Looking for a reliable PCB factory in Thailand? This blog post will help you understand how to choose the right factory and how to evaluate the lead time and technical capabilities of Thailand PCB manufacturers.

PCB factory in Thailand choices attract global engineers who want stable quality, shorter routes to Southeast Asia, and localized service. Today, many buyers compare each PCB factory in Thailand to see which one matches their prototypes or mass-production plans. This guide walks through Thailand’s PCB industry, factory capabilities, and selection advice in a simple and friendly way. You will also see how to avoid avoidable costs while improving project success from design to delivery.

Top 10 PCB Factory in Thailand List

| Company Name | Core Advantages | Process Capability | Prototype Lead Time | Mass Production Lead Time |

| Thai PCB Solutions Co., Ltd. | Local support & competitive pricing for small batches | 2-24L HDI, ENIG/OSP, AOI testing | 3-5 days | 7-12 days |

| Bangkok Electronics Manufacturing | Aerospace/automotive certification & strict QC | 2-32L rigid-flex, HF PCB, X-ray inspection | 5-7 days | 10-15 days |

| Siam Circuit Board Co. | Fast prototyping & bilingual communication | 2-16L FR-4/Rogers, HASL finish | 2-4 days | 6-10 days |

| Thailand PCB Tech | Consumer electronics specialization & low MOQ | 2-20L HDI(1+N+1), flexible PCBs | 3-6 days | 8-13 days |

| Asia Circuit Thailand | Long-term supply chain stability & certifications | 2-40L thick copper, military-grade | 7-10 days | 12-20 days |

| Chonburi PCB Manufacturing | Port proximity & cost-effective large orders | 2-18L ENIG/ImSn, AOI+Flying Probe | 4-6 days | 9-14 days |

| Thai Flex Circuit Co. | Medical device expertise & ISO 13485 certified | 2-12L flex/rigid-flex, medical PCBs | 5-8 days | 11-16 days |

| Bangkok HDI Solutions | 5G/AI cutting-edge technology | 4-28L HDI(2+N+2), high-density connectors | 6-9 days | 13-18 days |

| Thailand Electronics Circuitry | Affordable pricing & reliable delivery | 2-22L FR-4, quick-turn prototyping | 2-3 days | 7-11 days |

| Eastern Seaboard PCB Co. | IATF 16949 certified & automotive tailoring | 2-30L automotive-grade, high-temp materials | 5-7 days | 10-17 days |

How to Choose A Reliable PCB Factory in Thailand?

A Detailed Selection Guide to PCB Factory in Thailand:

1. Location and Logistics Network

- Prioritize factories in industrial clusters like Bangkok or Samut Prakan, close to ports (e.g., Laem Chabang) and airports to reduce transportation costs and time.

- Evaluate local warehousing and rapid delivery capabilities to ensure logistics efficiency from prototype to mass production.

