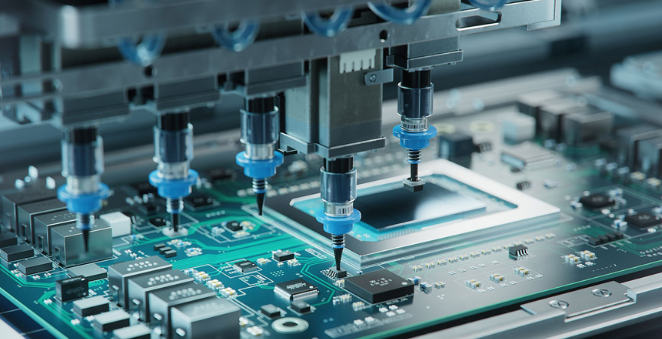

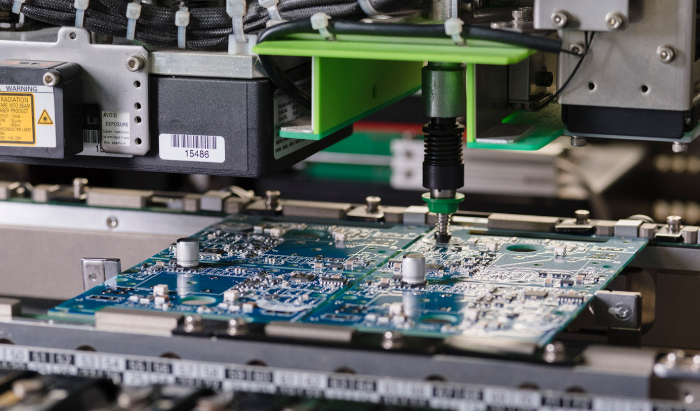

Are you searching for a PCB Manufacturer in Libya? This guide explores challenges, solutions, top manufacturers like EBest Circuit(EBest Circuit (Best Technology)), and key tips for production evaluation and quality inspection.

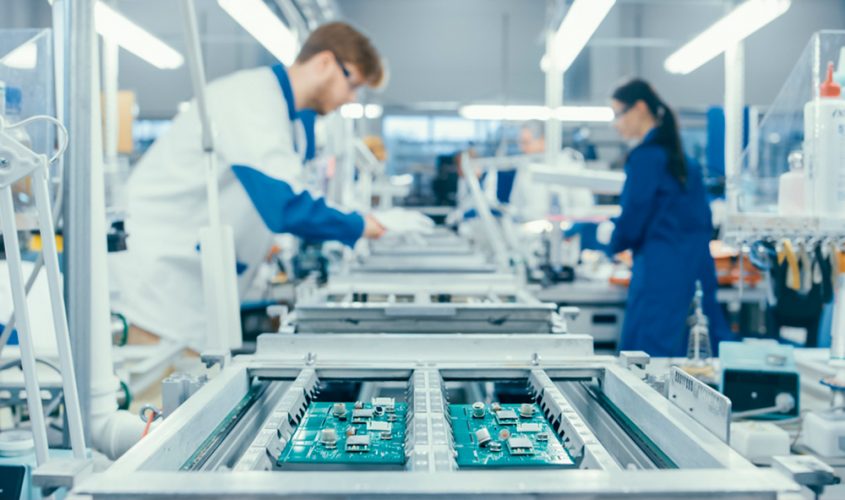

The PCB manufacturing industry in Libya is evolving, with growing demand for reliable PCB fabrication, quick-turn prototyping, and high-quality mass production services. For those seeking trustworthy partners, exploring the top 10 PCB manufacturer in Libya is a crucial step to ensure project success. Understanding the strengths and capabilities of the top 10 PCB manufacturers in Libya helps in filtering out unqualified suppliers and reducing risks in the production process. This blog aims to address core challenges in Libya’s PCB manufacturing sector, provide actionable solutions, and offer a comprehensive guide to evaluating manufacturers and solving common problems.

Are You Facing These Challenges of Libya PCB Manufacturing?

- Do you struggle with delayed delivery of PCB prototypes that hinder your project progress?‚Äč

- Is the quality of mass-produced PCBs inconsistent, leading to frequent rework and cost overruns?‚Äč

- Have you encountered difficulties in getting professional design feedback to optimize PCB manufacturability?‚Äč

- Do you find it hard to secure cost-effective solutions for small-batch PCB production?‚Äč

- Is the lack of strict quality inspection processes from local manufacturers causing product reliability issues?‚Äč

- Do you face challenges in meeting international environmental and industry standards for your PCBs?

