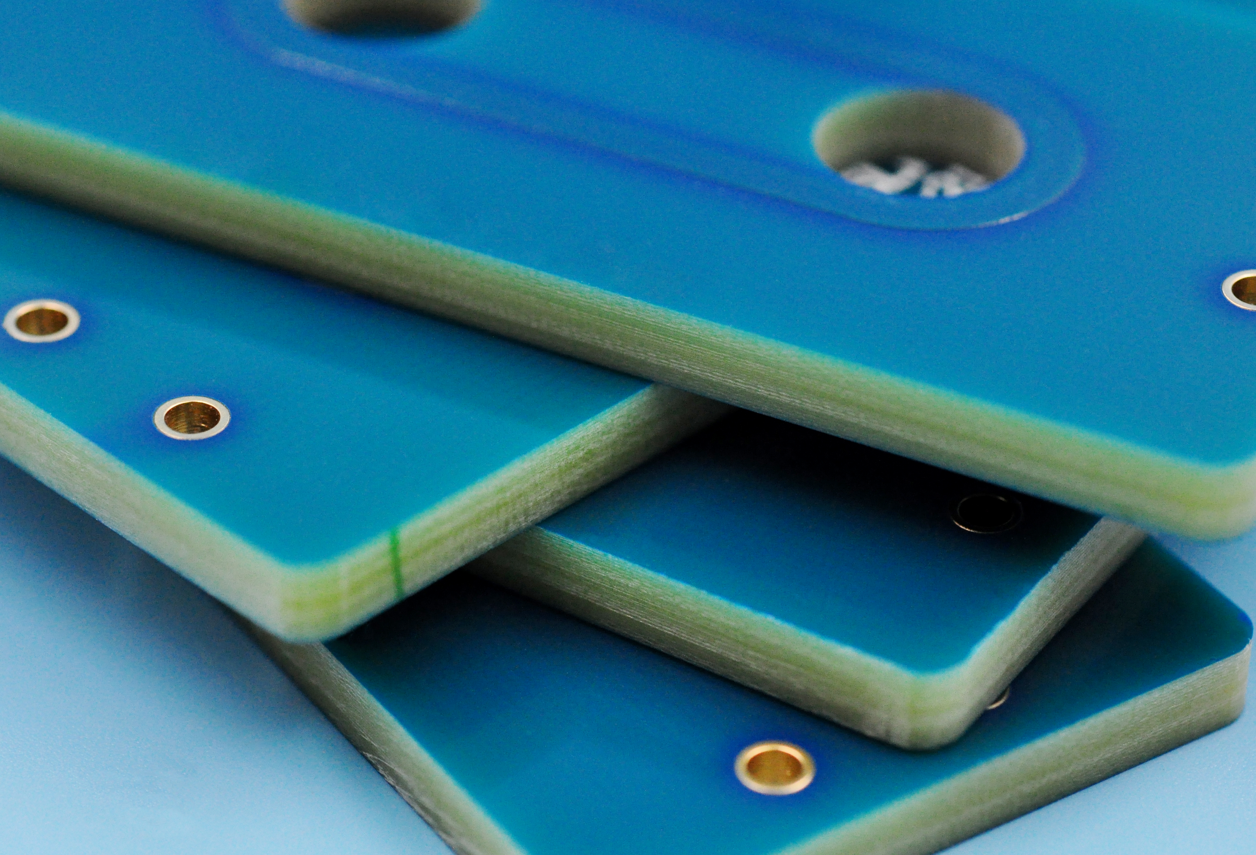

How thick is copper in a heavy copper PCB?

Thickness matters. A standard PCB has 1 oz copper (35¬Ķm). For heavy copper PCBs, the thickness ranges from:

- 2 oz (70¬Ķm): Entry-level heavy copper

- 3 oz to 6 oz (105¬Ķm to 210¬Ķm): Common for power electronics

- 8 oz to 20 oz (280¬Ķm to 700¬Ķm): Extreme copper PCB for very high power

The choice depends on current requirements, thermal performance, and mechanical strength. If your design demands high current flow, you need more copper.

What are the common problems in heavy copper PCB design?

Designing a heavy copper PCB is not as simple as adding more copper. It brings challenges:

- Etching Issues: Thick copper needs deeper etching, which requires advanced technology.

- Uneven Trace Widths: Incorrect design may lead to imbalance.

- Plating Difficulties: High copper density affects via plating and reliability.

- High Cost: More copper equals higher material and manufacturing cost.

With a professional heavy copper PCB manufacturer like BEST Technology, these challenges are easily solved. Our team uses controlled etching and advanced plating to ensure accuracy and quality.

How much does heavy copper price affect cost?

The price of heavy copper PCBs depends on:

- Copper weight (2 oz, 4 oz, 6 oz, etc.)

- Board size and layer count

- Design complexity

- Quantity

Copper is not cheap. A 6 oz PCB will cost more than a 2 oz PCB due to more copper and processing time. If you want exact pricing, contact us at sales@bestpcbs.com. Our experts will provide a detailed quotation and free consultation.

What are the benefits of thick copper PCB?

The benefits are undeniable:

- High current carrying capacity: Perfect for power supplies and converters.

- Excellent heat dissipation: Reduces thermal stress on components.

- Stronger mechanical strength: Holds heavy connectors and components.

- Compact design: Combine power and control circuits on one board.