2. Production Capacity and Technical Expertise

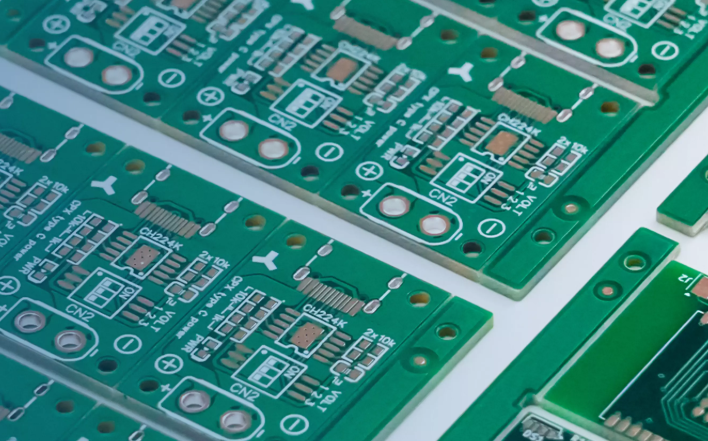

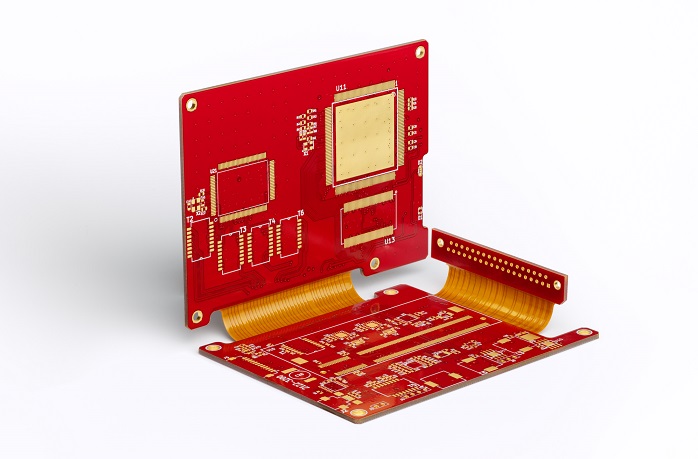

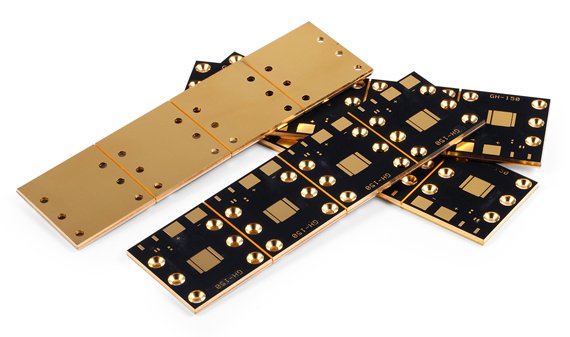

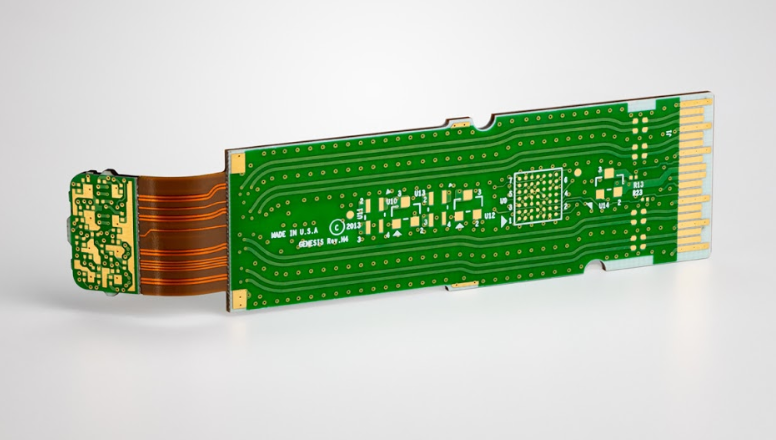

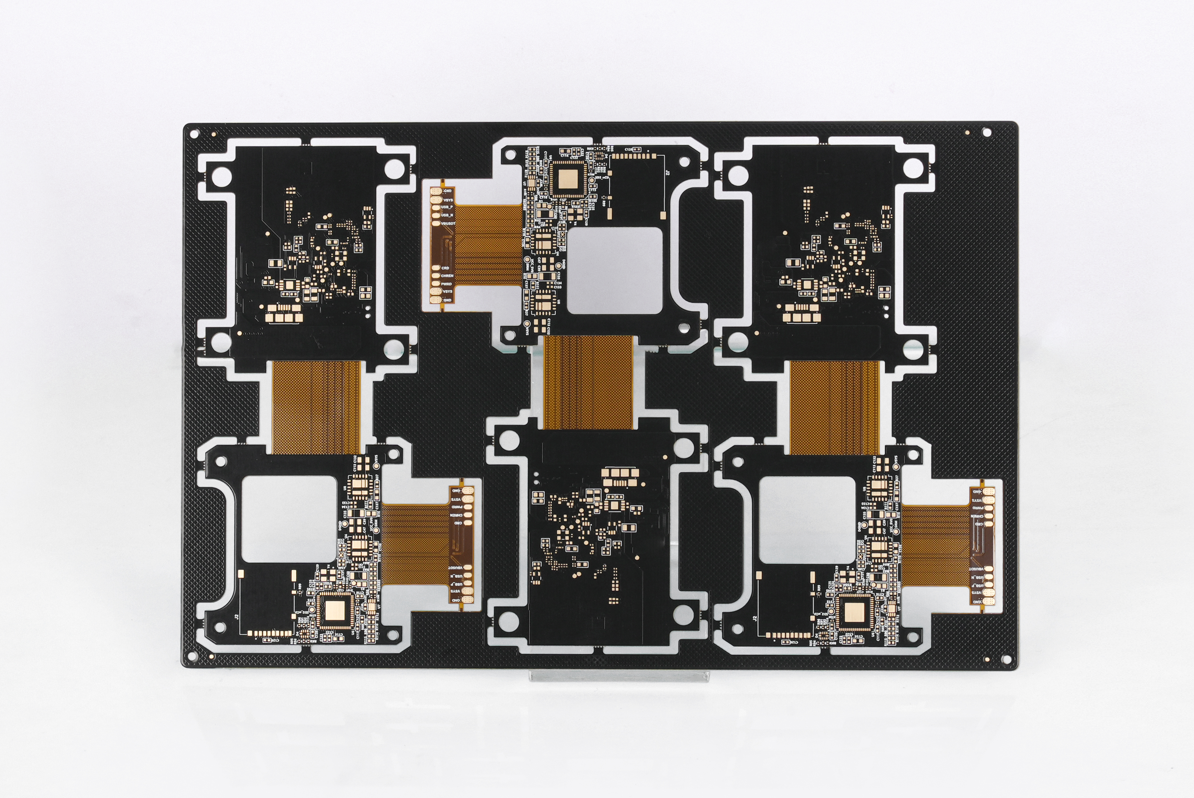

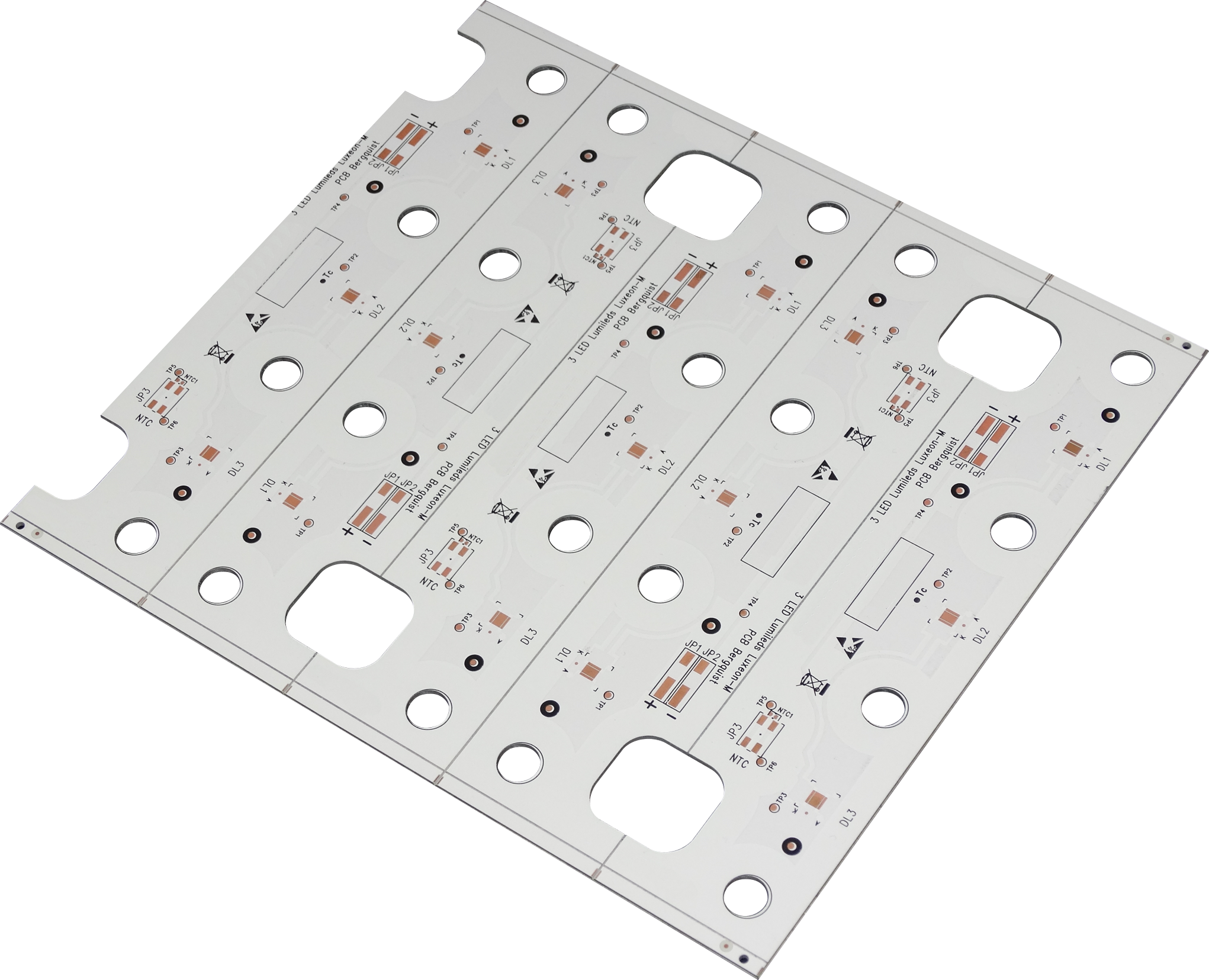

