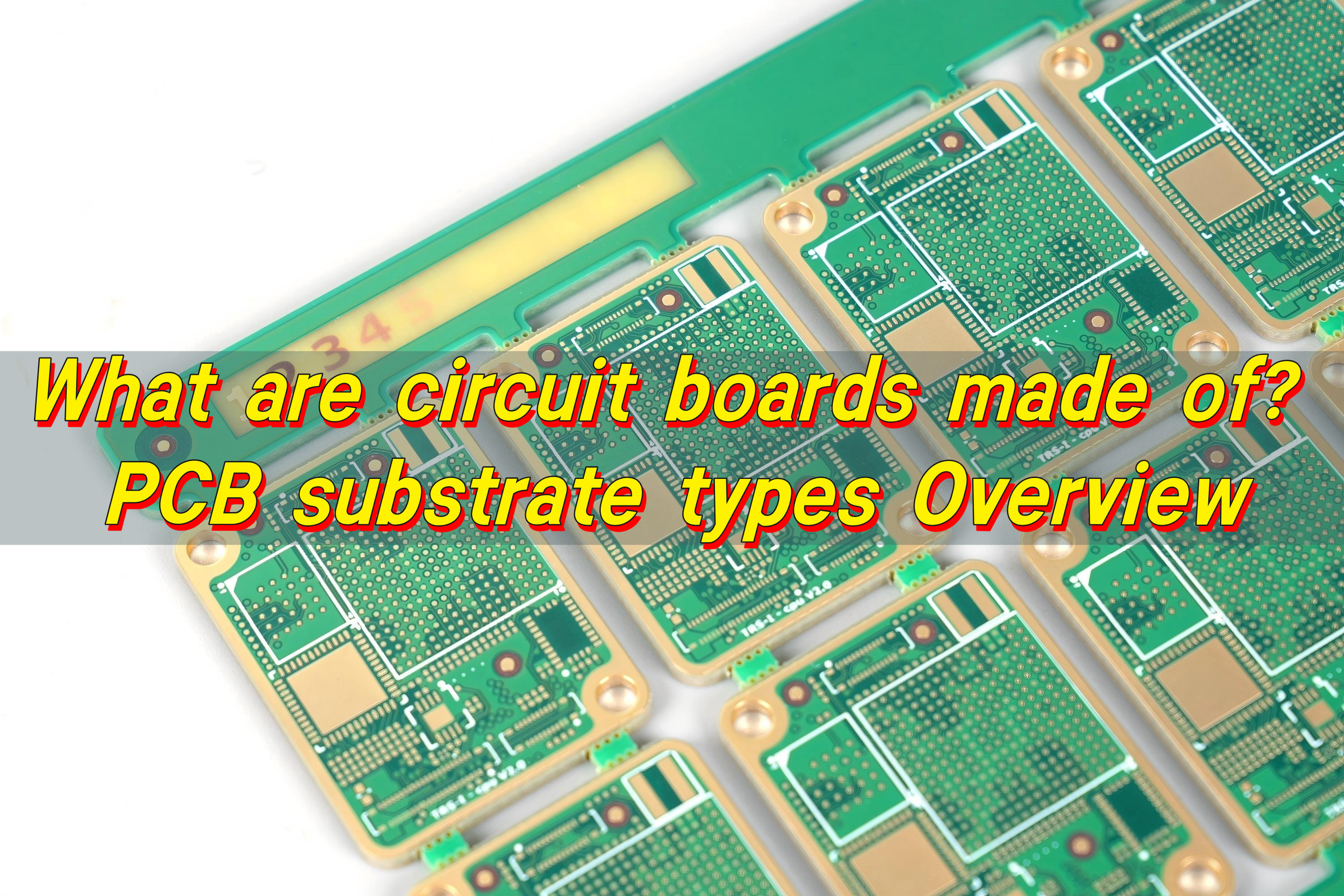

What are circuit boards made of? Are mainly made of a fiberglass epoxy substrate (FR-4) that provides strength and insulation. For special applications, flexible plastic or metal-core materials may also be used.

A thin layer of copper is bonded to the surface and etched into traces to carry electrical signals between components. On top, a solder mask (often green) protects the copper from damage and short circuits, while a silkscreen layer adds labels for assembly and testing.

What Are Printed Circuit Boards Made Of?

Printed circuit boards are made of multiple bonded layers rather than a single material. These layers work together to support electrical connections, protect conductors, and keep the board stable during manufacturing and operation.

