Power of inverter describes how much usable energy an inverter can provide, and the power of inverter also shows how stable it can run home or industrial loads. Many people use inverters in places where steady current is needed, yet they often want clearer answers about how these units work, how to size them, and how to pick the right design.

In this guide, we will walk through the full picture. We will start with what an inverter does and move into its history, purpose, capacity, limits, and practical use cases. You will also learn how to calculate inverter power, how much electricity an inverter uses, and what a mid-size unit like a 400-watt model can run. By the end, you will have a solid understanding that can help you make confident decisions.

What is Power Inverter?

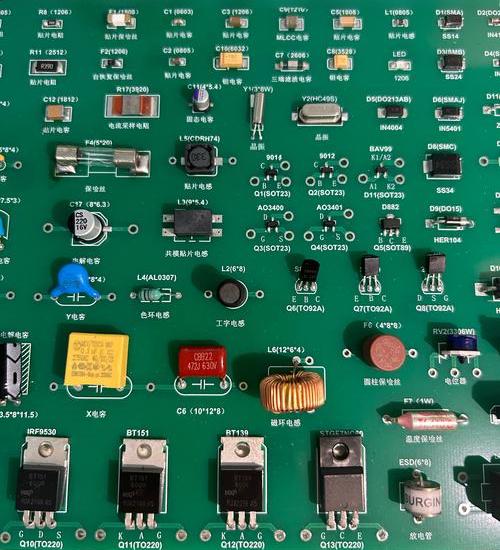

What Is the Power Inverter? Brief History of Power Inverter

A power inverter is an electronic device that converts direct current (DC) into alternating current (AC). Most homes run on AC power. Many power sources, such as batteries, solar panels, and vehicle outlets, deliver DC power. An inverter bridges this gap so you can run AC appliances from DC power sources. This simple function supports many modern conveniences.

