The UK is home to leading PCB manufacturing companies in UK, grounded in strict quality standards and advanced technical capabilities. A top PCB Manufacturer in UK stands out for precision production and adherence to local regulations, including UKCA and RoHS compliance, to serve automotive, medical and telecommunications sectors. Demand for high-performance PCBs grows with AI computing and automotive electronics expansion, making a reliable PCB Manufacturer in UK critical to project success. This guide breaks down core aspects of UK PCB manufacturing to help you navigate the market and choose the right partner.

Top 10 PCB Manufacturer in UK List in 2026

| Company Name | Main Business | Core Advantages | Process Capabilities | Lead Time |

| EBest Circuit Co., Limited (Best Technology Circuit Co., Limited) | Custom PCB fabrication, PCB assembly, high-precision PCB production | 20-year industry experience, global supply chain, 24/7 technical support, ISO & UKCA certified | 1-32 layers PCB, HDI boards, minimum track/gap 0.05mm, blind/buried vias <0.12mm | Prototype: 24-48 hours, mass production: 3-7 days |

| PW Circuits Ltd (UK) | PCB fabrication, surface finishing, small-batch industrial PCB production | UK-based factory in Hampshire, ISO 9001 certified, strict industrial quality control | 1-32 layers PCB, max board thickness 10mm, immersion gold/silver/OSP finishes | Prototype: 3-5 days, mass production: 7-10 days |

| Exception Group Ltd (UK) | High-reliability PCB, military & aerospace-grade PCB manufacturing | Defense industry certification, UKAS-accredited testing, low-volume high-mix capacity | 1-20 layers PCB, metal core boards, RoHS/REACH compliant finishes | Prototype: 5-7 days, mass production: 10-14 days |

| Fineline Global Ltd (UK) | Flexible PCB, rigid-flex PCB, custom flexible circuit production | Specialized in flexible circuits, UK design team, quick iteration support | Flexible/rigid-flex boards, 1-12 layers, minimum hole 0.1mm, polyimide materials | Prototype: 4-6 days, mass production: 8-12 days |

| Circuitwise UK Ltd | Quick-turn PCB prototypes, small-batch commercial PCB fabrication | UK-owned factory, online order tracking, competitive pricing for small runs | 1-8 layers PCB, standard HASL/OSP finishes, minimum track 0.1mm | Prototype: 2-3 days, mass production: 6-9 days |

| Elvia PCB Group UK (Local Factory) | Medical PCB, high-precision PCB assembly for healthcare devices | ISO 13485 certified, Class 8 cleanroom assembly, medical regulatory compliance | 1-24 layers PCB, HDI boards, biocompatible surface finishes | Prototype: 5-7 days, mass production: 9-13 days |

| PCB Technology Ltd (UK) | RF PCB, high-frequency PCB manufacturing for telecom & industrial use | High-frequency material expertise (Rogers/Arlon), EMI shielding solutions, UK technical team | 1-16 layers PCB, RF boards, impedance control ¬Ī5%, high-frequency laminates | Prototype: 7-10 days, mass production: 14-20 days |

| Premier Circuits Ltd (UK) | Industrial PCB, ruggedized PCB for harsh environments | Environmental testing capabilities, UK-based production, durable design optimization | 1-18 layers PCB, thick copper boards up to 15oz, corrosion-resistant finishes | Prototype: 6-8 days, mass production: 10-16 days |

| Rapid Circuits UK | PCB fabrication, turnkey SMT/through-hole assembly services | One-stop UK solution, global component sourcing with local stock, on-time delivery guarantee | 1-12 layers PCB, through-hole & SMT assembly, functional testing | Prototype: 3-4 days, mass production: 7-11 days |

| Ellington Electronics Technology Group (UK) | Printed circuit boards, custom PCB fabrication for automotive | IATF 16949 certified, automotive industry expertise, UK quality audit | 1-16 layers PCB, heat-resistant materials, lead-free HASL finishes | Prototype: 6-8 days, mass production: 12-15 days |

| PFC Flexible Circuits Limited (UK) | Flexible PCB, FPC assembly, custom flexible circuit packaging | UK flexible circuit specialist, ISO 9001 certified, small-to-medium batch capacity | 1-8 layers flexible PCB, minimum track 0.1mm, adhesive bonding solutions | Prototype: 5-7 days, mass production: 9-14 days |