At the core of most boards is an insulating substrate. This substrate provides the mechanical foundation of the PCB and prevents unwanted electrical conduction between copper layers. Copper foil is laminated onto this substrate to form traces, pads, and planes that carry signals and power.

Between and around these layers are resin systems that bind everything together. On the outer surfaces, protective coatings such as solder mask are applied to shield copper from oxidation and contamination. Surface finishes are then added to ensure reliable soldering during assembly.

The exact materials vary by application, but the principle remains the same. A PCB is a controlled stack of insulating, conductive, and protective materials designed to work as a single structure.

What Material Are Circuit Boards Made Of?

Circuit boards are made from a combination of insulating materials and conductive metals. No single material can meet all electrical, thermal, and mechanical requirements on its own, so PCBs rely on carefully matched material systems.

The most important insulating materials include fiberglass-reinforced epoxy, polyimide films, ceramic substrates, and metal-backed laminates. These materials prevent electrical shorts while supporting the physical structure of the board.

Copper is the primary conductive material used in circuit boards. It forms the signal traces, power planes, and ground planes that connect electronic components. Copper thickness can vary depending on current requirements and thermal needs.

Resins are used to bond layers together and control properties such as heat resistance and moisture absorption. Protective coatings, including solder mask, protect exposed copper and improve assembly reliability.

What Is the Most Common PCB Material?

