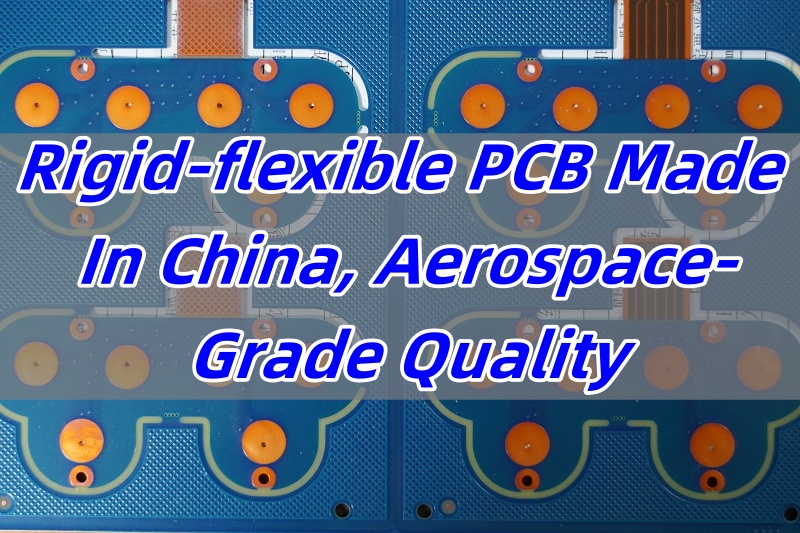

Rigid-flexible PCB made in China¬†is becoming the first choice for engineers in aerospace and high-end applications. Why? Because the demand for reliable, compact, and high-performance boards continues to grow. Whether you’re designing satellites, drones, or aircraft systems, selecting the right rigid-flex PCB supplier is critical.

EBest Circuit (Best Technology) provides aerospace-grade rigid-flexible PCB manufacturing in China. Low volume, turnkey solutions, reliable quality, and quick delivery are our marketing positioning. We offer prototype, fabrication, and PCBA services for 2L, 3L, or 4L Rigid-Flex PCBs, as well as multilayer rigid-flex PCBs. A warm welcome to contact us via sales@bestpcbs.com for specific rigid-flex circuit solutions tailored to various applications.

What Is the Best Manufacturer of Rigid-flexible PCB Made in China?

Finding a dependable rigid-flexible PCB manufacturer in China is not easy. Many suppliers offer rigid-flexible PCB services, but only a few deliver aerospace-grade quality. EBest Circuit (Best Technology) stands out as one of the top PCB manufacturers in China due to its precision process control, advanced MES tracking, and deep engineering support. We strictly follow ISO9001, ISO13485, IATF16949, and AS9100D standards. Our team understands the real concerns of aerospace clients and builds boards with strict quality compliance.

Rigid Flexible PCB Made in China Manufacturers

When sourcing rigid flexible PCB made in China, it’s important to work with manufacturers who understand the complexity of flex-rigid designs and can deliver consistent quality. While many factories offer flex PCB services, only a few truly meet the demands of high-reliability industries such as aerospace, medical, and automotive. Below are three trusted manufacturers known for their experience, process control, and customer support.

1. EBest Circuit (Best Technology) Co., Limited

EBest Circuit (Best Technology) is widely recognized among the top PCB manufacturers in China, especially for aerospace-grade rigid-flex PCBs. We offer end-to-end support‚ÄĒfrom design review to manufacturing‚ÄĒand are certified with ISO 9001, ISO 13485, IATF 16949, and AS9100D. Our MES system ensures full traceability, and we‚Äôre known for handling complex builds with precision. Our DFM support and ability to handle fast turn rigid-flex PCB orders make us a preferred choice for critical applications.

2. Sun & Lynn Circuits

Sun & Lynn is a veteran PCB supplier established in 2002, with strong capabilities in multilayer, HDI, and rigid-flex PCB manufacturing. With UL and ISO certifications and a focus on North American and European markets, they have earned trust through stable quality and technical support. They serve medical, telecom, and aerospace clients with medium to large volume needs.

3. Victory Giant Technology (VGT)

Victory Giant is one of China’s leading public PCB manufacturers. While best known for large-volume rigid board production, their advanced facilities also support flex and rigid-flex production. They invest heavily in automation, material quality control, and environmental systems. VGT is ideal for companies looking to scale up from prototype to mass production with reliable output.

Choosing the right rigid-flex PCB manufacturer in China means balancing technical capability, quality control, and supply chain reliability. There are many rigid-flex PCB manufacturers across China. However, very few can manage the complexity of aerospace projects. At EBest Circuit (Best Technology), we combine innovation and proven processes to deliver rigid-flex PCB assembly with higher stability and longer service life. From DFM checks to final testing, we support clients at every step.

Are Rigid-Flexible PCB Made in China Reliable?

Reliability depends on both design and execution. While some factories cut corners to lower cost, EBest Circuit (Best Technology) takes another path. We use¬†advanced materials¬†that are tested for high temperature, humidity, and vibration. Each board undergoes thorough inspection to meet the demands of space, aviation, and medical industry. Clients working in these industries trust us not only because of what we promise‚ÄĒbut because of what we deliver.