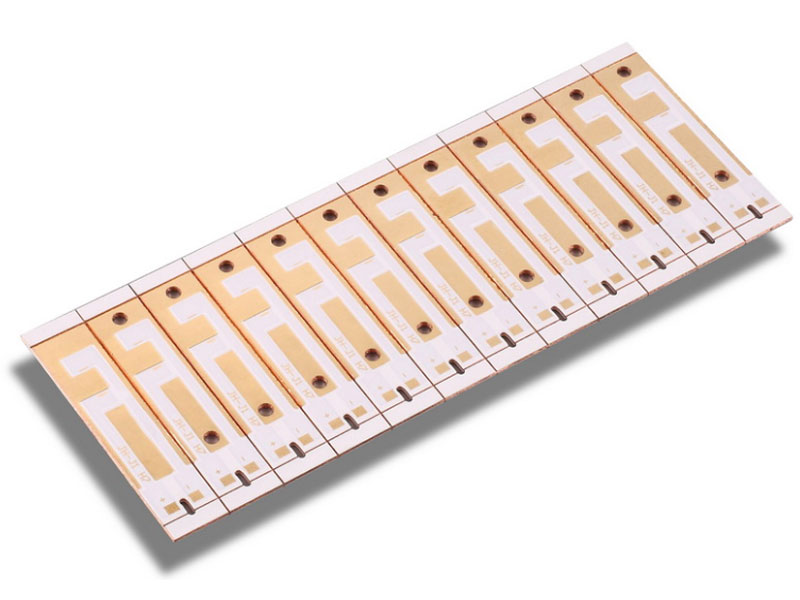

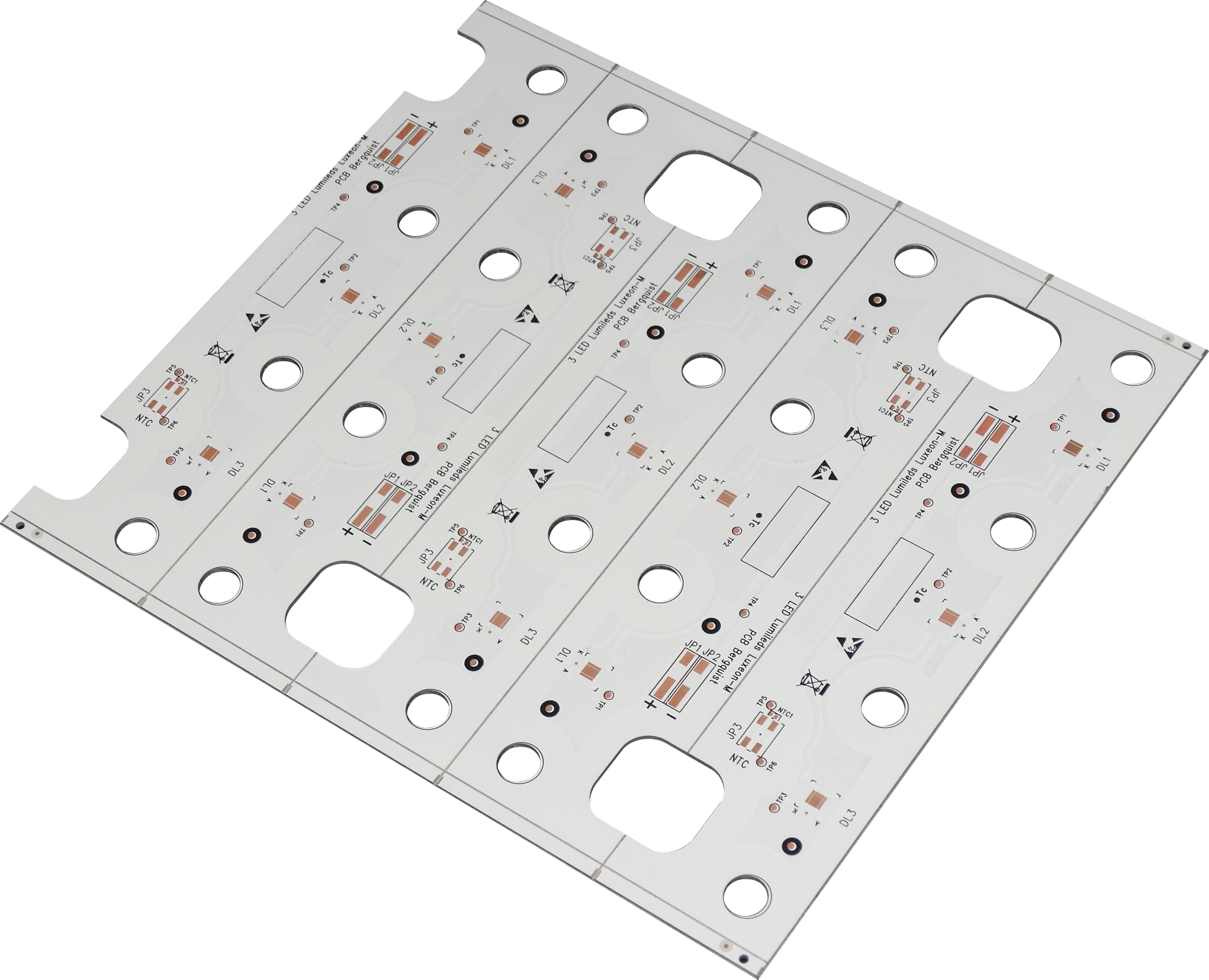

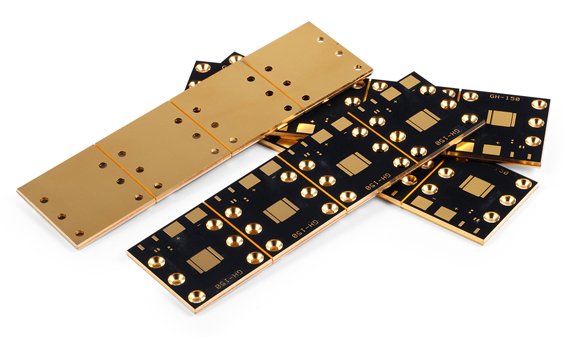

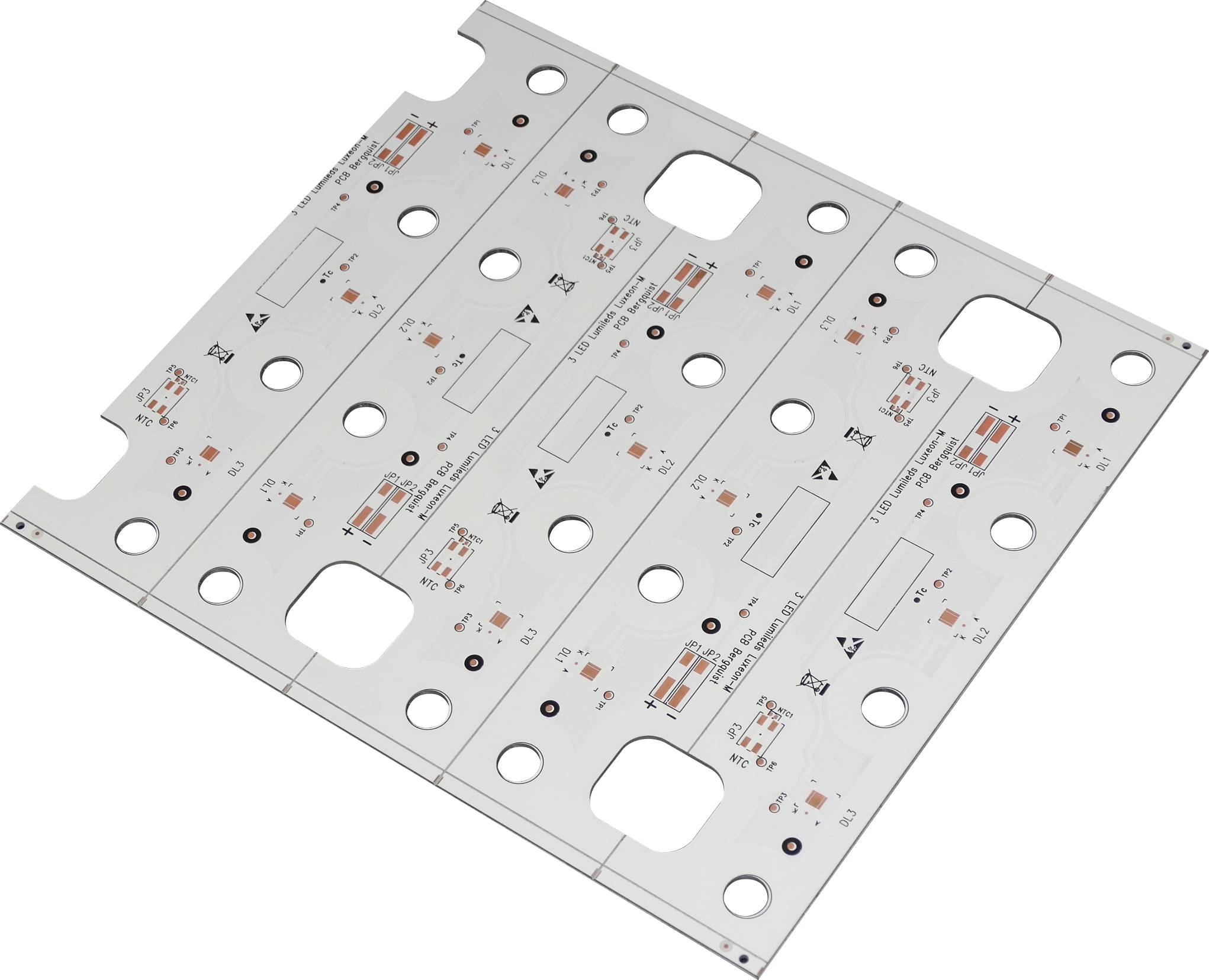

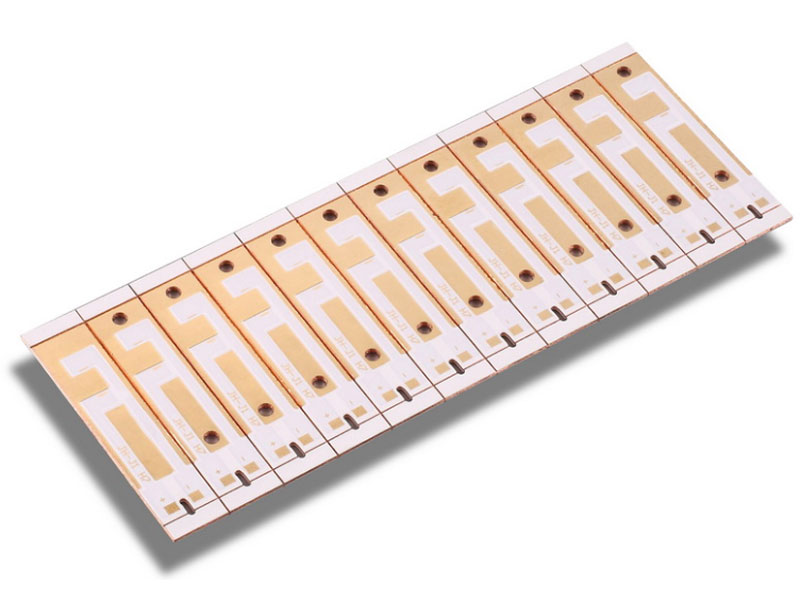

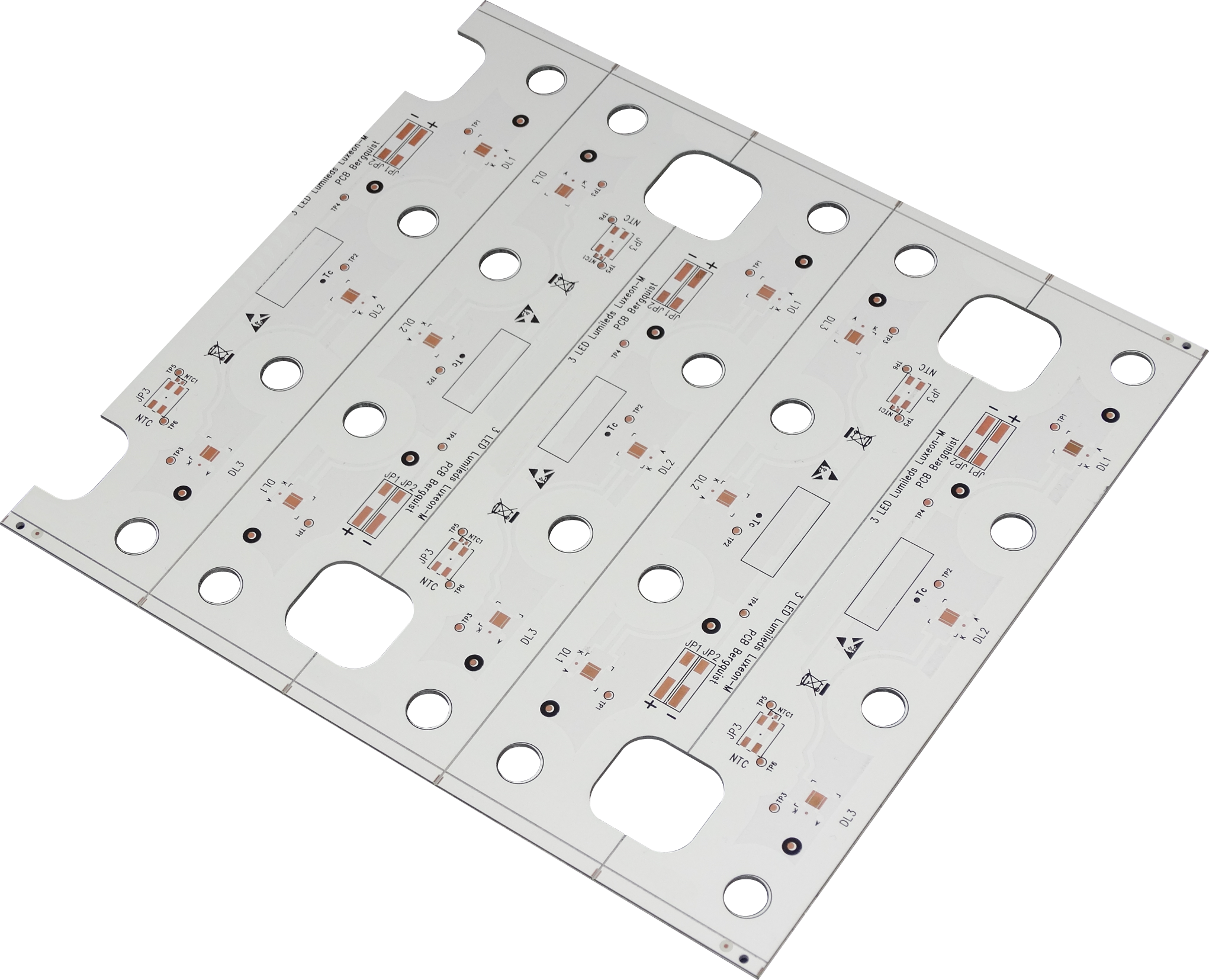

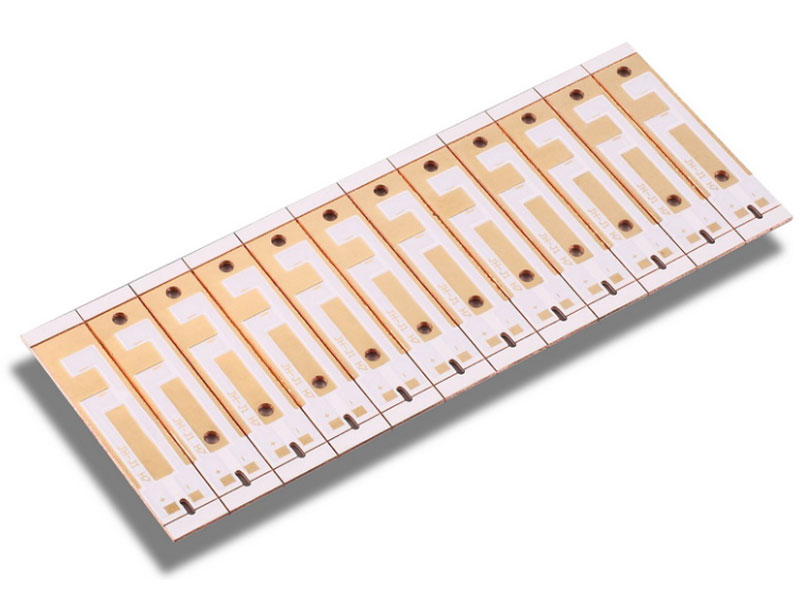

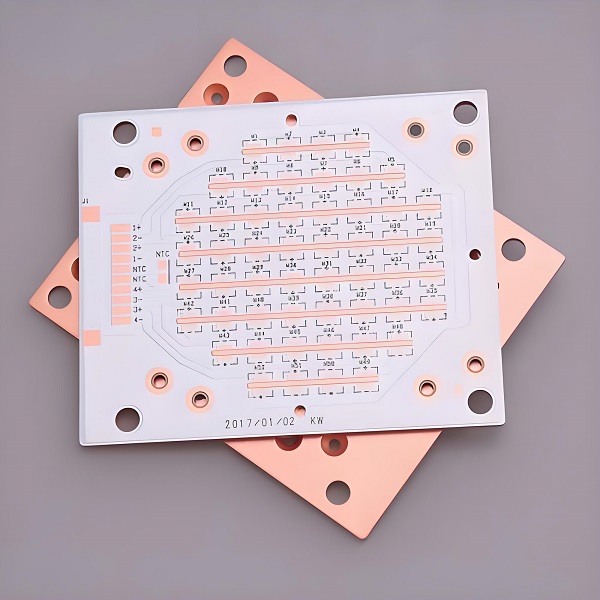