Our PCB Solutions to These Challenges

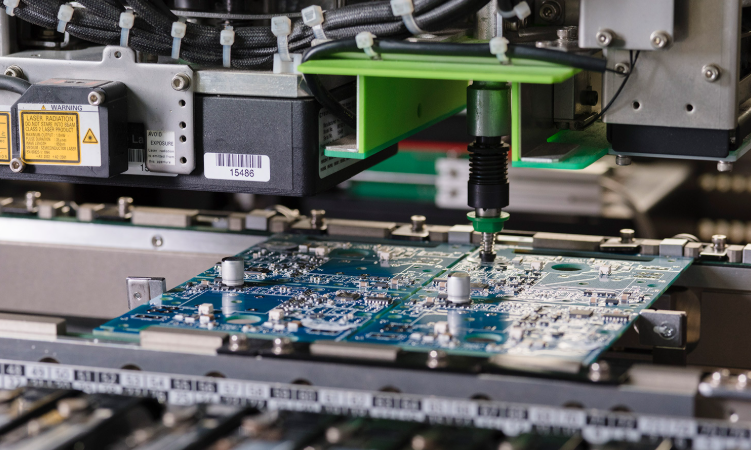

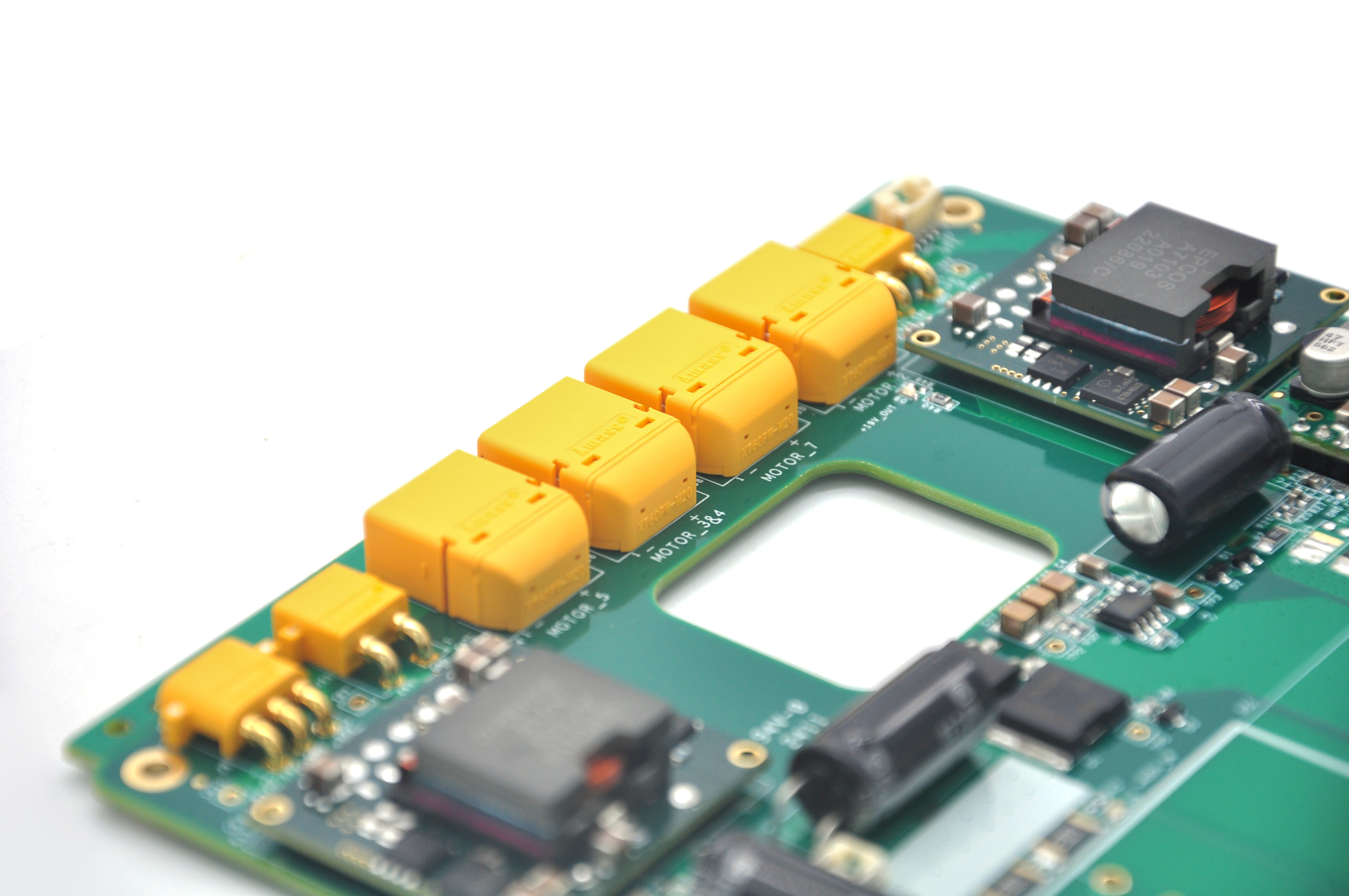

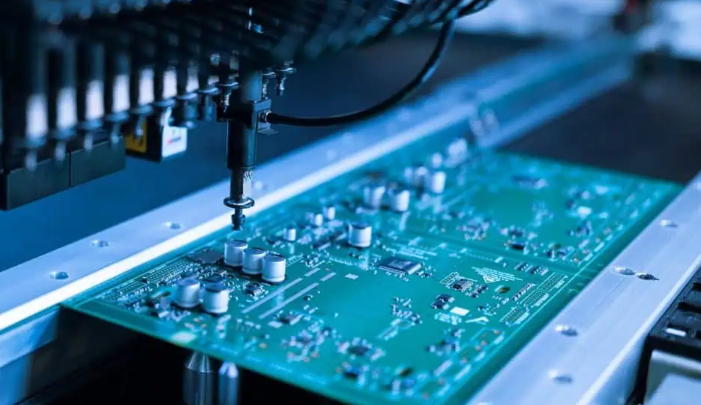

- 24-Hour Quick-Turn Prototyping: Dedicated urgent lines and intelligent scheduling ensure 1-16 layer prototypes delivered within 24 hours, 99.8% on-time shipment to keep projects on track.‚Äč