- Reliable in harsh environments: Ideal for automotive and military.

Simply put, heavy copper PCBs improve performance and extend the lifespan of your devices.

Why choose BEST Technology for heavy copper PCBs?

Because we deliver:

- Copper thickness from 2 oz to 20 oz with precision.

- Advanced etching technology for accurate trace widths.

- Superior plating process for reliable via connections.

- ISO9001:2015 certified manufacturing.

- Short lead time: Fast delivery for your projects.

Our heavy copper boards are used in power converters, inverters, automotive systems, and defense equipment worldwide.

BEST Technology Heavy Copper PCB Capabilities

| Specification Category | Details |

| Base material | FR4/Aluminum |

| Copper thickness | 4OZ ~ 10OZ |

| Extreme Heavy Copper | 20OZ ~ 200OZ |

| Outline | Routing, Punching, V-Cut |

| Soldermask | White/Black/Blue/Green/Red Oil |

| Surface finishing | Immersion Gold, HASL, OSP |

| Max Panel size | 580 √ó 480 mm (22.8″ √ó 18.9″) |

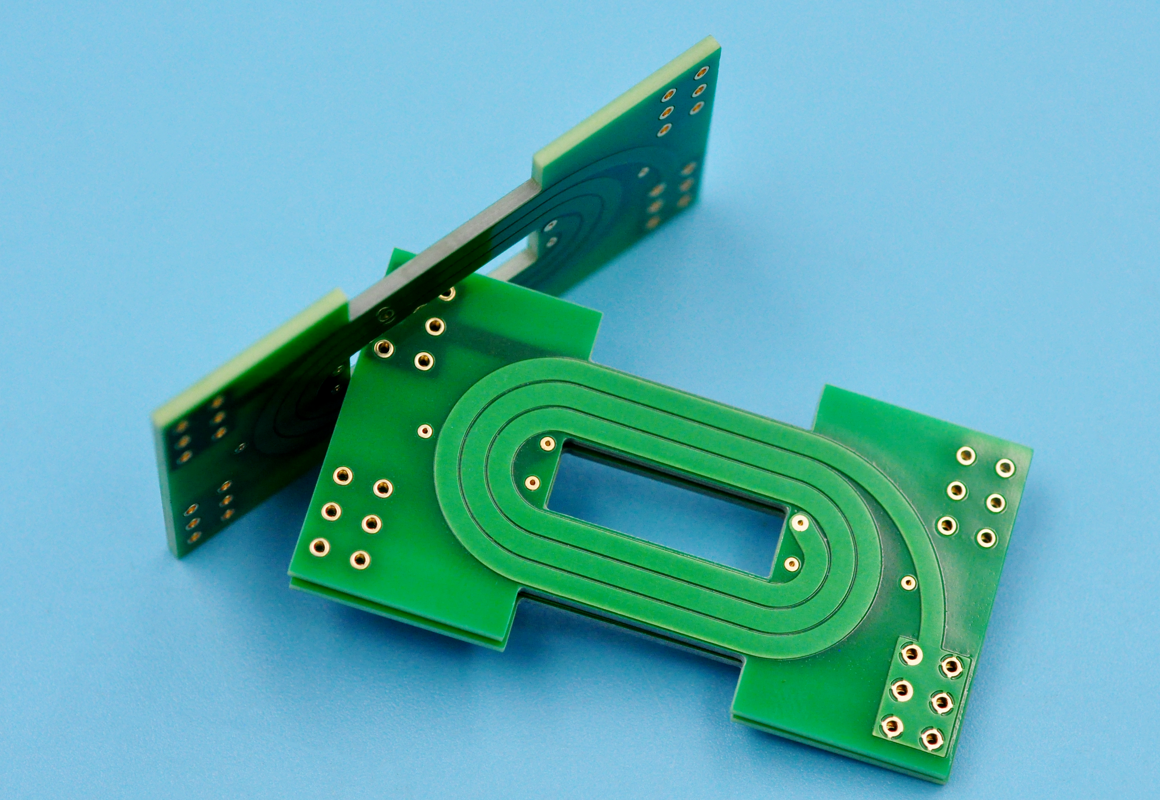

What are the applications of heavy copper PCBs?

These boards are everywhere in high-power industries:

- Power Supply Modules

- Automotive Electronics

- Military and Defense Systems

- Renewable Energy Systems (Solar, Wind)

- Industrial Control Equipment

- Telecom Base Stations

If your design needs high current handling and thermal stability, heavy copper is the only way.

Heavy copper PCB manufacturers ‚Äď BEST Technology

Not all manufacturers can handle thick copper PCBs. It requires specialized equipment, strict process control, and experience. That’s where BEST Technology stands out.

We’ve been manufacturing heavy copper PCBs since 2006. Our factory is equipped for multi-layer heavy copper boards, extreme copper designs, and custom prototypes. We handle everything from design support to mass production.

When you choose us, you get:

- Expert engineering support

- Competitive pricing

- On-time delivery

- High-quality boards for critical applications

Conclusion:

Heavy copper PCB design is a requirement for high-power electronics. They offer superior current capacity, heat dissipation, and mechanical strength.

If you’re looking for professional heavy copper PCB manufacturers, BEST Technology is your trusted partner. Contact us at sales@bestpcbs.com for a quote, technical support, or free consultation.