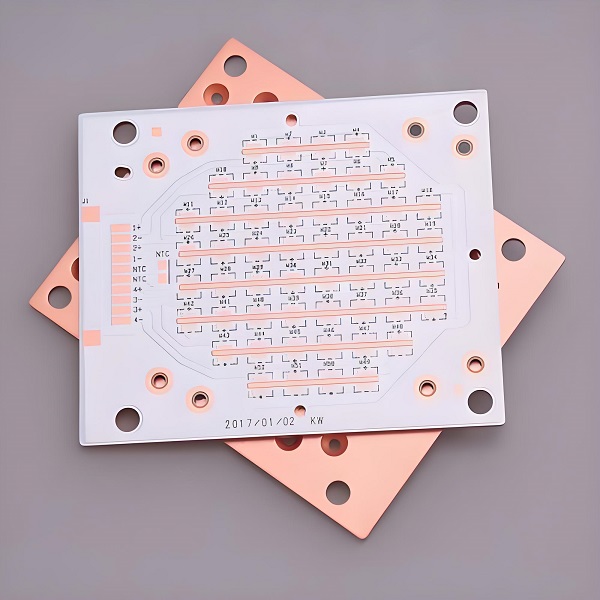

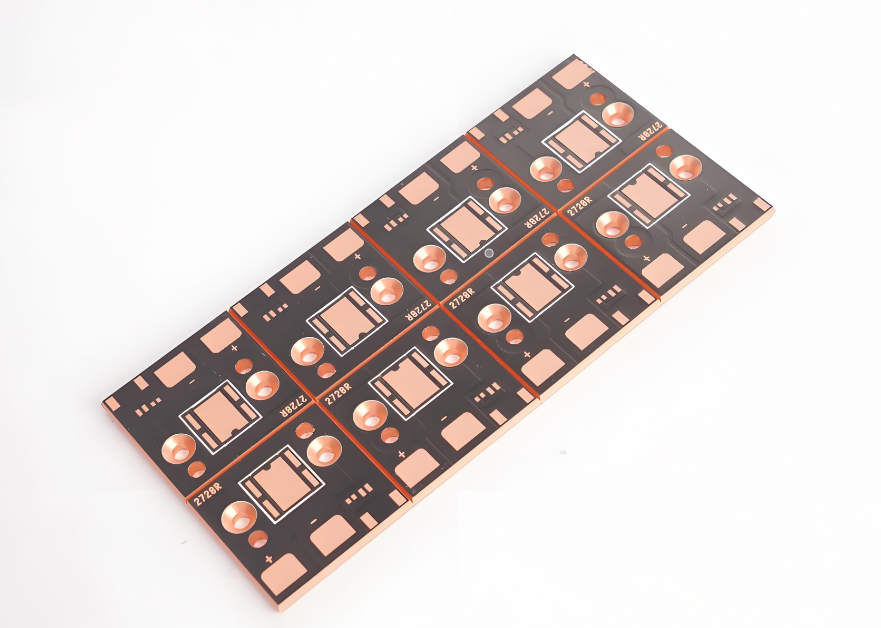

- Clarify factory technical focus: support for multilayer boards, HDI, flexible boards, metal-core substrates, etc.

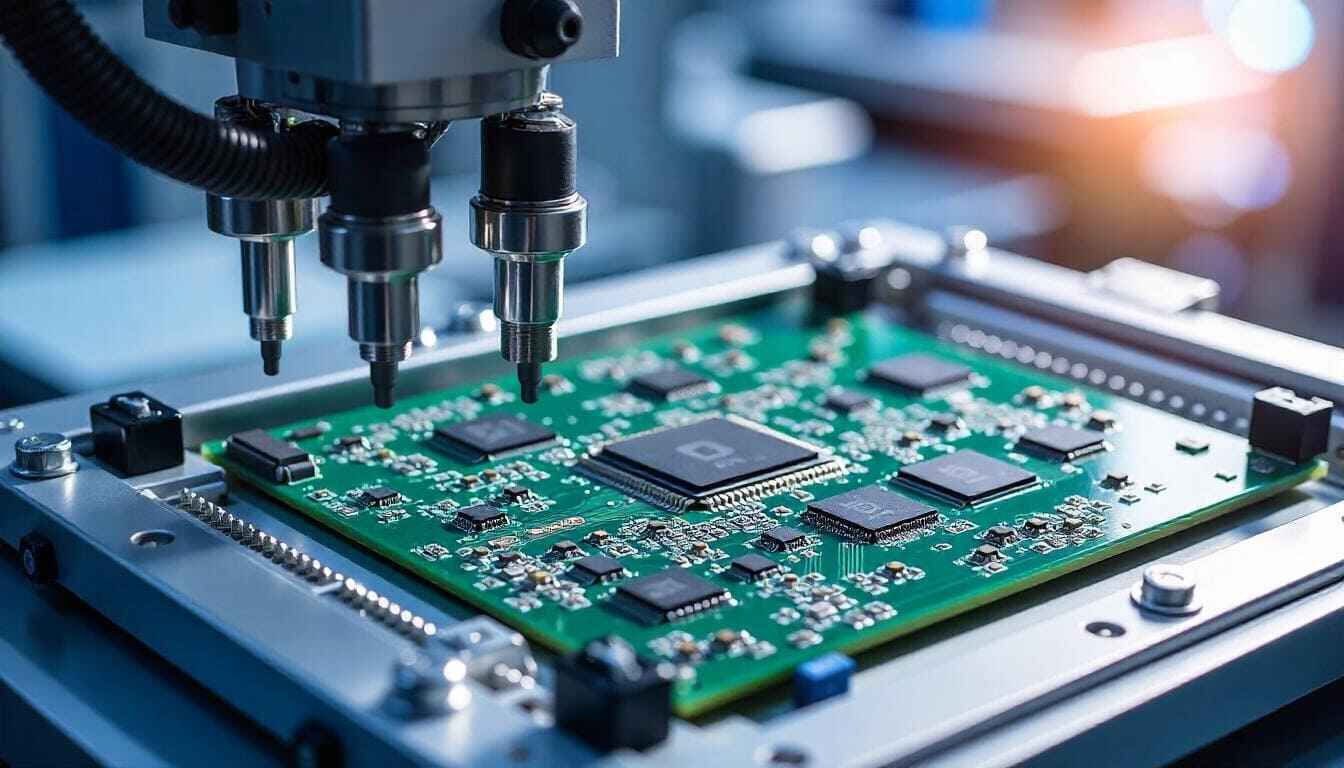

- Confirm automation level of production lines (e.g., laser drilling, copper plating thickness control) to avoid technical limitations affecting design realization.

- Special process support: embedded components, high-frequency/high-speed materials (e.g., PTFE), impedance control accuracy, etc.

3. Quality Certifications and Environmental Standards

- Essential certifications: ISO 9001 (quality), ISO 14001 (environmental), UL certification (safety), RoHS/REACH (environmental materials).

- Local certifications: TISI certification (Thailand Industrial Standards) to comply with local regulations.

- Quality control processes: batch traceability, AOI/X-RAY inspection, etc.