Types of PCB Manufacturing Services in UK

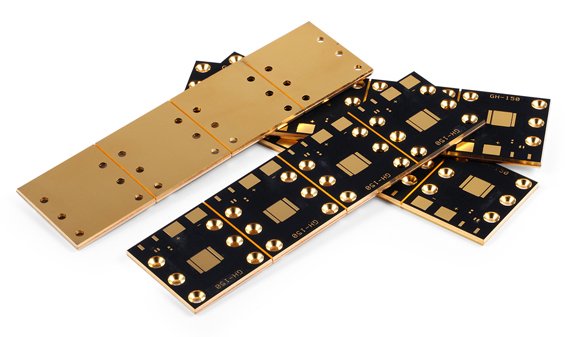

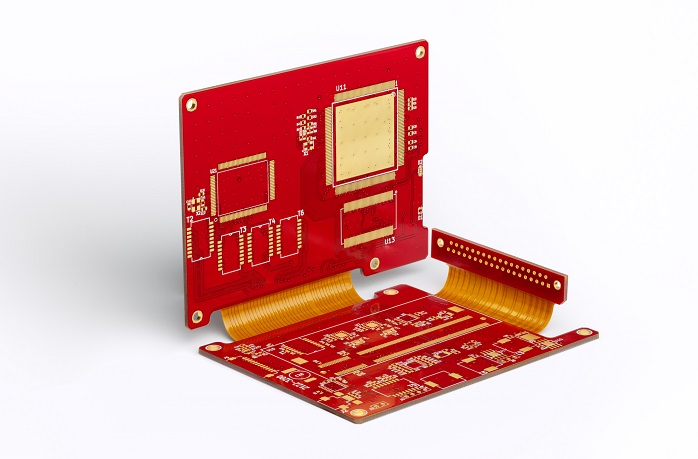

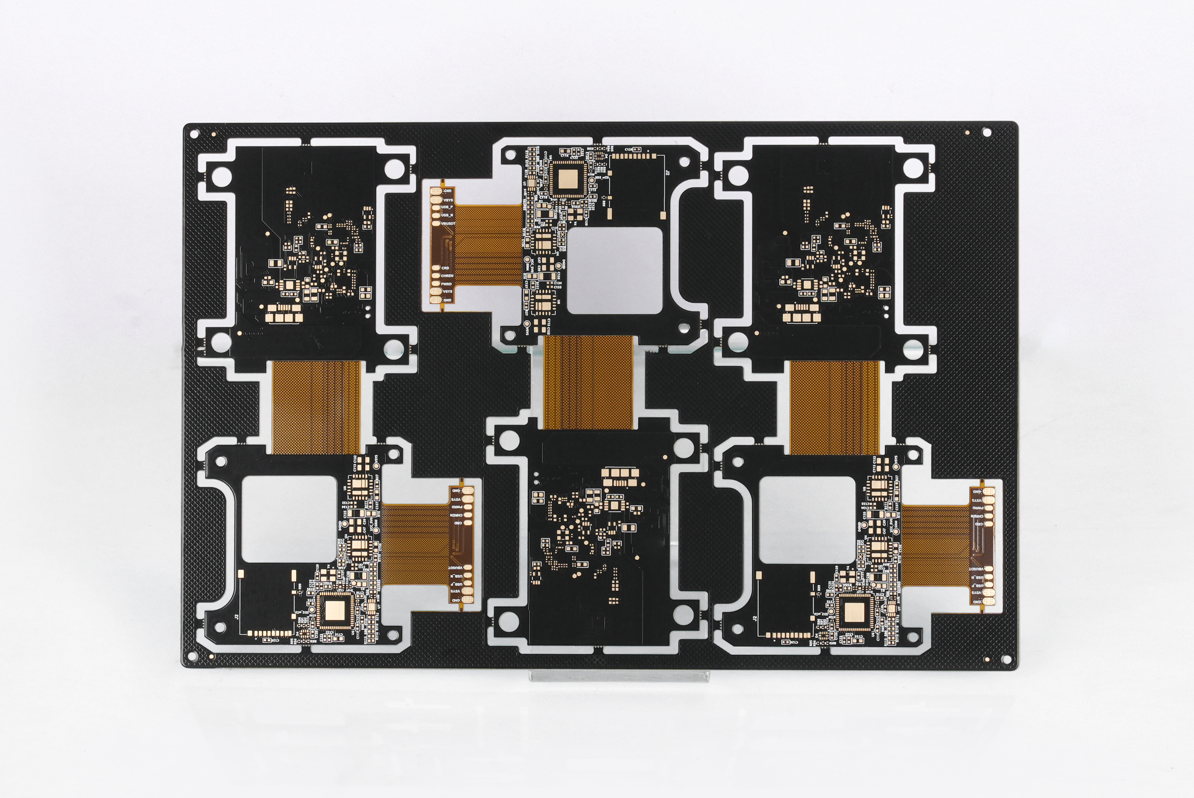

- Custom PCB Fabrication: Tailored to specific dimensions, layer counts and material requirements, covering rigid, flexible and rigid-flex PCBs for diverse industries.

- Quick-Turn Prototyping: Fast prototype production with 24-48 hour lead times for urgent projects, supporting design validation and iteration.

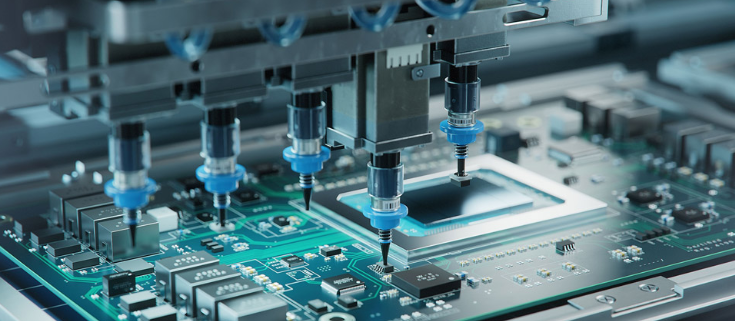

- PCB Assembly Services: Comprehensive SMT and through-hole assembly, including component sourcing, soldering and functional testing.

- High-Precision PCB Production: Specialized in HDI boards, RF boards and high-frequency PCBs with tight tolerance control for advanced applications.

- Turnkey Solutions: End-to-end services from design review, fabrication and assembly to final testing and packaging, simplifying project management.

What Quality Certifications Should PCB Manufacturer in UK Hold?

- UKCA Certification: Mandatory for placing PCBs on the UK market, covering EMC and LVD compliance with technical documentation and conformity declaration.‚Äč

- ISO 9001: Quality management system certification, ensuring consistent production processes and product reliability.‚Äč

- RoHS Compliance: Restricts hazardous substances in PCBs, mandatory for electronic products sold in the UK and EU.‚Äč

- IATF 16949: Required for automotive PCB manufacturers, aligning with automotive industry quality standards.‚Äč

- ISO 13485: Mandatory for medical PCB production, ensuring compliance with medical device regulations.

How to Evaluate the Technical Capability of PCB Manufacturer in UK?