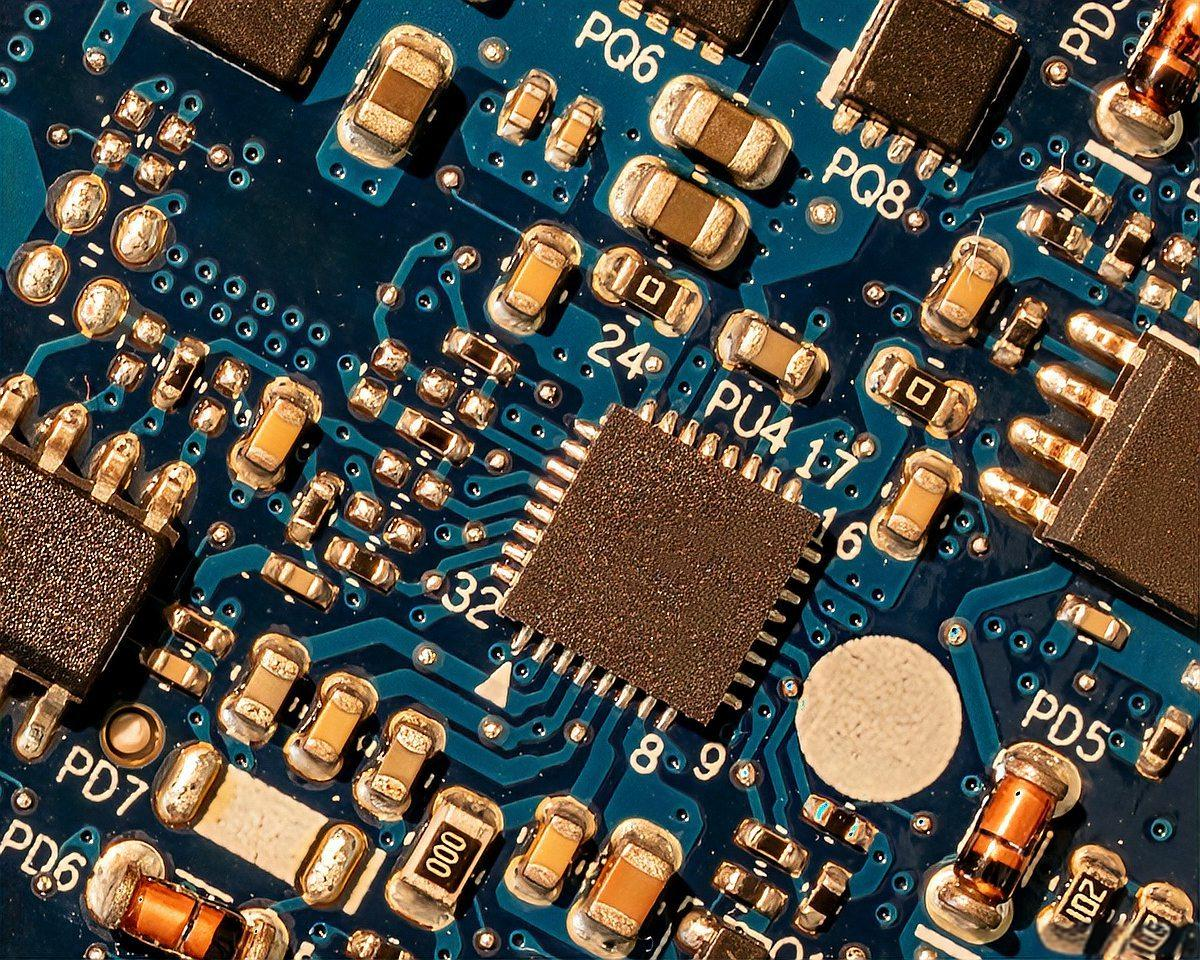

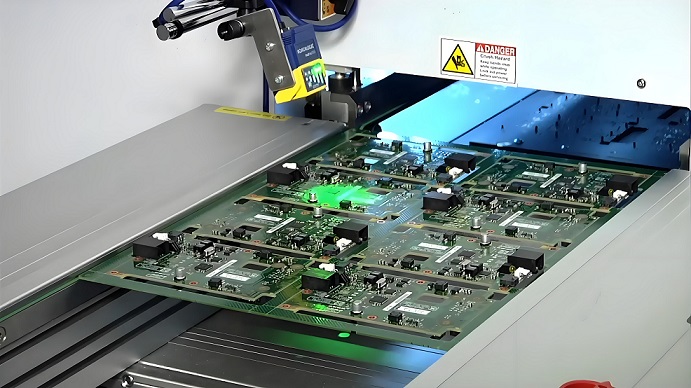

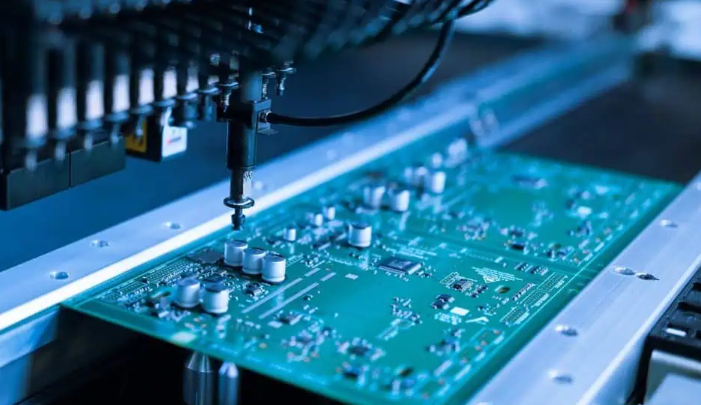

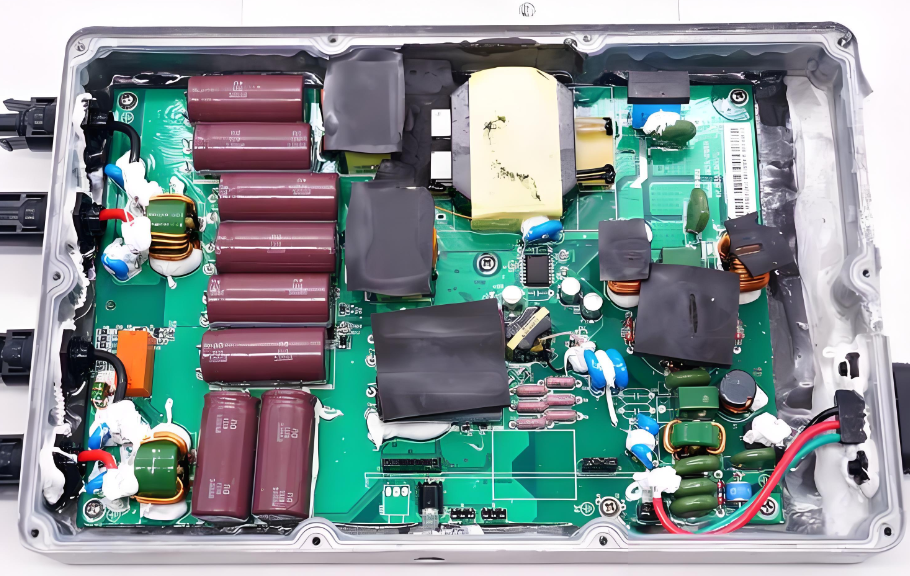

The history of the power inverter goes back more than a century. Early versions were large industrial systems that used mechanical switches to generate AC. They were slow, loud, and not very efficient. When semiconductor technology advanced, inverters became smaller, faster, and more stable. Solid-state components replaced mechanical parts. These improvements led to the compact, efficient units we use today.

Modern inverters support stable voltage, clean output, and high conversion efficiency. They appear in homes, cars, RVs, boats, telecom systems, industrial machines, and solar energy solutions. Over time, the power of inverter technology has kept improving. Efficiency is higher, heat loss is lower, and output is cleaner. Many inverters now support sensitive electronics that require a smooth wave.

Types of Power Inverters

There are several types of power inverters. Each type fits a different need. Knowing them helps you select the right model for your application.

Pure Sine Wave Inverter

A pure sine wave inverter produces a wave that looks almost identical to grid power. It is smooth and clean. Sensitive devices run best on this type, including medical equipment, laptops, smart TVs, and high-end audio. Pure sine wave inverters cost more but provide stable, low-noise performance.

Modified Sine Wave Inverter

A modified sine wave inverter uses a simpler design. It creates a wave that steps up and down rather than flowing smoothly. Many devices still work well on it, such as fans, simple tools, and basic appliances. However, some electronics may not run at full efficiency. Audio and motor devices may show some noise or vibration.

Square Wave Inverter