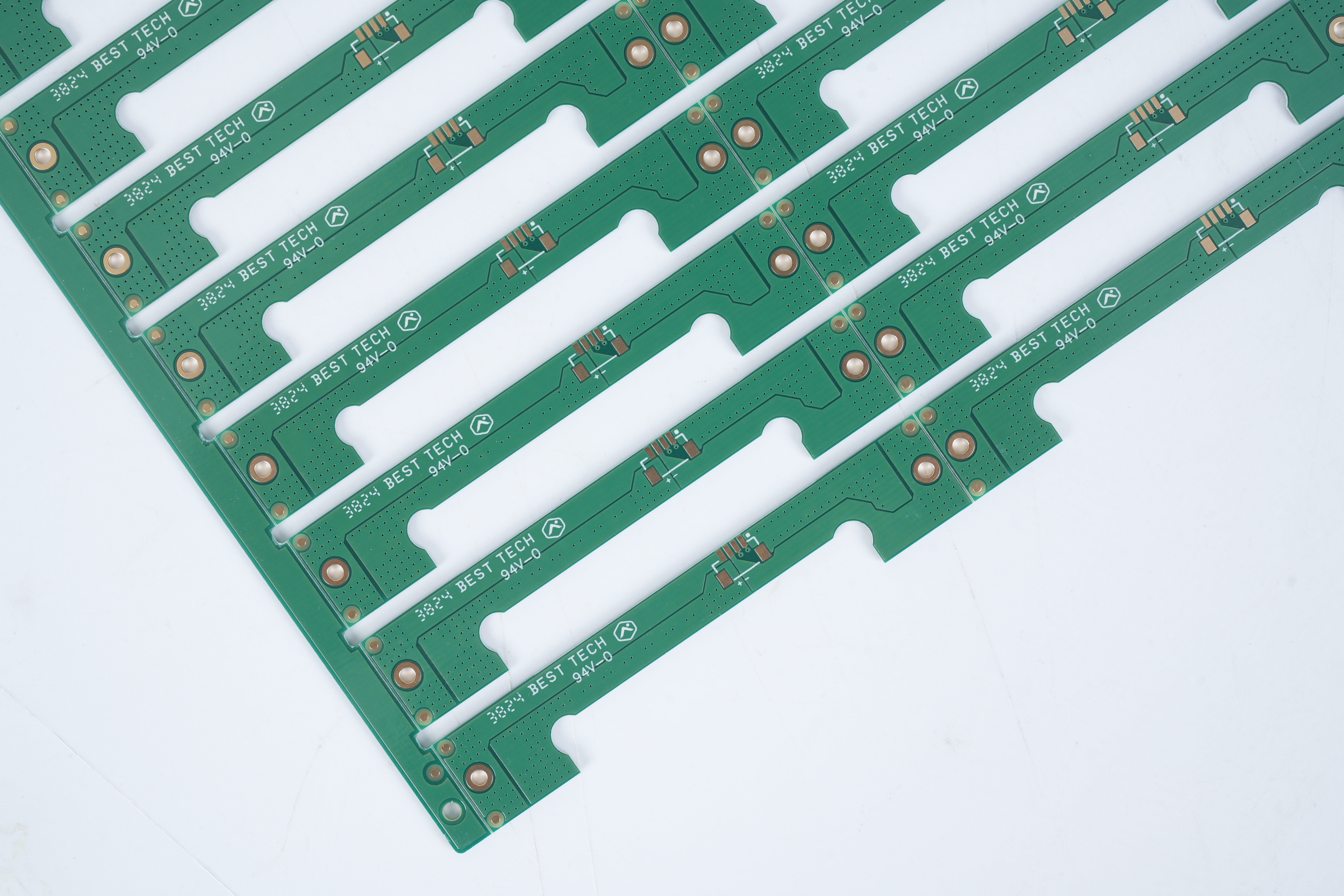

The most common PCB material used worldwide is FR4. It is the default choice for a wide range of electronic products, from consumer devices to industrial equipment and many medical systems.

FR4 is widely adopted because it offers a reliable balance between performance and cost. It provides good electrical insulation, strong mechanical stability, and sufficient heat resistance for standard lead-free soldering processes.

Another reason FR4 is so common is consistency. Supply chains for FR4 laminates are mature, making it easy to source in large volumes.

PCB Substrate FR4 Explained

FR4 is a fiberglass-reinforced epoxy laminate. The structure consists of woven glass fiber cloth impregnated with epoxy resin and cured under heat and pressure. This creates a rigid, electrically insulating material with good dimensional stability.

The fiberglass provides strength and resistance to warping. The epoxy resin binds the fibers together and provides insulation. Together, they form a substrate that can withstand mechanical stress and repeated thermal cycles.

FR4 has stable electrical properties for low to moderate frequency applications. Its dielectric constant remains relatively consistent across typical operating temperatures, which supports predictable signal behavior.

There are different grades of FR4. High-Tg FR4 offers improved heat resistance for demanding assemblies. Low-loss FR4 reduces signal attenuation in higher-speed designs. Halogen-free FR4 meets environmental compliance requirements.

Despite these variations, the core concept of PCB substrate FR4 remains the same. It is designed to be reliable, manufacturable, and cost-effective across a wide range of applications.

What Are the Different Types of Circuit Boards?

Circuit boards can be classified by their structure and substrate material. Each PCB type reflects a different material strategy.

- Rigid circuit boards are the most common type and are typically made with FR4 substrates. They provide strength and stability for fixed installations.

- Flexible circuit boards use thin, bendable substrates such as polyimide. These boards can flex and fold, making them ideal for compact devices and moving assemblies.

- Rigid-flex boards combine rigid FR4 sections with flexible interconnects. This design reduces the need for connectors and improves reliability in vibration-sensitive environments.

