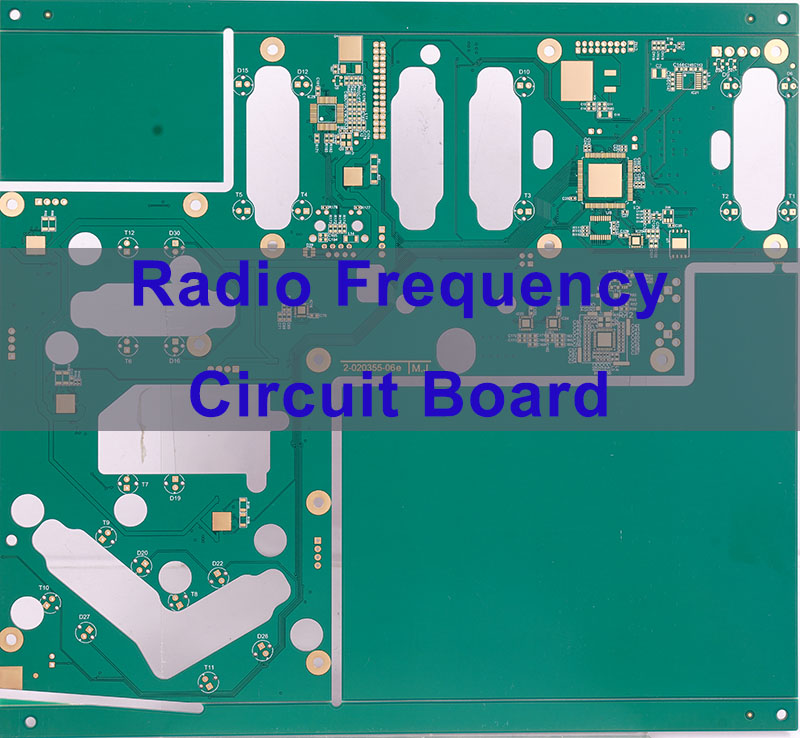

Radio frequency circuit board is a specialized printed circuit board designed to carry, process, and control high-frequency electromagnetic signals typically ranging from 100 MHz to 110 GHz. It forms the critical backbone of modern wireless and high-speed communication systems, enabling devices to transmit and receive signals with high precision and minimal loss across RF, microwave, and millimeter-wave bands.

Engineers and procurement managers often face significant hurdles when sourcing and developing high-frequency boards. Are you struggling to balance performance, cost, and speed in your RF development cycle?

- Design Complexity: Small routing errors cause major high-frequency issues.

- Signal Integrity: GHz signals need strict impedance and low-loss materials.

- Manufacturing Gaps: Many factories lack true microwave-grade capability.

- High Material Cost: Premium RF laminates increase BOM pressure.

- Slow Cycles: Traditional prototype loops delay launches.

How a Specialized RF PCB Provider Delivers Solutions:

- RF Design Support: Expert guidance for cleaner, correct layouts.

- Better Materials: Rogers, Taconic, and proven RF options on hand.

- Impedance Control: Tight tolerances ensure consistent RF performance.

- Cost-Smart Selection: Materials matched to performance needs.

- Quick-Turn PCBA: Fast PCB + assembly to speed development.

This comprehensive guide will explore the design, materials, manufacturing leaders, and best practices that define high-performance RF PCB‚Äč technology, with a focus on achieving tailored solutions and rapid production. EBest Circuit (Best Technology) is a professional RF PCB manufacturer specializing in high-performance, low-loss boards for RF, microwave, and millimeter-wave applications. We hold ISO 13485 medical certification and AS9100 aerospace certification, ensuring compliance with strict reliability and safety requirements.

Our PCB fabrication and SMT assembly lines are supported by a full MES system, providing complete production traceability and stable process control. Combined with expert RF design support and quick-turn PCBA services, we help customers achieve both high-frequency performance and fast development cycles. For your next RF board requirement, feel free to contact us at sales@bestpcbs.com.

What Is a Radio Frequency Circuit Board and How Does It Enable High-Frequency Performance?

A Radio Frequency Circuit Board (RF PCB) is a specialized printed circuit board engineered to transmit, route, and manage high-frequency electromagnetic signals across the RF, microwave, and millimeter-wave spectrum, typically spanning 100 MHz to 110 GHz. At these frequencies, PCB materials, stack-ups, and routing rules must be optimized to preserve signal integrity, minimize loss, and maintain strict impedance control.

