Are you looking for best UK PCB manufacturer? This blog is mainly about how to choose, evaluate production capability and delivery time for best UK PCB manufacturer.

As a Chinese PCB manufacturer focusing on the global market over 19 years, EBest Circuit (Best Technology) are dedicated to providing cost-effective PCB solutions for our UK customers. Our core strengths enable you to find the optimal balance between cost, timeliness, and quality, making us your reliable global PCB manufacturing partner.

Are You Struggling With the Following Questions?

- Prolonged PCB prototyping lead times, with unfulfilled promises of 8-hour expedited prototyping, seriously delaying R&D progress.

- Lack of professional review for design schemes, leading to unfeasible processes only discovered during mass production and soaring rework costs.

- Opaque manufacturing processes, with no way to trace responsibilities when issues like cold solder joints and circuit offsets occur.

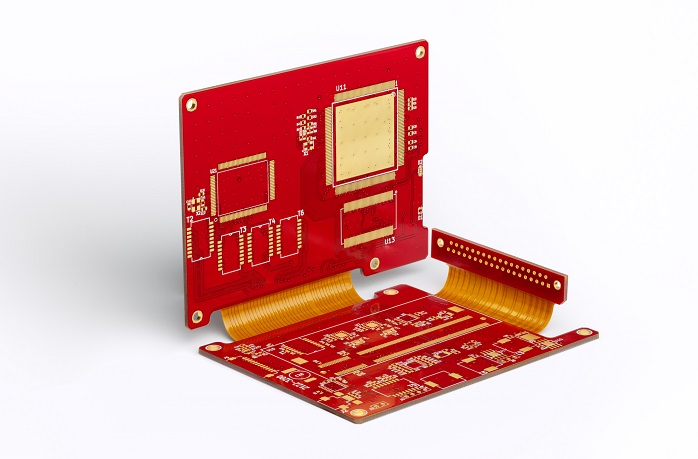

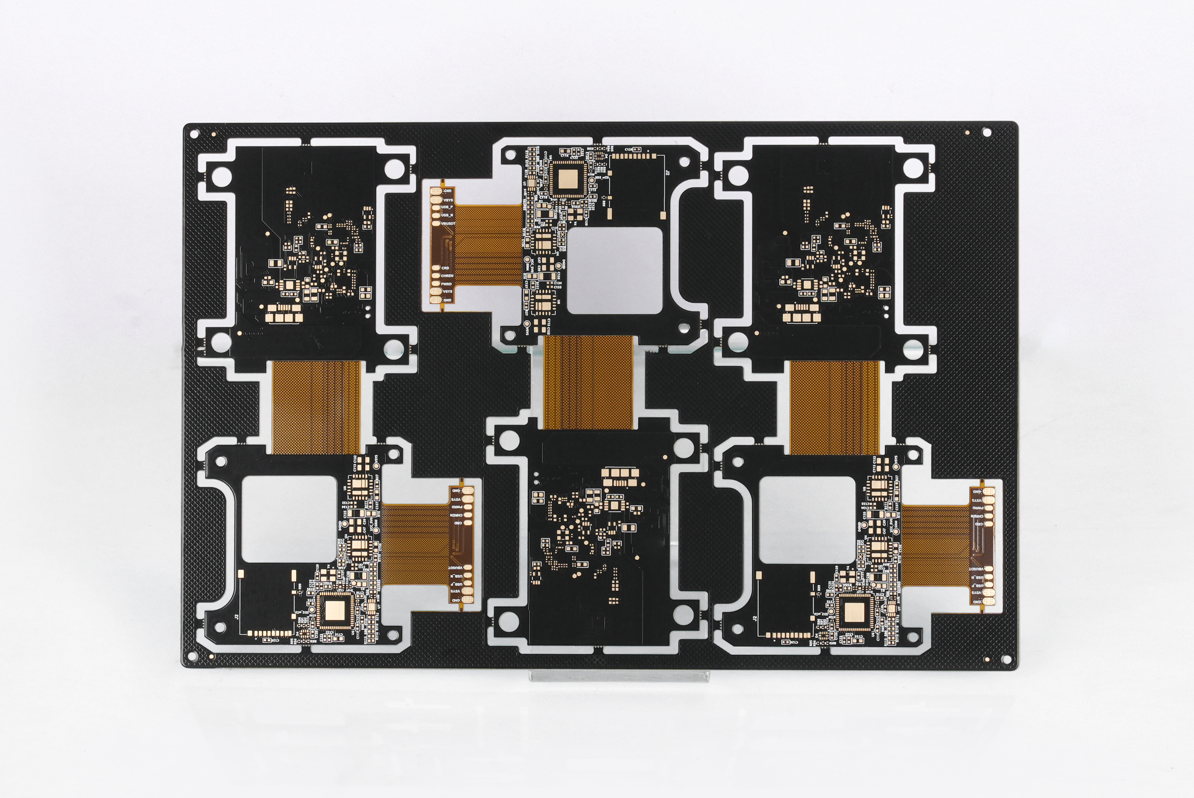

- Rejection of special process requirements, making it difficult to find contractors for customized orders such as multi-layer PCBs and flexible PCBs.

- Frequent changes in delivery times and unsubstantiated verbal commitments, forcing downstream production lines to shut down.

Our Solutions to These Questions

- Free DFM Pre-Review to Avoid Design Rework: Our engineer team completes design review within 24 hours, uses Cadence software to simulate mass production feasibility, marks issues such as circuit conflicts and impedance deviations, and provides optimization solutions, helping designers save over 30% of modification time.

