China PCBA manufacturer plays a pivotal role in the global electronics industry by bridging design concepts with reliable, mass-produced products. This article explains how China-based PCBA providers differ from non China PCBA manufacturers. It then shows practical selection criteria.

Do you face these challenges?

- Uncertain prototype delivery timelines, slowing down R&D iterations.

- High costs for small-batch production, making budget control difficult.

- Unstable BOM component supply, risking shortages or delayed lead times.

- Poor communication between design and manufacturing, causing repeated revisions and project delays.

- Difficulty ensuring product quality and consistency, increasing risk before mass production.

To resolve the difficulties presented, pls kindly consider the following methods.

- Dedicated prototype lines with transparent SLA (Service Level Agreement): Ensure fast prototype delivery and shorten R&D cycles.

- Flexible small-batch production and cost optimization: Efficient production scheduling reduces small-batch manufacturing costs.

- Strict BOM management and preferred supplier system: Identify critical component risks early and ensure timely supply.

- Engineering-led DFM support and cross-functional collaboration: Optimize manufacturability during design to minimize rework.

- Full-process quality control with MES traceability: Track all steps from SMT, through-hole assembly, testing to box-build integration to ensure consistency and reliability.

EBest Circuit (Best Technology) is a professional PCB manufacturer and SMT factory offering end-to-end PCB and PCBA solutions, from rapid PCB prototyping to turnkey assembly and box-build services. We specialize in rigid, flex, aluminum backed PCBs, alumina ceramic PCB, and rigid-flexible PCB boards, as well as PCB assembly, ensuring high-quality, reliable, and fully traceable production. Our core strengths include engineering-led DFM support, flexible production lines for prototypes and small batches, and strict process control to reduce rework and accelerate time-to-market. Contact us at sales@bestpcbs.com to request a quote or start a DFM review.

What are the features of a China PCBA manufacturer?

A mature China PCBA manufacturer bundles supply density, flexible capacity, engineering support, and traceability into one workflow.

- Dense component ecosystem. China has many component distributors, PCB substrate vendors, and testing equipment suppliers within easy reach. This reduces sourcing time. It reduces freight costs. For prototype runs, that proximity converts to faster turnarounds.

- Flexible production scale. Domestic factories can shift between small batches and volume runs. That helps teams running iterative designs. A single supplier can handle NPI and scale-up without repeated re-qualifications.

- Integrated NPI and DFM support. Experienced manufacturers provide hands-on design-for-manufacturability (DFM) feedback early. They catch layout issues, BOM risks, and testability gaps before boards are fabricated.

- Comprehensive testing and box build. Modern sites include AOI, X-ray, ICT, functional test stations and box build lines. The integration of assembly and final integration reduces handoffs and improves first-pass yield.

- Traceability and process control. Good suppliers run MES to record lot history, operator steps and test results. That data matters when defects appear in the field. Traceability helps with root cause analysis.

- Cost structure and speed. Lower direct labor cost and a mature supplier base allow competitive pricing. Faster component procurement shortens lead times for prototypes and standard builds.

In summary, a top-tier China PCBA manufacturer combines supply chain density, flexible production, engineering expertise, and strict process control to deliver fast, reliable, and cost-effective solutions from prototype to volume production.

Top 10 China PCBA prototyping manufacturers

PCBA prototyping plays a critical role in product development, bridging design concepts with functional verification and small-batch production. Choosing the right manufacturer is essential for fast iterations, cost control, and ensuring product reliability.

1. EBest Circuit (Best Technology)

Founded in 2006, EBest Circuit (Best Technology) provides a one-stop service from PCB design and materials procurement to full PCBA assembly. We serve high-end industries including 5G, automotive, and medical. Our facilities include SMT, X-ray, AOI, and functional test systems. We offer decent quality prototyping, fast delivery and accommodate small-batch orders.

2. PCBWay

A global leader in PCBA prototyping, PCBWay features highly automated production lines, multi-layer board capabilities, and supports fast prototyping.