Core Enablers of High-Frequency Performance:

- Controlled Impedance:‚Äč Precise management of trace geometry and dielectric properties to maintain a consistent characteristic impedance (e.g., 50ő©), preventing signal reflections.

- Low-Loss Materials:‚Äč Use of specialized RF PCB materials‚Äč with low dielectric loss (Df) and stable dielectric constant (Dk) across frequency and temperature, crucial for microwave PCBs.

- Minimized Signal Path:‚Äč Careful RF PCB routing‚Äč to keep high-frequency traces short and direct, reducing attenuation and radiation.

- Grounding & Shielding:‚Äč Extensive use of ground planes and shielding techniques to contain electromagnetic fields and reduce crosstalk between the RF circuit‚Äč and other board sections.

- Quality of Conductors:‚Äč Use of high-surface-quality copper with minimal roughness to reduce conductor loss at high frequencies.

In summary, an RF board‚Äč is a carefully engineered system where every element‚ÄĒfrom laminate to layout‚ÄĒis optimized to guide high-frequency signals efficiently and predictably, forming the foundation of any reliable wireless device.

Why Do China Radio Frequency Circuit Board Suppliers Lead in Cost-Effective RF Manufacturing?

China-based suppliers have become dominant in the global RF PCB‚Äč market by creating a powerful ecosystem that balances advanced technical capability with significant cost advantages. This leadership stems from a combination of scale, supply chain integration, and evolving expertise.

Key Drivers of Cost-Effectiveness:

| Driver | Explanation |

|---|---|

| Integrated Supply Chain | Local sourcing of laminates, copper, and chemicals cuts logistics cost and shortens lead time. |

| Economies of Scale | High-volume RF production lowers per-unit pricing. |

| Skilled Engineering Talent | Mature RF design and manufacturing workforce ensures stable quality. |

| Advanced Manufacturing Equipment | LDI, AOI, and impedance-control systems support complex RF builds. |

| Government & Industry Support | Policies encourage investment, R&D, and continuous capability upgrades. |

While cost is a primary factor, leading China radio frequency circuit board‚Äč suppliers have moved beyond being just low-cost providers. They now compete on their ability to reliably produce complex, multi-layer radio frequency printed circuit boards‚Äč with strict impedance control, making them a go-to for both cost-sensitive and performance-oriented projects.

How Do Radio Frequency Circuit Board Manufacturers Ensure Stability at High Frequencies?

Stability at high frequencies is non-negotiable for RF circuits. It ensures that a device performs consistently under varying operating conditions like temperature shifts, frequency changes, and over time. RF PCB manufacturers‚Äč achieve this through meticulous control over materials, processes, and design for manufacturability (DFM).

Manufacturers ensure stability by focusing on several critical fronts:

- Material Consistency:‚Äč Using laminates with a stable Dielectric Constant (Dk) across temperature and frequency. Variations in Dk directly change impedance and signal velocity. Premium RF PCB materials‚Äč from Rogers or Taconic offer superior stability over standard FR-4.

- Precision Fabrication:‚Äč Maintaining extremely tight tolerances on trace width, spacing, and dielectric thickness. A small deviation can alter the characteristic impedance, causing reflections and signal loss. This is paramount for microwave PCB‚Äč performance.

- Low-Loss Processing:‚Äč Employing processes that minimize surface roughness of copper traces. At high frequencies, signal travel is confined to the conductor’s surface (skin effect). Rough surfaces increase the effective path length and resistance, leading to higher insertion loss.

- Robust Lamination:‚Äč Ensuring perfect bonding between layers without voids or delamination. Imperfections can create localized changes in the dielectric environment, harming performance.

- Environmental Protection:‚Äč Applying appropriate surface finishes (such as ENIG or immersion silver) that provide a solderable, flat surface and protect the copper from oxidation, which can degrade performance over time.

Through this multi-pronged approach, a reliable RF PCB manufacturer‚Äč delivers boards that not only meet specifications on the test bench but also maintain their radio frequency circuit‚Äč performance in the real world, ensuring the long-term reliability of the end product.

Top 10 Radio Frequency Circuit Board Manufacturers

Selecting the right manufacturer is crucial for the success of your RF PCB projects. The best partners combine technical expertise in high-frequency materials and processes with reliable execution. Here is a brief introduction to ten notable manufacturers in this space, including our own capabilities at EBest Circuit (Best Technology).