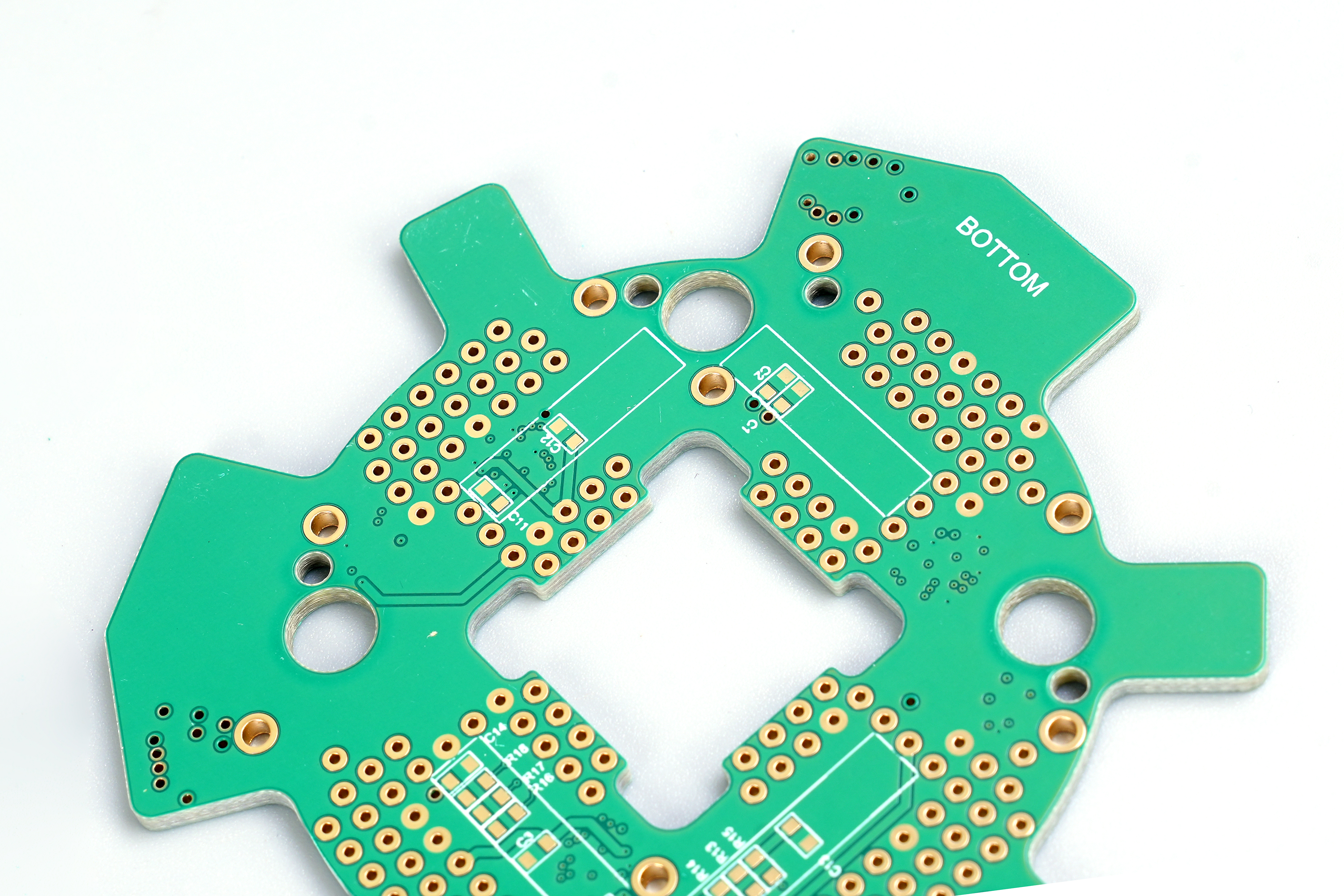

- Metal core circuit boards replace traditional fiberglass substrates with aluminum or copper bases. These boards improve heat dissipation and are widely used in LED lighting and power electronics.

- Ceramic circuit boards use materials such as alumina or aluminum nitride. They handle high temperatures and harsh environments, making them suitable for aerospace and industrial applications.