3. ALLPCB

ALLPCB leverages its online platform for instant quoting, order placement, and rapid delivery. The company provides full-process quality inspection, including AOI, ICT, and functional testing. It enjoys high reputation in the global electronics maker community.

4. PCBGOGO

Specializing in small-to-medium batch PCBA, PCBGOGO offers full-chain services from component procurement to assembly. They can handle multi-layer, flexible, and high-frequency boards, enabling rapid prototype iterations.

5. Shenzhen Grande Electronic

Certified with ISO9001 and TS16949, Shenzhen Grande Electronic delivers fast prototypes, low-volume runs, and customized PCBA. They operate eight high-speed SMT lines, supporting high-density and high-reliability requirements.

6. Kunshan Quanhua Electronics

Known for its ‚Äúone-stop‚ÄĚ PCBA services, Quanhua Electronics covers component procurement, PCB fabrication, and functional testing. They excel at flexible switching between large and small batch production.

7. Seeed Fusion (Seeed Studio)

Integrating the open-source hardware ecosystem, Seeed Fusion provides rapid prototyping, flexible PCB production, and small-batch assembly. They own proprietary SMT equipment and comprehensive testing workflows, favored by makers and innovation-driven companies.

8. Jinghua Electronics

Jinghua Electronics supports multi-layer and rigid-flex PCB production, rapid prototyping, and full-process quality testing. They cater to small-batch customization and fast delivery requirements.

9. Shenzhen Jinghua

A notable candidate for ISO-certified, flexible, and fully tested PCBA prototypes with cross-border logistics experience, suitable for international clients seeking small-to-medium runs.

10. Other Worthy Candidates

Other noteworthy providers include Kunshan Quanhua and Shenzhen Grande. Key advantages include ISO certifications, flexible production, comprehensive testing, logistics expertise, and strong engineering support. These suppliers can be shortlisted for specific project needs.

To conclude, by comparing the core capabilities of these ten manufacturers, you can evaluate each supplier based on a structured checklist: delivery time, engineering support, testing capability, certifications, supply chain transparency, low-volume cost, system integration, IP security, logistics experience, and customer service. This method allows you to select the most suitable partner for prototyping projects, ensuring quality, cost efficiency, and timely delivery‚ÄĒultimately improving the success rate of subsequent mass production.

What are the full China PCBA contract manufacturing process?

The contract manufacturing workflow is a sequence of controlled steps. Each step has clear deliverables and KPIs.

- Design review and DFM ‚ÄĒ deliverable: DFM report and suggested BOM alternatives.

- Validate footprints, tolerances, and test points.

- Flag long-lead or obsolete parts.

- BOM management and sourcing ‚ÄĒ deliverable: approved BOM and sourcing plan.

- Cross-check each line item against multiple suppliers.

- Use authorized distributors to reduce counterfeit risk.

- PCB fabrication ‚ÄĒ deliverable: bare PCBs with fabrication report.

- Specify stack-up, controlled impedance, and material selection.

- Confirm thermal and mechanical constraints for assembly.

- SMT and component placement ‚ÄĒ deliverable: assembled SMT boards.

- Stencil design and process window setup are critical.

- AOI during line stops defects early.

- Thru-hole and mixed assembly ‚ÄĒ deliverable: assembled boards with through-hole components soldered.

- Inspection and test ‚ÄĒ deliverable: test reports and C of C.

- Run AOI, X-ray for BGAs, ICT for connectivity, and functional test per spec.

- Record data to MES and attach to lot history.

- Conformal coating / potting ‚ÄĒ deliverable: environmental protection per spec.

- Box build and final validation ‚ÄĒ deliverable: fully integrated product and user-acceptance test (UAT) report.

- Include wiring harnesses, mechanical frames, firmware programming and final burn-in.

- Packing, labeling and logistics ‚ÄĒ deliverable: export-ready shipment with traceability labels and documentation.

KPIs to track (examples): first-pass yield, defect per million (DPM), on-time delivery, NPI time-to-volume, and test coverage rate. A serious supplier reports these metrics and acts on trends.