This type is less common in modern systems. It produces a simple square wave, which is not ideal for most electronics. It may still appear in older or very basic equipment. It is inexpensive but limited and not suited for sensitive loads.

Hybrid Inverter

Hybrid inverters combine DC-AC inversion with solar charging or battery management. They are widely used in solar energy systems and backup power systems. Many hybrid models support grid-tie, off-grid, or mixed working modes. They help manage power flow between solar panels, batteries, and the grid.

High-Frequency vs. Low-Frequency Inverter

High-frequency inverters are compact and efficient. They are suitable for many portable and home applications. Low-frequency inverters are larger, but they handle high surge loads better. They are useful for pumps, compressors, and other heavy startup loads. This choice matters when your equipment draws strong initial current.

Each type brings its own strengths. Your final choice depends on what you want to power, how long you need to run it, and the quality of output you expect.

Purpose of Power Inverter

The main purpose of power inverter technology is to let users operate AC devices from DC sources. This simple function creates a wide range of options for power supply in many environments.

Common purposes include:

- Running home appliances during power outages.

- Powering tools and equipment at outdoor job sites.

- Supplying electricity inside vehicles and boats.

- Supporting solar power systems and battery banks.

- Providing backup power for telecom and IT systems.

- Enabling portable power for camping and off-grid living.

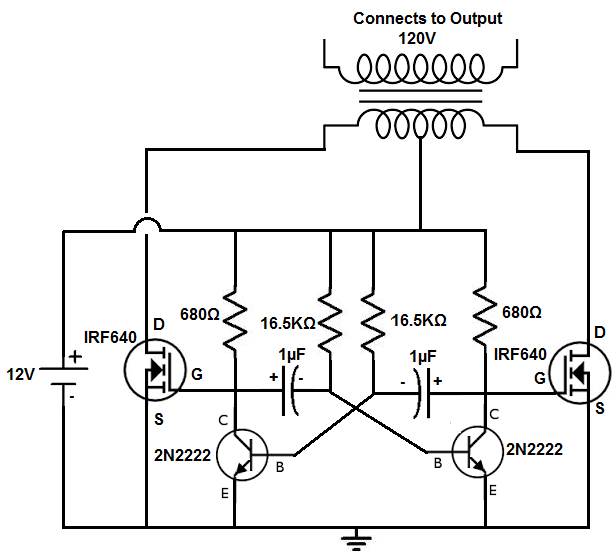

Here is how it works:

Firstly, the input direct current is converted into high-frequency alternating current through an oscillation circuit.

Secondly, the high-frequency alternating current is boosted to the standard voltage (such as 220V) using a transformer„Äā

Finally, the voltage is processed by a filtering circuit to output a stable sine wave or corrected alternating current.