- Strict Mass Production Quality Control: ISO 9001:2015-based 100% full inspection with three-stage testing (incoming, in-process, finished), defect rate <0.03% to avoid rework costs.‚Äč

- Professional Design Support: Free DFM analysis with pre-production collaboration; optimize routing/via/solder mask to avoid common issues, signal integrity simulation for high-speed PCBs.‚Äč

- Cost-Optimized Solutions: Custom cost plans via material optimization, process simplification and small-batch merging, reducing costs by 10-25% without quality compromise.‚Äč

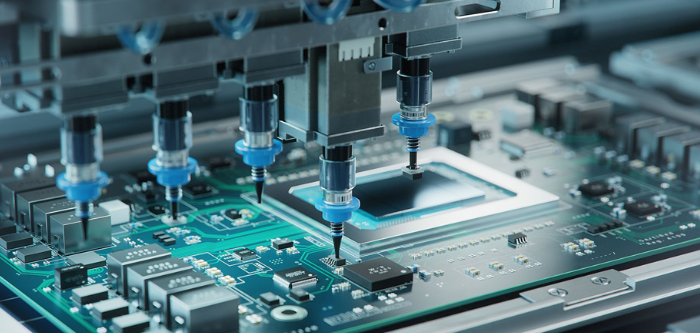

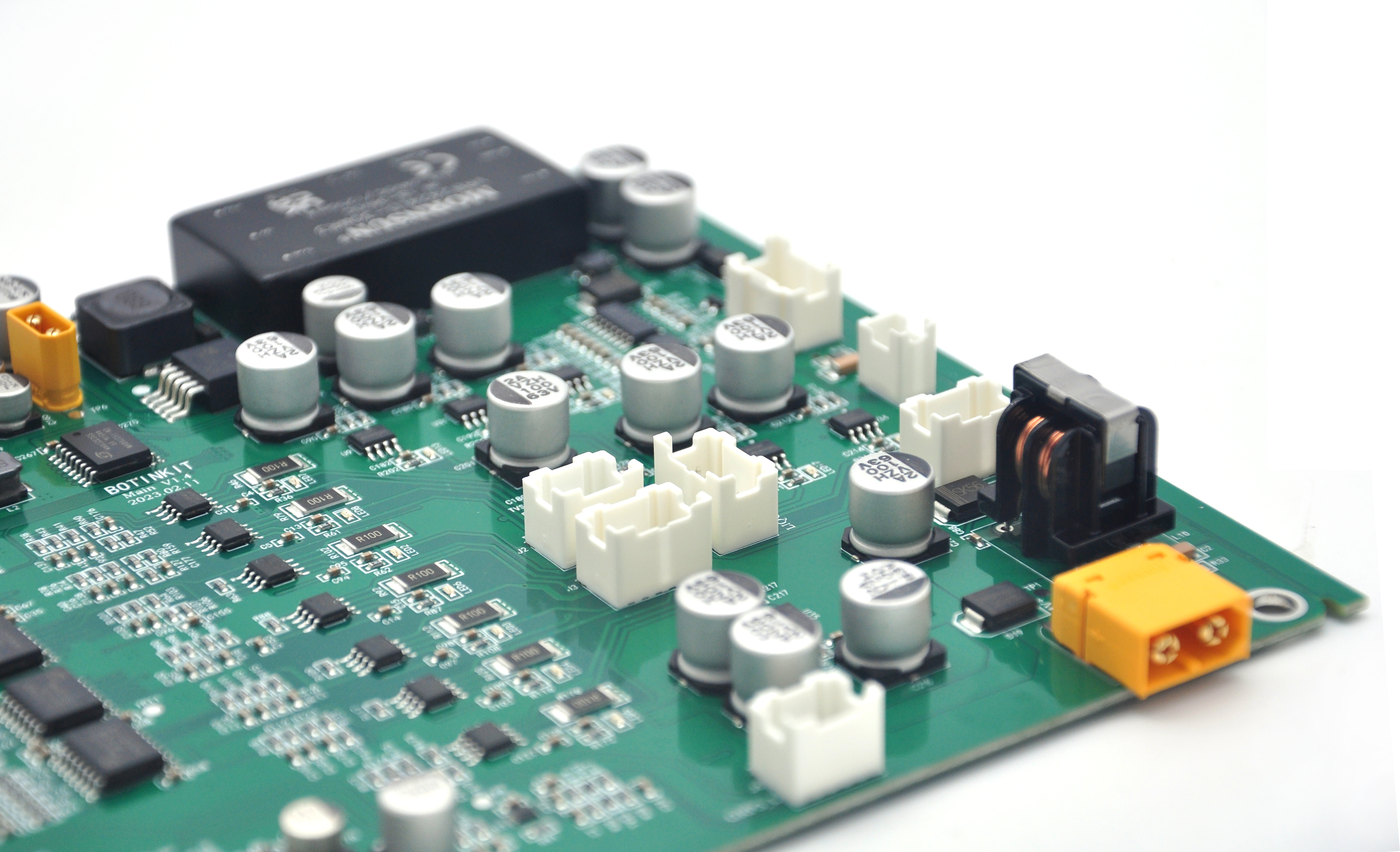

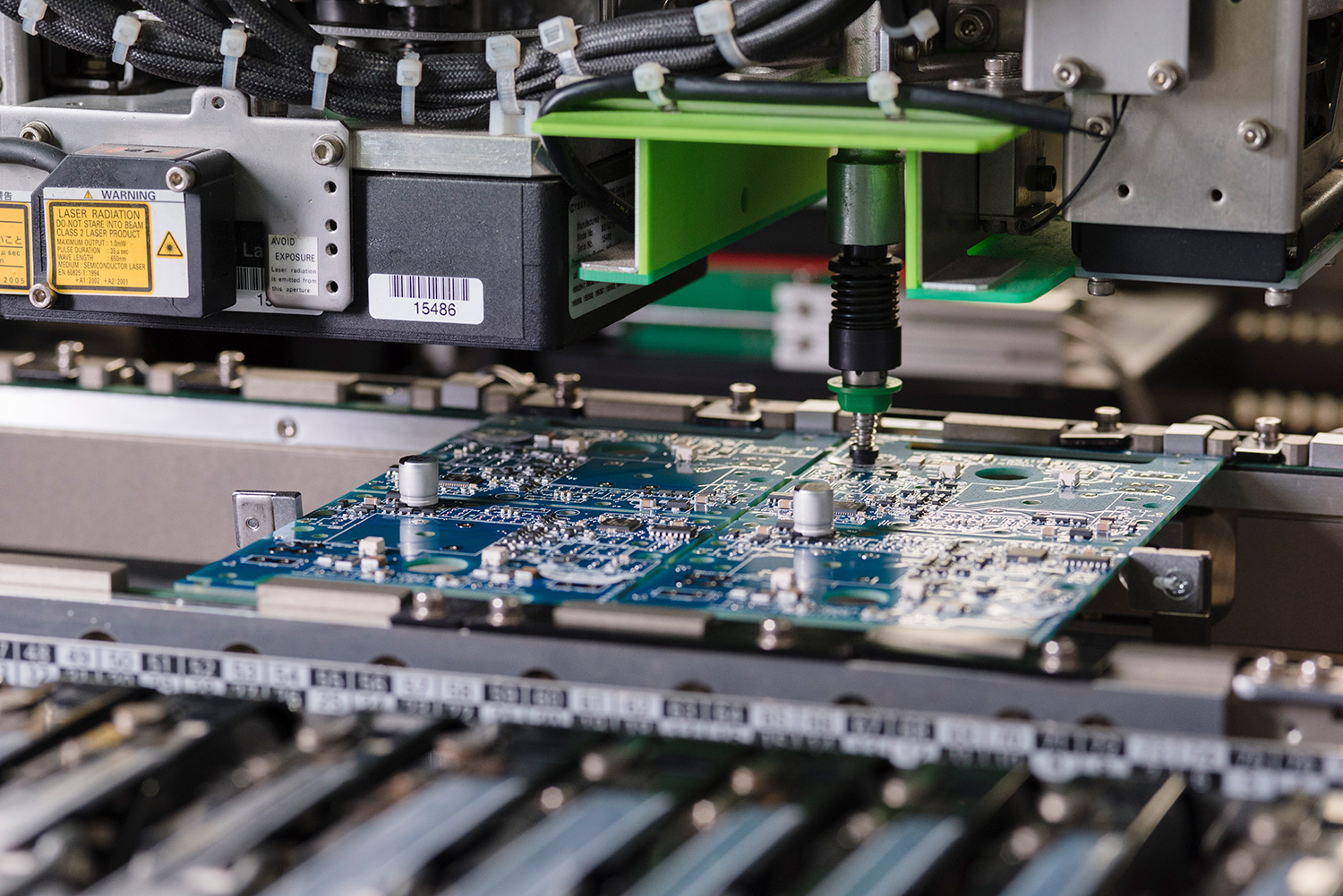

- Comprehensive Quality Inspection System: Advanced testing equipment (3D AOI, X-Ray, impedance tester) and full-process traceability; 100% incoming sampling, 5% mass production random inspection.‚Äč

- International Standard Compliance: Fully compliant with ISO 9001:2015, ISO 13485:2016, REACH, RoHS, IATF 16949; heavy metal content <0.1%, with compliance reports for global market access.