Core competencies: China PCB assembly manufacturers vs. non China PCBA manufacturers

The practical difference lies in supply chain proximity, scale economics, and flexibility during NPI. Below is a concise comparison across eight axes.

- Supply chain density

China: dense local vendors for capacitors, resistors, ICs, and substrates. Delivery windows tighten. Non China: longer import lead times in many regions. - Cost base

China: lower direct labor and mature subcontracting.

Non China: higher labor rates and often higher overhead per unit. - NPI agility

China: many factories offer quick-turn prototypes and small runs.

Non China: often optimized for stable volume production; prototyping may be slower. - Testing and equipment

Both can host modern equipment. But China factories often scale equipment across many lines, lowering per-unit test costs. - Regulatory and certification

Non China manufacturers may have local compliance advantages.

China suppliers often hold the major international certifications needed for automotive, aerospace and medical. - IP and security

Non China suppliers closer to end customers can ease IP concerns.

China suppliers mitigate risk via NDAs, restricted access and contracted security workflows. - Logistics and lead time risk

China: fast regional sourcing but dependent on sea/air freight.

Non China: shorter inland transport for some customers, but may face longer component lead times. - Communication

Non China: time-zone alignment can ease live collaboration.

China: nominated PMs and structured reports solve most collaboration gaps.

In a nutshell, choose by priority. If fast prototyping, cost flexibility, and supplier depth matter, China suppliers often lead. If proximity, regulatory interpretation or single-source risk reduction matter more, a non China manufacturer may fit better. For many global teams, a hybrid model ‚ÄĒ design and prototyping in China, final assembly near end markets ‚ÄĒ balances risk and cost.

What are the core considerations when selecting a China PCB assembly manufacturer?

Use an evidence-based checklist to avoid wishful thinking. Below are the essential checks, in priority order.

- Certifications and audit records: Ask for audit summaries, process maps and corrective action histories. Certificates alone are not proof ‚ÄĒ audit results are.

- Traceability and MES: Probe whether the plant links board serials to component lot IDs and test outcomes. Traceability shortens root cause time.

- Engineering and DFM depth: Request a recent DFM report and examples of design changes that prevented failures.

- Test strategy and coverage: Compare AOI/X-ray/ICT/functional test scope to your risk profile. Ask for test reports from similar products.

- Supply chain resilience: Check dual-source options, lead times for critical components, and local stocking policies.

- Quality metrics: Obtain FPY, DPM and NCR trends for the last 12 months. Look for stable or improving trends.

- Small-batch policy and pricing: Ensure clear pricing for prototypes and small volumes. Hidden setup fees are common; demand transparency.

- Box-build competencies: Verify capability for harnesses, sub-assemblies, firmware programming and final UAT procedures.

- Communication and PM structure: Ask who your point-of-contact is, how often you will receive updates, and the escalation path for issues.

Use supplier scorecards. Re-run scoring every six months. That maintains continuous improvement.

Why choose EBest Circuit (Best Technology) as your reliable China PCBA manufacturer?

EBest Circuit (Best Technology) combines engineering-first service, traceable processes, and flexible box-build lines to solve common customer pain points.

Customer pain points and EBest Circuit (Best Technology) responses:

- Pain: Unclear lead times and late prototypes.

Response: Dedicated prototype lines and a transparent prototyping SLA shorten turnaround and set clear expectations. - Pain: Hidden cost from component shortages or rework.

Response: BOM risk alerts and preferred vendor lists help avoid last-minute premium buys. MES-based lot tracking reduces rework incidence. - Pain: Poor NPI support and repeated design fixes.

Response: Hands-on DFM workshops with cross-functional engineers reduce revisions and speed approvals.

Competitive edges:

- Multi-standard certifications that support automotive, medical and aerospace needs.

- MES traceability across PCB fabrication, placement, testing and box build.

- Integrated engineering teams for DFM, firmware support and in-line test development.

- Flexible lines for prototypes, small batches and volume manufacturing under one roof.