- EBest Circuit (Best Technology):‚Äč A specialized provider focused on quick-turn, high-mix, and prototype to mid-volume production. We excel in offering tailored RF PCB design‚Äč support and rapid PCBA services, making us an ideal partner for fast-paced development cycles and specialized medical and IOT applications.

- W√ľrth Elektronik:‚Äč A global leader offering high-quality PCB substrates (like their WE-series laminates) and full PCB manufacturing services, known for strong technical support and material science expertise.

- Rogers Corporation:‚Äč Primarily a material innovator, Rogers also offers advanced PCB fabrication services through their facilities, providing unparalleled expertise in processing their own high-performance laminates for extreme microwave PCBs.

- TTM Technologies:‚Äč A major volume manufacturer with extensive capabilities in advanced technologies, including RF/microwave PCBs for aerospace, defense, and high-end communications infrastructure.

- Sierra Circuits:‚Äč Well-known in the North American market for their proto-to-production services and strong emphasis on RF PCB design‚Äč guidelines and educational resources, catering well to engineers.

- Eurocircuits:‚Äč A European-based manufacturer popular for prototyping and small-batch production, offering user-friendly platforms and consistent quality for various PCB types, including RF.

- PCBWay / JLCPCB:‚Äč These China-based giants dominate the online, low-cost, quick-turn PCB market. They offer basic RF material options (like Rogers) and are a cost-effective choice for prototypes and simple RF board‚Äč designs, with JLCPCB providing deeply integrated PCBA services.

- San Francisco Circuits:‚Äč Specializes in complex, high-tech PCBs with a strong focus on RF/microwave and HDI boards, offering comprehensive engineering and manufacturing services.

- Advanced Circuits (Now a Part of Sierra Circuits):‚Äč A well-established US-based manufacturer with a broad range of capabilities, including RF and microwave production, known for reliable service.

- NCAB Group:‚Äč A global PCB producer and supplier that focuses on high-quality, reliable PCB series production for industrial and telecom markets, with expertise in managing complex supply chains for RF PCBs.

What RF PCB Material Options Are Commonly Used for Advanced Microwave PCBs?

Material selection is the first and most critical decision in RF PCB design, especially as frequencies climb into the microwave range (> 1 GHz). The right RF PCB material‚Äč dictates the board’s electrical performance, thermal management, and mechanical reliability.

Common high-frequency laminate materials include:

| Material Type | Key Properties | Typical Applications |

|---|---|---|

| Rogers RO4000 Series | Low loss, stable Dk, cost-effective | Automotive radar, cellular RF |

| Rogers RT/duroid (PTFE) | Ultra-low loss, highly stable Dk | Aerospace, defense, satellite |

| Taconic TLY / RF Series | Very low loss, consistent RF performance | Power amps, filters, antennas |

| Isola FR408HR / I-Speed | Improved FR-4, moderate loss, affordable | High-speed digital + RF sections |

| Panasonic Megtron 6/7 | Extremely low loss, high-speed capable | Routers, servers, networking |

| Arlon AD Series | Ceramic-filled PTFE, strong thermal stability | High-power, high-frequency |

The choice involves balancing Dielectric Constant (Dk)‚Äč for size, Dissipation Factor (Df)‚Äč for loss, Thermal Coefficient of Dk‚Äč for stability, and cost. For advanced microwave PCBs, PTFE-based materials (Rogers, Taconic) are often mandatory, while ceramic-filled hydrocarbons (like the RO4000 series) offer an excellent balance for many radio frequency circuit board‚Äč applications below 20 GHz.

How Should Engineers Apply RF PCB Design Guidelines PDF Principles to Real Projects?

A comprehensive RF PCB design guidelines PDF‚Äč is an invaluable toolkit, but applying its principles to a real, constrained project requires strategic translation. The key is to prioritize guidelines based on your project’s specific frequency, power, and integration requirements.

Strategic Application of Guidelines:

- Impedance Control is Non-Negotiable:‚Äč Use the guide’s formulas or calculators to determine your trace geometry. Always collaborate with your RF PCB manufacturer‚Äč early to understand their process capabilities and adjust your design to their controlled impedance stack-up.