- Full-Process Quality Control to Ensure Engineering Reliability: There are 16 inspection procedures from copper-clad laminate incoming inspection to finished product delivery. With triple checks including AOI optical inspection, X-ray flaw detection and ICT online testing, the defect rate is controlled within 0.2%, meeting engineers’ requirements for product stability.

- Express Delivery to Connect Production Plans: The fastest delivery time for 1-piece prototype is 8 hours, and bulk orders can be delivered to the UK within 4-7 days. Emergency orders activate the air freight green channel, which is 40% shorter than the industry average lead time, avoiding the risk of production suspension for purchasers due to delays.

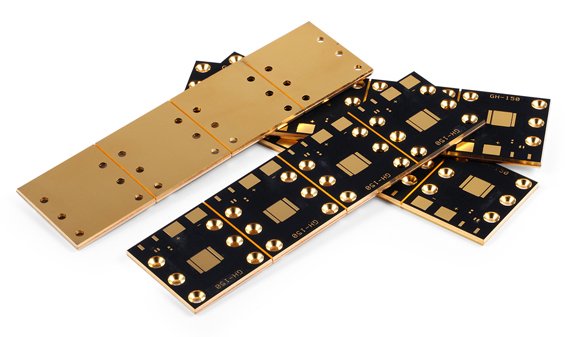

- Customized Processes to Meet Special Needs: Supporting 0.1mm fine line width and 0.2mm small aperture processing, the dielectric constant deviation of high-frequency boards is ≤±3%, and the flexible boards can withstand 100,000 bending cycles, meeting the technical requirements of engineers in high-end fields such as communications and medical care.

- Transparent Collaboration to Reduce Purchasing Communication Costs: A production schedule is provided upon order signing, key processes are fed back with real-time photos, and quality inspection reports are delivered together with goods. Purchasers do not need to follow up repeatedly and can easily control the entire process.

Why Choose EBest Circuit (Best Technology) for Global PCB Manufacturer?

- Comprehensive and Compliant Authoritative Certifications: Holding ISO13485 (medical), IATF16949 (automotive), REACH and RoHS certifications, products comply with EU CE standards, so purchasers do not need to worry about access issues.