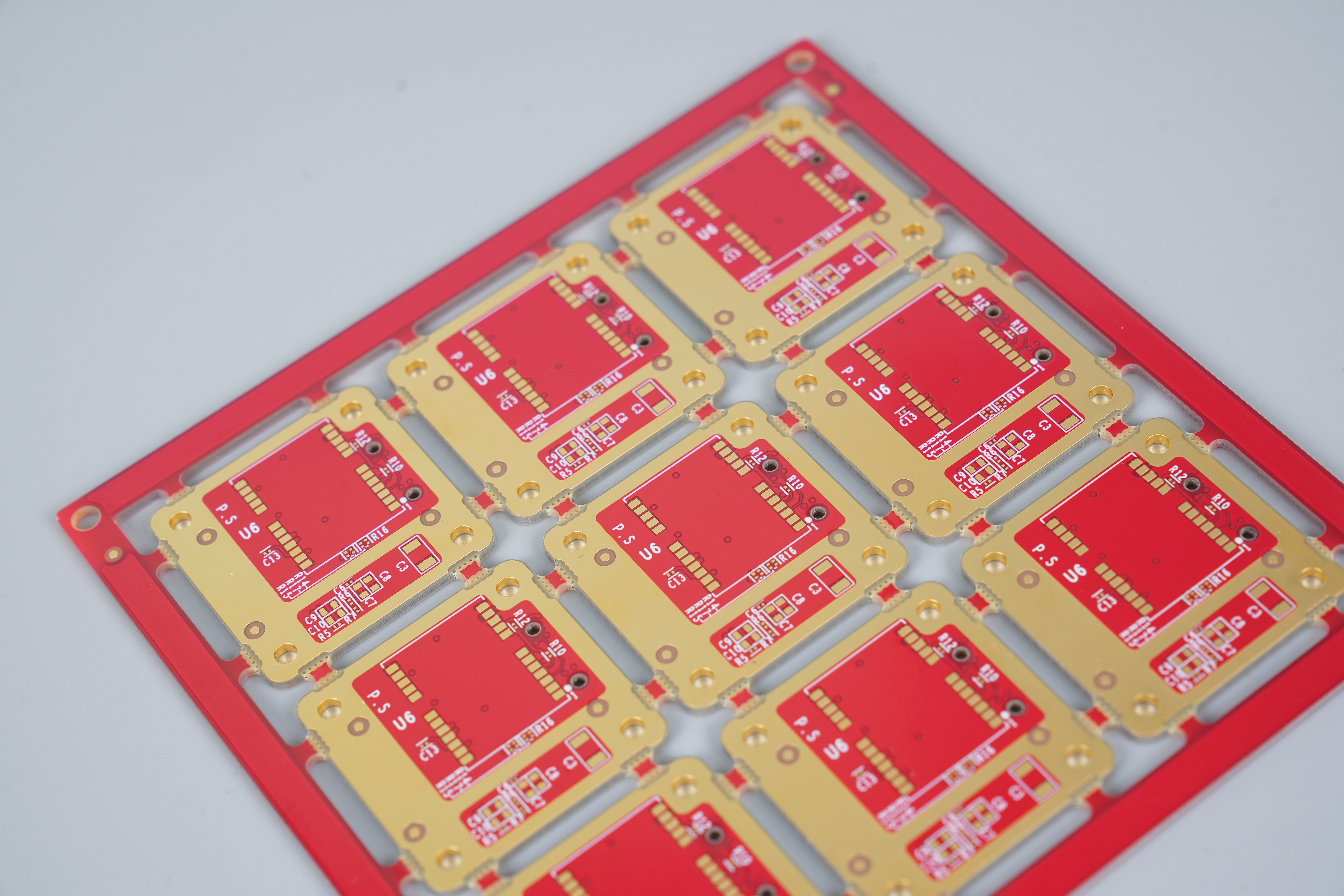

Why Are Circuit Boards Green?

Most circuit boards are green because of the solder mask applied during fabrication. The green color is not chosen for appearance alone. It provides practical benefits during manufacturing and inspection.

Green solder mask offers high contrast against copper traces and silkscreen markings. This makes visual inspection easier for operators and improves accuracy for automated optical inspection systems.

Green solder mask also has stable curing characteristics and consistent performance under heat. It has been refined over decades, making it reliable and widely available.

Although other colors are used for branding or special purposes, green remains the industry standard.

What Are Green Circuit Boards Made Of?

Green circuit boards are made of the same materials as other printed circuit boards. The green color comes solely from the solder mask layer applied to the outer surfaces.

Beneath the green solder mask, the board typically consists of an FR4 or similar insulating substrate, copper conductors, and resin systems that bond the layers together. The solder mask covers copper areas that should not be soldered and leaves openings where components are attached.

The green pigment does not change electrical or thermal performance. Its function is protective and visual rather than structural.

So when asking what are green circuit boards made of, the correct explanation is that they are standard PCBs with a green protective coating on top.

What Is the Purpose of the Solder Mask on a Circuit Board?

The solder mask serves several critical functions on a printed circuit board. Its primary purpose is to prevent solder from flowing onto unwanted areas during assembly.

By insulating exposed copper traces, the solder mask reduces the risk of solder bridges, especially in dense layouts with fine-pitch components. This directly improves assembly yield and reduces rework.

The solder mask also protects copper from oxidation, moisture, and chemical exposure. This protection extends the life of the PCB and improves long-term reliability.

In addition, solder mask openings define where solder paste should be applied. This helps control solder joint shape and consistency, which is important for mechanical strength and electrical performance.

Without solder mask, circuit boards would be far more vulnerable to defects and environmental damage. Its role is essential in modern PCB manufacturing.

Conclusion:

So, what are circuit boards made of? They are built from layered materials that include insulating substrates, copper conductors, resin systems, and protective coatings. Green circuit boards owe their color to solder mask, a layer that protects copper and improves assembly quality.

If you need support selecting PCB substrate material or evaluating PCB substrate types for your project, professional guidance can make a meaningful difference.

For technical inquiries or manufacturing support, please contact: sales@bestpcbs.com