- Partition the Layout:‚Äč Strictly follow the guideline to separate RF, analog, and digital sections. Use solid ground planes as shields between sections. In a real radio station control board, this prevents digital noise from drowning out sensitive received signals.

- Optimize Component Placement & Routing:‚Äč Place critical RF circuit‚Äč components to minimize trace lengths. Route RF traces first, using curved bends (not 90¬į). Use the guideline’s suggested via fencing for shielding in dense boards.

- Grounding for Real Estates:‚Äč Implement a robust, low-impedance ground system. Use multiple vias to connect ground pads and pours to the ground plane, as per guidelines, to avoid ground loops and ensure stability.

- Leverage Simulation:‚Äč Before finalizing layout, use the design principles to set up and run electromagnetic (EM) simulations. This “virtual prototype” catches impedance discontinuities and coupling issues that static guidelines can’t predict.

In practice, engineers must treat the RF PCB design guidelines PDF‚Äč as a foundation, not a rigid script. Success comes from understanding the physics behind the rules(e.g., why a shorter return path minimizes inductance) and making informed trade-offs, all while maintaining clear communication with your fabricator to ensure the design is manufacturable.

How Do RF PCB Manufacturers Optimize RF PCB Routing for Low Loss and High Signal Integrity?

RF PCB routing‚Äč is an art form focused on preserving signal energy and integrity. Manufacturers, in collaboration with designers, optimize routing by enforcing a set of golden rules that minimize loss and prevent signal degradation.

Optimization Techniques for RF Traces:

- Shortest Path Possible:‚Äč Absolute trace length is minimized to reduce resistive and dielectric losses. This often dictates component placement.

- Controlled Impedance Consistency:‚Äč Trace width and spacing are maintained as calculated for target impedance (e.g., 50ő©) along the entire path, including at bends (which are curved or 45¬į).

- Minimized Discontinuities:‚Äč The use of vias on RF traces is avoided or strictly minimized, as each via introduces inductance and an impedance discontinuity. If necessary, via dimensions are carefully engineered.

- Adequate Isolation:‚Äč RF traces are spaced far apart (typically 3x the trace width or more) and shielded with ground planes or guard traces (via fences) to prevent crosstalk.

- Continuous Reference Plane:‚Äč RF traces are routed over an unbroken ground plane. Splits, gaps, or voids under the trace disrupt the return current path, increasing inductance and radiation.

By adhering to these principles, the RF PCB manufacturer‚Äč ensures the physical board implements the ideal electrical pathway envisioned in the schematic. This direct, clean, and controlled routing is what transforms a good RF PCB design‚Äč into a high-performance, reliable radio frequency circuit.

What Makes the Best Radio Frequency Circuit Board Suitable for RF PCB Projects?

The best radio frequency circuit board‚Äč is not defined by a single attribute but by its perfect alignment with the specific demands of the RF PCB project‚Äč it serves. It is a holistic product where design, materials, and manufacturing converge to meet electrical, mechanical, and economic goals.

Hallmarks of a Superior RF PCB:

- Application-Specific Design:‚Äč The layout is optimized for its primary function, whether it’s low-noise signal reception for an RFID board, high-power transmission for an amplifier, or wide-bandwidth operation for a radio station control board.

- Correct Material Selection:‚Äč It uses the most appropriate RF PCB material‚Äč that provides the necessary Dk, Df, and thermal performance without unnecessary cost over-specification.

- Manufacturing Precision:‚Äč It exhibits flawless fabrication with exacting trace control, perfect layer alignment, and reliable plated through-holes, resulting in predictable performance.

- Proven Reliability:‚Äč It performs consistently across the required temperature range, voltage, and operational lifespan, with robust solder joints and surface finish.

- Supply Chain Synergy:‚Äč It is produced by a capable RF PCB manufacturer‚Äč who can support the project from prototype through volume production, potentially offering integrated Quick PCBA‚Äč to accelerate development.

Ultimately, the best board is a tailored solution. It enables the RF circuit‚Äč to perform its intended function flawlessly, integrates seamlessly into the larger system, and is delivered by a partner that makes the procurement and assembly process efficient and predictable.

How Does RF PCB Design Impact Overall RF Board Reliability and System Performance?

RF PCB design‚Äč is the decisive factor that determines whether a collection of high-quality components functions as a reliable, high-performance system. It directly governs electrical performance, thermal management, and long-term durability of the entire RF board.