- Transparent Pricing with No Hidden Costs: Detailed quotations are provided, listing raw material costs, processing fees, inspection fees and logistics fees one by one. There are no additional charges in the later stage, allowing purchasers to accurately calculate costs with more secure budgets.

- Strict Quality Control and Outstanding Quality: An ISO9001 quality system is established, equipped with 20 sets of imported inspection equipment. Each batch of products is accompanied by third-party inspection reports. Automotive-grade PCBs pass high and low temperature cycle tests (-40℃ to 125℃) with stable performance.

- Fast and Stable Delivery: Owning 3 major production bases with a monthly capacity of 500,000 square meters, and the stock of commonly used base materials exceeds 100 tons. A transit warehouse is set up in the UK, with a 99.8% on-time delivery rate for regular orders, and emergency orders can be prioritized.

- Free DFM Design Support: Exclusive engineers provide one-on-one communication, not only identifying design issues but also optimizing processes to reduce production costs, helping designers achieve seamless connection between design and mass production.

- Cost Advantages of Global Supply Chain: Relying on China’s PCB industrial cluster, the procurement cost of raw materials is 15% to 20% lower than that in Europe, with no middlemen markup, providing purchasers with cost-effective options.

- Flexible Adaptation to Various Orders: Supporting R&D prototyping from 1 piece to mass production of 100,000 pieces, with no minimum order threshold for small-batch orders. The process switching cost is 25% lower than that of peers, meeting the differentiated needs of start-ups and large enterprises.

- Native English-Speaking Exclusive Service: 7×24-hour English customer service response, daily updates on order progress, and solutions for quality issues provided within 24 hours, ensuring barrier-free communication for purchasers.

Best UK PCB Manufacturer List

1. Our PCB Ltd

- Core Business: PCB prototyping and small-batch production, covering industrial and consumer electronics fields

- Advantages: Rapid response for 8-hour expedited prototyping service, real-time production progress updates, and customers can check at any time through the exclusive system, especially suitable for emergency R&D projects

- Process Capability: Manufacturing of 1-24 layer high multi-layer PCBs, flexible PCBs and metal substrates, supporting impedance control and resin plugging processes, with a minimum line width of 0.15mm

- Lead Time: 8-hour delivery for expedited prototyping, 3-5 days for regular orders, and 7-10 days for bulk orders

2. EC Electronics

- Core Business: Integrated PCB manufacturing and SMT assembly services, focusing on automotive electronics and industrial control fields

- Advantages: 40 years of industry experience, 99.5% delivery rate for bulk orders, long-term cooperation with multiple UK automotive companies, and sound quality traceability system

- Process Capability: Manufacturing of blind and buried via PCBs and high-power density circuit boards, supporting the entire SMT assembly process and enabling integrated delivery of PCBs and components

- Lead Time: 10-15 days for standard orders, 20-25 days for bulk customized orders, supporting partial delivery

3. Cambridge Circuit Company Ltd

- Core Business: PCB prototype and small-batch production, serving scientific research institutions and start-ups

- Advantages: ISO9001 quality system certification, transparent quotation with no hidden costs, outstanding cost-effectiveness for small and medium-batch orders, and timely response from the technical support team

- Process Capability: Manufacturing of single and double-layer PCBs, multi-layer PCBs (up to 12 layers) and flexible PCBs, with an exclusive production line for prototypes and mature and stable processes

- Lead Time: 5 days for standard orders, 3 days for expedited orders, and R&D samples can be prioritized

4. GSPK Circuits

- Core Business: Specialized PCB manufacturing, focusing on medical equipment and aerospace fields

- Advantages: Lean Champion certified enterprise, fast response for customized solutions, rich cases of medical equipment PCBs, and compliance with strict EU medical industry standards

- Process Capability: Manufacturing of 1-24 layer PCBs, lead-free surface treatment, supporting the production of circuit boards with special materials such as ceramics and polyimide, with excellent temperature resistance and stability