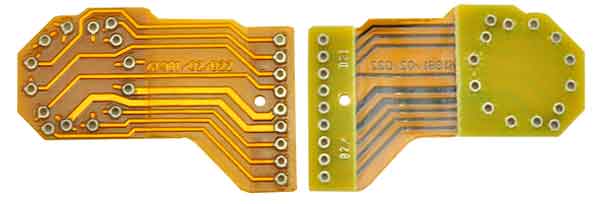

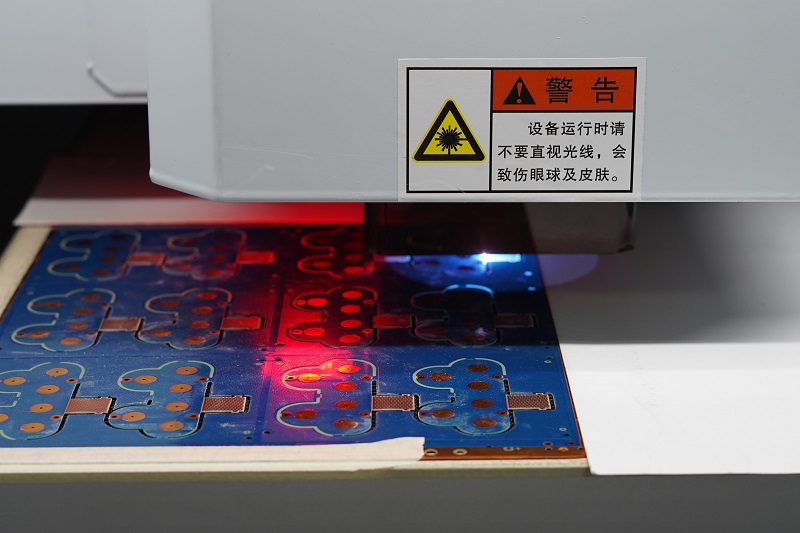

How Are Rigid Flex PCB Manufacturing Process?

The rigid flex PCB manufacturing process includes several precise steps. It begins with material prep, imaging, etching, lamination, and continues to drilling and plating. Then, flexible layers are combined with rigid parts using heat and pressure. All this must happen in a clean and controlled space. Our engineers pay close attention to tolerances, layer alignment, and adhesive bonding strength. This results in boards that resist bending fatigue and electrical failure.

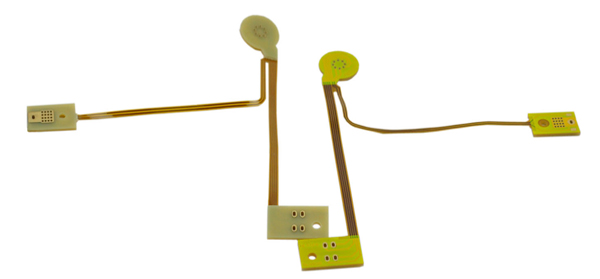

What Materials Are Used in a Rigid Flex PCB?

Choosing the right materials is critical. Common materials include polyimide for flexible layers and FR4 or PI-reinforced materials for rigid zones. But material compatibility and reliability matter more in aerospace. That’s why EBest Circuit (Best Technology) only sources from trusted suppliers like Shengyi, DuPont, and Panasonic. Our team also provides guidance on layer stackups to avoid warping and ensure stability across environments.

How Much Does Rigid-Flexible PCB Made in China Cost?

The¬†rigid-flexible PCB made in China cost¬†varies based on layer count, board size, material grade, and testing requirements. A standard 4-layer rigid-flex PCB may cost more than a traditional rigid board, but the benefits‚ÄĒspace savings, durability, and signal reliability‚ÄĒfar outweigh the difference. At EBest Circuit (Best Technology), we offer competitive pricing without sacrificing quality. Our engineers help optimize your design to reduce material waste and processing time.

How Do I Find the Best Manufacturer of Rigid-Flexible PCB Made in China?

Start by asking the right questions. Do they follow industry standards? Do they provide engineering support during prototyping? Can they share similar case studies in aerospace or medical? EBest Circuit (Best Technology) checks all the boxes. With fast turn rigid flex PCB capabilities, complete traceability via MES, and deep DFX insights, we support you from idea to volume production. Plus, we understand your pain points:

- Material Compatibility: We pre-screen materials to ensure thermal and mechanical match.

- Complex Process: Our refined steps and automation reduce defects.

- Design Flaws: Our experts catch layout issues before fabrication.

- EMI Problems: We optimize signal paths to minimize interference.

- Thermal Weakness: We implement smart copper balancing and heat spreading methods.

In conclusion, rigid-flexible PCB made in China¬†is no longer a low-cost alternative. It is now a reliable, smart choice for engineers building the future of aerospace, medical. At EBest Circuit (Best Technology), we provide more than just manufacturing‚ÄĒwe bring technical confidence, clear communication, and tailored solutions to your table. Choose a partner who understands your challenges. Choose a team that meets the standard every time.

Ready to start your¬†flex PCB¬†project? Reach out to EBest Circuit (Best Technology) via sales@bestpcbs.com‚ÄĒyour trusted¬†PCB manufacturer in China.