Inverters create mobility and resilience. You can bring AC energy anywhere a battery or DC source exists. They support business operations, daily living, and recreation. Their purpose continues to grow as more devices rely on stable electricity.

Power of Inverter Calculation

Knowing how to calculate the power of an inverter helps you choose the correct size and avoid overload. The basic method is straightforward and practical.

Step 1: Find the Total Wattage of Your Devices

Add the watt numbers of all the devices you want to run at the same time. For example:

- Laptop: 65 W

- Fan: 50 W

- Phone charger: 15 W

Total: 130 W

Step 2: Add Extra Buffer

Many devices draw more power at startup. A safe buffer is about 20% to 30% above the total. Using the example:

130 W √ó 1.3 = 169 W

Step 3: Check Surge Rating

Some appliances such as refrigerators, pumps, and motors need a short burst of high power to start. Surge can be two to three times running power. Make sure the inverter supports this surge rating to avoid shutdown.

Step 4: Consider Efficiency

Inverter efficiency usually ranges from about 85% to 95%. A 1000 W inverter might deliver only 900 W in real use because some energy is lost as heat. You should size the inverter slightly higher than your expected load.

When you know these factors, choosing the right inverter size becomes simpler and more reliable. It ensures stable performance and protects your devices.

What Is the Maximum Power of an Inverter?

The maximum power of an inverter depends on its rated capacity and surge rating. Every inverter has two important values:

- Continuous power rating ‚Äď the amount it can supply all the time.

- Peak or surge power rating ‚Äď the short burst of power available at startup.

Small inverters may offer around 300 to 500 W. Mid-range models range from 1000 to 3000 W. Large inverters for homes or solar systems may exceed 5000 W. Industrial models can go far beyond that.

Common Inverter Power Levels

| Inverter Size (Continuous) | Typical Surge Power | Suitable For | Common Applications |

| 150‚Äď300 W | 300‚Äď600 W | Very light loads | Phone chargers, LED lights, small fans, camera chargers |

| 300‚Äď500 W | 500‚Äď800 W | Light loads | Laptops, monitors, routers, small TVs, tool chargers |

| 600‚Äď800 W | 900‚Äď1200 W | Light‚Äďmedium loads | Small kitchen tools, projectors, camping gear |

| 1000 W | 1500‚Äď2000 W | Medium loads | Small refrigerators, pumps with low surge, printers |

| 1500‚Äď2000 W | 2500‚Äď3500 W | Medium‚Äďheavy loads | Power tools, coffee makers, larger fans, small heaters |

| 3000 W | 4500‚Äď6000 W | Heavy loads | Air compressors, microwaves, larger fridges, workshop tools |

| 4000‚Äď5000 W | 6000‚Äď8000 W | Heavy loads with strong startup | Deep well pumps, larger AC units, high-load appliances |

| 6000 W+ | 9000‚Äď12000 W | Very heavy industrial or home backup | Full home backup, large workshops, solar energy systems |

The maximum usable power also depends on the battery or solar source feeding the inverter. If the source cannot deliver enough current, the inverter cannot reach its rated capacity. A strong input source ensures stable output and longer life.

Does an Inverter Really Save Electricity?

This question comes up often in practice. An inverter itself does not create energy. It converts it from DC to AC. However, in many systems, it helps users manage power more efficiently.

Here is how it can support better energy use:

- In solar setups, an inverter allows clean AC power from sunlight, which can reduce dependence on grid electricity.

- In energy-storage systems, stored energy discharges when needed, which can lower peak usage.

- Many modern inverters use smart control to reduce waste and improve battery life.

So, while the inverter does not ‚Äúsave‚ÄĚ electricity by itself, it helps systems use energy with better control and timing. This can lead to lower utility costs and more stable power use.

How Much Power Does an Inverter Use?

Inverters draw a small amount of power even when idle. This is called standby power. Many units use between 5 and 20 watts when switched on with no load.

During operation, the power used depends on the load and the inverter’s efficiency. If an inverter powers a 100-watt device and has 90% efficiency, it will draw about 111 watts from the battery:

100 W √∑ 0.90 ‚Čą 111 W

The extra energy compensates for heat loss and the internal electronics inside the inverter. High-quality inverters with better efficiency reduce this loss. This means your battery lasts longer under the same load.

Choosing the right inverter size and turning it off when not in use are simple ways to keep power consumption under control.