- Lead Time: 7-12 days for standard orders, 15-20 days for special material orders, with expedited service available (additional fees apply)

5. Rush PCB UK Ltd

- Core Business: High-end communication PCB manufacturing, serving communication equipment manufacturers and university R&D projects

- Advantages: Focus on high-end communication fields, impedance control accuracy of ±5%, and R&D cooperation with multiple UK universities

- Process Capability: Manufacturing of high-frequency and high-speed PCBs, rigid-flex boards, supporting a minimum line width of 0.1mm and a minimum aperture of 0.2mm, with outstanding signal integrity optimization capabilities

- Lead Time: 8-10 days for regular orders, 12-15 days for high-frequency and high-speed PCB orders, and 5-7 days for R&D samples

How to Choose a Reliable UK PCB Manufacturer?

A detailed selection guide to UK PCB manufacturer:

1. Verify the Authenticity of Qualification Documents

- Prioritize manufacturers holding authoritative certifications such as ISO9001 (basic quality), IATF16949 (automotive), and ISO13485 (medical). Request original certification documents for verification to avoid the risk of forged qualifications and ensure compliance with quality systems.

2. Conduct In-Depth Inspection of Production Entities

- Confirm whether they have their own factories and core production equipment (such as fully automated drilling machines and AOI inspection equipment) through online videos or on-site visits. Clarify whether the production links are outsourced to avoid choosing trading enterprises that only act as intermediaries and ensure production controllability.

3. Comprehensively Evaluate Technical Capabilities

- Gain a detailed understanding of their production experience in special processes such as multi-layer PCBs, flexible PCBs, and high-frequency and high-speed PCBs. Request 3-5 successful cases in similar industries and corresponding test reports to determine whether the technology matches the needs of your own projects.

4. Strictly Verify Delivery Capabilities

- Inquire about the on-time delivery rate data of the past 12 months, request an explanation of exclusive response plans for emergency orders (such as standby production lines and priority scheduling mechanisms), and clarify compensation clauses for delays to avoid affecting the progress of your own projects.

5. Focus on Value-Added Service Details

- Confirm whether free value-added services such as DFM design review and PCB performance optimization suggestions are provided. Understand the after-sales response process, including whether there is 7×24-hour customer service and how soon solutions can be provided after quality issues are reported, to ensure a full-process service experience.

6. Rationally Analyze Cost Structure

- Request detailed quotation breakdowns (raw materials, processing fees, inspection fees, etc.), compare the cost structures of different manufacturers, remain vigilant against the trap of “low-price attraction plus later price increases”, and focus on the cost-effectiveness of quality and price rather than simply pursuing low prices.

7. Conduct Multi-Channel Research on Customer Reputation

- Understand the market reputation of manufacturers through channels such as the UK Electronics Industry Association and professional forums. Prioritize manufacturers with service experience in similar industries. If necessary, contact their existing customers to obtain real cooperation feedback and reduce cooperation risks.

8. Confirm Supply Chain Stability

- Inquire about the supplier list and inventory cycle of core raw materials (such as copper-clad laminates and copper foil). Understand the response measures in the face of raw material price fluctuations or supply chain disruptions to ensure that orders will not be suspended due to material issues.

9. Clarify Intellectual Property Protection

- Include intellectual property protection clauses in the formal cooperation contract. Require manufacturers to promise not to disclose design drawings and technical parameters, and not to use customers’ PCB designs for other commercial purposes to ensure the security of core technologies

How to Evaluate the Production Capability of a UK PCB Manufacturer?

Methods about how to evaluate the production capability of a UK PCB manufacturer:

1. Check the production equipment list to confirm whether core equipment such as fully automated drilling machines, AOI inspection equipment, and X-ray inspection machines are available.

2. Understand the production capacity scale, inquire about the average monthly production area and maximum order undertaking capacity to determine whether it can match the needs of your own mass production.