Why Choose EBest Circuit (EBest Circuit (Best Technology)) for PCB Manufacturer?

- Competitive Pricing with Cost-Sensitive Solutions: We offer transparent and competitive pricing, and customize cost optimization plans according to your design and production needs to help reduce overall project costs.‚Äč

- 24-Hour Quick-Turn Prototyping for Urgent Orders: Our dedicated urgent order team and advanced production lines enable us to complete prototyping within 24 hours, meeting your tight project schedules.‚Äč

- High On-Time Delivery Rate: Boasting a 99.2% on-time delivery rate, we use an intelligent production scheduling system to ensure timely delivery of both prototypes and mass production orders.‚Äč

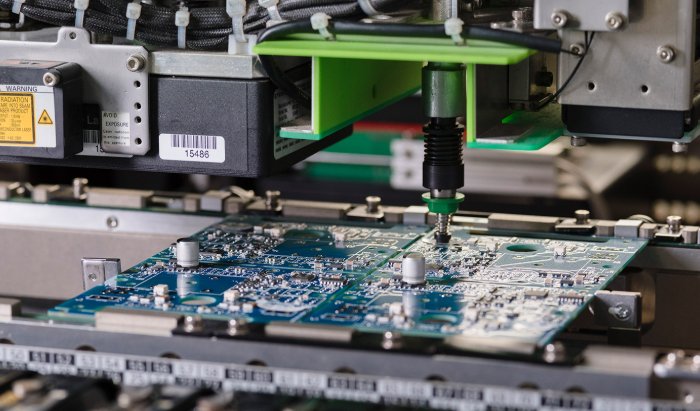

- Superior Quality with Full Inspection: Implement 100% full inspection for mass production, supported by strict quality control processes covering raw material selection, production processes and finished product testing to ensure stable product quality.‚Äč

- 19 Years of Production Experience: With 19 years in the PCB manufacturing industry, we have accumulated rich experience and established a production error database to help avoid common pitfalls and reduce costs.‚Äč

- Free DFM Analysis: Provide free Design for Manufacturability analysis before production, identifying potential design issues and offering optimization suggestions to improve production efficiency and product reliability.‚Äč

- Complete International Certifications: Hold ISO9001:2015, ISO13485:2016, REACH, RoHS, IATF16949 and other authoritative certifications, ensuring products comply with global industry and environmental standards.‚Äč

- One-Stop Service Support: Offer a full range of services from PCB design consultation, prototyping, mass production to assembly, providing convenient one-stop solutions to meet diverse needs.

Top 10 PCB Manufacturer in Libya

| Company Name | Main Business | Core Advantages | Process Capabilities | Delivery Time |

| EBest Circuit (Best Technology) Co., Ltd | One-stop PCB solutions including design, manufacturing, and assembly | 18+ years of experience, multiple certifications, defect rate <0.09% | Single-sided to 40-layer PCBs, HDI, flexible, and metal-core PCBs | Prototypes: 24-72 hours; Mass production: 3-20 days |

| Afaq Al Ghad (HEI) | Telecom equipment and oil industry PCB assembly | Local market leader, government partnerships, citywide after-sales network | SMT/DIP assembly, component testing, custom solutions | Standard: 15-20 days; Rush: 7-10 days |

| Al Ishara Al Electronia | Security monitoring equipment PCB assembly | Established 1989, security electronics specialization, local technical support | Double-sided PCB assembly, system integration, PCB repair | Assembly: 10-15 days; Repair: 3-7 days |

| Tawasul Libya for Electronics | Communication device PCB assembly | International telecom partnerships, desert communication experience, technical training | 2G/3G/4G device assembly, outdoor PCB weatherproofing | Telecom orders: 10-18 days; Spare parts: 5-7 days |

| Al Masa Electronic Industries | Inverter and voltage regulator PCB assembly | Renewable energy focus, local manufacturing, grid customization | Single/double-sided PCB assembly, power circuit production, efficiency testing | Renewable: 12-16 days; Standard: 8-12 days |

| Libya Electronics Manufacturing Co. | Consumer electronics PCB prototyping and repair | Flexible small-batch production, local design support, affordable pricing | 1-2 layer prototyping, low-volume assembly, basic testing | Prototypes: 5-7 days; Small batch: 10-15 days |

| Benghazi Electronics Center | Industrial automation PCB assembly | Benghazi base, eastern Libya coverage, industrial control expertise | Double-sided PCB assembly, automation integration, troubleshooting | Assembly: 12-18 days; Maintenance: 3-5 days |

| Al Motawaset For Oil Services | Oilfield control equipment PCB assembly | Oil sector specialization, remote operation capability, safety compliance | Harsh environment assembly, control system integration, drilling equipment repair | Industrial: 14-21 days; Emergency: 48-72 hours |

| Link Electronics Co. (Tripoli) | LED power supply PCB assembly | Energy-efficient electronics focus, local market pricing advantage, rapid response | Single/double-sided PCB assembly, LED driver production, consumer-grade quality control | Small batch: 7-12 days; Large batch: 15-25 days |

| Baida Co. | Oilfield equipment PCB assembly and component supply | Global brand authorized distributor, critical component supply chain, oil application expertise | 1-4 layer assembly, component kitting, industrial testing | Standard: 12-18 days; Express: 5-8 days |