4. Cost and Lead Time

- Compare quotation models (e.g., NRE fees, tiered pricing by layers, volume discounts), noting hidden costs (e.g., mold fees, testing fees).

- Clarify lead times: prototypes (typically 3–7 days), small batches (1–2 weeks), mass production (4–6 weeks), and confirm rush service availability.

5. Technical Support and Customization Capability

- Assess if the engineering team provides local design support (e.g., DFM/DFA feedback, manufacturability optimization).

- Procurement specialists should evaluate supply chain stability (e.g., key material sources, inventory management).

- Designers may focus on design tool compatibility (e.g., Altium, OrCAD) or design rule check (DRC) services.

6. Communication and After-Sales Service

- Prefer factories with bilingual (Chinese/English) teams for seamless technical communication.

- After-sales terms: warranty period, response time for issues, repair process, etc.

7. Avoiding Pitfalls

- Beware of “low-price traps”: excessively low quotes may hide process defects or non-compliant environmental practices.

- Factory audits: recommend on-site visits by procurement/engineers to verify equipment status and quality control processes.

- Reference cases: request successful project examples (e.g., automotive electronics, consumer electronics, industrial control) to validate technical compatibility.

Quality Certification Requirements for PCB Factory in Thailand

- ISO 9001: Mandatory for quality management systems, ensuring product consistency and compliance with international standards.

- ISO 14001: Required for environmental management, addressing waste reduction, eco-friendly practices, and regulatory compliance.

- TISI Certification: Mandatory for certain electronics under Thai Industrial Standards. Requires factory inspections, product testing, and adherence to local safety/quality norms.

- UL Certification: Necessary for safety compliance in international markets (e.g., U.S.).

- IATF 16949: Compulsory for automotive electronics PCB manufacturers. Validates quality management in auto-parts production

- RoHS/REACH Compliance: Ensures materials meet EU environmental standards (e.g., lead-free solder).

- IPC Standards (e.g., IPC-A-600, MIL-STD-105E): Industry-specific benchmarks for PCB quality, appearance, and reliability. Adherence ensures alignment with global manufacturing best practices.

How to Evaluate the Technical Capability of PCB Factory in Thailand?

Methods About How to Evaluate the Technical Capability of PCB Factory in Thailand:

1. Inquire about their monthly production volume and match it with your order scale. For example, if you need 50,000 pieces per month, confirm the manufacturer’s monthly output can reach at least 80,000 pieces to reserve buffer for unexpected demand.

2. Ask for detailed equipment specifications. Focus on key machines like laser drilling equipment for HDI boards, AOI (Automated Optical Inspection) systems for defect detection, and X-ray machines for inner-layer inspection, these directly determine production efficiency and quality.

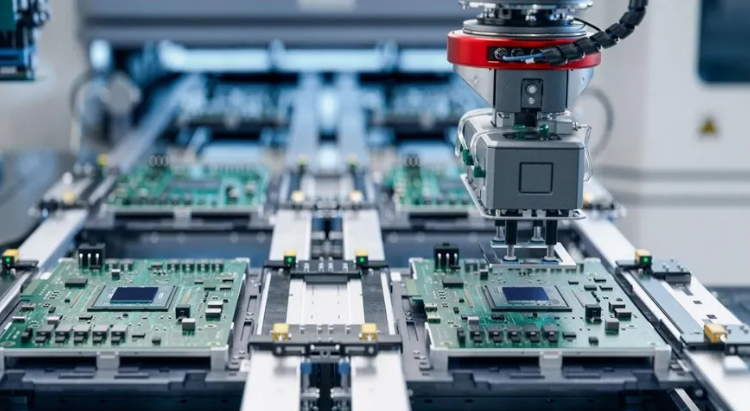

3. Check their factory area and the number of production lines. A facility over 10,000 square meters with 5+ independent lines usually indicates stronger scalability, which is crucial if your business plans to expand order quantities in the future.

4. Evaluate the stability of their raw material supply chain. Ask about their long-term cooperative suppliers for core materials like copper clad laminates and solder mask. Manufacturers with 3+ alternative suppliers are less likely to face delays due to material shortages.

5. Ask about their production shift arrangements. Manufacturers operating 24/7 with three shifts can significantly shorten lead times, especially when you have urgent orders that need to be processed without interruption.

6. Inquire about their current capacity utilization rate. A rate between 60% and 80% is ideal—it means they have enough bandwidth to take your order while maintaining stable production quality, avoiding rushed work caused by overcapacity.

7. Request their recent quality yield rate data. A yield rate above 98% for standard PCBs and 95% for complex HDI boards reflects mature production processes and strict quality control, reducing the risk of defective products.

8. Check if they offer flexible production scheduling. Confirm whether they can adjust production sequences or modify small order details (like minor design revisions) without causing major delays, which is important for agile product development.

How to Evaluate the PCB Lead Time of Thailand PCB Manufacturer?

Methods About How to Evaluate the Lead Time of PCB Factory in Thailand:

1. Secure clear, written commitments for lead times across all order types. This should specify exact days for prototypes (e.g., 3 days for 2-layer boards), small batches (e.g., 7 days for 500 units), and mass production, with no ambiguous wording about “approximate” timelines.

2. Inquire about specific factors that could delay your order. Common issues include limited stock of special materials like Rogers laminates, peak production seasons (typically Q3 for electronics), and unplanned quality audits—ask how they flag and communicate these risks upfront.

3. Ask for details on expedited services, including exact timeframes and cost structures. For example, find out if a 24-hour prototype service is available for simple designs, what percentage of standard cost it adds, and if there are any limitations on layer count or material.

4. Verify their on-time delivery (OTD) track record by requesting data from the past 12 months. A reliable manufacturer will share OTD rates by order type, aim for 95%+ for standard orders and 90%+ for expedited orders and may even provide client references to confirm.

5. Evaluate their production update process to stay ahead of delays. Ask how often they share status reports (e.g., daily for urgent orders, every 3 days for standard) and what channels they use—prefer manufacturers that offer a portal or direct email from the production team, not just sales.

6. Inquire about their contingency plans for supply chain disruptions. For example, if a key material supplier is delayed, do they have pre-negotiated agreements with backup vendors? If a production line breaks down, can they shift orders to another facility without adding days?

7. Clarify lead times for pre-production steps like design reviews and revisions. A common bottleneck is unplanned design fixes—ask how long their DFM review takes (target: 24 hours for standard designs) and if revisions add to the overall timeline, or if they’re included in the initial quote.

