Star MCPCB is a reliable solution for LED lighting systems that require consistent thermal management and high brightness. When developing LED prototypes, using a well-designed MCPCB star board helps ensure steady performance and longer lifespan. However, finding a dependable supplier for small batches often challenges engineers and buyers alike. At EBest Circuit (Best Technology), we provide fast, quality service to help customers overcome this issue, improving both inquiry efficiency and product outcomes.

EBest Circuit (Best Technology) is a Chinese Star MCPCB Manufacturer, providing DFM analysis, prototype, fabrication, SMT assembly, and box build service. Rigorous quality control system, rich design and manufacturing experience, sophisticated equipment and technology, quick response, and short lead times really puts a competitive edge to us over the average metal core manufacturers. Our factory supports multiple materials and the customized sizes that meet a variety of LED application needs. Just connect with us at sales@bestpcbs.com for comprehensive solutions.

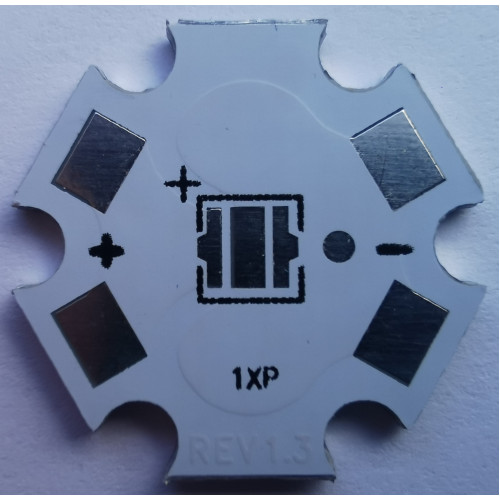

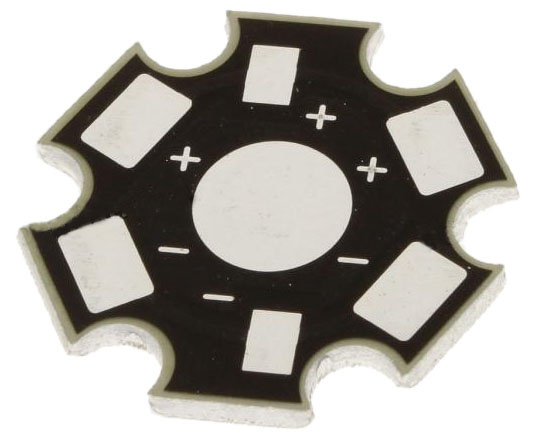

What is a Star MCPCB?

Star MCPCB refers to a metal core PCB shaped like a star or hexagon, typically used in LED lighting. It consists of a copper layer for circuitry, a dielectric for insulation, and a metal base (usually aluminum) for heat dissipation. These boards help LEDs maintain brightness while managing heat effectively. They are small, lightweight, and ideal for use in compact lighting assemblies.

What is the Material of Standard Star MCPCB?

Most standard star MCPCBs use aluminum as the base material because it is both cost-effective and efficient in conducting heat. The circuit layer uses copper, often 1oz or 2oz thickness. Between these layers is a thermally conductive dielectric, which enables fast heat transfer while ensuring insulation. These materials combine to form a durable, high-performance board for LED applications. At EBest Circuit (Best Technology), we use only RoHS-compliant materials, which are safe and environmentally friendly.

What are the Star MCPCB Dimensions?

Star MCPCB dimensions vary based on LED type and application. Standard sizes include 20mm, 16mm, and 12mm in diameter, with thickness typically around 1.0mm to 1.6mm. Custom shapes and sizes are also available. Our engineers support flexible design options to match specific customer needs. Importantly, tight tolerance is kept to maintain performance and ease of assembly.

How to Do the MCPCB Design?

MCPCB design begins with selecting the proper LED footprint. For star MCPCBs, this often includes layouts for 1W, 3W, or 5W LEDs. Designers need to focus on pad spacing, thermal paths, and hole placement. Clearances should match LED manufacturer guidelines. EBest Circuit (Best Technology) supports customers with DFM (Design for Manufacturing) checks, which help identify design risks before production. This reduces delays and avoids costly revisions.

What Are the Manufacturing Processes of the MCPCB LED Star?

Producing an MCPCB LED star involves several steps:

- Copper Clad Laminate Cutting: Sheets are cut to size based on the required star shape.

- Drilling: Holes for LED placement or mounting are drilled using precise tools.

- Imaging: Circuit patterns are printed using photoresist methods.

- Etching: Unwanted copper is removed to form the correct traces.

- Dielectric Application: A thermal dielectric is layered for insulation.

- Solder Mask and Surface Finish: These protect copper and improve solderability.

- Routing and Final Shaping: Boards are cut into star shapes, and edges are cleaned.

Our advanced equipment ensures repeatable, accurate production even for small batches.

What is the Quality Inspection Process During LED Star MCPCB Manufacturing?

Quality is critical. At EBest Circuit (Best Technology), we perform the following checks during production:

- Incoming Material Inspection: All raw materials are verified for conformity.

- In-process Checks: Imaging, etching, and drilling are monitored for defects.

- AOI (Automated Optical Inspection): Circuit accuracy is checked against design files.

- Dielectric Strength Testing: Insulation is tested under voltage to prevent failures.

- Final Inspection: Visual and mechanical checks ensure correct dimensions and finish.

Customers often worry about receiving inconsistent quality in prototypes. Our strict process and MES system (Manufacturing Execution System) help maintain traceability and consistency from start to finish.

What Are the Applications of the MCPCB Star Board?

MCPCB star boards are widely used in LED lighting, including:

- LED flashlights

- Spotlights

- Automotive lighting

- Decorative lighting

- Medical devices

They support both high and low-power LEDs. Due to the star shape, they are easy to mount onto heat sinks, which helps extend LED life. Our customers in Europe and the US often request customized designs for unique lighting projects, and our fast prototyping service helps them meet tight deadlines.

Where to Get MCPCB Star Board?

Choosing a dependable supplier for MCPCB star boards can greatly improve project outcomes. At EBest Circuit (Best Technology), we understand the value of both time and budget. That‚Äôs why we provide reliable support at every stage‚ÄĒfrom design to final delivery.

1. Full-Service Support from Start to Finish

- We assist with design, material selection, and layout optimization.

- Fast and accurate quotations help you plan your costs easily.

- Rapid prototyping ensures you meet tight deadlines without stress.

2. Quick and Responsive Communication

- We reply to all inquiries promptly.

- Our engineering team offers practical solutions for your specific needs.

- You will always know the status of your order.

3. Solving Common Customer Pain Points

- Delay: We shorten lead times with efficient processes.

- Poor Communication: We keep you informed at every step.

- Inconsistent Quality: Strict quality checks ensure reliable boards every time.

4. Certified Quality You Can Trust

- ISO 9001, ISO 13485, IATF 16949, and AS9100D certifications show our commitment to world-class manufacturing.

5. Consistent Quality for Every Order

- Whether it’s a standard star MCPCB or a custom board, we deliver on time.

- Quality is consistent, even for low-volume or prototype batches.

All in all, star MCPCB plays a key role in LED lighting. From efficient heat management to ease of installation, it supports reliable performance in various applications. However, sourcing quality boards quickly remains a challenge. EBest Circuit (Best Technology) helps customers overcome this by offering fast, reliable prototyping and production services. Our team’s experience, combined with strict quality control and responsive communication, helps customers improve project outcomes and reduce risks. Contact EBest Circuit (Best Technology) at sales@bestpcbs.com for better star MCPCB solutions and experience dependable support from design to delivery.