Core Pain Points of PCB Manufacturer in Libya

- Insufficient advanced production equipment, unable to meet high-precision requirements.‚Äč

- Lack of strict quality control, leading to unstable quality and high defect rates.‚Äč

- Limited technical capabilities, unable to provide professional design support and DFM analysis.‚Äč

- Unreliable supply chains, frequent raw material shortages causing delivery delays.‚Äč

- Inadequate staff training, low operational proficiency and production efficiency.‚Äč

- Failure to meet international standards, restricting export capabilities.‚Äč

- Poor emergency response, unable to handle urgent orders timely.

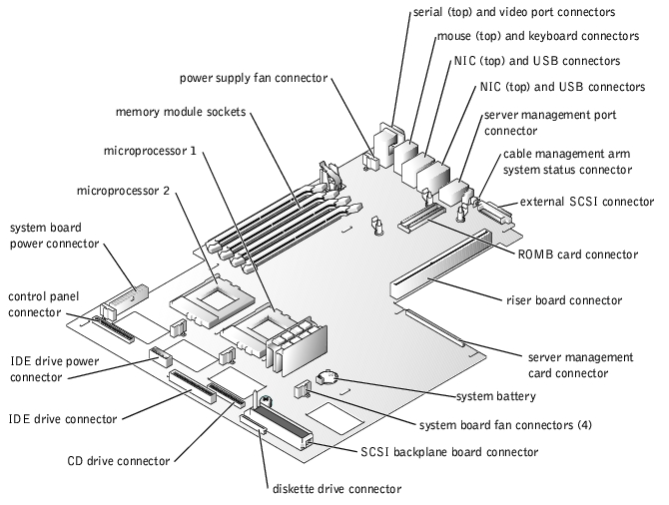

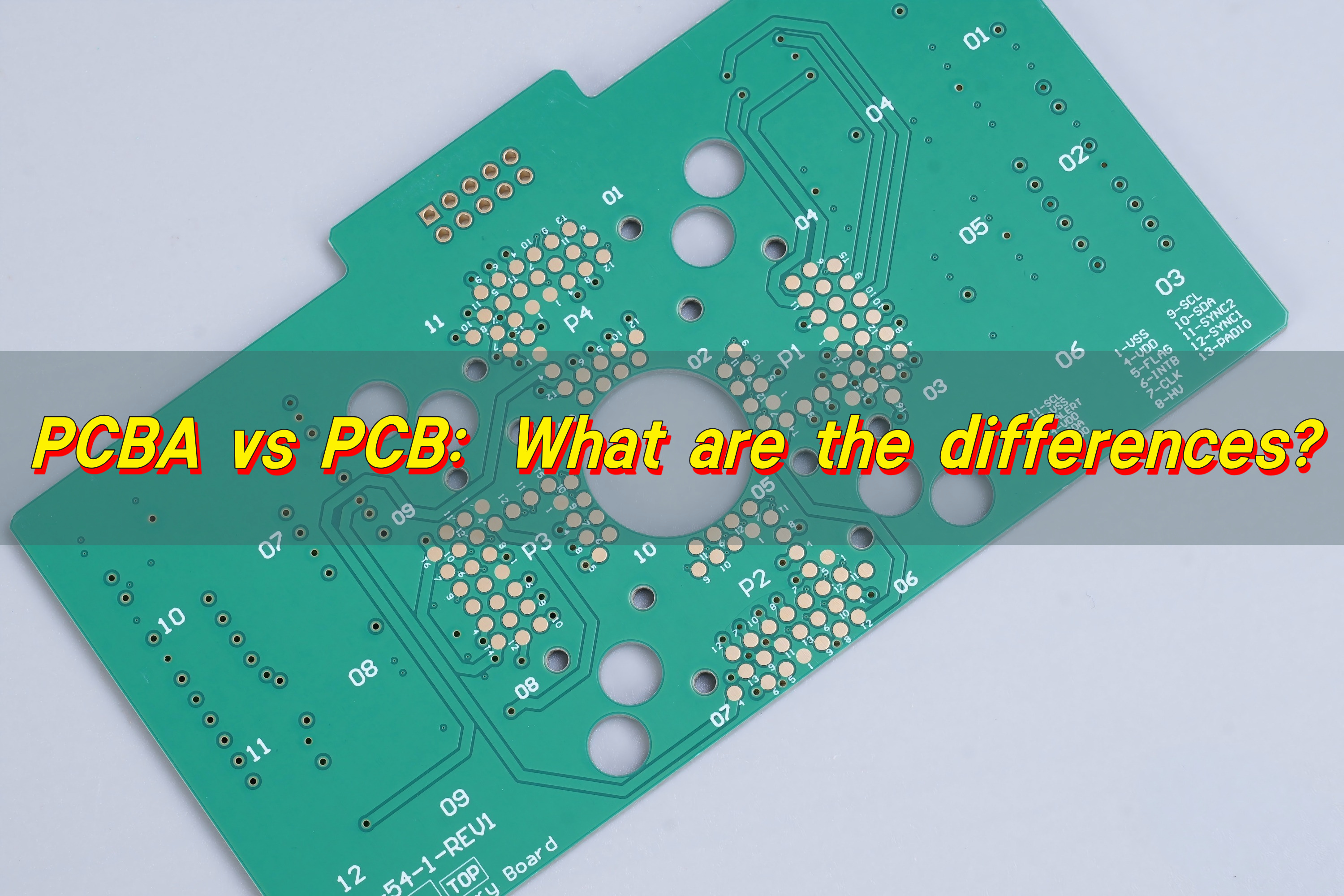

How to Evaluate the Production Capability of PCB Manufacturer in Libya?

Evaluation Guide to the Production Capability of PCB Manufacturer in Libya:

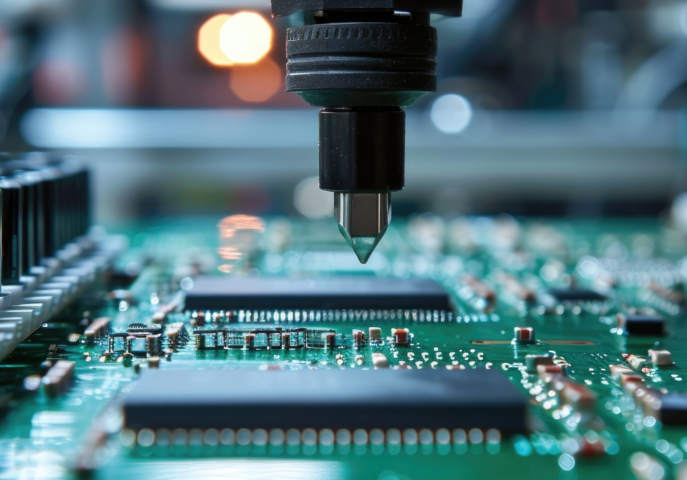