Evaluated Methods to Technical Capability of PCB Manufacturer in UK:

- Verify maximum layer count: up to 32 layers for mainstream, 40 layers for high-end and minimum track/gap, standard precision reaches 0.05mm, while advanced processes achieve 0.038mm (1.5mil) for high-end AI and server PCBs.‚Äč

- Assess surface finishes (immersion gold, OSP, HASL) and material range: high-frequency applications require materials with Dk‚ȧ0.02 and Df‚ȧ0.004, such as Rogers and Arlon laminates, for stable signal transmission.‚Äč

- Review impedance control accuracy: 5% tolerance for general RF PCBs, and ¬Ī3% for high-speed PCBs (‚Č•10Gbps), verified by TDR impedance testers for consistency.‚Äč

- Check blind/buried via capabilities: laser-drilled micro blind hole down to 0.05mm, mechanical drilling minimum 0.1mm, supporting up to 4-layer HDI boards for dense packaging needs.‚Äč

- Evaluate quality control processes: 100% AOI testing coverage, X-Ray for inner layers, and CPK‚Č•1.33 (corresponding to 63PPM defect rate) to meet automotive and medical industry standards.‚Äč

- Inquire about R&D investment: (3%-5% of revenue is industry benchmark) and patent portfolio, 5+ core process patents indicate strong innovation capacity in advanced manufacturing.‚Äč

- Request sample testing per IPC-A-600J standards: verifying dimensional accuracy (¬Ī0.02mm) and thermal stability (-40‚ĄÉ to 125‚ĄÉ cyclic testing for 500 times).

How to Evaluate the Lead Time of PCB Manufacturing Companies in UK?

Evaluated Methods to Lead Time of PCB Manufacturing Companies in UK:

- Verify prototype lead time differentiation: The fastest PCB manufacturer in UK delivers standard prototypes in 24-48 hours, while local mainstream factories take 3-7 days for specialized prototypes (e.g., flexible or high-frequency boards).‚Äč

- Validate mass production cycle matching: 1-8 layer PCBs should have a 3-7 day turnaround, 10-20 layer complex boards 7-14 days, and confirm if layer count or surface finish (e.g., immersion gold) extends cycles by 1-2 days.‚Äč

- Check order tracking efficiency: Confirm availability of real-time digital tracking systems, with automatic notifications for key nodes (material in-stock, production start/finish) and delay alerts sent within 4 hours of identification.‚Äč

- Clarify rush order terms: Ask about 24-hour expedited service scope, additional costs (usually 15%-30% of standard pricing), and whether quality inspections remain uncompromised for urgent batches.‚Äč

- Assess supply chain resilience: Verify backup material suppliers (minimum 2 local/ European alternatives for core laminates) and average response time to component shortages (target ‚ȧ2 days).‚Äč

- Audit historical on-time delivery rate: Require data from the past 6 months, with a benchmark of ‚Č•95% for reliable scheduling, top PCB manufacturers in UK typically maintain this or higher.

How to Choose the Right UK PCB Manufacturer?

Selection Guide to UK PCB Manufacturer:

- Prioritize UK PCB manufacturers with an on-time delivery rate of ‚Č•98%: Verified through actual delivery data over the past six months, not just customer recommendations. Each day of delay increases project costs by an average of 3%, so choose suppliers with delay warning mechanisms for proactive risk control.

- Select suppliers with a defect rate ‚ȧ100 PPM (equivalent to 0.01%): And require 100% AOI + X-ray dual inspection. Ensure a process capability index Cmk ‚Č• 1.33, corresponding to a 4ŌÉ process level, to minimize rework losses.

- Choose UK PCB manufacturers holding industry-specific mandatory certifications: Automotive projects require IATF 16949 certification, medical applications require ISO 13485 + Class 8 cleanroom certification, and all products must comply with UKCA + RoHS standards and provide complete traceability documentation.

- Evaluate technical compatibility: Aim for a match of ‚Č•95% with core parameters (number of layers, line width/spacing, impedance tolerance). Confirm compliance with IPC standards and support for special materials (e.g., Rogers laminates for high-frequency applications).

- Select manufacturers offering 24/7 technical support: Require an initial response within 1 hour and a solution within 4 hours. This can reduce troubleshooting time by an average of 30%, avoiding production bottlenecks.

- Compare total cost of ownership (TCO) rather than unit price: Hidden costs (testing, rework, material waste) account for 5%-8% of TCO; prioritize suppliers with transparent pricing, including a detailed breakdown of copper clad laminate (accounting for 27.31% of PCB cost) and copper foil costs.