What Can a 400-Watt Power Inverter Run?

A 400-watt power inverter is popular because it fits many daily scenarios. It is small enough for vehicles, boats, or camping setups, yet it can still run useful equipment.

Typical devices supported by a 400-watt inverter include:

- Laptop and tablet chargers.

- Small fans.

- LED light strings or lamps.

- USB chargers for phones and gadgets.

- A small monitor or TV.

- Portable speakers.

- Tool battery chargers.

- Wi-Fi router or small network device.

- Some compact kitchen appliances with low power ratings.

A 400-watt unit cannot run large appliances with heating elements or big motors. Devices such as kettles, microwaves, full-size refrigerators, and air conditioners need much higher capacity and stronger surge ratings.

Still, a 400-watt model is a practical choice for travelers and light off-grid setups. It delivers solid value in a compact and easy-to-use package.

Best Brand of Power Inverter

The best brand of power inverter depends on your needs. Some brands focus on automotive use. Others specialize in solar systems or industrial applications. The best choice balances performance, safety, price, and durability.

Well-known global inverter brands include:

- Renogy ‚Äď popular for solar and off-grid systems.

- Victron ‚Äď known for high-end performance and smart control.

- AIMS Power ‚Äď offers a wide range of models and sizes.

- Xantrex ‚Äď recognized for stable output and safety features.

- BESTEK ‚Äď widely used for vehicle and travel applications.

Before choosing a brand, check:

- Surge rating and continuous power rating.

- Efficiency and heat management.

- Waveform type (pure sine or modified sine).

- Built-in safety protection, such as over-voltage and short-circuit protection.

- Warranty terms and service support.

- Real customer reviews and field feedback.

Evaluating these points will help you select a brand and model that fits your application and provides long-term value.

Uses of Power Inverter

The many uses of power inverter technology cover a wide range of daily and professional needs. Their flexibility is one of the main reasons they are so common.

Typical use cases include:

- Powering home appliances during grid outages.

- Running devices inside cars, trucks, and RVs.

- Supporting power on boats and marine systems.

- Converting solar energy for home or business AC loads.

- Supporting field tools at remote job sites without grid access.

- Enabling mobile offices and outdoor events.

- Powering drones, cameras, and test equipment in the field.

- Charging electronics during travel or camping.

- Providing backup power for network and telecom equipment.

Because inverters create AC power from DC sources, you can take them almost anywhere. They bring comfort, safety, and convenience to many setups, from casual camping to professional work sites.

FAQs

1. How big of a power inverter do I need?

List all the devices you want to run and add their wattage. Add about 20% to 30% as a buffer. Check surge needs for motors and compressors. Choose an inverter with enough space above this total so it runs cool and stable.

2. Can I run sensitive electronics on an inverter?

Yes. A pure sine wave inverter works best for sensitive electronics. It provides clean, stable output. Devices such as laptops, audio systems, game consoles, and medical equipment run more smoothly with this type of inverter.

3. How long will an inverter run on a battery?

This depends on battery size, load, and inverter efficiency. A larger battery bank will run equipment longer. A small load runs longer than a heavy one. High efficiency and careful use can extend runtime.

4. Can I leave an inverter on all the time?

Many users leave inverters on for long periods. However, idle power will drain the battery over time. Turning the inverter off when not in use is a simple way to save energy and extend battery life.

5. Is a bigger inverter always better?

Not always. Oversized inverters may waste energy at low loads and cost more than you need. It is better to choose a size close to your actual needs with a reasonable buffer for growth and surge.

6. Do inverters get hot?

Inverters produce some heat during operation, especially at higher loads. Good models have cooling fans, heat sinks, and efficient circuits. Make sure the inverter has enough ventilation space to keep temperatures under control.

7. Are modified sine wave inverters safe to use?

They are safe for most simple devices such as lights, fans, and some tools. Some sensitive electronics may not run as smoothly or may make noise. If you want quiet operation and the best performance, choose a pure sine wave inverter instead.

Final Thoughts

The power of inverter plays a major role in modern life. It supports mobility, safety, and comfort in homes, vehicles, and workplaces. When you understand how it works, how to size it, and what type fits your needs, you get better performance from your power system.

Whether you use an inverter at home, in your car, or in a solar energy setup, the right choice ensures stable power wherever you go. With the right knowledge and planning, choosing and using an inverter becomes simple, reliable, and stress-free.