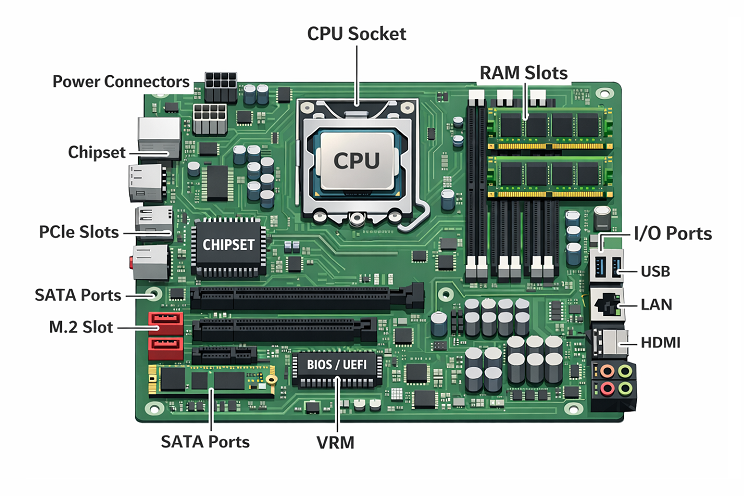

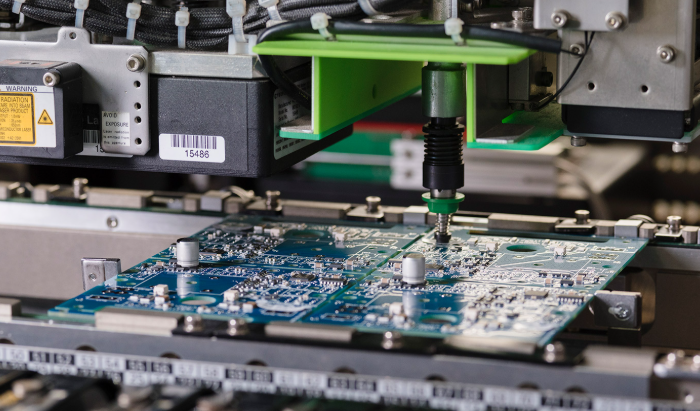

- Verify the performance of advanced production equipment: Etching machines should achieve a line width/spacing control accuracy of 3/3 mil; drilling machines should have a positioning accuracy of ¬Ī1 mil; SMT placement machines should have a placement accuracy of ¬Ī0.03 mm.

- Evaluate process capabilities using quantifiable metrics: Maximum PCB layers ‚Č• 18 layers; minimum line width/spacing ‚ȧ 3/3 mil; minimum hole diameter ‚ȧ 8 mil (0.2 mm), with a tolerance of ¬Ī2 mil.

- Check monthly production capacity: Ensure it matches your order volume; small to medium-sized manufacturers typically have a monthly capacity of 5,000-20,000 square meters.

- Assess experience with special processes: HDI should support 3/3 mil line width/spacing; rigid-flex PCBs should support up to 12 layers; thick copper PCBs should have a copper thickness of up to 30 ounces.