EBest Circuit (Best Technology) is a China PCBA manufacturer specializing in rapid PCB prototyping, turnkey assembly and box build services. We handle rigid, flex and mixed-technology boards with strict process control and full traceability. Our engineering team works with customers to reduce rework and shorten time-to-market. Contact us at sales@bestpcbs.com.

Case of PCBA manufacturing at EBest Circuit (Best Technology)

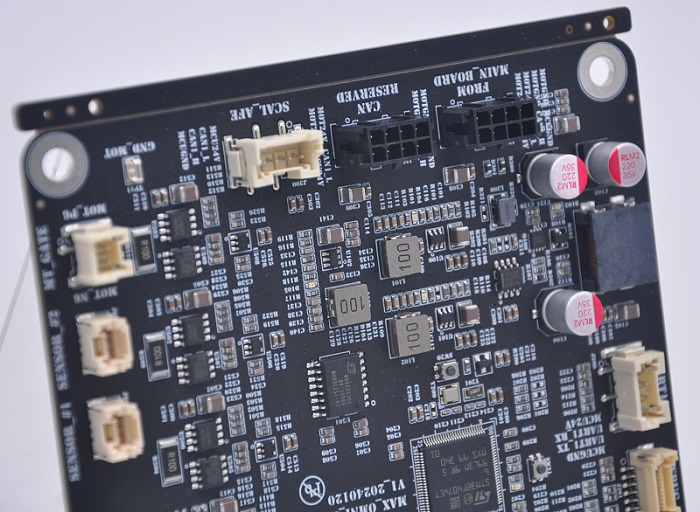

This case study highlights EBest Circuit (Best Technology)’s role as a key PCBA manufacturing partner for a leading innovator in the food service automation industry. We manufacture the critical main controller PCBA for our client’s product‚ÄĒan advanced intelligent cooking robot.‚Äč

Our client aims to solve core industry challenges like food consistency, labor costs, and operational efficiency through automation. Their product is designed for demanding commercial kitchen environments characterized by high temperatures, humidity, and continuous operation. This placed stringent requirements on the core control PCBA:

- ‚ÄčHigh-Density Integration & Power Management:‚Äč‚Äč The main controller board needed to integrate complex motor control circuits (for precise stirring), high-power induction heating systems, and multiple sensor interfaces, ensuring perfect synchronization of all automated actions.

- ‚ÄčSuperior Reliability & Thermal Management:‚Äč‚Äč The PCBA required robust components and a layout designed for effective heat dissipation to withstand long-term exposure to high ambient temperatures, ensuring device longevity and minimizing failure rates.

- ‚ÄčAbsolute Manufacturing Consistency:‚Äč‚Äč Every single PCBA had to be built to identical industrial-grade quality standards to guarantee uniform performance across thousands of units deployed globally, which is fundamental to the client’s promise of consistent output.

As the designated SMT partner, we delivered engineering-driven manufacturing focused on robust process design for this complex controller board.

- ‚ÄčDFM & Process Optimization‚Äč: Our engineering team optimized component placement and thermal management strategies during the DFM phase, ensuring reliability in high-temperature operating conditions.

- ‚ÄčPrecision SMT & Mixed Technology‚Äč: Advanced SMT equipment enabled accurate placement of fine-pitch components (0.4mm BGA, 0201), while maintaining reliable soldering for through-hole power connectors.

- ‚ÄčFull-Process Quality Assurance‚Äč: Implementing SPI, AOI, in-circuit testing, and functional validation, supported by complete MES traceability for data-driven quality control.

In closing, EBest Circuit (Best Technology) ensured the AI cooking robot’s main controller PCBA met strict reliability, thermal, and performance standards through optimized DFM, precision SMT, and full-process quality control.

To wrap up, a good China PCBA manufacturer brings more than low unit costs. You gain speed, engineering leverage and integrated workflows that lower program risk.

If you need a partner that pairs fast prototypes with robust box-build services, EBest Circuit (Best Technology) aims to fill that role. We focus on tangible fixes for your pain points: predictable lead times, excellent quality, and hands-on engineering. Welcome to reach out to sales@bestpcbs.com to start a DFM review or request a prototype quote.