Pain Points of PCB Manufacturing Companies in UK

- Small-batch prototype costs are 3-5 times higher than mass production, and quick-turn prototyping trades speed for precision, raising defect rates and disrupting validation.‚Äč

- 10-15% delivery delays from copper-clad laminate shortages; 20% YoY copper foil price hikes force budget changes, with PCB manufacturers in UK struggling to maintain stable pricing.‚Äč

- Design-manufacturing mismatch causes repeated revisions and delays; few UK PCB manufacturer have capabilities to adapt to advanced technologies.

- Component lead times exceed 50 weeks in some cases; high-density assemblies have 2-3% rework rates due to inconsistent soldering, adding costs and delays.‚Äč

- Lack of real-time design-manufacturing data sync leads to last-minute adjustments, common with in experienced PCB manufacturing companies in UK.

Future Challenges for UK PCB Manufacturer

- Escalating raw material costs and supply chain volatility: London Metal Exchange (LME) copper prices have surged nearly 40% since early 2025, while copper foil makers raised prices by 5%-10% and copper-clad laminate manufacturers by 8%-10% in late 2025, squeezing profit margins of PCB manufacturers in UK.‚Äč

- Adapting to advanced packaging technologies: Requires new laser drilling and inspection equipment, with single-unit equipment investment accounting for 15%-20% of annual revenue, and technical thresholds such as line width tolerance tightened from 0.05mm to 0.03mm.‚Äč

- Stricter environmental regulations: The UK‚Äôs Industrial Decarbonization Strategy mandates a minimum 2/3 reduction in industrial emissions by 2035 and 90% by 2050, alongside PAS 2050 carbon footprint standards, forcing UK PCB manufacturer to upgrade low-carbon processes.‚Äč

- Intense global competition from Asian manufacturers: Asian firms hold over 85% of the global PCB market share, with production costs 18%-25% lower than UK counterparts, pressuring local PCB manufacturing companies in UK to cut prices and compressing profit margins by 5%-8%.‚Äč

- Skill shortages in high-precision manufacturing: The UK high-precision PCB sector faces a 12% job vacancy rate, with specialized technical roles taking 3-6 months to fill, limiting annual production capacity expansion to less than 4%.‚Äč

- Rapidly evolving industry standards: IPC standards undergo at least 1 major update annually, requiring PCB manufacturers in UK to invest 2%-3% of revenue in certification updates and process adjustments to maintain compliance.

FAQs of UK PCB Manufacturing

Q1: How to resolve solder joint discoloration and weakness during production?

A1: Caused by contaminated solder or excessive temperature. We use 99.99% high-purity tin solder and ¬Ī2‚ĄÉ precision temperature control, reducing discoloration rate to <0.5% with FMEA-optimized preheating parameters.‚Äč

Q2: Why do open circuits occur in multi-layer PCBs and how to prevent them? ‚Äč

A2: Result from poor layer alignment or trace damage. Our ¬Ī0.01mm laser alignment and 100% post-lamination AOI testing achieve 99.99% alignment success, eliminating open circuit risks.‚Äč

Q3: How to handle impedance mismatch in high-frequency UK PCB manufacturing? ‚Äč

A3: Arises from material/trace issues. We adopt Rogers 4350 laminates and impedance simulation, controlling trace width/spacing for ¬Ī3% accuracy, meeting high-frequency application needs.‚Äč

Q4: What causes copper bubbles in electroplating and how to solve it? ‚Äč

A4: Triggered by contamination or improper pretreatment. Our closed-loop plating and 3-stage pretreatment (cleaning, micro-etching, activation) reduce defects to near zero, with 100% post-plating inspection.‚Äč

Q5: How to shorten prototype lead times without compromising quality? ‚Äč

A5: As the fastest PCB manufacturer in UK, we use automated lines and stock 80% common materials. Our 24-hour service cuts lead times by 50% via parallel testing, maintaining ISO standards.