- Review production planning and emergency response capabilities: Confirm that urgent prototype orders can be started within 24 hours; bulk orders should have a clear schedule with a buffer of ‚ȧ 3 days to account for potential delays.

- Investigate the raw material supply chain: Ensure that critical materials (FR-4, copper foil) have ‚Č• 30 days of inventory; verify ‚Č• 3 qualified long-term material suppliers.

- Evaluate the technical team’s capabilities: Require a response time of ‚ȧ 24 hours for production technical issues; confirm a historical problem resolution rate of ‚Č• 90%.

- Check historical on-time delivery rate: Reliable manufacturers should maintain an on-time delivery rate of ‚Č• 95% for bulk orders and ‚Č• 99% for prototype orders.

How to Check the Quality Inspection of Libya PCB Manufacturing Company?

Evaluation Guide to the Quality Inspection of Libya PCB Manufacturing Company:

- Verify quality inspection equipment performance: AOI with ‚Č•99.5% defect detection rate; X-Ray supporting 0.1mm microvia inspection; impedance tester with ¬Ī1% measurement accuracy.

- Check valid quality management certifications (ISO9001:2015 mandatory) with at least 1 annual internal audit to ensure implementation effectiveness.

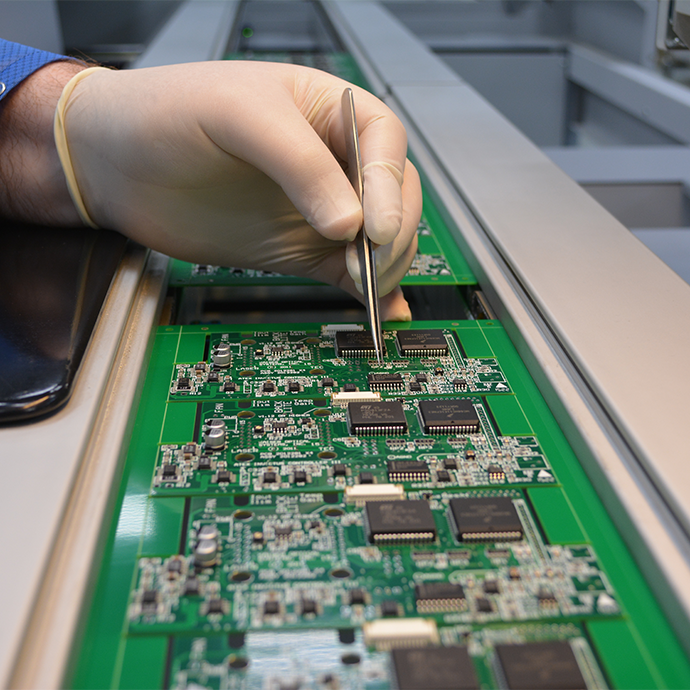

- Confirm full-process inspection procedures: Incoming material sampling rate ‚Č•30% (key materials 100%); in-process inspection every 2 hours per production line; finished product full inspection for mass production.

- Investigate defect rate data: Acceptable batch defect rate ‚ȧ0.05%; non-conforming products must be handled (rework/scrap) within 24 hours with traceable records.

- Request sample testing reports: Must include impedance (tolerance ¬Ī10%), insulation resistance (‚Č•100Mő©) and solderability test results; sample size ‚Č•3 pcs per batch.

- Check product traceability system: Able to trace raw material batches, production shifts and inspection records; data retention ‚Č•3 years for future inquiry.

- Review quality inspection team qualifications: ‚Č•90% of inspectors hold professional certificates; annual skill training ‚Č•40 hours to ensure proficiency.

- Investigate customer quality feedback: Target customer complaint rate ‚ȧ1% for quality issues; problem resolution rate ‚Č•95% with documented follow-up records.

FAQs of PCB Manufacturer in Libya

Q1: What if the received PCB prototype doesn’t match the design?

A1: Provide design docs and prototype photos for confirmation. We offer pre-production design review and 24-hour technical response; free DFM analysis upfront reduces mismatches. Discrepancies will be resolved with rework or compensation.

Q2: How to ensure consistent quality between mass production and prototypes?

A2: Confirm unified quality standards and same raw materials/equipment. We implement 100% full inspection for mass production and provide batch quality tracking reports to guarantee consistency.

Q3: Is quick-turn small-batch PCB production available in Libya?

A3: Most local manufacturers have limitations. We offer 24-hour small-batch prototyping and 5-7 working days for small-batch production via dedicated lines, ensuring timely delivery and quality.

Q4: How to confirm PCB compliance with RoHS and other environmental standards?

A4: Request RoHS certification and raw material test reports. Our products meet RoHS/REACH standards, with complete certification docs and raw material traceability available on demand.

Q5: What affects PCB delivery time and how to avoid delays?

A5: Key factors: raw material supply, production scheduling, quality inspection. Clarify delivery terms in the contract and choose suppliers with stable supply chains. Our 99.2% on-time delivery is guaranteed by intelligent scheduling, raw material inventory, and real-time progress tracking.