3. Inspect the scope of process coverage, confirm the parameters of PCB layers, board thickness, line width and line spacing that can be produced, and whether they meet the project specifications.

4. Review the quality control system, request SOP (Standard Operating Procedures) and historical quality inspection reports to understand the defect rate data.

5. Evaluate flexible production capabilities, inquire about the production cycle and switching efficiency of small-batch orders to determine whether they can meet the needs of multiple varieties.

6. Understand the raw material supply system, confirm whether there is a stable list of qualified suppliers and whether there is an emergency material reserve mechanism.

7. Inspect the team configuration, understand the working years and professional qualifications of engineers and technical workers to determine the technical support capabilities.

8. Visit the production site (online or offline) to observe the production order, equipment maintenance status and workshop environment management level.

How to Evaluate the Delivery Time of a UK PCB Manufacturer?

Methods about how to evaluate the delivery time of a UK PCB manufacturer:

1. Request a breakdown of delivery time components, clarify the specific time for document review, material procurement, production and processing, inspection and packaging, and other links.

2. Inquire about material inventory status, confirm the inventory cycle of commonly used components to determine whether the procurement link time can be shortened.

3. Understand the production line priority mechanism, confirm whether there is exclusive production line support for emergency orders and the implementation capacity of expedited services.

4. Verify historical delivery data, request delivery records of the past 6 months to calculate the on-time delivery rate.

5. Confirm the logistics cooperation model, whether there is long-term cooperation with well-known local logistics enterprises and whether there is cross-border delivery experience.

6. Inquire about emergency plans for delays, understand the remedial measures and compensation plans when problems such as equipment failures and material delays occur.

7. Request a clear delivery agreement to include delivery time, delay responsibilities and liquidated damages clauses in the contract.

8. Evaluate information synchronization capabilities, confirm whether real-time progress inquiry services can be provided to avoid delivery risks caused by opaque operations.

Frequently Asked Questions About PCB Manufacturer UK

Q1: What is the minimum order quantity for small-batch R&D PCB samples, and what is the delivery cycle?

A2: We support orders starting from 1 piece. Regular single and double-layer boards are delivered within 48 hours, and multi-layer boards with less than 24 layers are delivered within 3-5 days. Emergency orders can activate the 8-hour expedited service.

Q2: How to handle quality issues with PCB products?

A2: We respond within 2 hours after receiving feedback and complete cause investigation within 24 hours. For confirmed production-related issues, we will re-produce for free and bear the round-trip logistics costs, while providing a 1-year quality guarantee service.

Q3: Can you provide PCB design support? I am worried about the feasibility of my design scheme in terms of process.

A3: We can provide free DFM analysis services. Engineers will optimize the design scheme according to production process requirements, including circuit optimization and component layout adjustment, to reduce mass production risks.

Q4: PCB products in the automotive electronics field have special requirements. Can you meet them?

A4: We hold the IATF 16949 automotive industry quality certification. The automotive PCBs we produce have passed reliability tests such as high and low temperature cycles and vibration impact, and we have provided supporting services for many local UK automotive companies.

Q5: How to choose PCB base materials for different application scenarios?

A5: We will recommend base materials accurately according to your application scenarios. FR-4 is suitable for industrial control (temperature resistance 130℃, moderate cost); high Tg FR-4 is preferred for automotive electronics (temperature resistance above 170℃, anti-vibration); ceramic base materials are recommended for medical equipment (good insulation, excellent biocompatibility); and PTFE base materials are used for high-frequency communications (stable dielectric constant). Engineers will provide optimal solutions based on your needs.

Conclusion

Among the best UK PCB manufacturer, we stand out with full-process guarantees and professional services. Choosing us means selecting a reliable partner among the best UK PCB manufacturer to facilitate the efficient advancement of your electronic projects. Contact us now to get a free quote: sales@bestpcbs.com.