8. Check if they manage shipping or rely on third parties, as this impacts final delivery. Manufacturers with in-house logistics teams often have faster access to Thai ports (Laem Chabang, Bangkok) and can provide tracking numbers immediately after shipping—ask about typical transit times to your location.

Our ISO Quality System Inspection Process

1. Pre-design and Standard Calibration Phase: Upon receiving an order, the technical team performs a dual verification process against your requirements (such. as Gerber files and performance parameters) and ISO 9001 and IPC-A-600 standards. For complex PCBs (such as HDI and high-frequency boards), an additional DFM (Design for Manufacturability) review is conducted to proactively avoid design defects that may cause quality problems, such as line width and spacing issues. All calibration results are documented for your confirmation.

2. Comprehensive Raw Material Incoming Inspection: Upon arrival, core materials (FR-4 substrate, Rogers high-frequency materials, copper foil, etc.) undergo a “three-step inspection mechanism.” First, supplier qualifications and material certificates (MSDS) are verified. Second, material composition is tested using a spectrometer. Finally, samples are tested for temperature resistance and insulation properties to ensure compliance with RoHS/REACH environmental requirements. Non-conforming materials are immediately isolated, and a backup supplier plan is initiated.

3. In-process Key Node Inspection: Eight fixed inspection points are set up during the production process, focusing on core processes such as lamination, drilling, plating, and solder mask application. After lamination, X-ray inspection is used to check interlayer alignment (deviation ≤ 0.02mm); after drilling, AOI (Automatic Optical Inspection) is used to check for hole diameter errors; during plating, copper thickness is monitored in real-time (error controlled within ±5μm), and inspection data is recorded every two hours to ensure stable process parameters.

4. Semi-finished Product Special Testing: After PCB circuit fabrication, electrical performance and structural integrity tests are conducted. A flying probe tester is used to test 100% of the products for continuity, preventing open and short circuits; flexible PCBs undergo additional bending tests (simulating 1000 bends in a usage scenario without breakage); HDI boards are tested for blind and buried via accuracy using a laser thickness gauge to ensure compliance with design specifications.

5. Finished Product Full Inspection and Sampling Review: In the finished product stage, automated equipment performs a full visual inspection (e.g., for scratches and solder mask bubbles), and then samples are subjected to enhanced testing according to AQL 2.5 standards, including high-temperature and high-humidity environment testing (85℃/85%RH, 48 hours without performance degradation) and solderability testing, to ensure product suitability for subsequent assembly. Each batch of finished products comes with a unique quality inspection number, enabling full traceability.

6. Closed-loop handling of non-conforming products: If non-conforming products are found during testing, the ISO standard corrective and preventive action process is immediately initiated. After identification and isolation, a quality engineer leads the root cause analysis (such as equipment accuracy, operational errors), develops corrective measures, and verifies their effectiveness. We will also keep you informed of the problem details and solutions to ensure that similar problems do not recur. All processing records are kept for at least 3 years.

7. Final verification and archiving before delivery: Before shipment, the finished product test report, material certificate, and compliance certificate are compiled and finally checked against your order requirements. Anti-static materials are used in the packaging process, and a humidity indicator card is included to ensure quality stability during transportation.

8. After-sales quality traceability and optimization: After product delivery, we will regularly follow up on usage feedback. If quality issues arise (not due to improper use), we will respond within 24 hours and arrange for our technical team to analyze the problem. We optimize our processes quarterly based on quality inspection data and customer feedback, continuously improving our quality control level through ISO internal audits and management reviews.

Our Production Lead Time for PCB Manufacturing

| Layers | Normal Service | Fastest Service |

| 1 | 7 Days | 24 H |

| 2 | 8 Days | 24 H |

| 4 | 10 Days | 48 H |

| 6 | 10 Days | 72 H |

| 8 | 12 Days | 72 H |

| ≥10 | TBD | TBD |

Why Thailand Clients Choose EBest Circuit (Best Technology) for PCB Manufacturer?

Reasons Why Thailand Clients Choose EBest Circuit (Best Technology) for PCB Manufacturer:

- 24-Hour Rapid Prototyping Service: Based on deep understanding of urgent project needs among Thai engineers, we offer “24-hour expedited prototyping for urgent orders.” Historical data shows this service reduces prototype verification cycles by 65% on average, accelerating product launch by 7-10 days.

- Full-Chain ISO Certified Quality Control: Certified under ISO9001:2015/ISO13485:2016 dual standards and IATF16949 automotive-grade certification (certification number: TISI-00123), we implement a full-process quality traceability system from raw material procurement to finished product delivery.

- Multi-Category Small-Batch Flexible Production: Supports 8 types of PCB small-batch production including FR4 PCB, rigid-flex boards, and HDI PCB, with minimum order quantity starting at 1 piece. 2024 service data reveals over 5,000 small-batch orders completed for Thailand’s electronics sector, with average delivery time of 3-5 days, inventory turnover improved by 40%, effectively reducing clients’ trial production costs and inventory pressure.

- Integrated PCBA Smart Solutions: Combines programming, testing, and assembly in a one-stop service, supported by a stable electronics supply chain network of 50+ suppliers. 2024 cases indicate 30% shorter supply chain response times for Thai procurement teams, while full-process “design-production-testing” turnkey service reduces project cycles by 15 days on average.

- EU Environmental Compliance Certification: Fully compliant with REACH/RoHS environmental regulations, providing 100+ batches of compliance certifications for Thai clients exporting to EU markets in 2024, ensuring zero environmental violations and smooth international market expansion.

- 19-Year Technical Expertise Guarantee: Nineteen years of dedicated PCB manufacturing experience has built a mature process database with 20,000+ parameters and a defect prevention system. 2025 data shows process defect rates reduced to 0.8% and 99% production stability, ensuring reliable technical support and capacity assurance for Thai clients.

- Precision Matching Thailand’s Industry Needs: Tailored to Thailand’s electronics industry characteristics of “multi-variety, short-cycle,” we provide flexible component selection services and custom process solutions. Over 500+ customized material and process schemes have been delivered to Thai designers, addressing specialized needs such as high-frequency high-speed materials (e.g., PTFE) and impedance control accuracy.

- Supply Chain Resilience Assurance: Leveraging a stable electronics component supply network (100+ suppliers) and intelligent warehousing systems, we ensure 99.2% on-time delivery rates for Thai clients, even during traditional Thai holidays, maintaining production stability through intelligent scheduling.

Welcome to contact us if you have any request for PCB design, prototyping, mass production and PCBA service: sales@bestpcbs.com.