Design’s Critical Impact Areas:

- Signal Integrity & System Sensitivity:‚Äč A poor layout with impedance mismatches, long stubs, or poor grounding causes signal reflections and attenuation. This degrades the signal-to-noise ratio, reducing the effective range and sensitivity of a receiver or the output power of a transmitter.

- Thermal Management & Lifetime:‚Äč High-power RF circuits‚Äč generate heat. Inadequate thermal design‚ÄĒsuch as insufficient copper pours for heatsinking or poor via placement under components‚ÄĒleads to localized hot spots. This stresses components, accelerates aging (reducing MTBF), and can cause material degradation or failure.

- Electromagnetic Compatibility (EMC):‚Äč A well-designed RF board‚Äč contains its own energy and resists external interference. Poor isolation or filtering in the design can lead to radiated emissions that fail regulatory tests (FCC, CE) or cause susceptibility to noise from other system parts.

- Manufacturing Yield & Cost:‚Äč A design that ignores Design for Manufacturability (DFM)‚Äč rules may be difficult or impossible to produce consistently. This leads to low yields, higher costs, and potential field failures related to soldering or assembly issues.

In essence, the RF PCB design‚Äč translates the theoretical radio frequency schematic symbols‚Äč into a physical reality. Its quality dictates not just initial bench-top performance but the real-world reliability, regulatory compliance, and service life of the final product. Good design mitigates risk at every stage.

In a nutshell, radio frequency circuit boards‚Äč are the precision-engineered foundation that makes modern wireless connectivity possible, demanding meticulous attention to design, material science, and manufacturing. This guide has explored the core aspects of RF technology‚ÄĒfrom material selection and design principles to the global manufacturing landscape‚ÄĒto equip you with the knowledge for your next RF connector PCB project.

EBest Circuit (Best Technology) combines deep expertise in RF PCB design and manufacturing with agile, quick-turn PCBA services to deliver tailored, high-performance solutions with no MOQ. We operate our own facilities with dedicated PCB fabrication and SMT assembly lines, enabling true end-to-end EMS support.

You can simply send us your Gerber files, BOM, and assembly drawings, and our engineering team will gladly provide a thorough, complimentary DFM review, checking for manufacturability risks such as undersized pads, inadequate spacing, or impedance deviations, together with practical optimization suggestions. We also offer one-stop component sourcing to streamline procurement and accelerate your build. For a reliable partner that understands the balance between high-frequency performance and rapid time-to-market, please feel free to contact us at sales@bestpcbs.com.

FAQs

What is the difference between RF PCB and normal PCB?

- RF PCBs are designed to carry high-frequency signals from about 100 MHz up to 110 GHz, covering RF, microwave, and millimeter-wave applications such as Wi-Fi, radar, 5G, and satellite systems. To maintain signal integrity at these frequencies, they use low-loss materials (like Rogers or Taconic), require strict controlled-impedance routing, and follow enhanced grounding and shielding rules.

- Normal PCBs handle low-frequency signals typically below 100 MHz, including common digital logic, microcontrollers, and low-frequency analog circuits. These applications are far less sensitive to dielectric loss, impedance deviation, and copper roughness, so standard FR-4 materials and conventional PCB design rules are usually sufficient.

Is RF signal AC or DC?

- An RF (Radio Frequency) signal is a type of alternating current (AC) signal. It is characterized by its high oscillation frequency, typically in the range of 3 kHz to 300 GHz, which allows it to be radiated as an electromagnetic wave for wireless communication.

Is Wi-Fi an RF signal?

- Yes, Wi-Fi is entirely based on RF technology. It uses specific RF bands (2.4 GHz and 5 GHz) to transmit and receive data wirelessly between your router and devices like laptops and smartphones.

What is an RFID board?

- An RFID (Radio-Frequency Identification) board is a type of RF PCB‚Äč that forms the core of an RFID system. It typically contains the transmitter/receiver circuitry, the antenna, and a microcontroller to communicate with and power RFID tags, enabling wireless tracking and data collection.

What is the purpose of the RF cabinet?

- An RF cabinet (or RF shield) is a metal enclosure designed to contain the electromagnetic emissions from an RF circuit‚Äč or board and to protect it from external interference. This ensures the device complies with electromagnetic compatibility (EMC) regulations and operates reliably without affecting or being affected by nearby electronics.